Distillation device for producing high-purity germanium tetrachloride

A germanium tetrachloride and distillation device technology, applied in the semiconductor field, can solve the problems of easily damaged raw materials, large fuel consumption, environmental pollution, etc., and achieve the effects of good temperature control effect and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

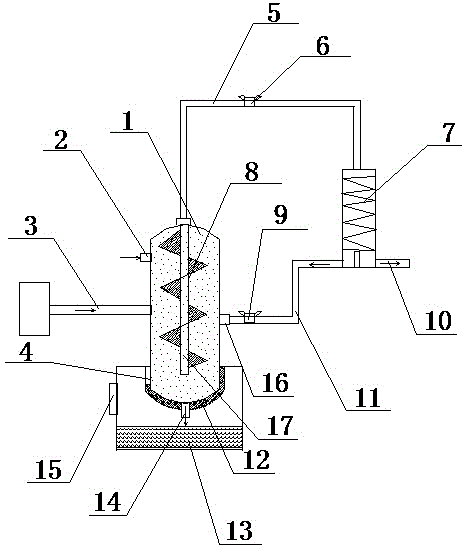

[0016] combine figure 1 A kind of distillation device for producing high-purity germanium tetrachloride shown comprises a distillation tank 1 and a condensation tank 7, and one side of the distillation tank 1 is provided with a feed port 2 and a first air inlet 3, and the other side of the distillation tank 1 is A second air inlet 16 is provided, an air outlet is provided on the top of the retort 1, a screw shaft 17 is vertically arranged at the inner axis of the retort 1, and a plurality of infrared heating blocks 8 are arranged on the screw shaft 17, and a plurality of infrared heating blocks 8 are arranged on the screw shaft 17. The heating block 8 is evenly arranged in a spiral shape on the outer wall of the screw shaft 17 along the vertical direction. The bottom of the retort 1 is provided with an infrared heating jacket 12. The infrared heating jacket 12 is provided with a temperature detector 4. The bottom of the retort 1 is provided with a The waste liquid port 14, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com