Vertical water lubrication transverse bearing test device and test simulation method thereof

A technology of radial bearing and testing device, applied in the direction of mechanical bearing testing, etc., can solve the problems of shortening the service life of seals, increasing the economic cost of testing, extending the development cycle of testing, etc., achieving strong compatibility, saving foreign exchange, and saving equipment costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

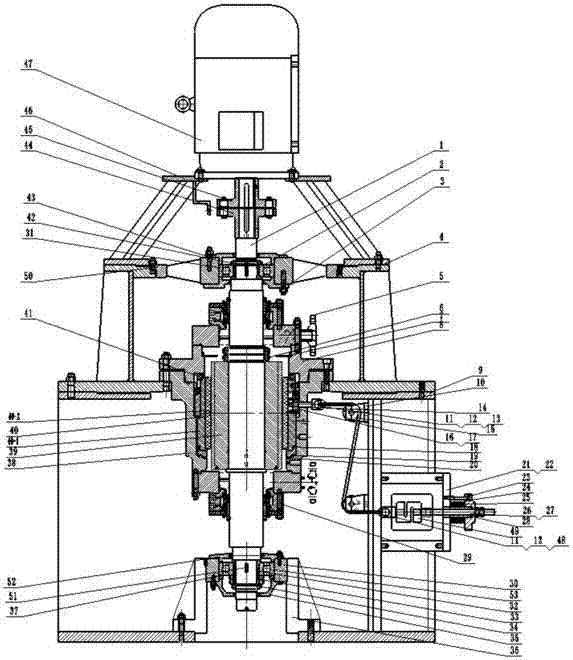

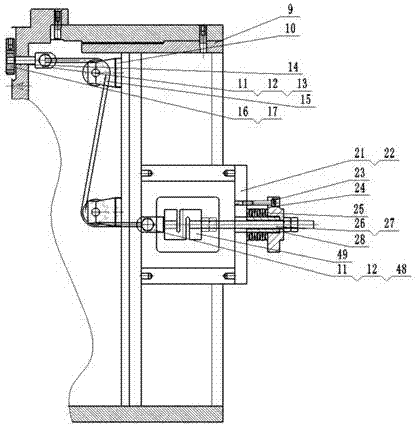

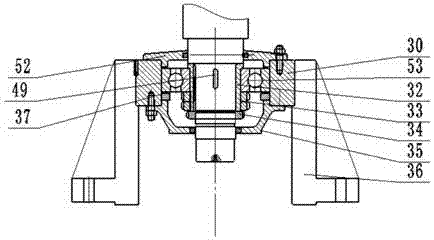

[0042] see figure 1 , a vertical water-lubricated radial bearing test device provided in an embodiment of the present invention, including a bracket composed of a motor bracket 46, an intermediate bracket 4 and a lower bracket 9, and an upper rotor arranged at the junction of the motor bracket 46 and the intermediate bracket 4 The supporting part, the test bearing fixing part arranged at the junction of the middle bracket 4 and the lower bracket 9, the lower rotor supporting part arranged on the bottom of the lower bracket 9, the load applying device arranged at the side of the lower bracket 9, and the motor bracket 46 The drive motor 47.

[0043]Wherein, the upper and lower ends of the middle support 4 are respectively connected with the motor support 46 and the lower support 9 by bolts to form a support as the main support of the test device. The test bearing fixing part includes the rotating shaft 1 , the bearing housing 38 and the bearing housing gland 8 . The two ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com