Fine-grain titanium aluminum powder forming method

A molding method and powder technology, which is applied in the field of titanium-aluminum intermetallic compounds and materials, can solve problems such as cold isostatic pressing of pre-alloyed titanium-aluminum powder, achieve short production cycles, facilitate engineering applications, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] (1) Preparation of titanium-aluminum alloy powder, the preparation method is one of the following:

[0035] Method 1 Weigh each component according to the ratio of titanium-aluminum alloy components, the atomic ratio is Al:Nb:Cr=48:2:2, and the balance is Ti, record the weighed components as raw materials, and divide the raw materials 1. Put the stainless steel balls into the mixing tank, seal the mixing tank and mix on the tumbling machine. The rotation frequency of the mixer is 27HZ, and the mixing time is 5-10h. Powder and steel balls are separated to obtain uniform titanium-aluminum mixed powder. The mass ratio of raw materials and steel balls is 10-40:1-3;

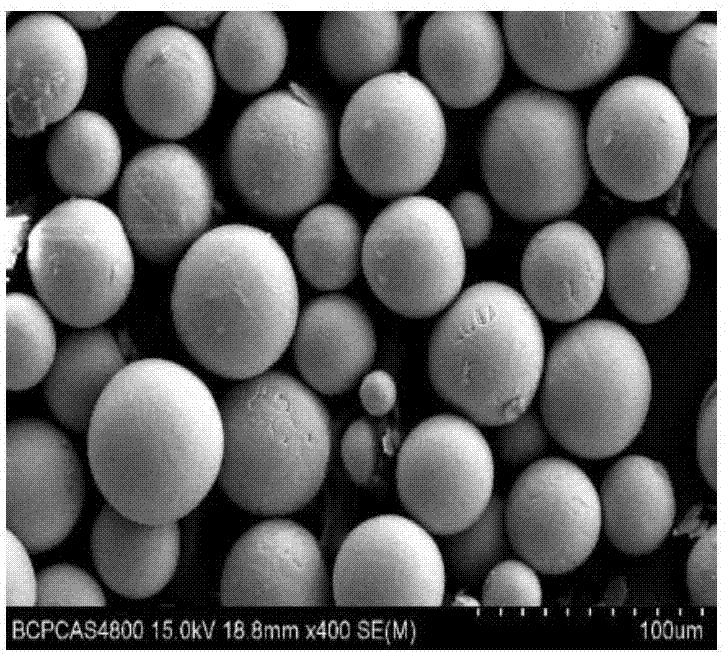

[0036] Method 2 selects spherical gas-atomized titanium-aluminum powder as the raw material, and the composition ratio of the gas-atomized titanium-aluminum powder is the same as method 1. Put the raw material and stainless steel balls into the ball milling tank respectively, seal the ball milling tank and carr...

Embodiment 1

[0048] The steps and technological process of this embodiment are as follows:

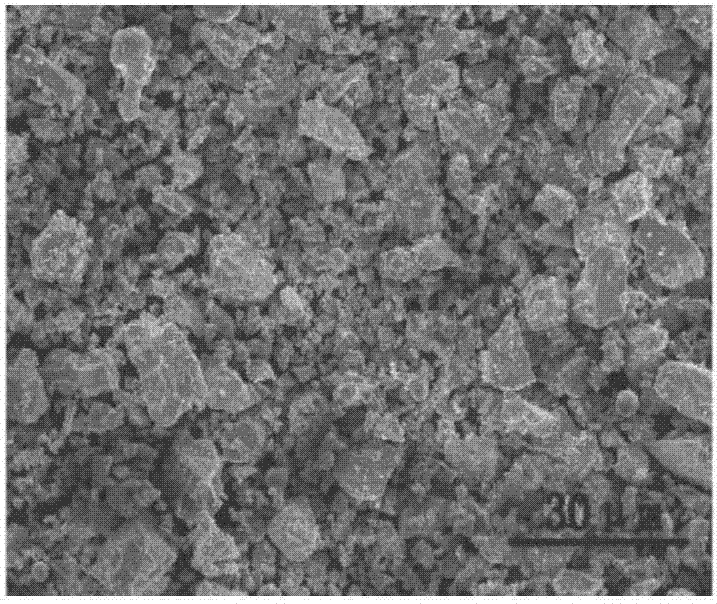

[0049] Mix powder. Original hydrodehydrogenation Ti powder (purity > 99%), Al powder (purity > 99%), Al-Nb powder (purity > 99%), Cr powder (purity > 99%) according to the atomic ratio of 48:48:2 :2 for proportioning, the original powder and stainless steel balls are put into the mixer for mixing, wherein the diameter of the stainless steel balls is and The two are mixed, the rotation frequency of the mixer is set at 27HZ, and the mixing time is 8h, and then the mixed titanium-aluminum powder and steel balls are separated by a screen to obtain uniformly mixed titanium-aluminum powder.

[0050] Powdered. Please refer to Figure 4 and Figure 5 1. Fill the mixed rhombic TiAl powder in the cavity 3 of the rubber sheath 1, and the powder particles need to be shaken and vibrated continuously during the powder filling process. The rubber sheath 1 used in this embodiment is a barrel-shaped sheath ...

Embodiment 2

[0054] The steps and technological process of this embodiment are as follows:

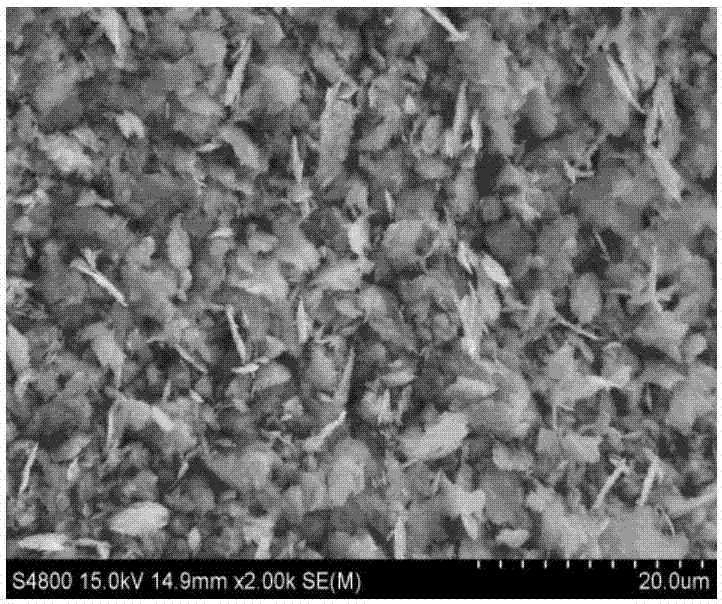

[0055] Milling. Original gas-atomized spherical titanium-aluminum powder (purity > 99.99%), put the raw material and stainless steel balls into the ball milling pot respectively, seal the ball milling pot and carry out dry ball milling, the rotating speed of the ball milling pot is 350r / min, and the ball milling time is set Set as 3.5h, the diamond-shaped titanium-aluminum powder after ball milling was obtained, and the particle size of the powder ranged from 20 to 60 μm.

[0056] Powdered. Please refer to Figure 4 and Figure 5 , the diamond-shaped TiAl powder after ball milling is filled in the cavity 3 of the rubber sheath 1, and the powder particles need to be constantly shaken and vibrated during the powder filling process. The rubber sheath 1 used in this embodiment is a barrel-shaped sheath with openings at both ends, and both ends are sealed by a natural rubber plug 4 and an adjustable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com