Pressing wheel mechanism of assembling machine

A technology of assembling machine and pressing wheel, which is applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc. It can solve the problem of uneven pressing effect and achieve a simple structure, easy installation and maintenance, and reduced gaps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

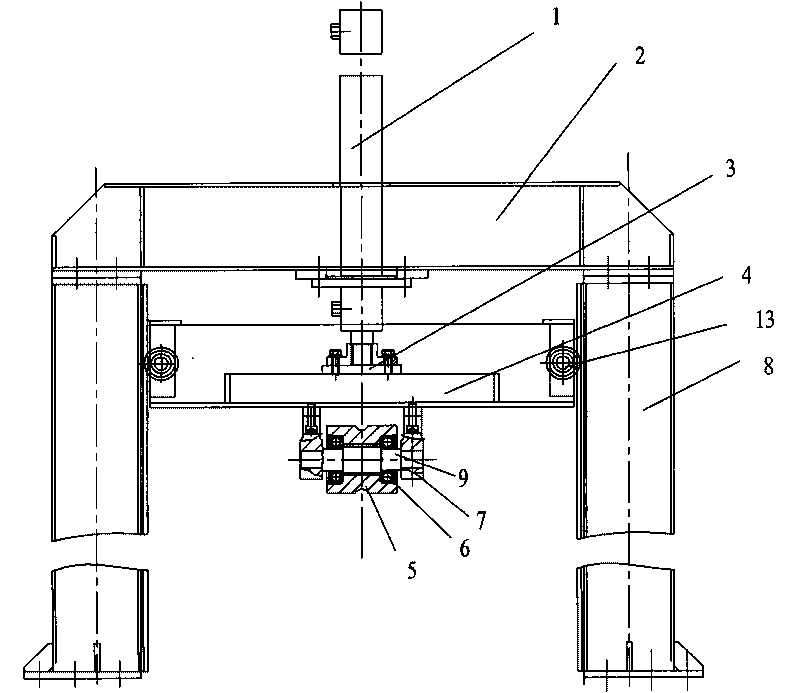

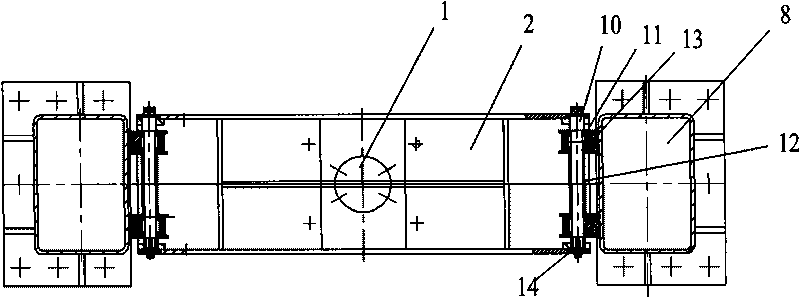

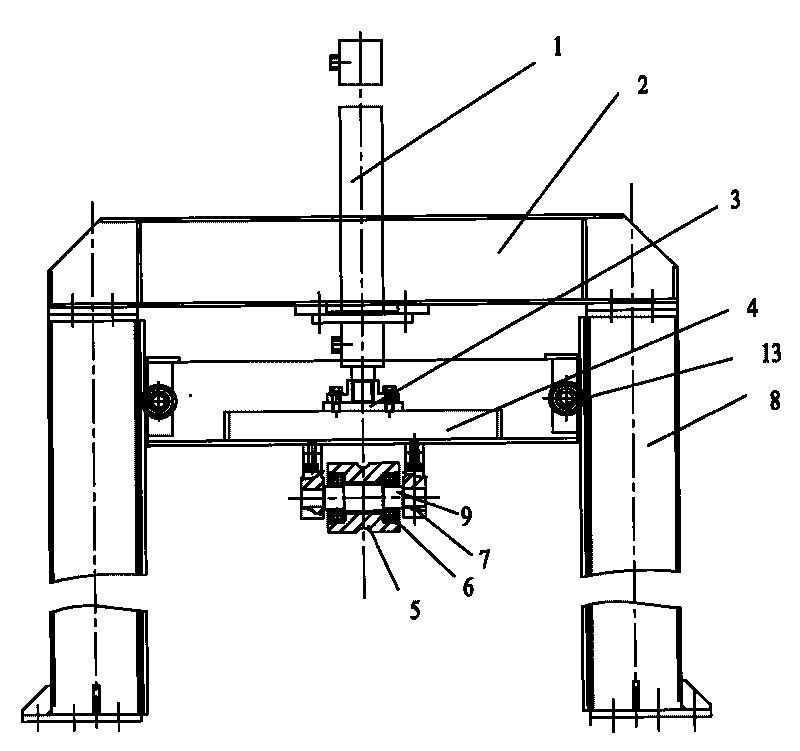

[0011] Such as figure 1 , figure 2 Shown: the present invention is made up of pressing oil cylinder 1, door top frame 2, flange 3, pressing frame 4, pressing roller 5, first bearing 6, roller seat 7, column 8 and guide assembly 3 etc. under pressing.

[0012] The door top frame 2 is fixed between the two columns 8, and the lower pressure cylinder 1 passes through the hole on the door top frame 2, and its shaft end is connected with the flange 3 by threads, and the flange 3 is fixed on the lower pressure frame 4 by screws. Above, the guide assembly is installed on the lower pressing frame 4 and contacts with the guide rail on the column. The two pressure wheel seats 7 are symmetrical about the central axis of the lower pressing oil cylinder 1. They are fixed on the lower pressing frame 4 with screws, and the two ends of the pressing shaft 9 are respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com