Lead-free solder for micro alloyed eutectic alloy of stannum and zinc

A technology of micro-alloying and eutectic alloy, which is applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problems of easy oxidation of liquid alloy surface, difficult removal of oxide film, poor wettability, etc., to achieve convenient Large-scale production organization and production process control, production organization and recycling are convenient and easy to stabilize the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

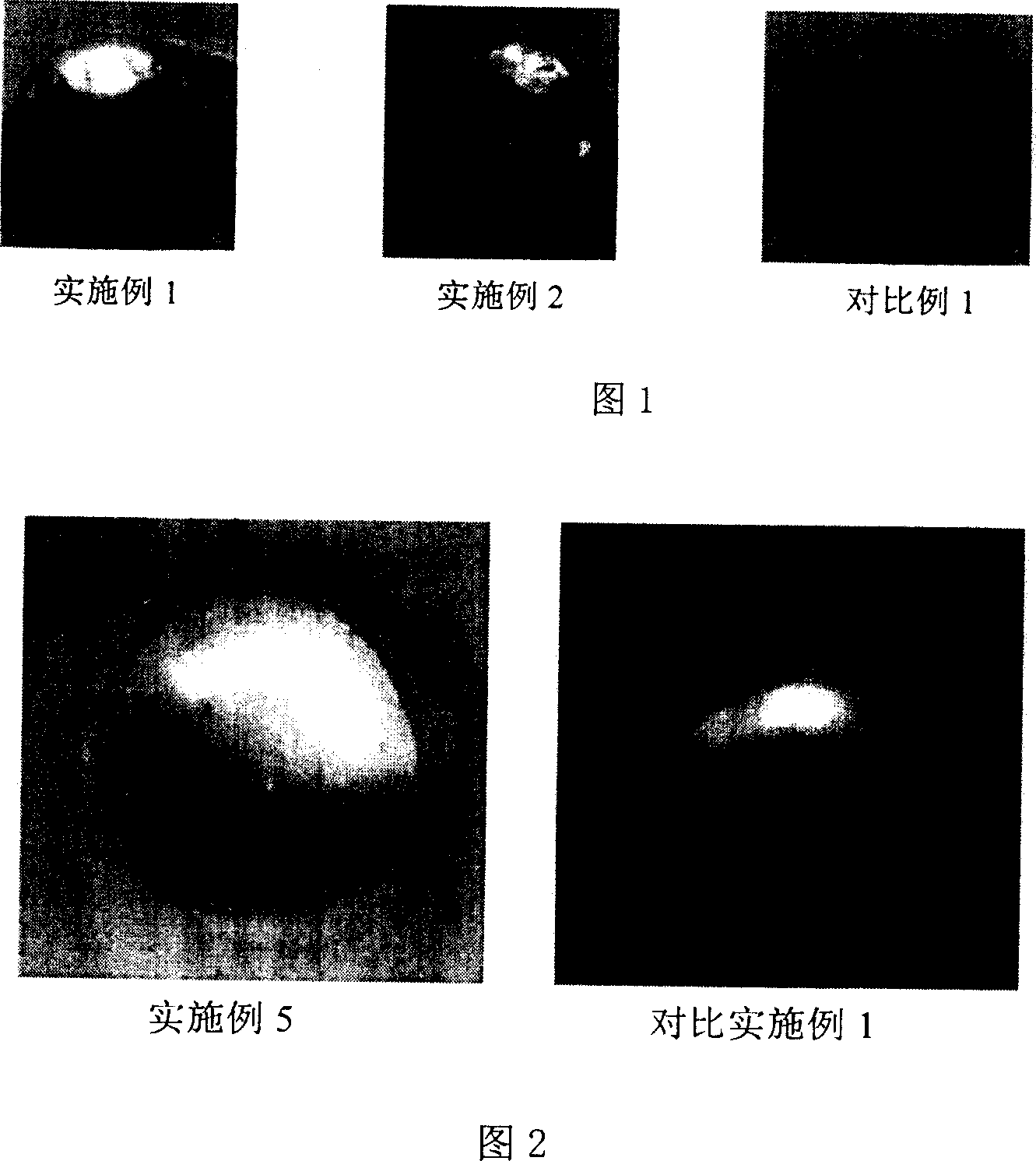

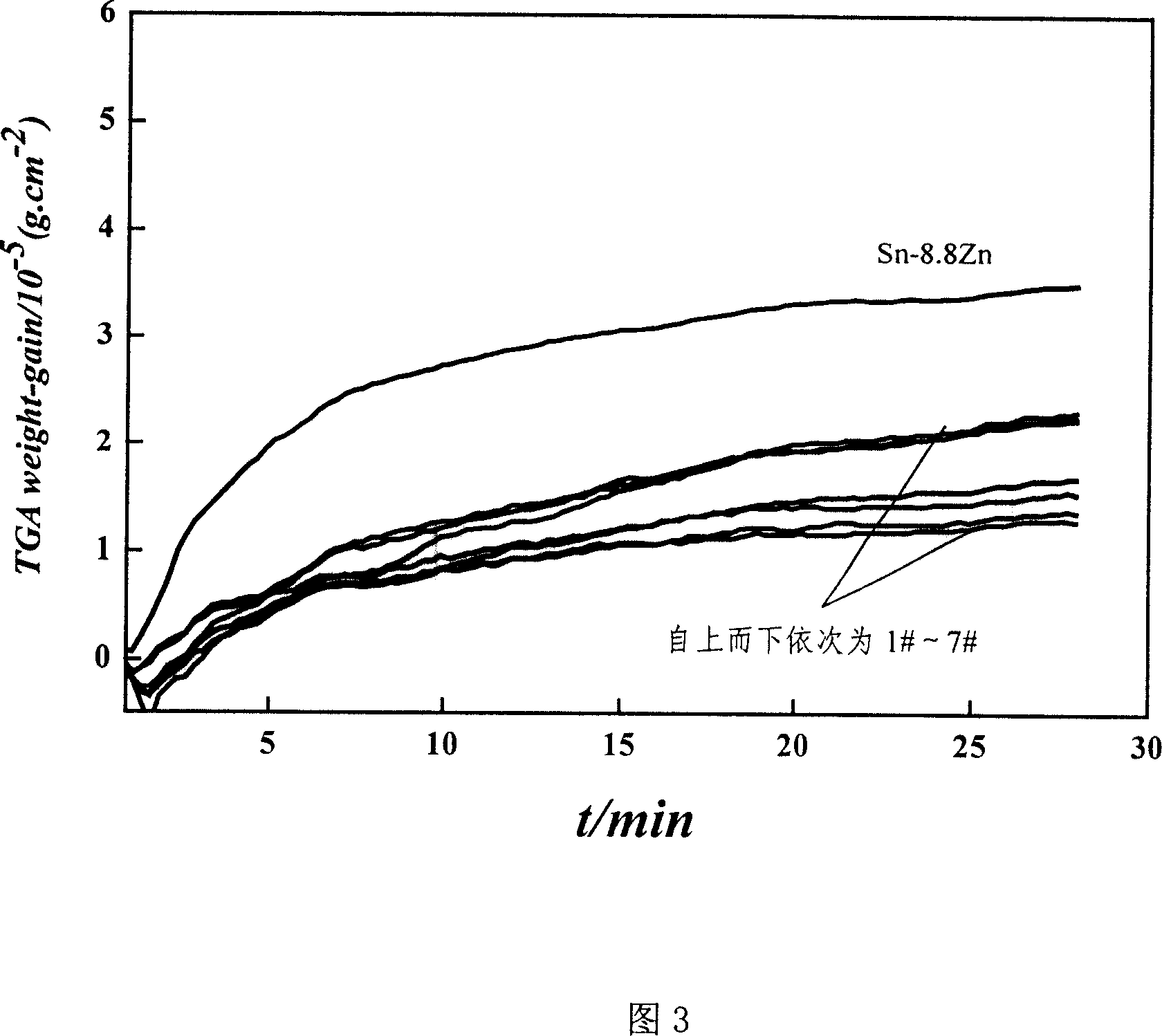

Examples

Embodiment 1

[0029] The prepared Sn, Zn, Sn-10Ge metal and alloy raw materials are prepared according to the composition formula of Sn-8.8Zn-0.08Ge to prepare 500g of alloy material, and the alloy is smelted under the protection of argon gas in a resistance furnace. The order of alloy addition is Sn, Zn , Sn-10Ge, after the alloy is completely melted, keep it at 400°C for 30 minutes to ensure the uniformity of the composition, reduce the heating power, and start pouring into the preheated stainless steel mold when the temperature of the solder melt drops to 250°C.

Embodiment 8

[0031] The prepared Sn, Zn, Ga, Sn-10Ge, Sn-10Al, Sn-5Ni and Sn-5P metal and alloy raw materials, according to Sn-8.7Zn-0.03Ga--0.015Ge-0.01Al-0.006P-0.04 Prepare 500g of alloy material with the Ni composition formula, and use the resistance furnace to melt the alloy under the protection of argon. Then keep it at 400°C for 30 minutes to ensure the uniformity of the ingredients, reduce the heating power, and start pouring the solder melt into the preheated stainless steel mold when the temperature of the solder melt drops to 250°C.

[0032] Other examples and comparative examples were prepared in the same manner as above-mentioned Examples 1 and 8, and their chemical compositions are shown in Table 1.

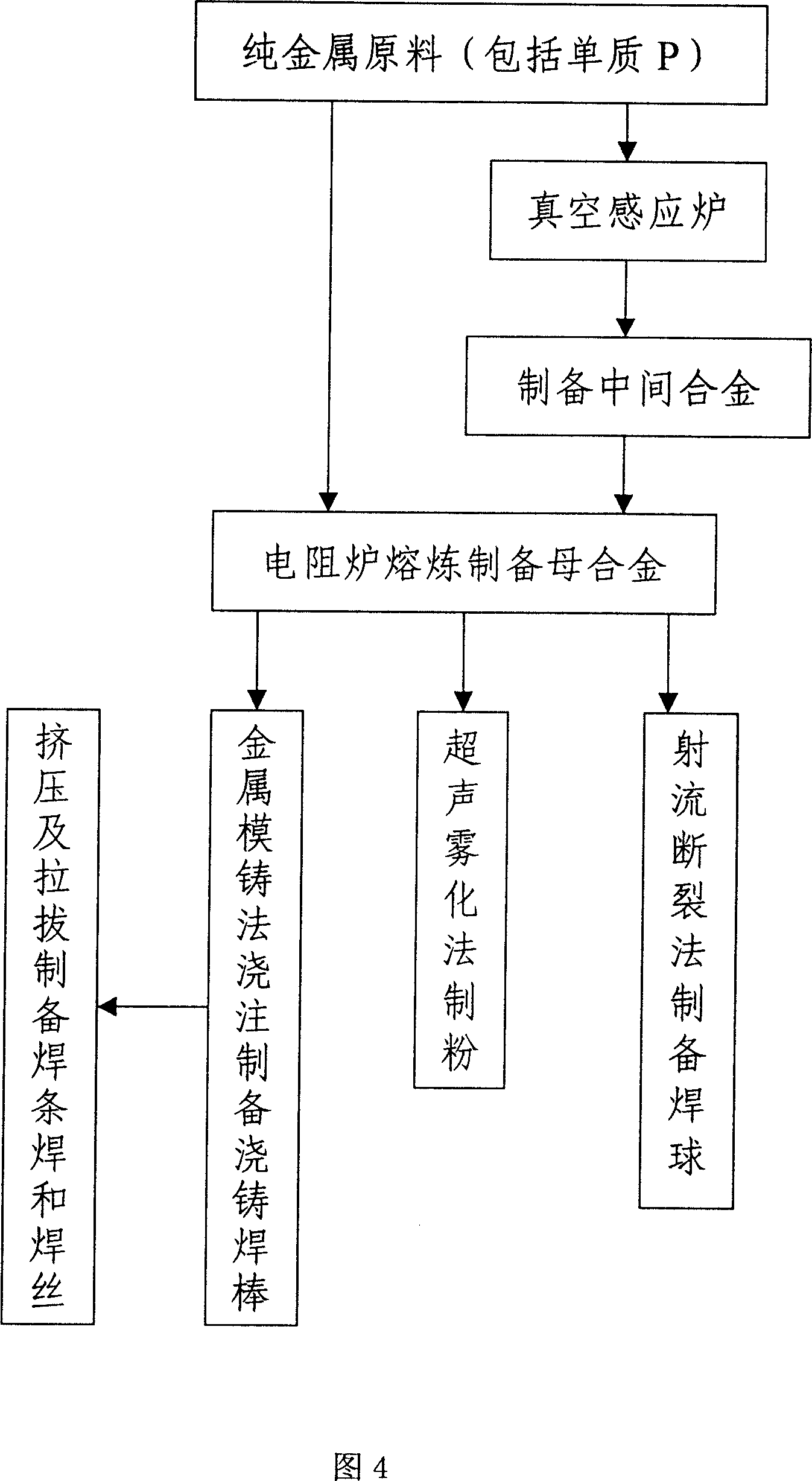

[0033] The alloy of the present invention can be prepared into master alloy blanks, welding rods, welding wires, welding balls and welding powders, and the specific preparation process is shown in Figure 4. It can be added in the way of pure metal, that is, adding pure metal ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com