Spray lance device and ladle lining refractory jet device

A refractory material and spray gun technology, which is applied to blast furnace parts, blast furnaces, furnace types, etc., can solve the problems of difficult adjustment of the spraying direction of the spray gun barrel, and achieve the effects of improving the construction environment, reducing labor intensity and ensuring the quality of spraying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

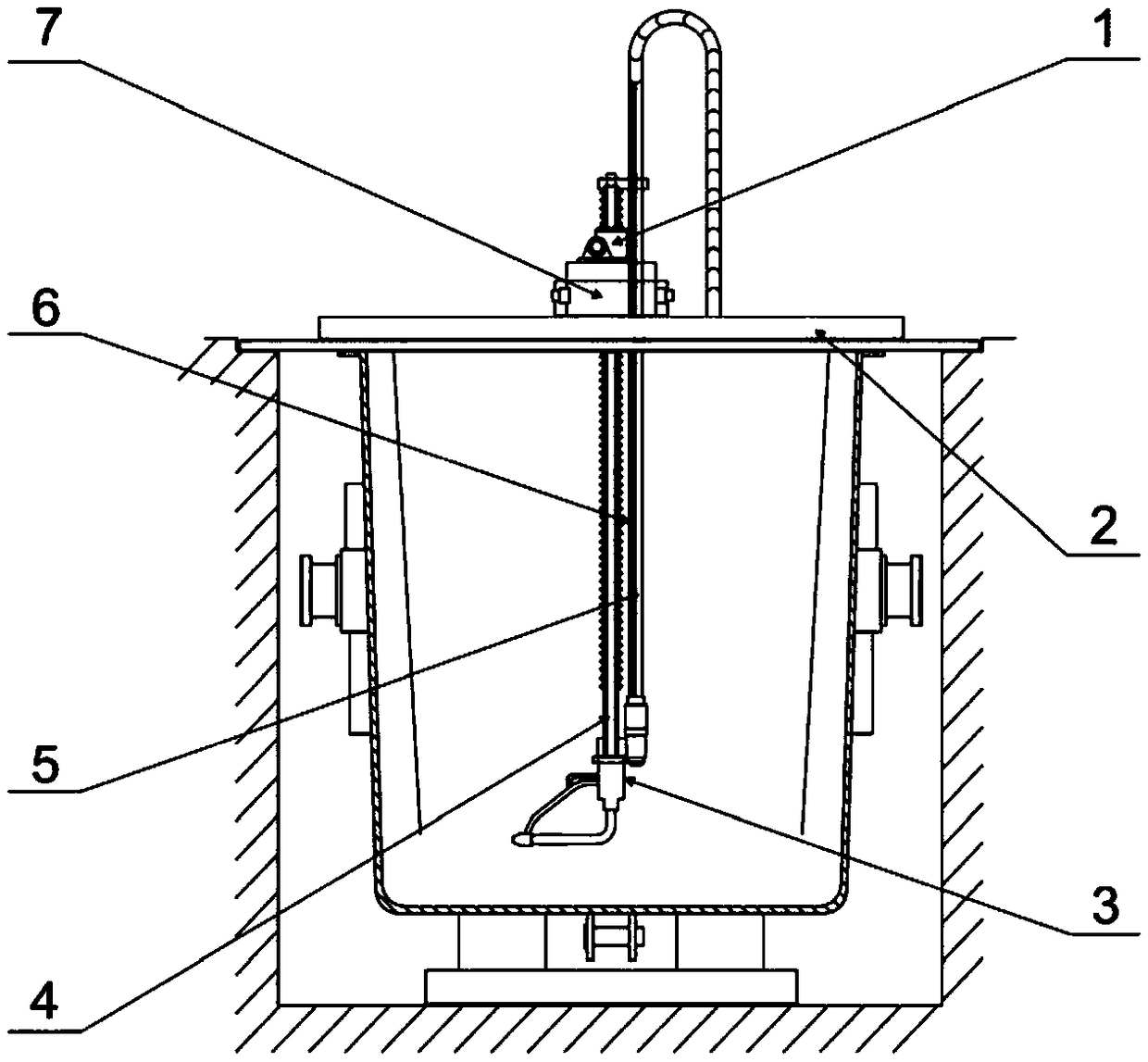

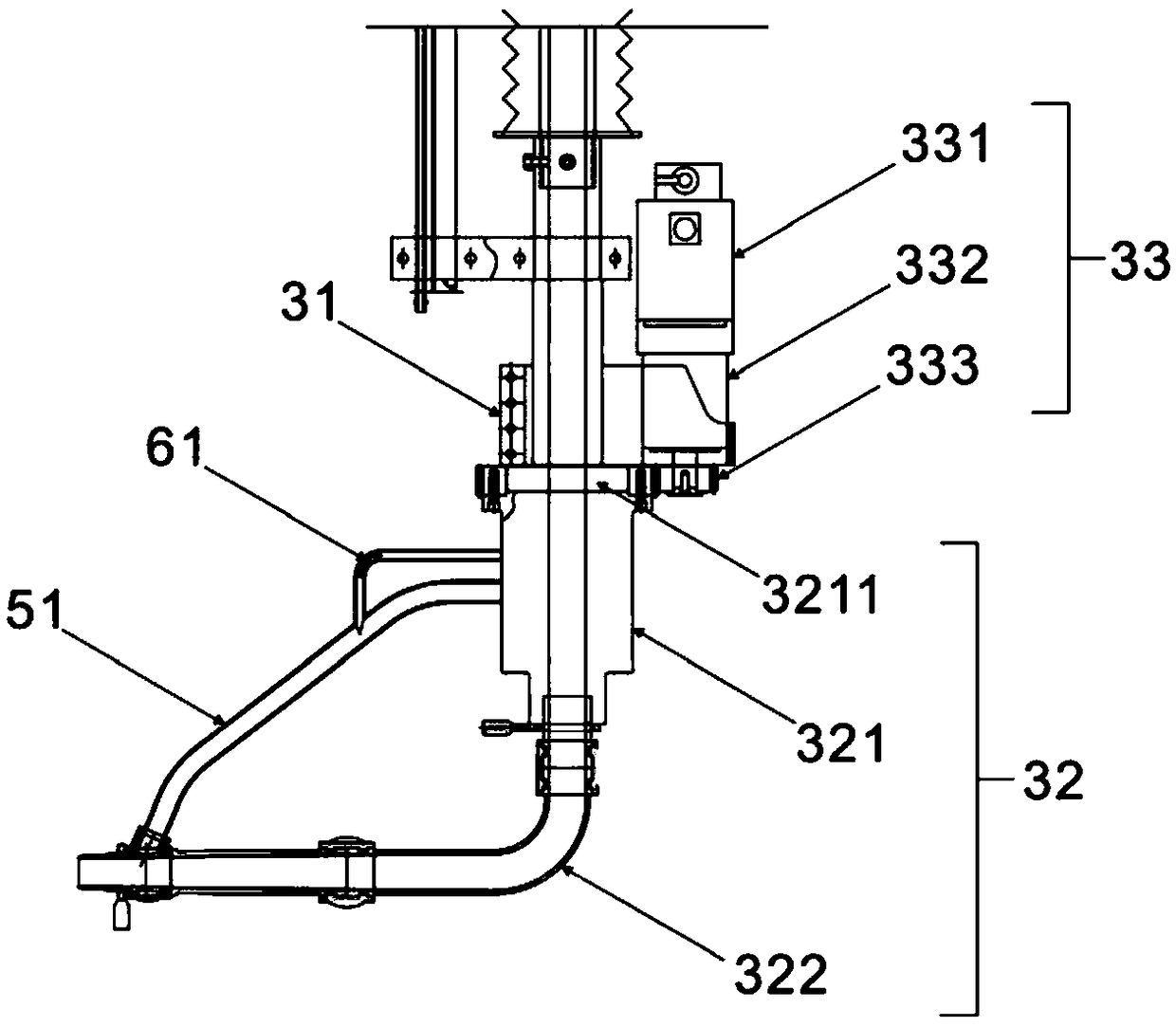

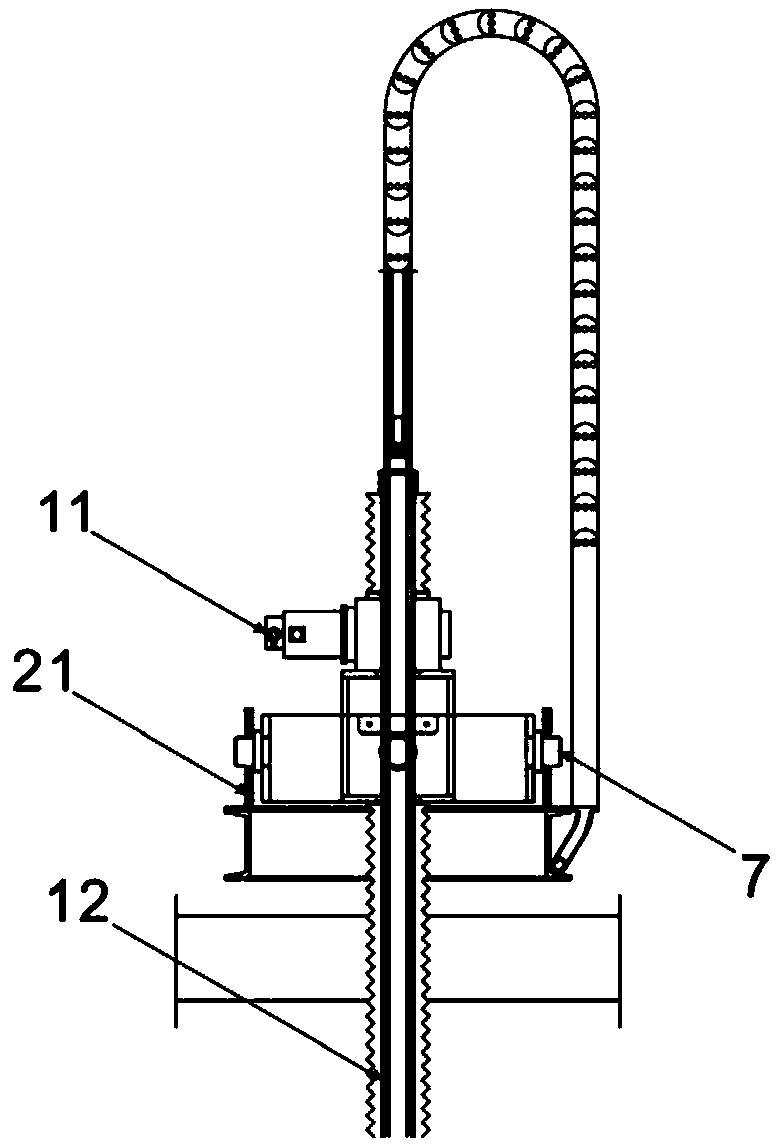

[0041] A kind of spray gun device provided by the invention, such as figure 2 Shown in the schematic diagram of the structure of the spray gun device in Embodiment 1 of the present invention, it includes a support box 31, a spray gun drive unit 33 and a rotary spray gun 32. The spray gun drive unit 33 is arranged on the support box 31 and is connected to the rotary spray gun 32. The spray gun drive unit 33 can Drive the rotary spray gun 32 to rotate, wherein: the rotary spray gun 32 includes a gas-liquid rotary joint 321 and a nozzle 322, the nozzle 322 is connected to the refractory material pipeline through the gas-liquid rotary joint 321, the gas-liquid rotary joint 321 and the nozzle 322 can be connected to the refractory material Piping turns.

[0042] When spraying, the spray gun driving device 33 drives the rotary spray gun 32 to rotate. At this time, the gas-liquid rotary joint 321 rotates, and the nozzle 322 is connected to the refractory material pipeline through th...

Embodiment 2

[0063] The difference between embodiment 1 and embodiment 2 is: as Figure 7 Structural schematic diagram and Figure 8 As shown in the structure diagram of the spray gun device in Embodiment 2 of the present invention, the rotary spray gun 32 also includes a rotating body bearing drag bar 323 and a rotating body 324, wherein: the rotating body bearing drag bar 323 is arranged between the gas-liquid rotary joint 321 and the rotating body 324 , and the gas-liquid rotary joint 321 and the rotating body 324 can rotate synchronously with respect to the rotating body bearing drag bar 323, and the rotating body bearing drag bar 323 is connected to the rotating body 324 through a bearing; the rotating body bearing drag bar 323 is axially provided with a second A channel, the first channel runs through the gas-liquid rotary joint 321 and the rotating body 324, the first channel is connected with the nozzle 322 for the flow of refractory materials; the nozzle 322 is detachably connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com