Metallurgy dust mud leaching device

A metallurgical dust and leaching technology, which is applied in metallurgical wastewater treatment, sludge treatment, water/sludge/sewage treatment, etc., can solve problems such as poor sheet forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention; obviously, the described embodiments are only some embodiments of the present invention; rather than all embodiments. Based on the embodiments of the present invention; all other embodiments obtained by persons of ordinary skill in the art without creative work; all belong to the protection scope of the present invention.

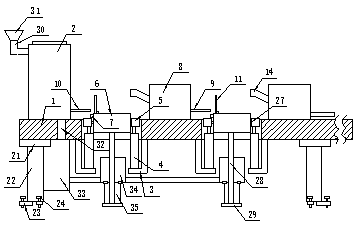

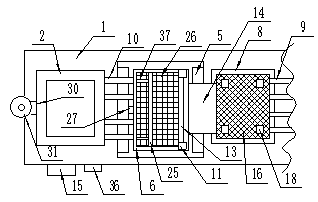

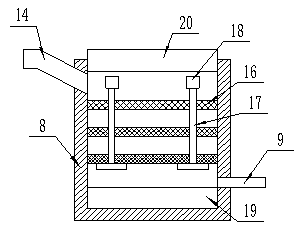

[0025] see Figure 1-7, a metallurgical dust and sludge leaching device, comprising a strip-shaped bearing base 1, a dust and sludge leaching mechanism is provided on the upper surface of the strip-shaped bearing base 1, a supporting and fixing mechanism is provided on the lower surface of the strip-shaped bearing base 1, the The dust and mud leaching mechanism consists of a metallurgical raw material carrying barrel 2 arranged on one end of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com