Intelligent oil pumping system

An intelligent, pumping unit technology, applied in transmission systems, production fluids, electrical components, etc., can solve problems such as unsatisfactory effects, high failure rates, and failure to grasp, and achieve the effects of light weight, avoiding damage, and reducing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

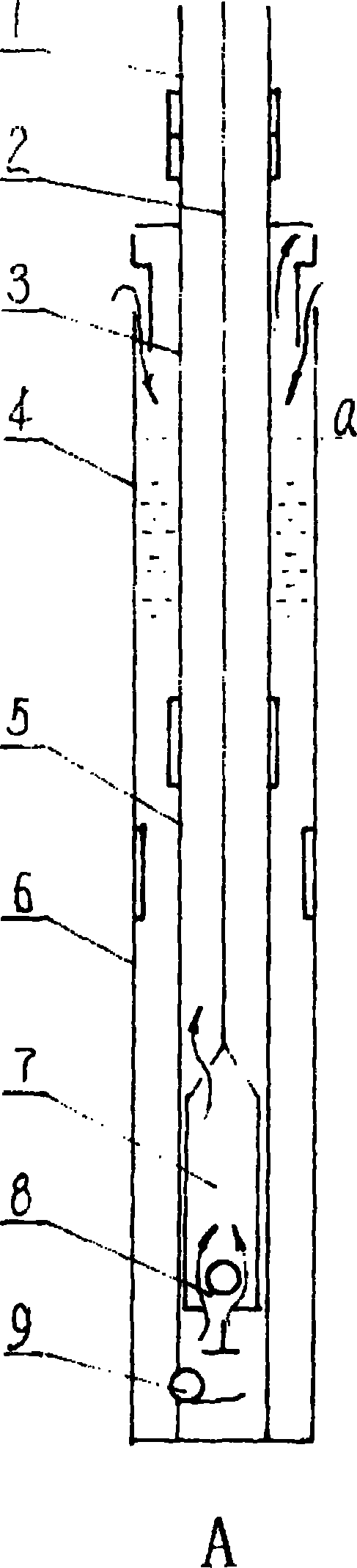

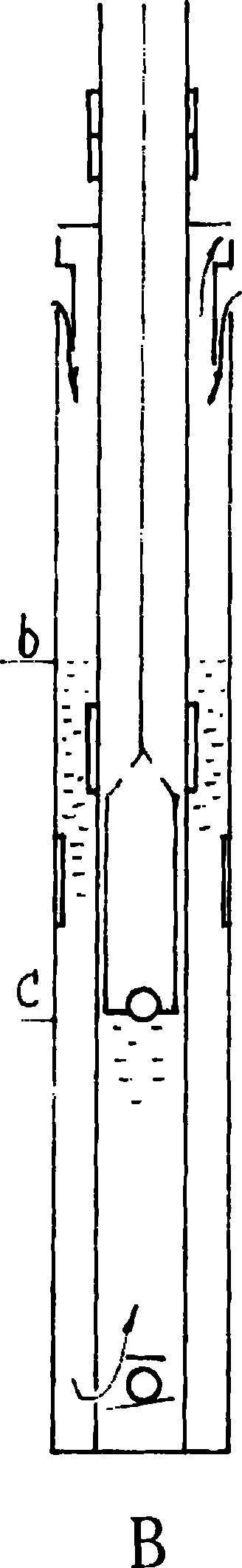

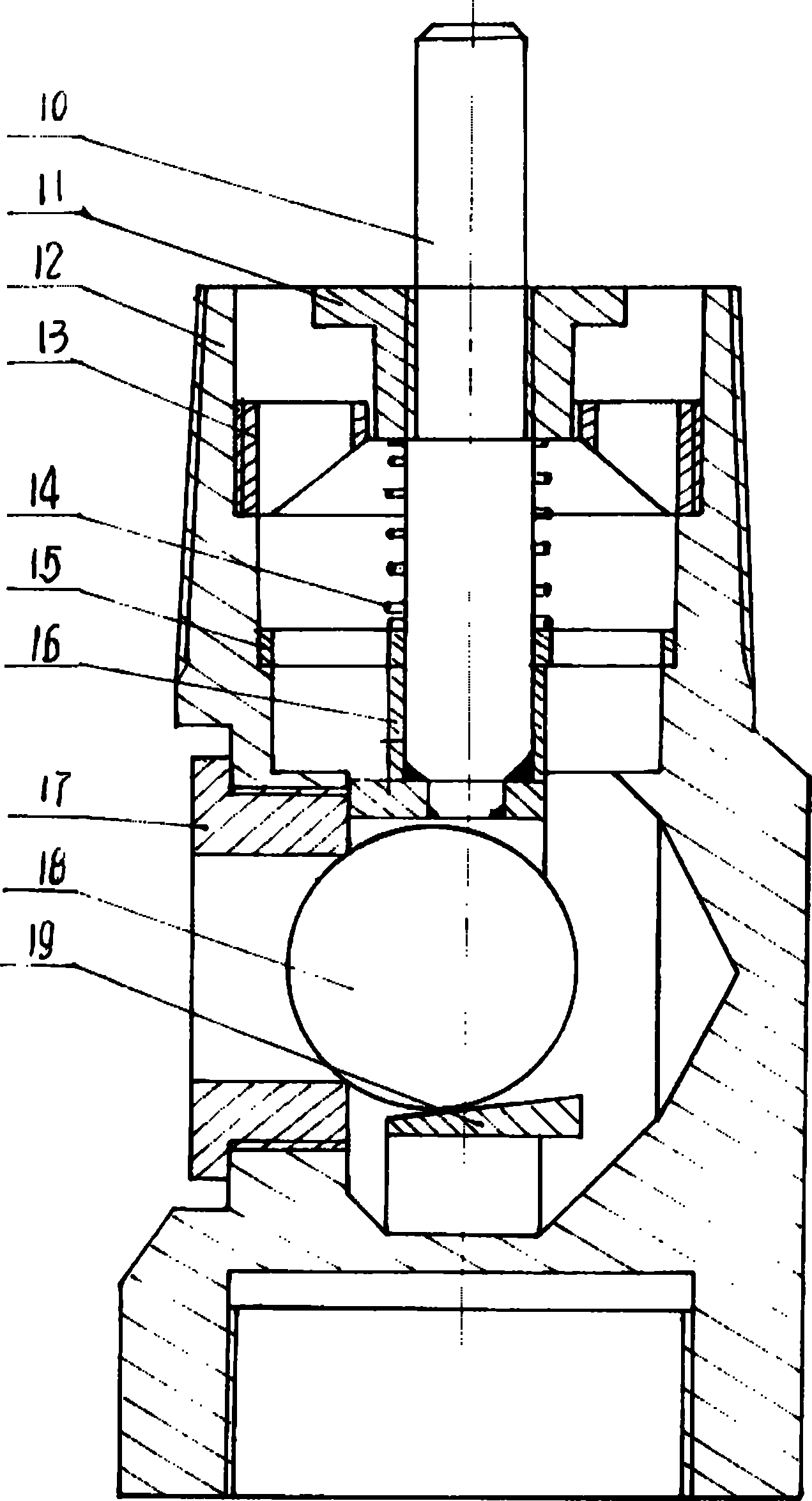

[0072] Such as Figure 1 to Figure 13 The high-efficiency intelligent oil pumping equipment shown includes a program-controlled pumping unit and an electronic control system, wherein the pumping unit is a double-pulley double-drive winch lifting structure, such as Figure 1 ~ Figure 3 shown. A four-axis reducer 40 is installed on the top of the frame 22, and its two output shafts are respectively equipped with two drums 25 opposite to the rotation direction of the rope groove. The input shaft on one side is connected to the automatic running motor 35 through a coupling 41, and the other Side input shaft dress outer garden is the power-off brake clutch 39 of roller sprocket, is connected by roller chain 38 and the manual running motor 37 that is equipped with power-off brake clutch, balance wheel A28, Two balance wheels B30 at a certain distance are installed on the rear lower frame of the reducer 40, double pulley rope suspension device A23 is arranged before the frame, and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com