An intermediate frequency induction melting furnace system and method

An induction melting furnace and intermediate frequency technology, applied in the field of vacuum induction heating refining equipment, can solve problems such as difficult to complete the refining processes such as dephosphorization and decarburization of molten steel, affecting the rhythm of continuous casting or vacuum refining, and difficult to guarantee metallurgical quality. Small environmental pollution, low smelting energy consumption and high metal recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

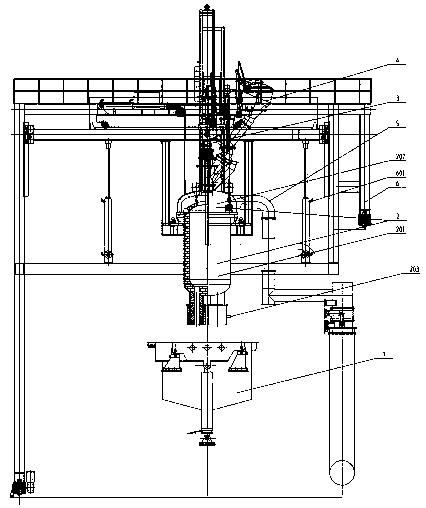

[0021] In order to further illustrate the technical means and effects adopted by the present invention to achieve the intended purpose, the specific implementation, structural features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

[0022] refer to figure 1 , this embodiment discloses a medium frequency induction melting furnace system (RHI) equipped with vacuum dephosphorization, decarburization and desulfurization. 4. Composed of air extraction pipeline 5, rail car 6, etc.

[0023] The vacuum cycle smelting device 2 is operated by the lifting system 601 of the railcar 6, so that the vacuum tank 201 and the vacuum cover 202 can be lifted and lowered freely in the vertical direction.

[0024] Oxygen lance spray gun lifting system 3 and vacuum feeding device 4 are installed on the vacuum cover. The oxygen lance spray gun can freely enter and exit the vacuum cover, alloy materials, dephosphori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com