Pressing type potato chip packaging and sealing device

A technology for sealing devices and potato chips, which is applied in packaging sealing/fastening, packaging, packaging machines, etc., and can solve problems such as long time consumption, large quantities, and difficulty in mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

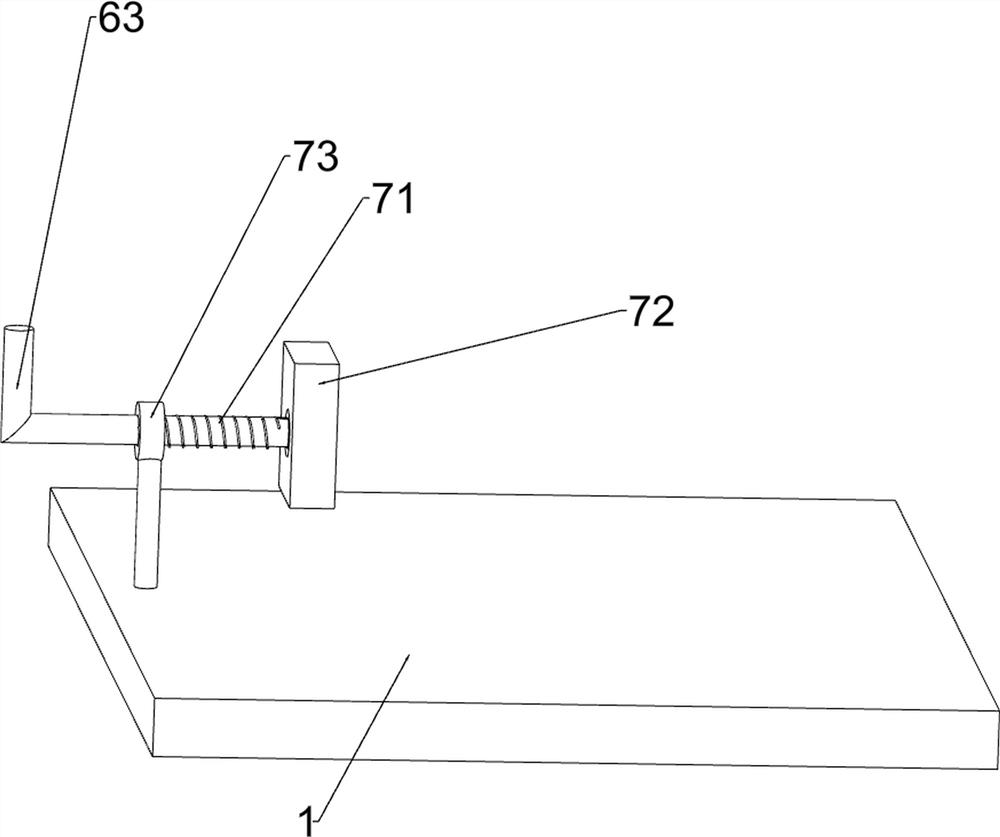

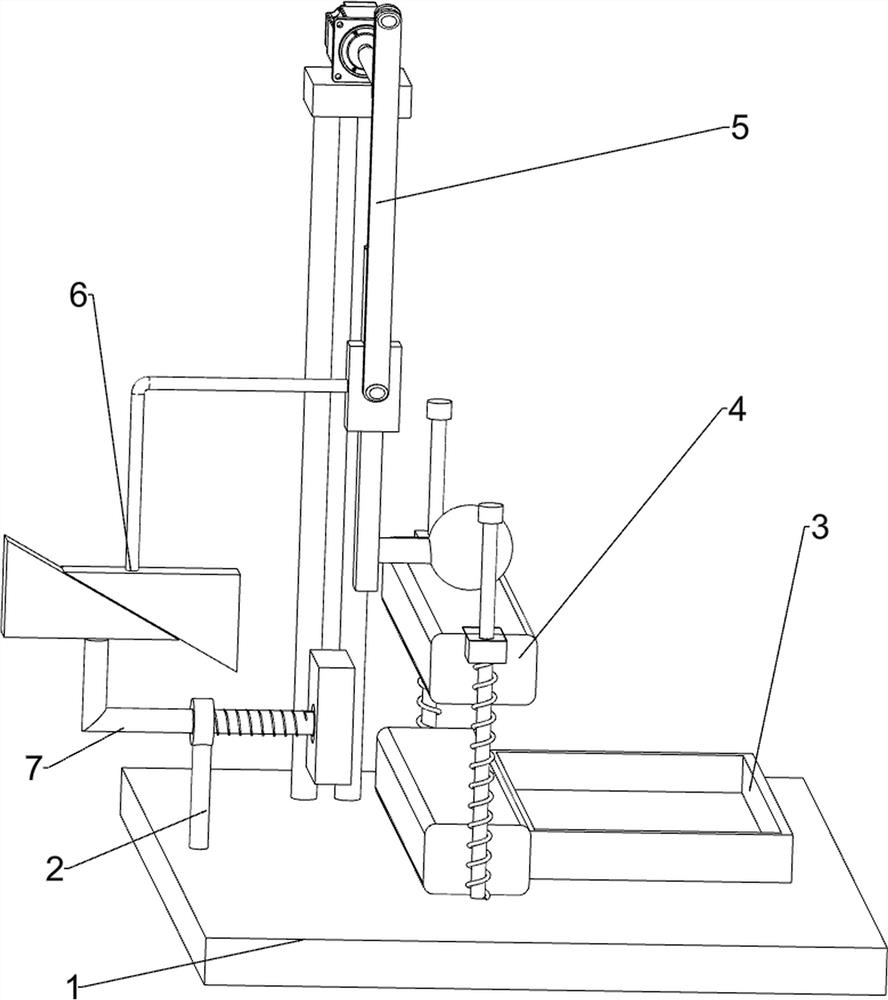

[0022] A kind of push-down type potato chip packaging and sealing device, such as Figure 1-Figure 3 As shown, it includes a fixed plate 1, a support rod 2, a collection frame 3, a pressing mechanism 4 and a reciprocating mechanism 5, the top of the left side of the fixed plate 1 is provided with a support rod 2, and the upper right side of the fixed plate 1 is provided with a collection frame 3. A pressing mechanism 4 is provided in the upper middle of the board 1 , and a reciprocating mechanism 5 is provided on the rear top of the fixed board 1 .

[0023] When people want to seal bagged food, they can use this push-down bagged food sealing device. First, the user places the food packaging bag to be sealed in the pressing mechanism 4, starts the reciprocating mechanism 5, and the reciprocating mechanism 5 Drive the movement of the pressing mechanism 4 to seal the food packaging bag. After the sealing is completed, the user pushes the sealed food packaging bag into the collect...

Embodiment 2

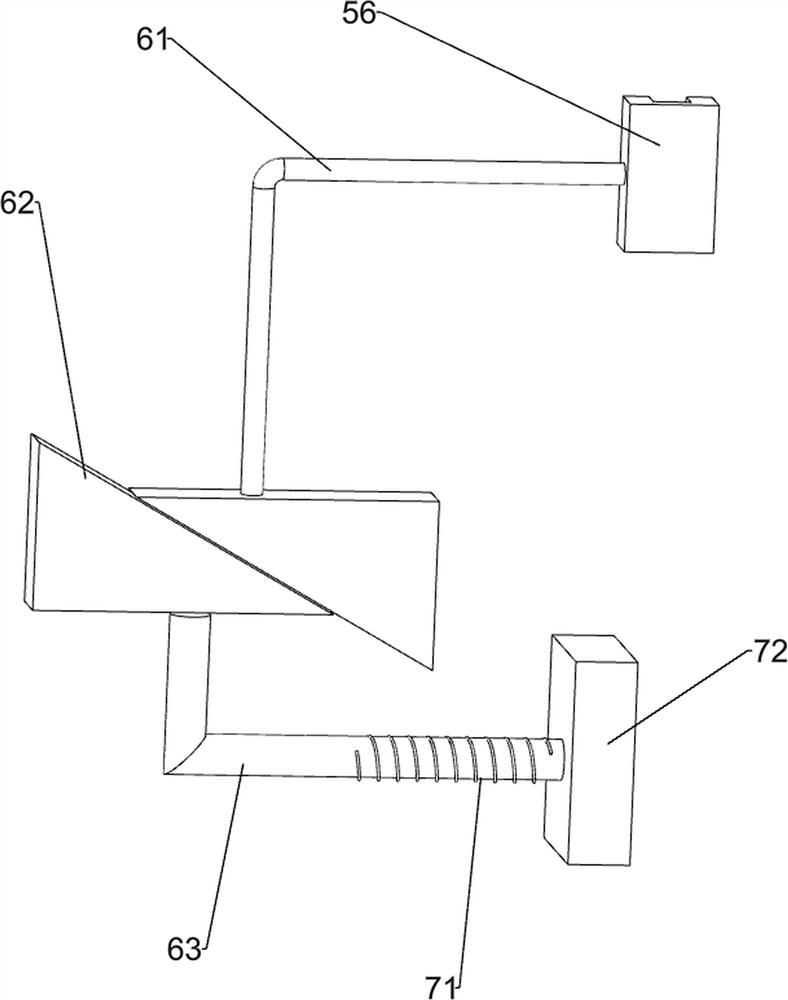

[0029] On the basis of Example 1, such as Figure 4 with Figure 5 As shown, a push-pull mechanism 6 is also included. The top of the support rod 2 is provided with a push-pull mechanism 6. The push-pull mechanism 6 includes a lower pressing rod 61, a wedge block group 62 and an L-shaped bar 63. The middle part of the left side of the U-shaped block 56 is provided with a lower Depression bar 61, fixed plate 1 left side top is provided with L-shaped bar 63, is provided with wedge-shaped block group 62 between the bottom end of lower pressure bar 61 and L-shaped bar 63 tops, and the top of wedge-shaped block group 62 is connected with lower pressure bar 61, The bottom of the wedge block group 62 is connected with the L-shaped bar 63 .

[0030] When the U-shaped block 56 moves downward, the U-shaped block 56 drives the lower lever 61 to move downward, and the wedge-shaped block on the upper side contacts the wedge-shaped block on the lower side, and the wedge-shaped block on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com