Single-table-board ink jet equipment capable of preventing large panel veneer from warping

A single-table, ink-jet technology, used in typewriters, printing, printing devices, etc., can solve the problem of not being able to clamp the sheet, and achieve the effect of improving the pass rate and reducing the repeated operation of pushing materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

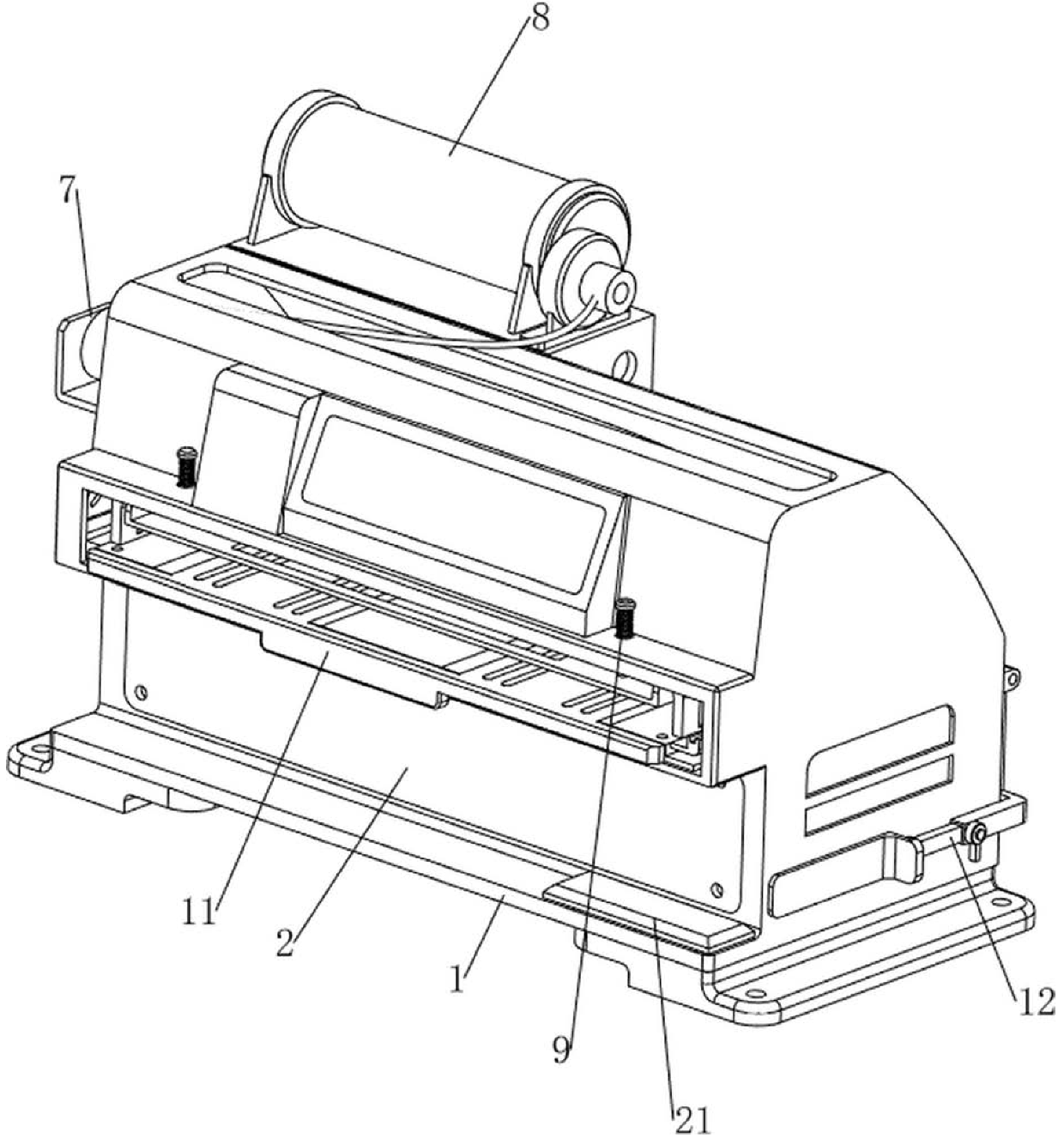

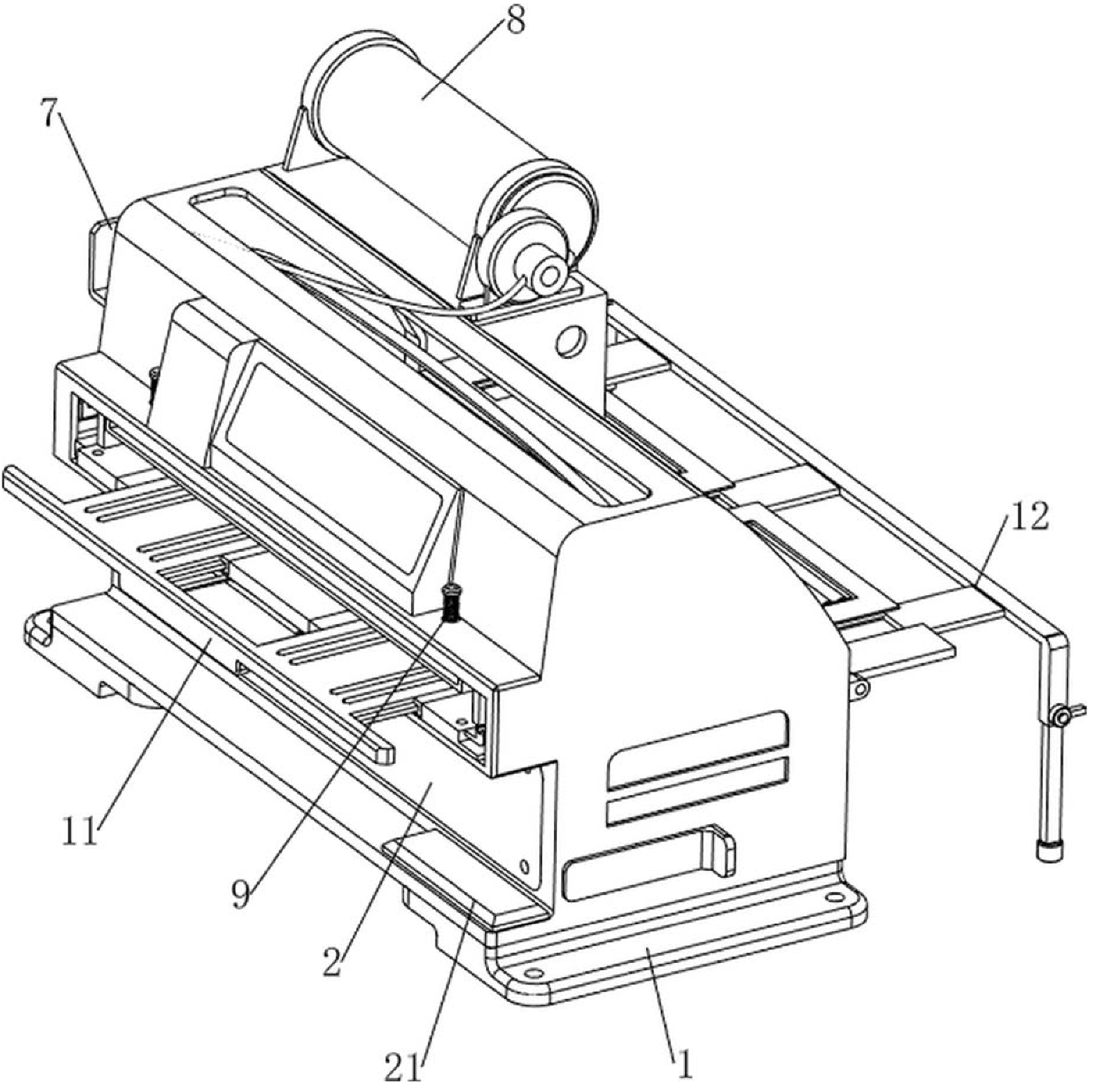

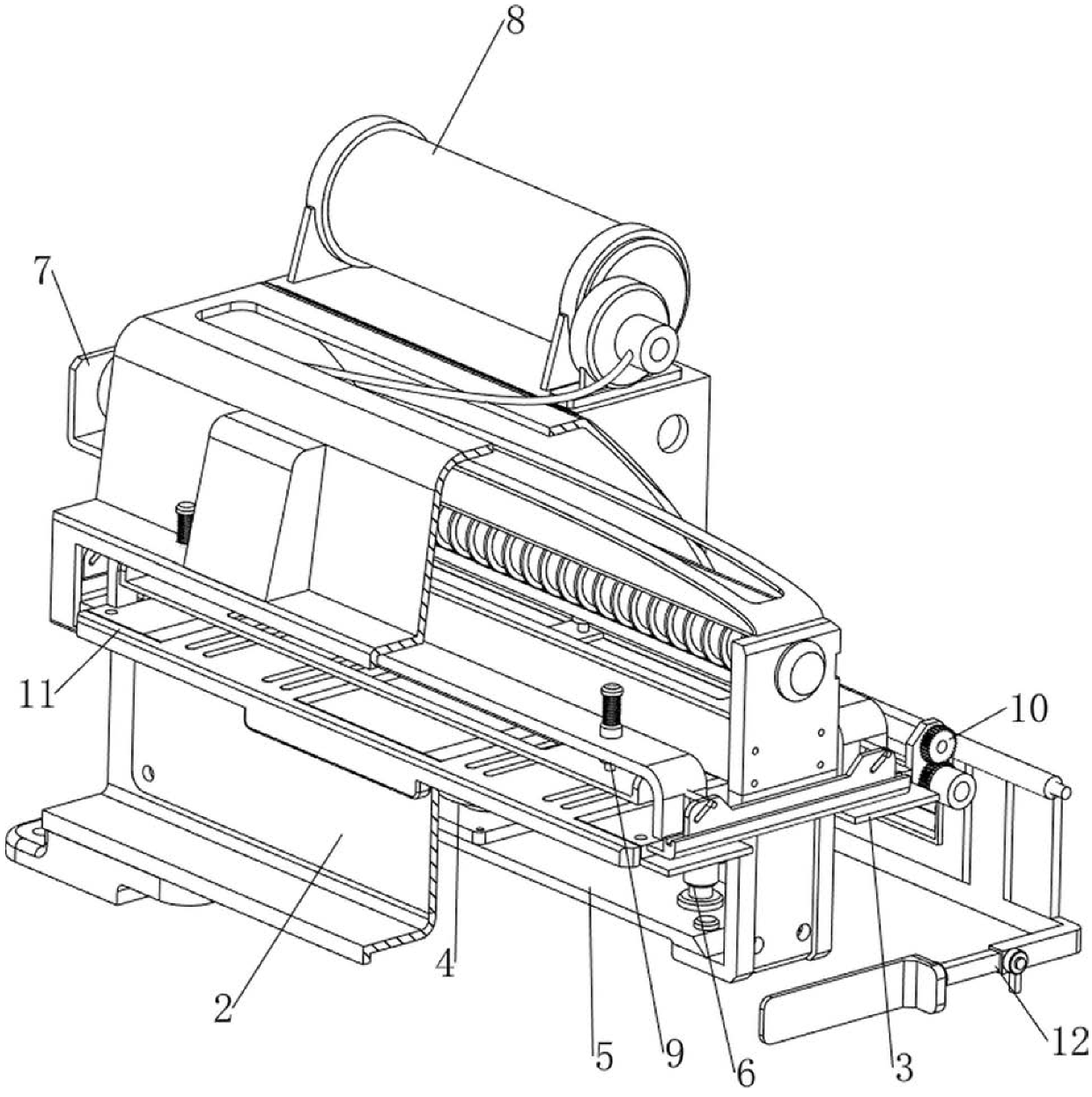

[0036] A single-stage inkjet device that prevents warpage of large sheets, such as Figure 1-17 As shown, it includes a casing 1, a first fixing plate 2, a supporting plate 3, a first electric push rod 4, a second fixing plate 5, a telescopic rod 6, a moving mechanism 7 and an inkjet mechanism 8. The front side of the casing 1 is provided with The first fixing plate 2, a support plate 3 is connected between the upper side of the first fixing plate 2 and the casing 1, the front side of the lower part of the support plate 3 is installed with a first electric push rod 4 through bolts, and the first electric push rod 4 is on the telescopic rod. A second fixed plate 5 is connected, a moving mechanism 7 is arranged on the second fixed plate 5, and telescopic rods 6 are provided on the left and right sides of the lower part of the support plate 3. The telescopic rod 6 is connected with the second fixed plate 5, and the moving mechanism 7 is connected with the casing. An ink jet mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com