A method for manufacturing an MEMS microphone support plate with porous sound inlet and single-hole sound transmission

A manufacturing method and microphone technology, which are applied to electrostatic transducer microphones, sensors, electrical components, etc., can solve the problems of increasing the overall thickness of the finished MEMS microphone, limiting the lifting space of the MEMS microphone, and the limited cavity space of the size of the steel sheet opening. Achieve the effect of improving microphone performance, simplifying the chip placement process, and improving the effect significantly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, a preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings. However, the scope of protection of the present invention is not limited to the following embodiments, that is, all simple equivalent changes and modifications made based on the scope of the patent application of the present invention and the content of the specification are still within the scope of the patent of the present invention.

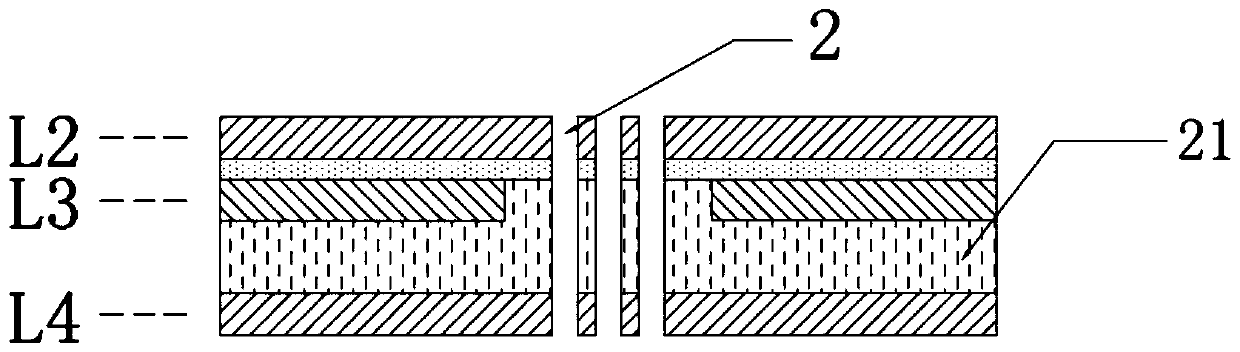

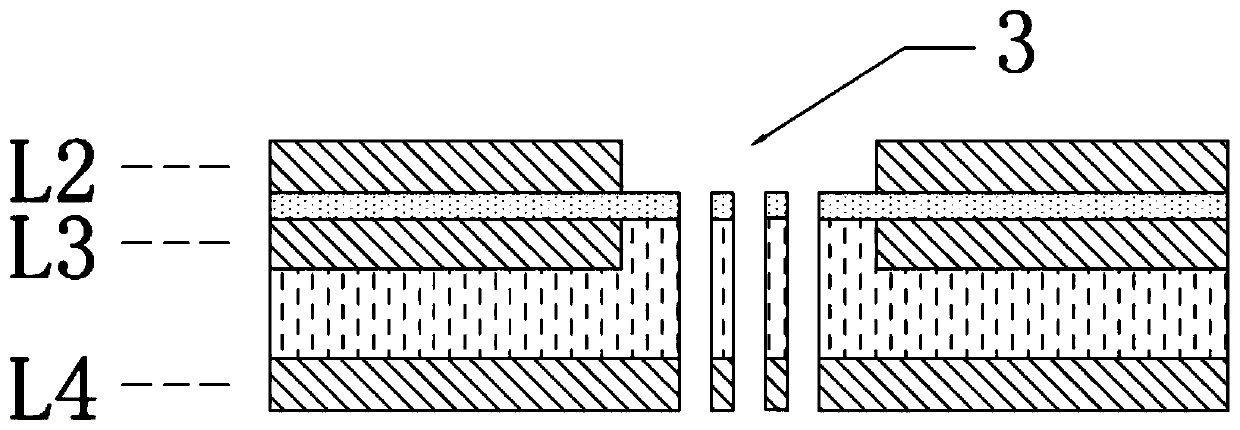

[0035] Refer to Figure 1-6 , Is a method for manufacturing a porous sound-inlet single-hole sound transmission MEMS microphone carrier board of the present invention, including the following steps:

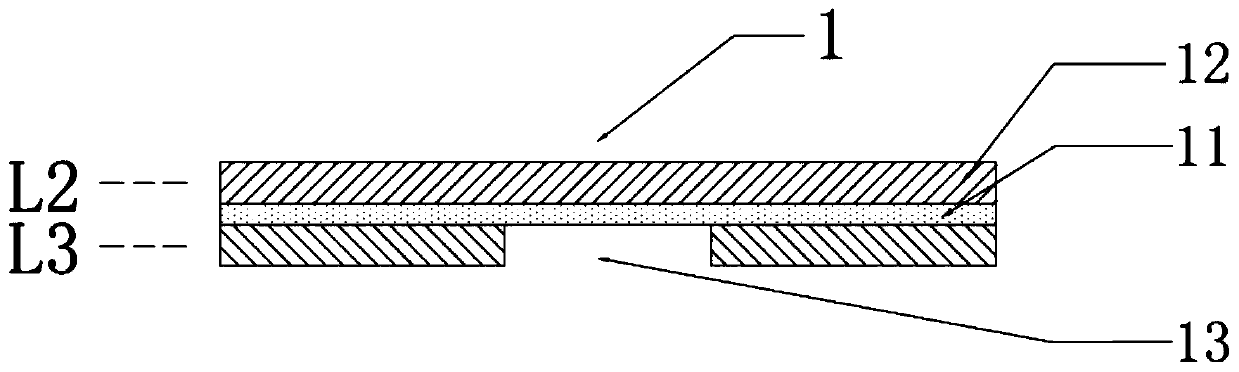

[0036] Step 1. Prepare an embedded capacitor substrate 1. The embedded capacitor substrate includes a capacitor layer 11 and a conductive copper foil layer 12 located on both sides of the capacitor layer 11. The two conductive copper foil layers form a second circuit layer L2 and a third circuit layer L2, respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com