Heparin pump

A technology of heparin pump and connecting block, which is applied in the field of heparin pump, can solve the problems of reduced reliability, difficult assembly, and high precision requirements for parts machining, and achieves the effects of reducing complexity, improving reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

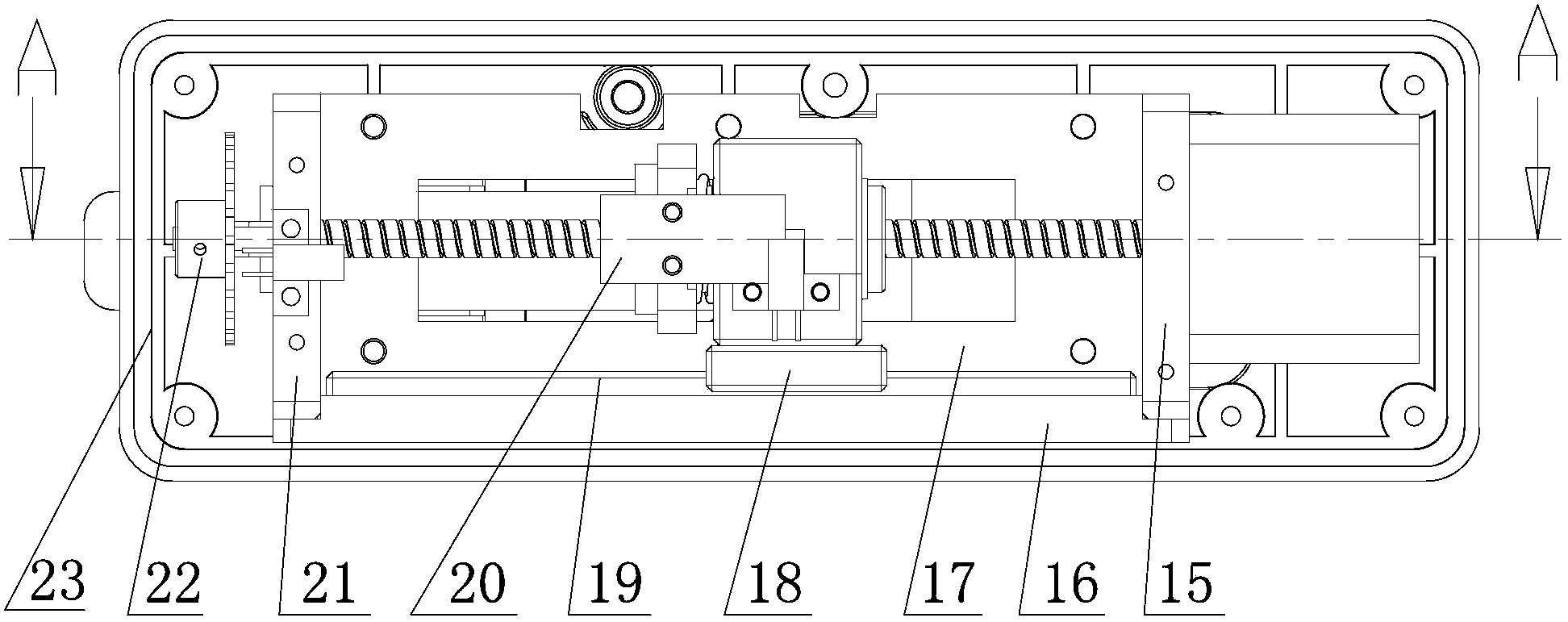

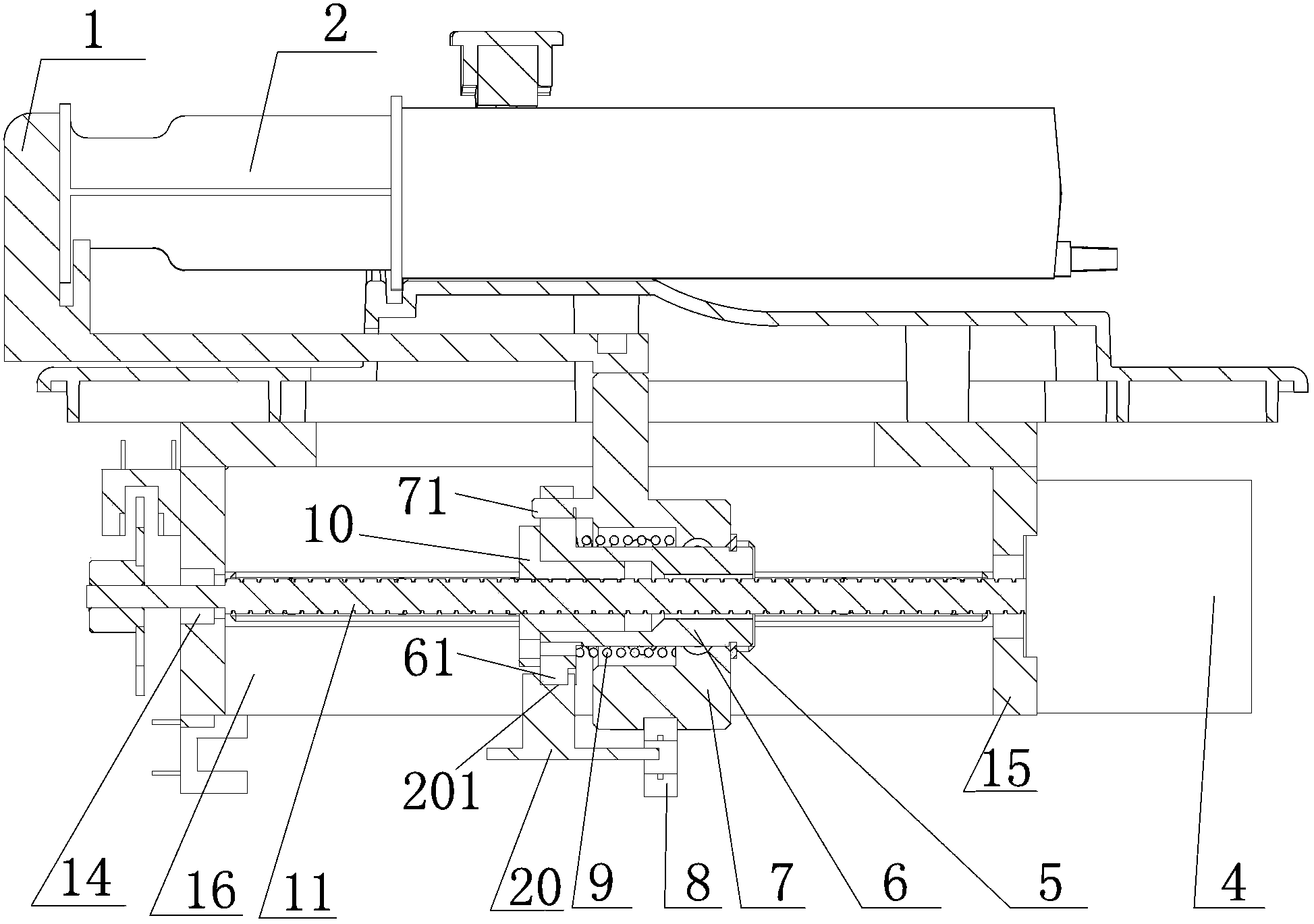

[0024] to combine figure 1 with figure 2 As shown, the present invention proposes a heparin pump with simple and reliable structure, blockage, empty liquid alarm, slow injection of heparin and rapid injection of heparin, which is used in conjunction with the syringe 2 .

[0025] Specifically, the heparin pump proposed by the present invention includes: a casing 23; a frame fixed in the casing 23 by screws, and the frame is composed of a motor mounting plate 15, a rear plate 21, a side plate 16 and a bottom plate 17; The motor transmission system on the top, the motor transmission system includes a stepper motor 4 and its control circuit board, screw mandrel 11 and lead screw nut 10, the stepper motor 4 is fixedly installed on the motor mounting plate 15 by a plurality of screws, and for the shaft Accurate positioning between the stepper motor 4 and the motor mounting plate 15 adopts a notch positioning connection structure, one end of the screw rod 11 is directly connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com