Method for extracting GeCl4 from smoke dust containing Ge

A germanium fume, microwave heating technology, applied in germanium halide and other directions, can solve the problems of large discharge of harmful waste liquid, slow heating of steam heating, unstable temperature control, etc., to improve recovery rate, fast heating speed, and reduce energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

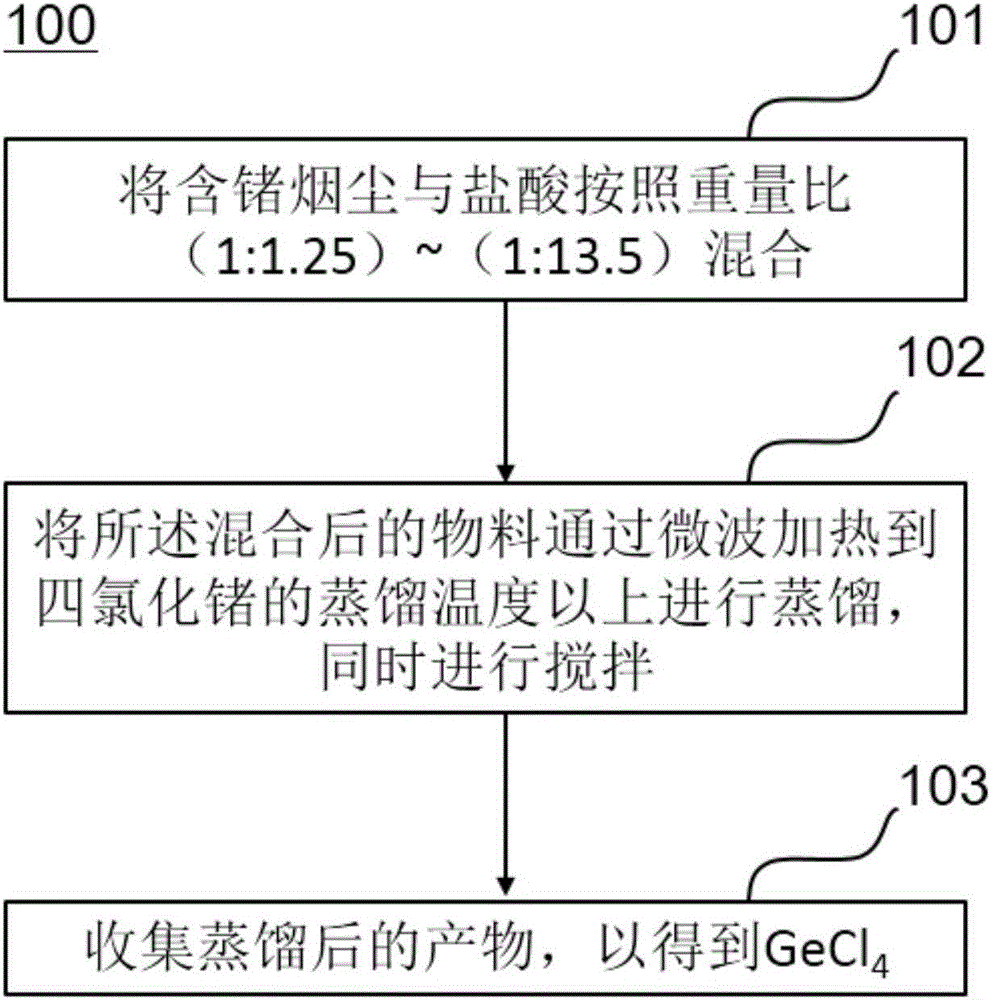

Method used

Image

Examples

Embodiment 1

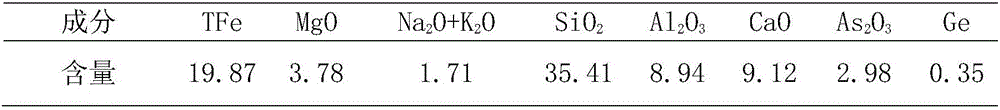

[0028] The composition content of germanium-containing fume is shown in Table 1:

[0029] Table 1 Composition of germanium-containing raw materials / %

[0030]

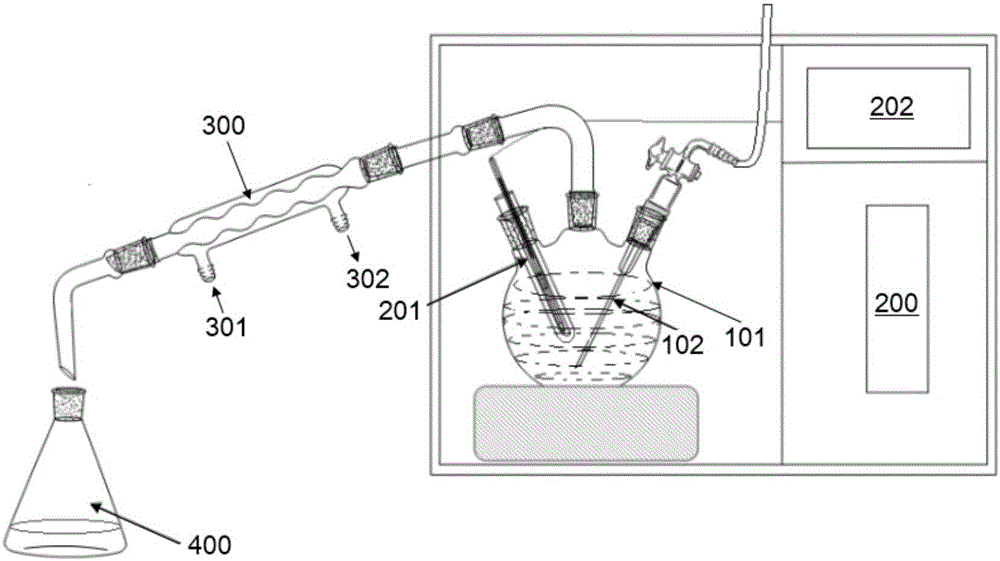

[0031] Such as figure 2 , dry the germanium-containing fumes at 50°C for 24h, then mix the germanium-containing fumes and 8mol / L hydrochloric acid in a ratio of 1:1.25 by weight and add them to the three-necked flask 101, and place the middle bottle of the three-necked flask 101 The mouth is connected with the condensation pipe 300, and the condensed water enters the condensation pipe 300 from the condensed water inlet 301, and is discharged from the condensation pipe outlet 302. A bottle mouth of the three-necked flask 101 is inserted into a gas stirring tube 102, and the gas stirring tube 102 is connected with a nitrogen tank. Put the three-necked flask 101 and the gas stirring tube 102 into a microwave oven. Insert a thermocouple 201 into the other mouth of the three-diameter flask 101, connect it to the micr...

Embodiment 2

[0033] Such as figure 2 , dry germanium-containing fumes at 40°C for 16h, then mix germanium-containing fumes and 8.5mol / L hydrochloric acid in a ratio of 1:5 by weight, and mix in potassium permanganate, the weight of potassium permanganate is 4.5% by weight of germanium soot. After mixing, add it to the three-necked flask 101 and connect the mouth of the three-necked flask 101 to the condenser tube 300 . A bottle mouth of the three-necked flask 101 is inserted into a gas stirring tube 102, and the gas stirring tube 102 is communicated with air. Put the three-necked flask 101 and the gas stirring tube 102 into a microwave oven. A thermocouple 201 is inserted into the other mouth of the three-diameter flask 101, connected to the microwave controller 202 through the thermocouple 201, the heating rate of the microwave oven is set to 8°C / min, the heating temperature is 105°C, and the holding time is 60min. Air was introduced into the flask 101 for extraction. The extracted p...

Embodiment 3

[0035] Such as figure 2 , dry the germanium-containing dust at 30°C for 30h, then mix the germanium-containing dust with 9mol / L hydrochloric acid in a weight ratio of 1:13.5, and mix in potassium permanganate, the weight of potassium permanganate is the weight of the germanium-containing dust 7.5% of the mixture was added to the three-necked flask 101 after mixing. The mouth of the three-diameter flask 101 is connected to the condenser pipe 300 , and the condensed water enters the condenser pipe 300 from the condensed water inlet 301 and is discharged from the condenser pipe outlet 302 . A gas stirring tube 102 is inserted into one mouth of the three-necked flask 101 . Put the three-necked flask 101 and the gas stirring tube 102 into a microwave oven, and the gas stirring tube 102 is connected with an argon tube. A thermocouple 201 is inserted into the other mouth of the three-diameter flask 101, connected to the microwave controller 202 through the thermocouple 201, the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com