Air tightness detection device

A technology of air tightness detection and sealing device, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of fluid, etc., which can solve the problem that automatic and quantitative leak detection cannot be realized, which affects the accuracy of measurement , Difficult to observe and other problems, to achieve the effect of improving product testing efficiency, reducing labor costs, and shortening the testing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

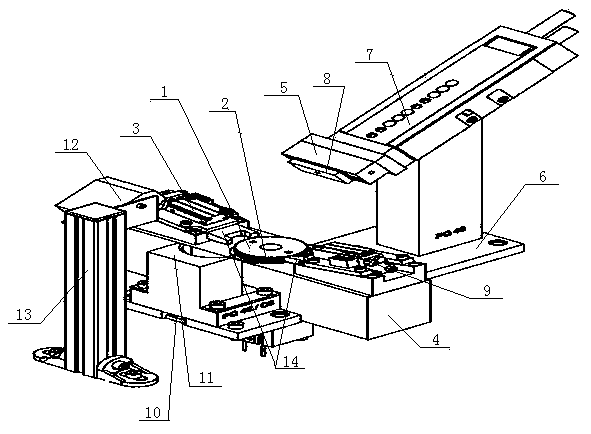

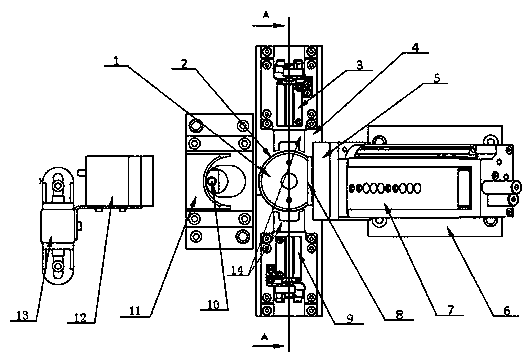

[0023] This device needs to be used with corresponding leak detectors. The brand and model of the leak detector can be optimally matched according to the site conditions of the products to be tested. In this embodiment, the CETATEST 710 leak detector is used, and the leak detector is tested with this device. The air source access board 5 can be connected to the test operation.

[0024] (1) Place the pre-tested product on the base 4, the product sensor 10 senses the product and outputs feedback information, the PLC receives the feedback information and processes the instruction information; the barcode scanner 12 receives the PLC instruction information to scan and identify the product and Store product information; the first sliding table cylinder 3 and the third sliding table cylinder 9 receive PLC instruction information and fix the pre-detected product through the claw 14 and output feedback information; at this time, PLC sends instruction information after processing the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com