Process for preparing high-purity quartz from vein quartz

A technology of vein quartz and quartz, which is applied in the field of preparation of high-purity ultra-fine British materials from vein quartz, can solve the problems such as the impurity is not effectively and precisely removed, the inclusion impurities are not effectively and precisely removed, and it is difficult to meet the application requirements of high-tech products, etc. The effect of roasting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

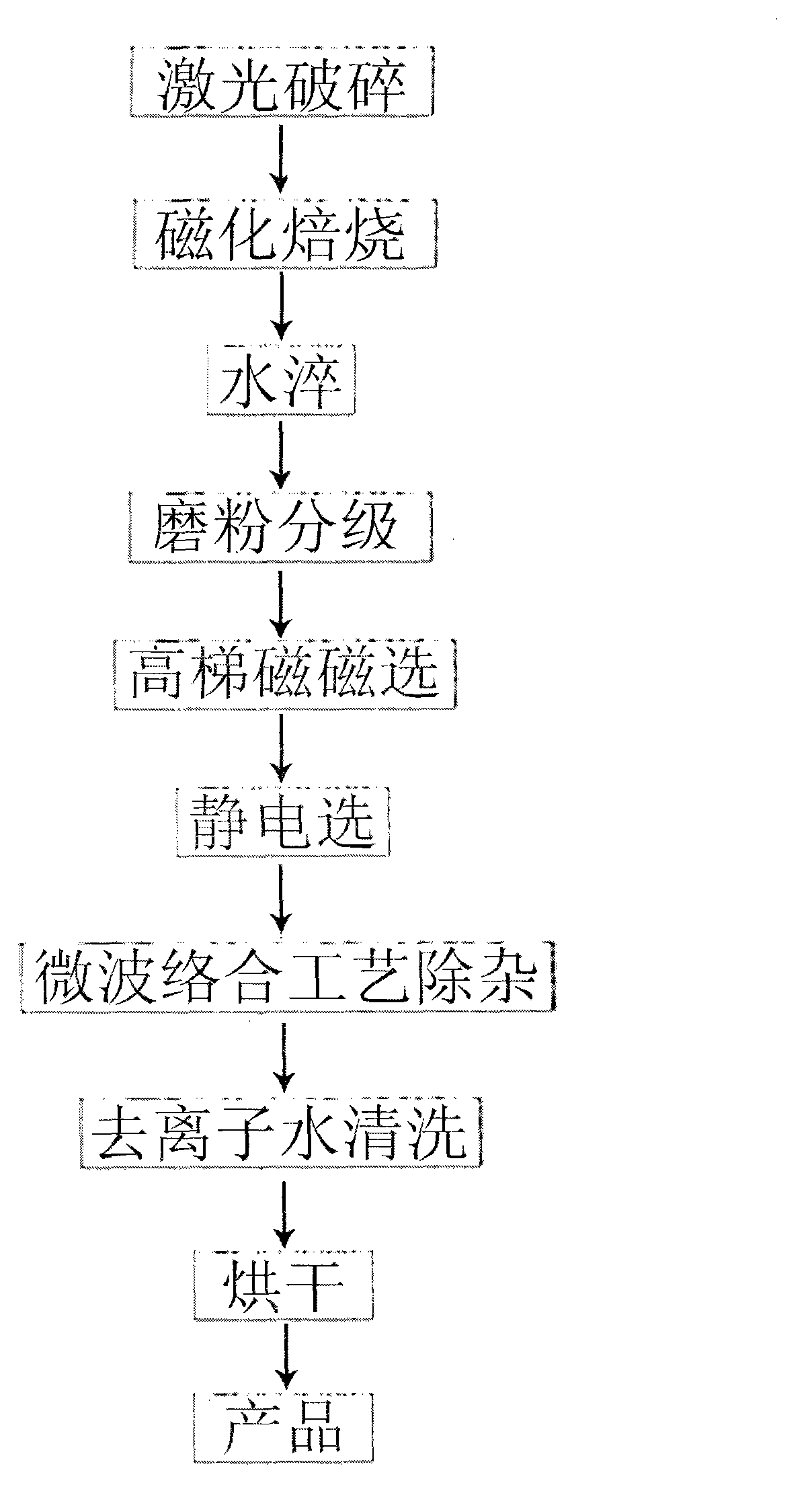

[0031] The present invention will be further described in detail below in conjunction with the process flow diagram of the present invention.

[0032] 1. The content of Sio2 ≥ 98.26% ~ Sio2 ≥ 99.2% of the vein quartz raw ore in Fengxin County, Jiangxi Province is used, the impurity content is 1.5 ~ 0.7%, and the raw ore size is ≤ 10cm;

[0033] 2. Laser crushing is used to crush the raw ore with a size of ≤10cm to 0.5-1.5cm, so that the associated minerals are separated from the quartz, and the quartz particles are broken down into countless tiny holes;

[0034] 3. Using electromagnetic roasting, place the quartz particles crushed to 0.5-1.5cm in an electromagnetic roasting furnace, and use the waste heat of laser crushing to roast at a roasting temperature of 500-700°C for 1-1.5 hours to make the quartz ore contain weak Magnetic iron minerals (hematite, limonite, siderite and pyrite, etc.) become strongly magnetic magnetite;

[0035] 4. Water quenching is adopted, and the qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com