A kind of gray cast iron and its smelting method

A smelting method and technology of gray cast iron, which is applied in the field of high-strength machine tool gray cast iron and its smelting, can solve the problems of limited proportion and limited reduction of raw material cost, and achieve reduced raw material cost, uniform and good metallographic structure, and reduced raw material cost. Effects on costs and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

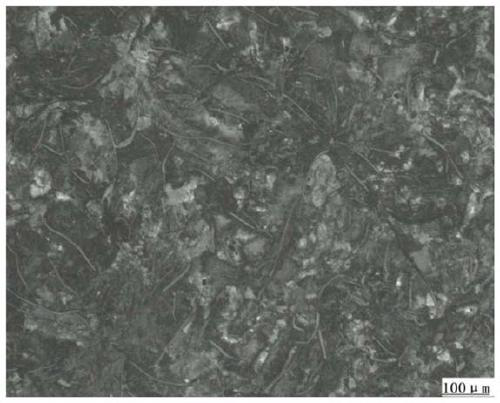

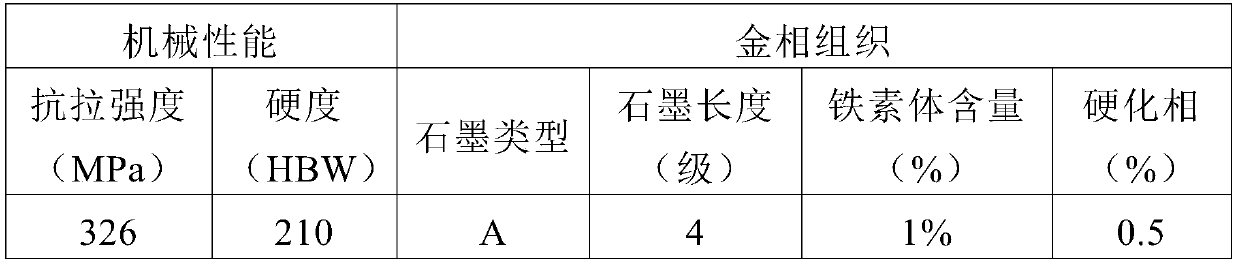

[0057] This embodiment is described by taking a certain type of machine tool bed (designation HT300) produced in the workshop as an example.

[0058] 1. Raw material smelting

[0059] ① The required casting mass is 5t. First, 3200kg of scrap iron and 800kg of scrap steel (that is, equivalent to 80% of the mass of molten iron required for castings, and the mass content of some scrap iron and scrap steel are 80% and 20% respectively) are added to the 5T intermediate frequency at one time. Melting in an induction furnace to obtain the second molten iron.

[0060] After the second molten iron is melted, raise the temperature of the furnace to about 1400°C, take a spectral sample to detect the composition and its mass percentage before the furnace: 2.81%C, 1.68%Si, 0.5%Mn, 0.035%P, 0.02%S , 0.24% Cu, 0.12% Mo, 0.08% Ni, 0.0003% Sn, 0.002% Sb, 0.01% Cr, and the balance is Fe and unavoidable impurities.

[0061] ②According to the test results of C and Si, it can be estimated that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com