Wire harness separator assembly, method of assembling same, battery and device

An assembly method and isolation board technology, which is applied in the manufacture of batteries, battery pack parts, secondary batteries, etc., can solve the problems of long time consumption, low production efficiency, cumbersome assembly process of wire harness isolation board components, etc., and simplify the placement process , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

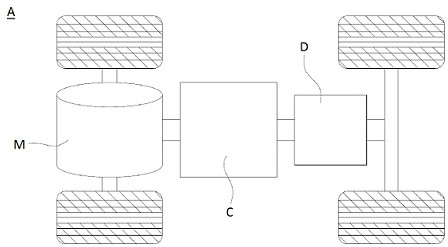

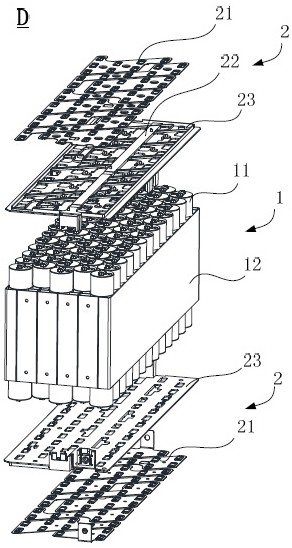

[0041] Embodiment 1 of the present application provides a battery D, especially an assembly method of the wire harness separator assembly 2 in the battery D, and a device using the battery D as a power source.

[0042] Devices that use the battery D as a power source include vehicles A, ships, small aircraft, etc. The device uses the battery D to provide electrical energy to generate driving force for driving the device. The device can also use electricity and other types of energy (such as fossil energy) at the same time to generate driving force. All devices that can use the battery D as a power source are within the protection scope of the present application.

[0043] figure 1 It is a schematic diagram of the structure of the vehicle in Embodiment 1 of the present application.

[0044] Such as figure 1 As shown, taking vehicle A as an example, vehicle A in the embodiment of the present application may be a new energy vehicle, and the new energy vehicle may be a pure ele...

Embodiment 2

[0091] The present application also provides an assembly method of the wire harness separator assembly 2 of the battery D.

[0092] Figure 14 It is a flow chart of the assembly method of the wire harness isolation board assembly according to the second embodiment of the present application. In this embodiment, the parallel connection of the battery cells 11 is taken as an example for illustration.

[0093] Such as Figure 14 As shown, the assembly method of the wire harness isolation plate assembly 2 of the present application includes the following steps:

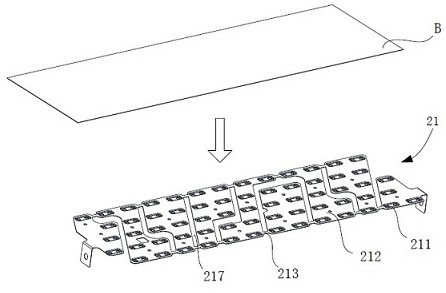

[0094] In step S1 , the plate B is integrally formed into a busbar set 21 , wherein the busbar set 21 includes a plurality of busbar units 212 and a connecting portion 213 connecting the plurality of busbar units 212 to each other.

[0095] In step S1 , first select a plate B of a suitable size according to the arrangement of the battery cells 11 , and then cut the plate B according to the connection method of the batt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com