Process for producing germanium tetrachloride by regenerated germanium

A germanium tetrachloride and process technology, applied in the field of GeCl4 preparation, can solve the problems of low germanium recovery rate, complex process, high residual acid content in products, etc., and achieve the effects of improving recovery rate, low impurity content and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

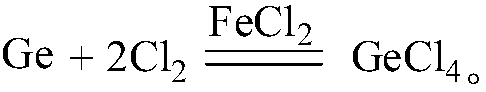

Method used

Image

Examples

Embodiment 1

[0030] Taking the annual production of 20T area molten germanium ingots of Hengyang Hengrong Semiconductor Materials Co., Ltd. as the raw material of regenerated germanium for the preparation of germanium tetrachloride, an example is given.

[0031] Prepare the hydrochloric acid solution that concentration is 6mol / L in reactor, and add ferrous chloride, the mass percentage concentration of ferrous chloride in hydrochloric acid solution is 10%. Add the regenerated germanium powder into the reaction kettle. The amount of germanium powder added is 20% of the mass of the hydrochloric acid solution. The particle size of the germanium powder meets a 100-mesh sieve and the pass rate reaches more than 98%. Stir for 40 minutes to make the solution system mix evenly and control the reaction. The temperature in the kettle is 30°C, and then chlorine gas is continuously fed into the hydrochloric acid solution for reaction. The amount of chlorine gas introduced is calculated according to the...

Embodiment 2

[0033] Taking the annual production of 20T area molten germanium ingots of Hengyang Hengrong Semiconductor Materials Co., Ltd. as the raw material of regenerated germanium for the preparation of germanium tetrachloride, an example is given.

[0034] Prepare the hydrochloric acid solution that concentration is 7mol / L in reactor, and add ferrous chloride, the mass percentage concentration of ferrous chloride in hydrochloric acid solution is 9%. Add the regenerated germanium powder into the reaction kettle. The amount of germanium powder added is 40% of the mass of the hydrochloric acid solution. The particle size of the germanium powder meets the 100-mesh sieve and the pass rate reaches more than 98%. Stir for 60 minutes to make the solution system mix evenly and control the reaction. The temperature in the kettle is 50°C, and then chlorine gas is continuously introduced into the hydrochloric acid solution for reaction. The amount of chlorine gas introduced is calculated accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com