Casing pipe detection equipment and detection method thereof

A technology for testing equipment and casings, which is used in measuring devices, optical testing flaws/defects, instruments, etc., and can solve problems such as inability to achieve online detection of defects in casings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

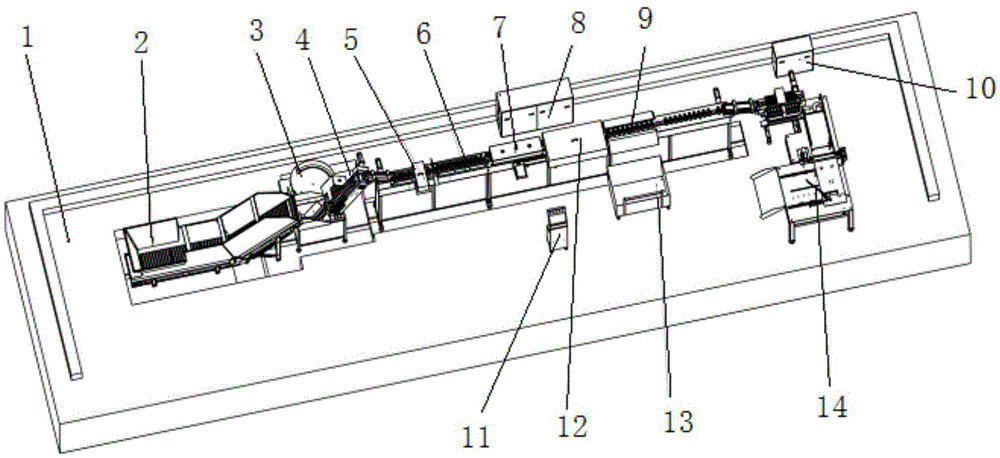

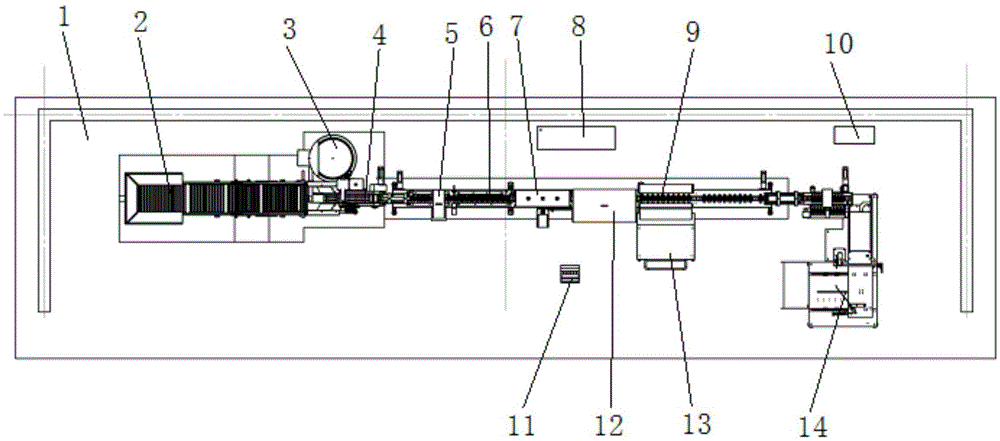

[0049] Please refer to figure 1 , figure 2 , a casing detection equipment, including a foundation 1, a material storage and feeding machine 2, a material sorting machine 3, a lifting and reversing device 4, a pre-judgment device 5, a conveyor 6, a drying device 7, a total electric control cabinet 8, Pneumatic rejecting system 9 (including collecting trolley 13), auxiliary electric control cabinet 10, console 11, visual inspection system 12, packaging system 14. The conveying device is connected with the lifting reversing device; the predicting device, drying device, visual inspection system, and pneumatic rejecting system are installed next to the conveying device in sequence according to the conveying direction.

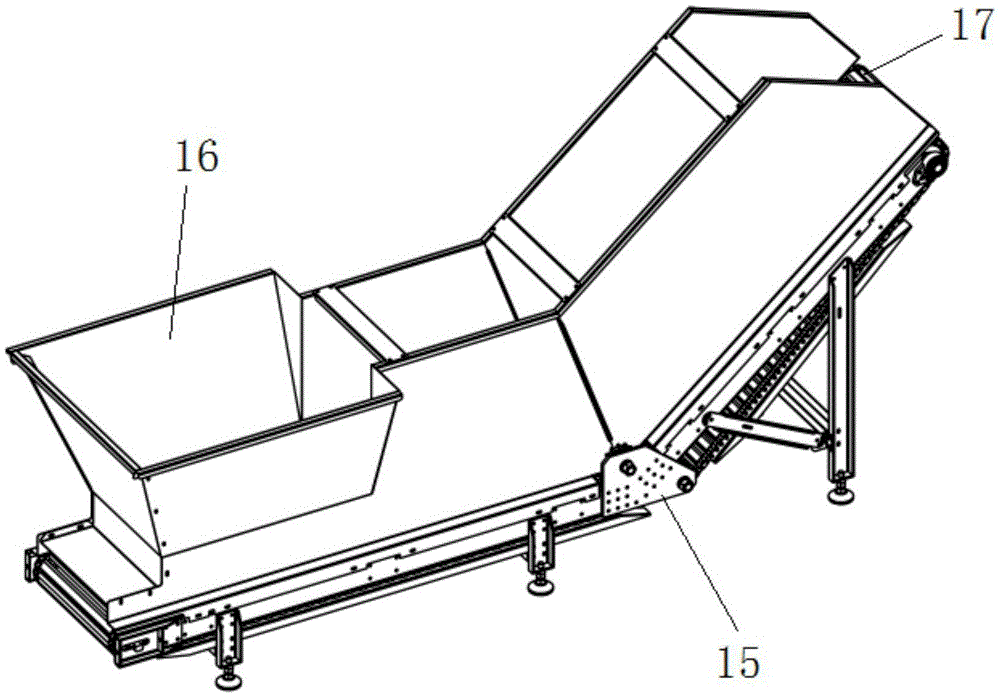

[0050] Please refer to image 3 , the storage and feeding machine includes a bracket one 15, a storage hopper 16, a feeding conveyor belt 17 connected to the storage hopper, and a feeding motor 18. The feeding motor is installed on the left side of the upper end...

Embodiment 2

[0068] The difference from Embodiment 1 is that the horizontal conveyor belt includes a horizontal conveyor belt 1 and a horizontal conveyor belt 2 arranged linearly in sequence according to the conveying direction, the horizontal conveyor belt and the conveying motor constitute a horizontal conveyor belt assembly, and the horizontal conveyor belt assembly has two One: the first horizontal conveyor belt assembly connected to the second passageway, and the second horizontal conveyor belt assembly adjacent to the first horizontal conveyor belt assembly. Horizontal conveyor belt assembly 1 includes horizontal conveyor belt 1 and conveyor motor 1 for driving and controlling the operation of horizontal conveyor belt 1, and horizontal conveyor belt assembly 2 includes horizontal conveyor belt 2 and conveyor motor for driving and controlling the operation of horizontal conveyor belt 2 two. The first horizontal conveyor belt and the second horizontal conveyor belt are on the same stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com