Inert atmosphere control device for laser forming and repair

An inert atmosphere and control device technology, applied in the field of material processing, can solve the problems of high cost, heavy equipment, waste of inert gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

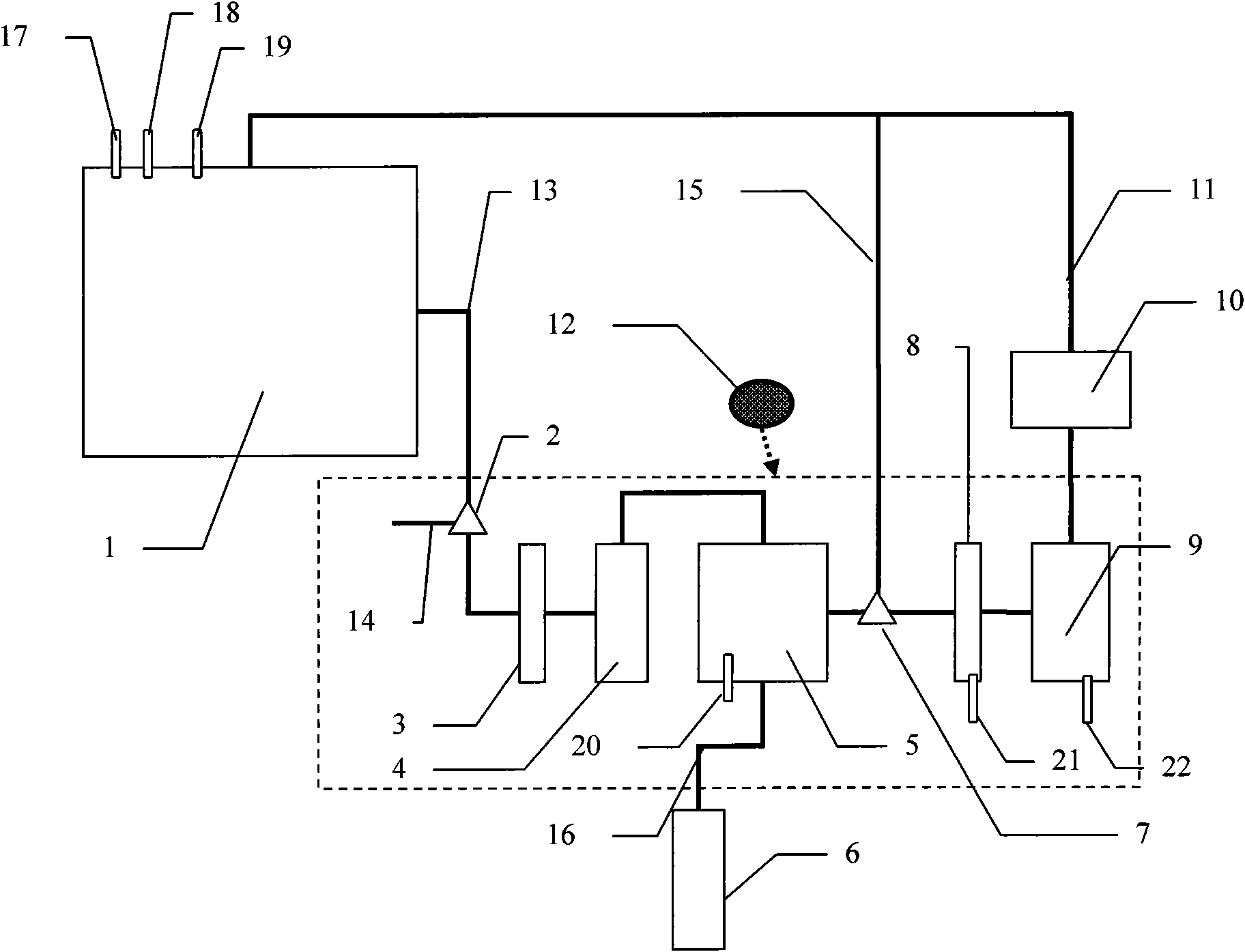

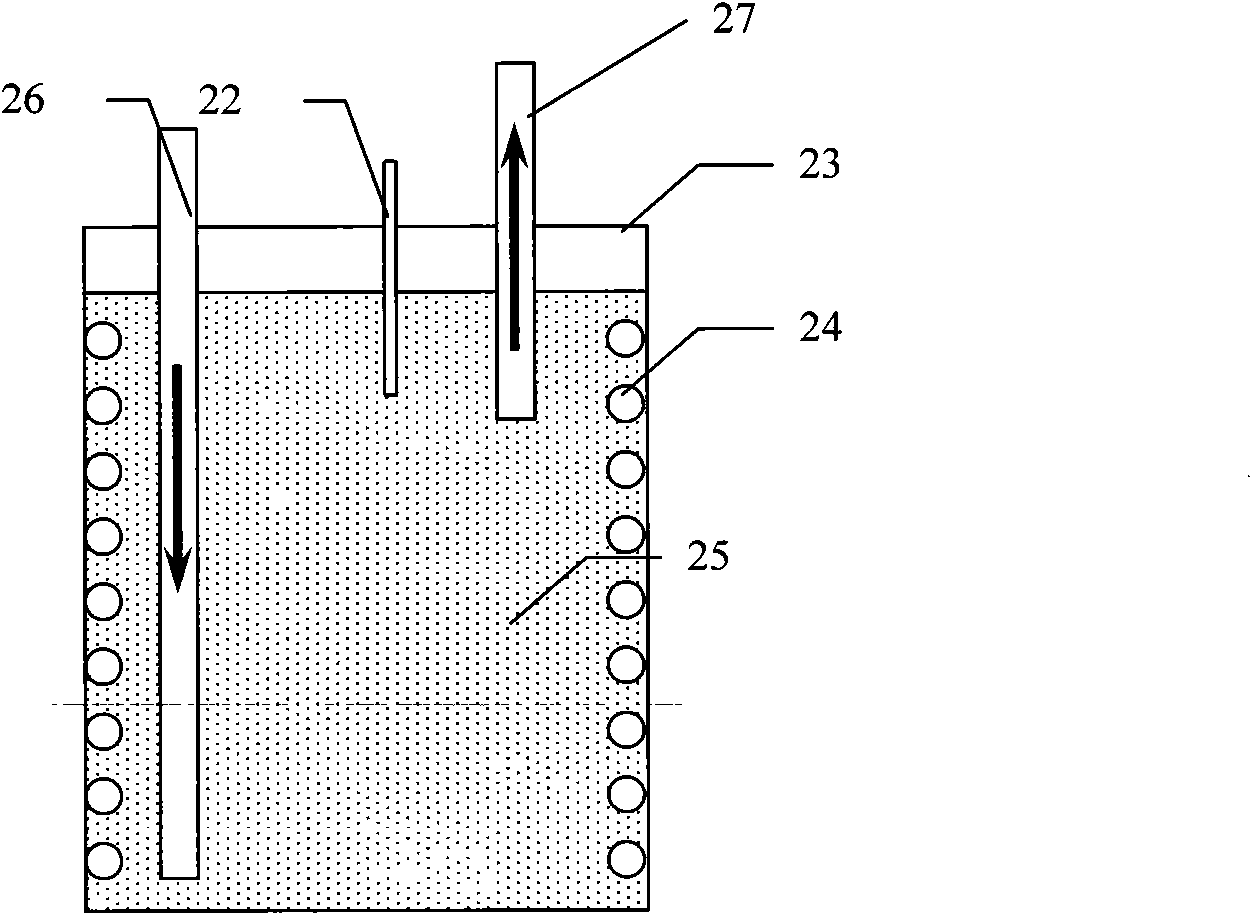

[0019] An inert atmosphere control device for laser forming and repairing, including an atmosphere protection cover 1, a diaphragm booster pump 4, a dust filter 3, a pressure gas storage tank 5, a water eliminator 8, an argon gas purifier 9, and a water cooling jacket 10. Control unit 12 and sensor, wherein:

[0020] The air return pipeline 13 starts from the atmosphere protective cover 1, and successively connects with the exhaust pipe three-way valve 2, dust filter 3, diaphragm booster pump 4, pressure gas storage tank 5, intake pipe three-way valve 7, water eliminator 8 and The argon gas purifiers 9 are sealed in series; the gas inlet pipe 11 is connected with the atmosphere protection cover 1 through the water cooling jacket 10 . The exhaust pipe 14 is connected with the three-way valve 2 of the exhaust pipe. The two ends of the air inlet pipe 15 of the air storage tank are respectively sealed and connected with the three-way valve 7 of the air inlet pipe and the air inle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com