Patents

Literature

36results about How to "Save acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

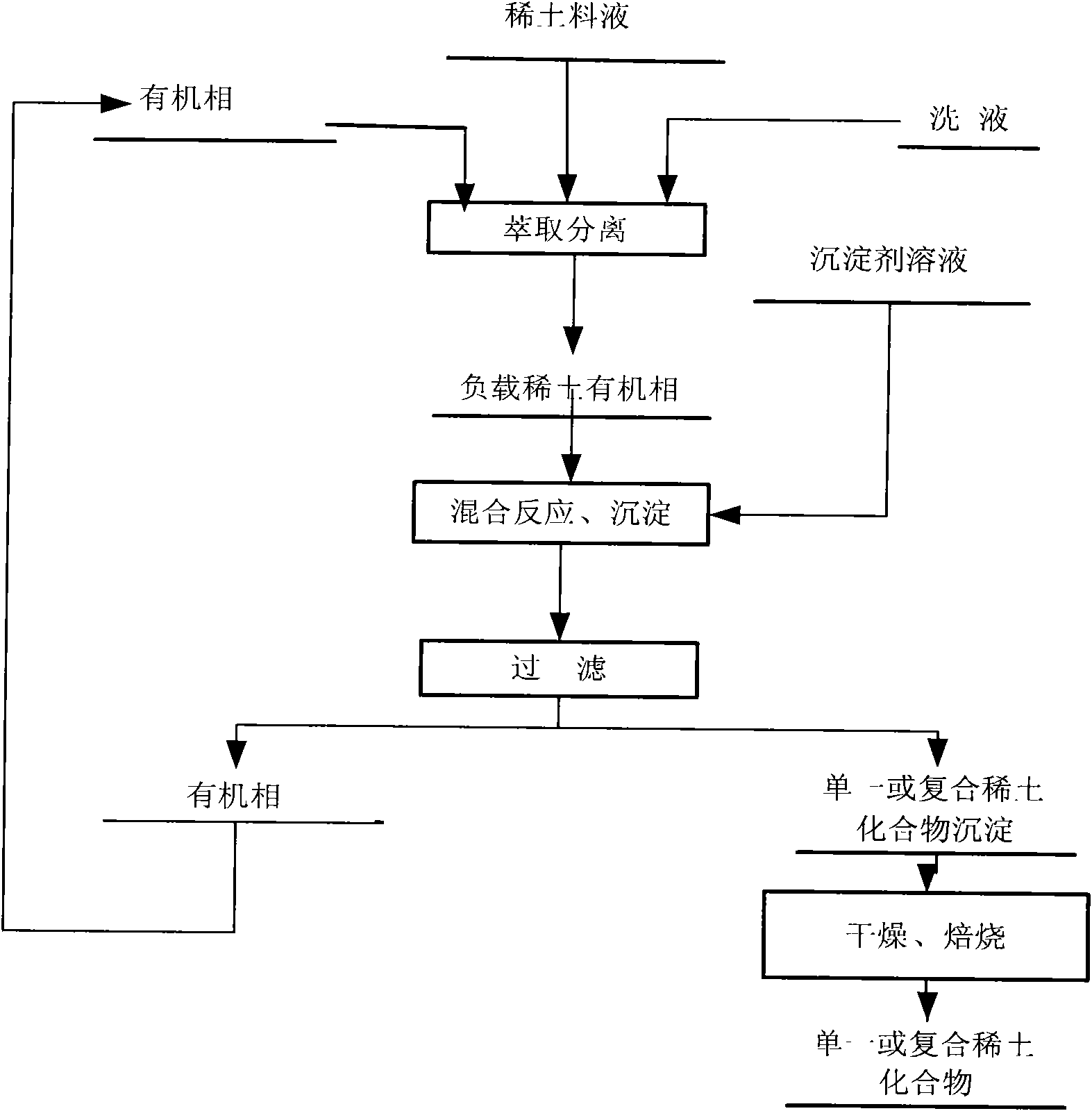

Process of directly preparing rare-earth compound from extraction separation load organic phase

InactiveCN101602519ASolve the problem of high residual acid and large acid consumptionEliminate the step of stripping rare earthRare earth metal compoundsProcess efficiency improvementDispersityRare earth

The invention provides a process of directly preparing a rare-earth compound from an extraction separation load organic phase. The process comprises following steps: carrying out a mixed precipitation reaction between a precipitator solution and the load organic phase which is obtained from extraction separation and contains rare-earth; post-treating the filter cake obtained by filtering slurry liquid so as to obtain the rare-earth compound with good dispersity and uniform particle size distribution; and returning the organic phase to the extraction separation working procedure for recycling use. The process of extracting and separating rare-earth omits the rare-earth stripping step, saves a great amount of acid needed by the rare-earth in a stripping load organic phase and solves the problems of stripping difficulty of medium-heavy rare-earth, high spent acid of a stripping solution, and the like. The invention uses the precipitator to precipitate the rare-earth from the organic phase, and the whole precipitation reaction is carried out on an oil-water interface to effectively control the grain size. Meanwhile, a trace organic phase is attached to grain surfaces and is used as a surface active agent to reduce the mutual adsorption action of grains for deflocculation. The invention can obtain products with good dispersity and uniform grain size distribution, thereby being a new method for preparing a high-quality rare-earth compound material. The invention has simple process, is easy to realize the industrialized production and has low production cost.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

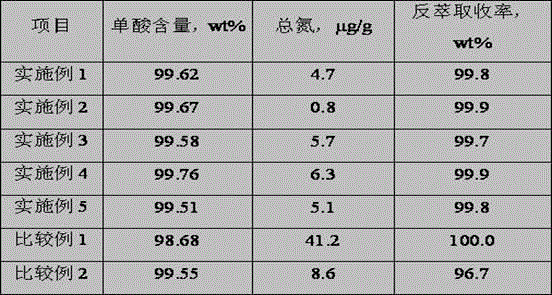

Purification method for long-chain dicarboxylic acid

ActiveCN104591998AHigh purityHigh yieldOrganic compound preparationCarboxylic compound separation/purificationPurification methodsTotal nitrogen

The invention discloses a purification method for long-chain dicarboxylic acid. The method comprises the following steps: subjecting terminated long-chain dicarboxylic acid fermentation broth to pretreatment and acidification; carrying out extraction with an organic solvent and adsorption, adding an emulsifier and an alkaline solution and carrying out treatment; and adding acetic acid into the obtained water phase and then carrying out cooling crystallization so as to obtain a long-chain dicarboxylic acid product. Compared with the prior art, the method of the invention has the following advantages: a small amount of raw materials are used; loss and cost are low; the purity of the obtained long-chain dicarboxylic acid is high; total nitrogen content meets requirements of the polymer grade; and the method is suitable for industrialized production.

Owner:CHINA PETROLEUM & CHEM CORP +1

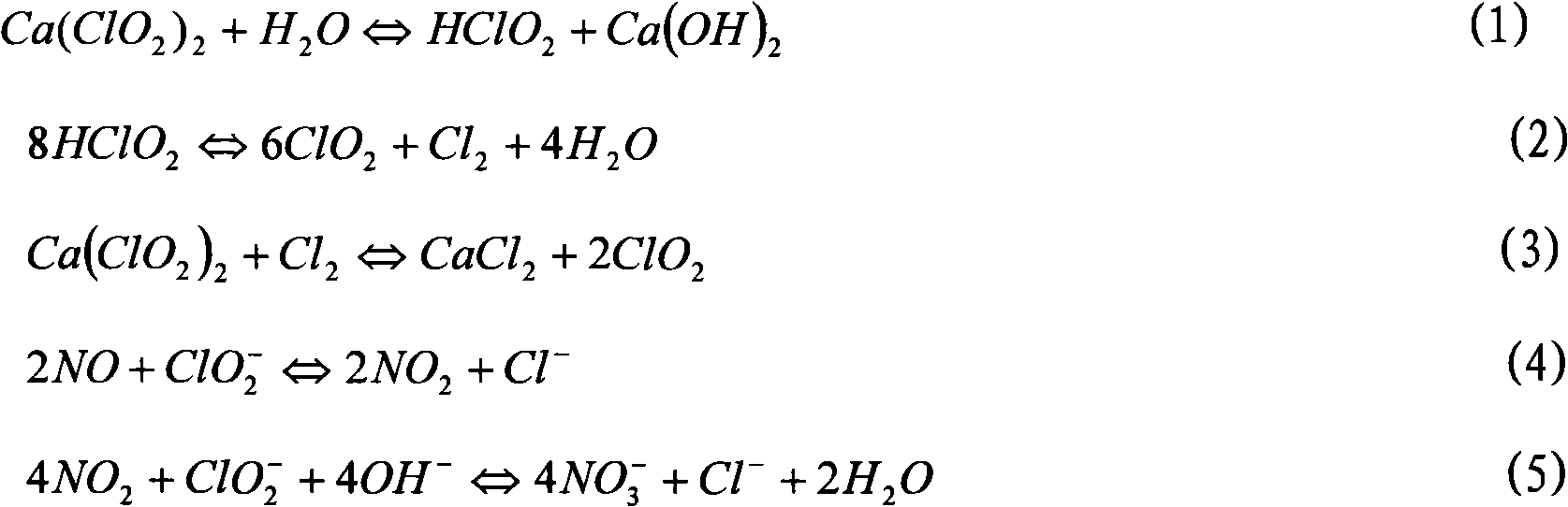

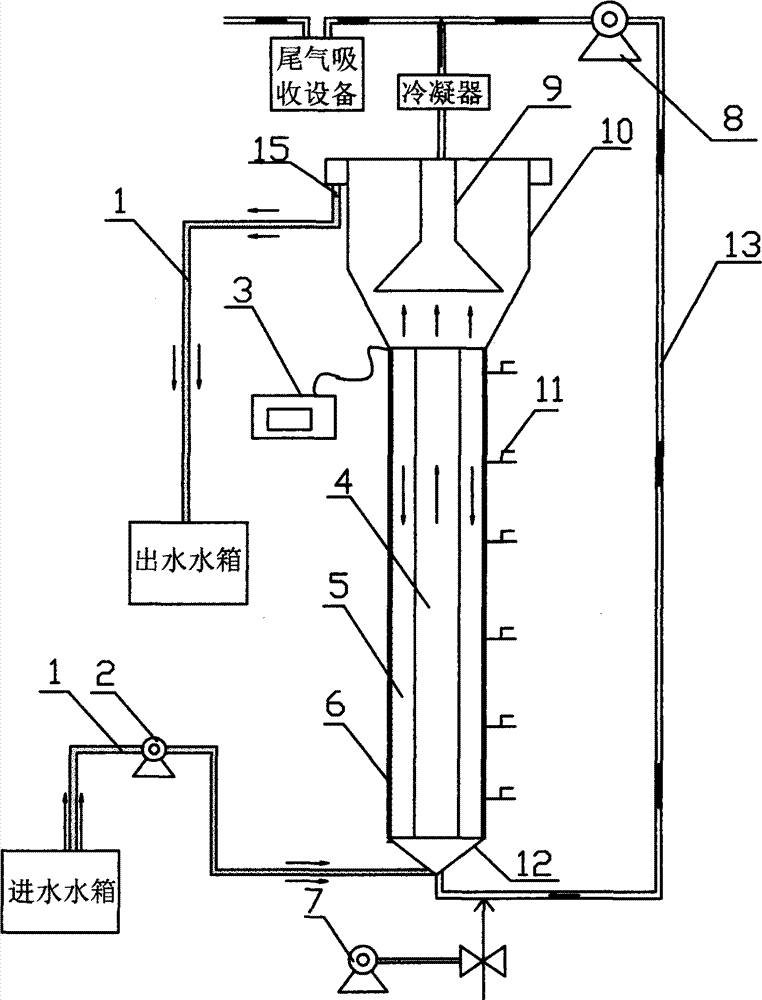

Deodorant waste lye absorbing treating smoke method

ActiveCN101143293ASolve the problems of low heat transfer efficiency and high equipment costThe method is efficient and stableDispersed particle separationAir quality improvementNitrogen oxidesDeodorant

The invention relates to a method of absorbing and treating gases by using deodorization waste lye. The invention uses deodorization waste lye processed wet air oxidation treatment to absorb sulfur dioxide, dust and nitrogen oxides in the gas. The invention uses two-stage absorption mode, and the forepart uses the absorption liquid discharged in posterior part to contact directly with the gas to reduce gas temperature, and at the same time to remove part of the pollutants in the gas. The posterior part uses deodorization waste lye as absorption liquid to contact with the cooled gas in the forepart, and the absorption pollutants in this stage contains sulfoxides or nitrogen oxides, and the purified gas can be released. The removal efficiency of sulfur dioxide and dust processed treatment by the invention can be achieved above 90 percent, and the removal efficiency of nitrogen oxides can be achieved above 40 percent. The method not only can effectively purify the gas, but also can effectively utilize waste lye. The invention has the advantages of that the method is extremely stable, is not easy to scale, has low investment, simple operation, low operation cost and so on.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for producing protein feed by using alcohol full grains and stalk solid fermentation

InactiveCN1457668AEradicate degradationHigh nutritional valueFood processingAnimal feeding stuffMixed materialsMoisture

The present invention belongs to the fermented protein feed producing technology. Grain alcohol residue in 70-94 wt%, straw in 0.6-1.5 wt%, solidifying agent comprising wheat bran, urea and ammonium sulfate are mixture to regulate the moisture content of grain alcohol residue of 40-60 %; and after further mixing with composite enzyme and composite bacteria, the mixed material is fermented at 25-35 deg.c and under anaerobic condition for 1-5 days to produce the protein feed. The present invention has the advantages of saving in energy source, no pollution and the high protein content up to 28 % in the produced feed.

Owner:TIANJIN UNIV

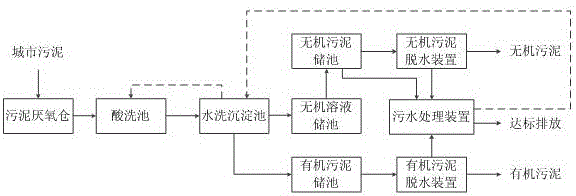

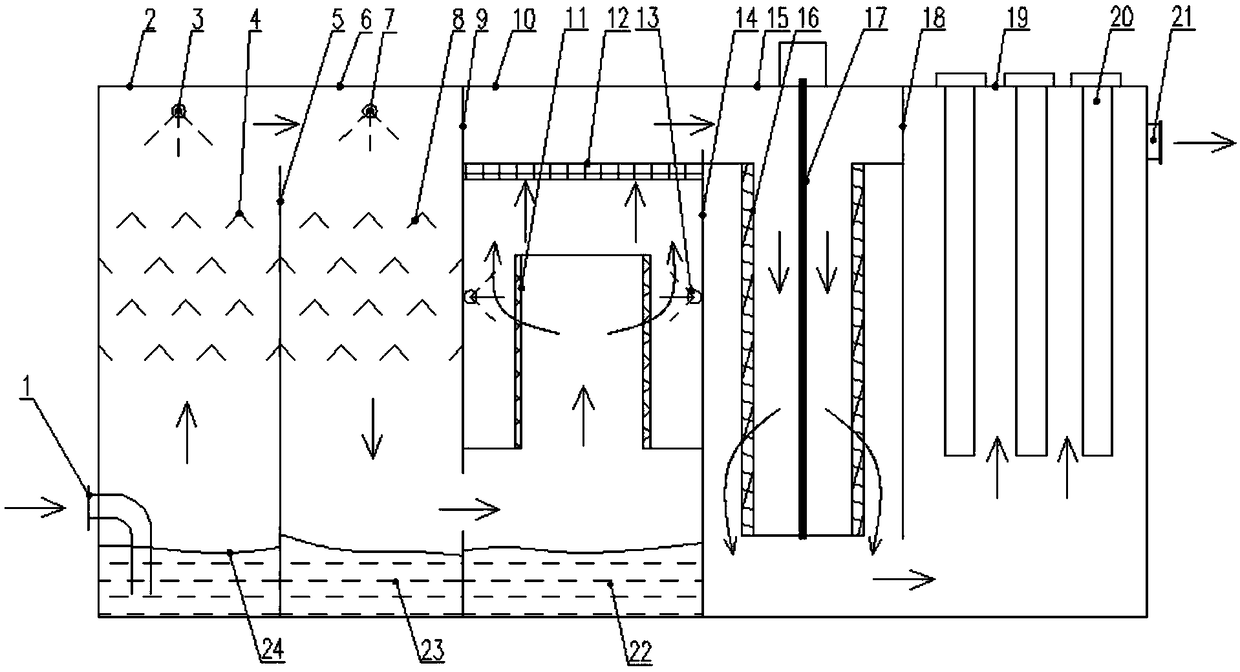

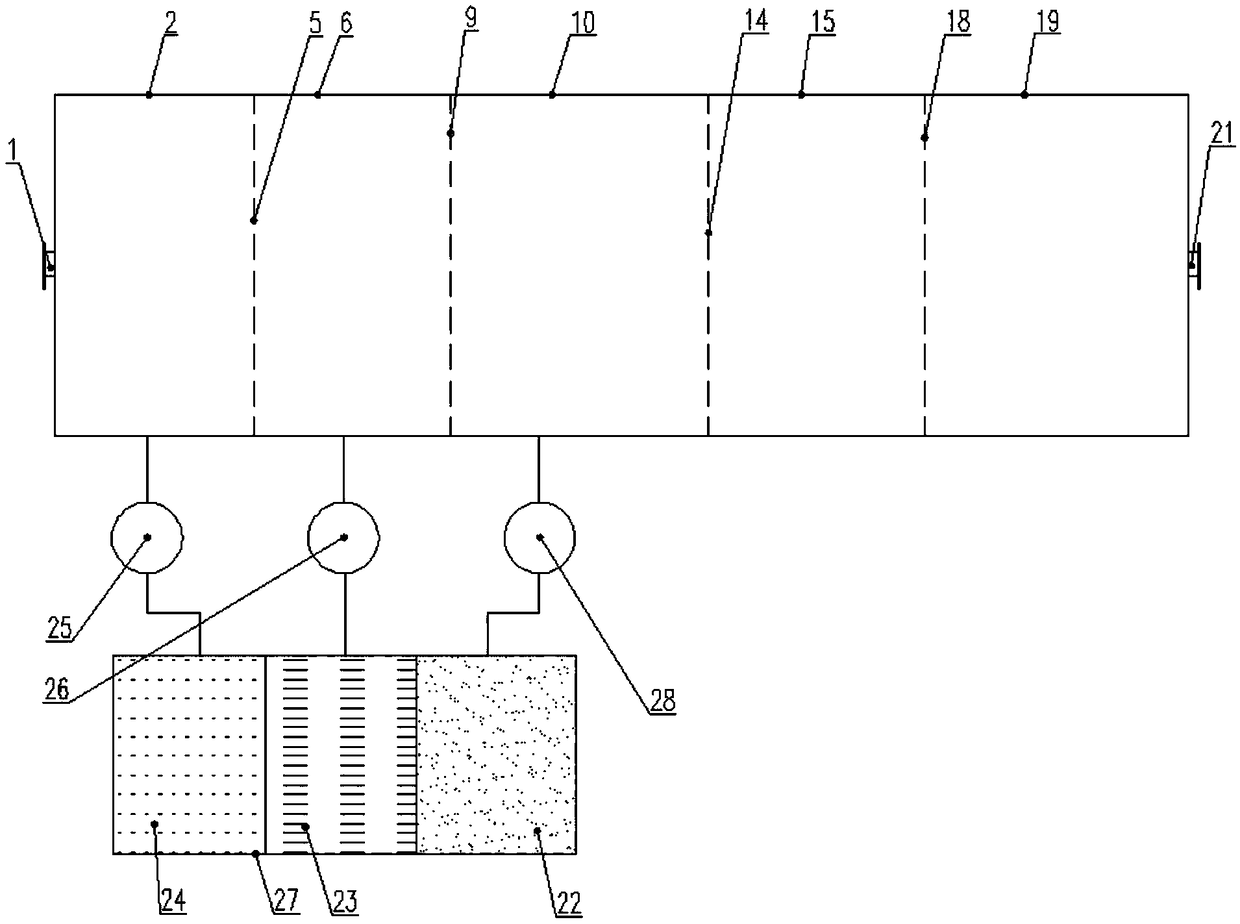

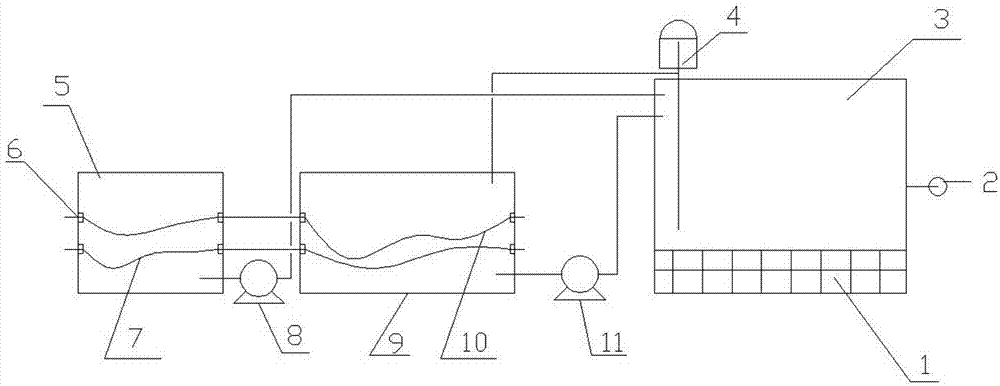

Efficient, energy-saving and multipurpose sludge recycling device and efficient energy-saving multipurpose sludge recycling method

InactiveCN106277689AHigh dissolution rateImprove resource utilization efficiencySludge treatment by de-watering/drying/thickeningSludge processingInorganic saltsSewage treatment

The invention provides an efficient, energy-saving and multipurpose sludge recycling device and an efficient, energy-saving and multipurpose sludge recycling method. The device and the method can be used for solving the problem that effective resources can not be completely utilized during sludge treatment in the prior art. The efficient, energy-saving and multipurpose sludge recycling device comprises a sludge anaerobic cabin, a pickling tank, a washing settling tank, an inorganic solution storage tank, an inorganic sludge storage tank, an inorganic sludge dewatering device, an organic sludge storage tank, an organic sludge dewatering device and a sewage treatment device. Organic sludge and inorganic sludge are separated and then are respectively utilized, so that the device and the method are capable of not only ensuring that the content of heavy metals in the organic sludge reaches the requirement, but also recycling the removed inorganic salts, and realizing complete recycling of sludge. The metal ion extraction efficiency is high, the chemical cost is low, and water in the system can be recycled, so that the device and the method belong to an efficient, energy-saving and multipurpose novel sludge treatment technology.

Owner:TIANJIN ENEW ENVIRONMENTAL PROTECTION ENGCO LTD

Surface treatment method for steel wire rod

The invention discloses a surface treatment method for a steel wire rod. The surface treatment method comprises the following steps: releasing a wire; mechanically shelling; blowing; performing hot washing; performing acid washing; washing; performing surface coating; drying; drawing; collecting, wherein the acid washing solution is mixed solution of hydrochloric acid and sulfuric acid, and the volume ratio of the two acid solutions is 1:1; the operation mode of the steel wire rod is a linear advancing mode. The surface treatment method has the advantages of less amount of acid and good cleaning effect, the production cost can be effectively reduced, and the surface treatment method is an energy-saving and environment-friendly production method.

Owner:KUSN QIAORUI METAL PRODS

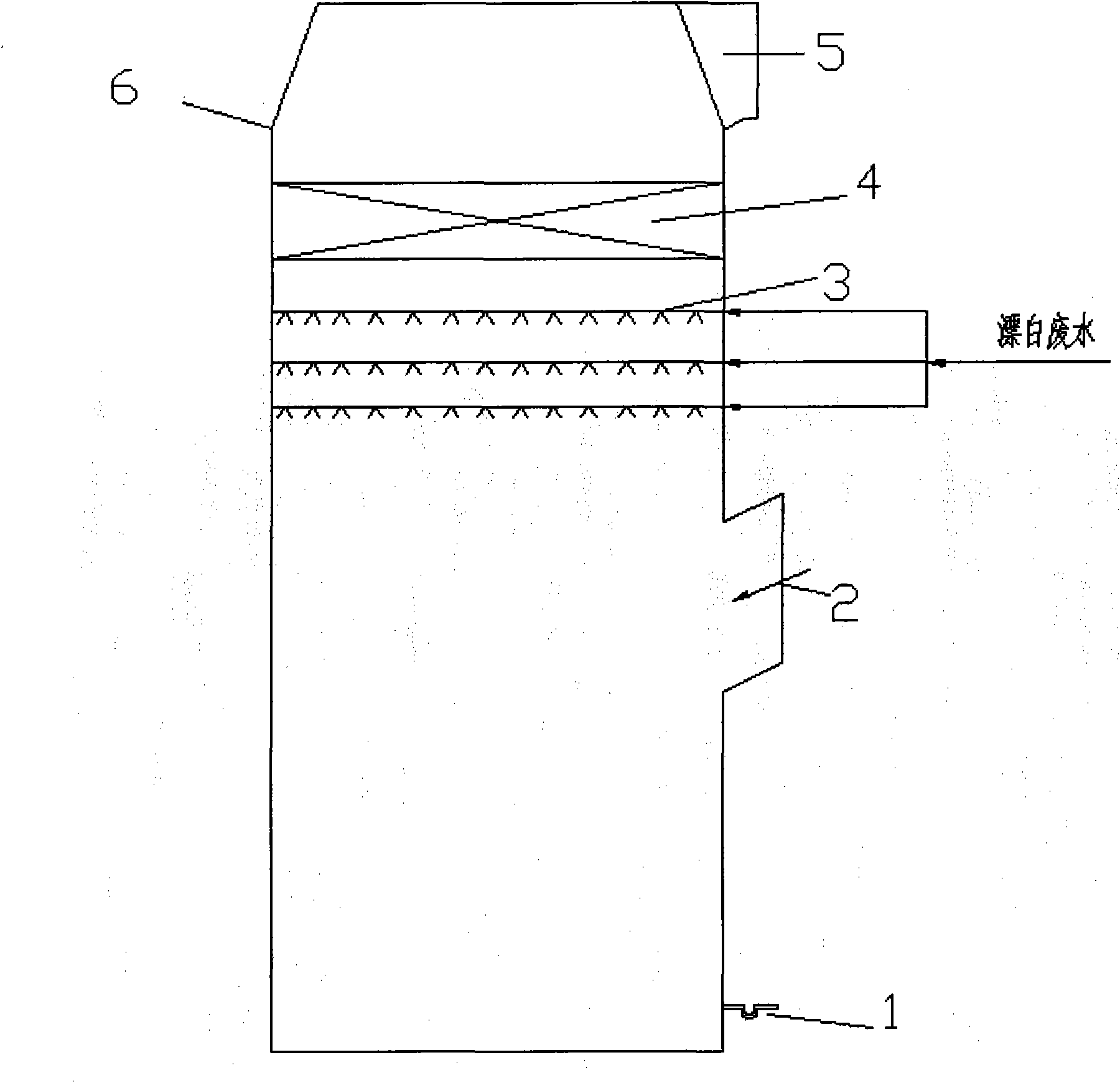

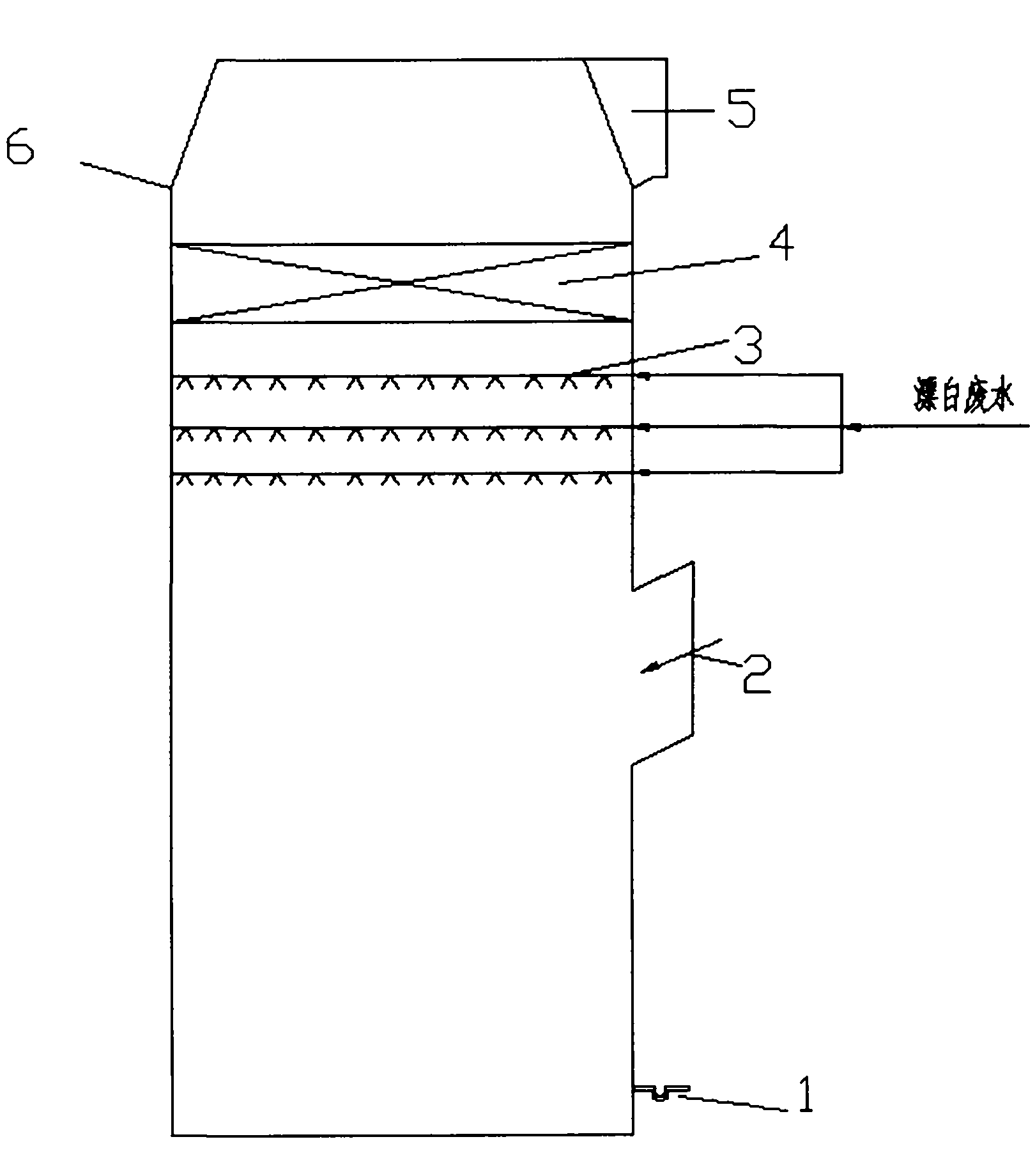

Absorption tower for denitrating flue gas by using bleaching effluent and denitrating method thereof

ActiveCN101804290AReduce shockIncrease contact timeDispersed particle separationChemical oxygen demandFlue gas

The invention relates to an absorption tower for denitrating flue gas by using bleaching effluent and a denitrating method thereof. The absorption tower comprises a tower body, wherein the top of the tower is provided with a flue gas outlet, the bottom is provided with an overflow vent, and the tower body is sequentially provided with a flue gas inlet, a slurry spraying area and a demister area from bottom to top. In the method for denitrating the flue gas by using the bleaching effluent, NOx in the flue gas is removed by using the bleaching effluent, therefore, the flue gas can be discharged after reaching standards, acidic materials which are added when the bleaching effluent is discharged can be saved, and the chemical oxygen demand (COD) of the bleaching effluent after denitration can be greatly reduced, which is beneficial to further treating the bleaching effluent at a sewage treatment station. By adopting the method, waste water and exhaust gas are comprehensively treated, and the cost for treating the waste water and the exhaust gas is greatly reduced.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER +1

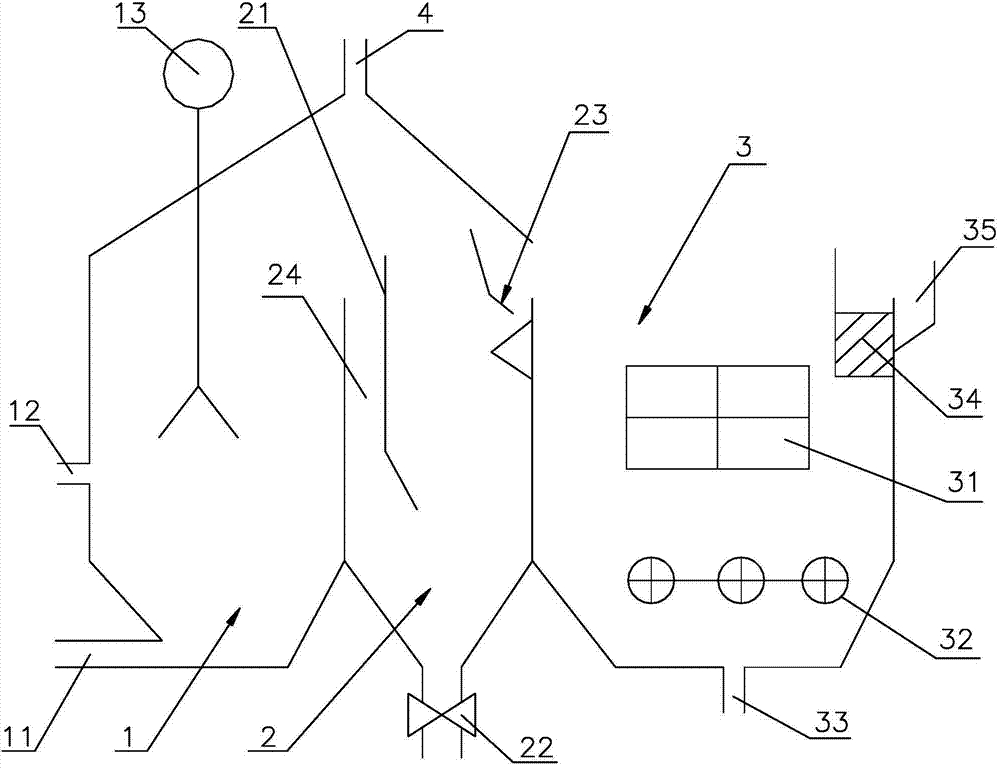

Malodorous gas comprehensive treatment device

InactiveCN109364745ACompact structureSave acidDispersed particle separationAir quality improvementMental healthAcid washing

The invention discloses a malodorous gas comprehensive treatment device. The device comprises an alkali washing section tank arranged, an acid washing section tank, a biological purification section tank, an adsorption purification section tank and a photocatalytic oxidation section tank side by side. Adjacent tanks are separated by means of a partition with channels. The above units are connectedin series by means of the channels on the partition. The alkali washing section tank and the photocatalytic oxidation section tank are respectively connected with an air inlet and an air outlet. Spray washing components for performing alkaline spray washing and acid spray washing are arranged inside the alkali washing section tank and the acid washing section tank, respectively. A biological purification module is arranged in the biological purification section tank for purifying the malodorous gas. An adsorption purification module for adsorbing malodorous gas is arranged inside the adsorption purification section tank. A photocatalytic module for catalytically oxidizing the malodorous gas is provided inside the photocatalytic oxidation section tank. The malodorous gas comprehensive treatment device provided by the invention has a high purification efficiency, not only the working environment of a worker is improved, the physical and mental health of an operator is guaranteed, but also the overall occupied area of the device is small, and the maintenance and replacement are convenient.

Owner:长沙工研院环保有限公司

Method for producing germanium dioxide by utilizing germanium-containing wastes

InactiveCN107324376ASave acidSave hydrogen peroxideGermanium dioxideGermanium halidesHydrolysateDistillation

The invention provides a method for producing germanium dioxide by utilizing germanium-containing wastes. The method is characterized by comprising the following steps: directly adding the germanium wastes into a concentrated hydrochloric acid containing ferric trichloride; using chlorine as a shielding gas and adopting a rectifying column for distilling and purifying germanium tetrachloride; preparing germanium dioxide by performing totally closed hydrolysis reaction on the purified germanium tetrachloride; washing the hydrolysate and drying, thereby acquiring dry germanium dioxide; and adding the germanium wastes into a return fluid after completing distillation, thereby continuously producing. The germanium tetrachloride can be continuously produced in the manner of adding the germanium wastes into the concentrated hydrochloric acid containing ferric trichloride, and then adding chlorine for oxidizing, distilling and preparing germanium tetrachloride and adding the germanium wastes after completing the distillation; the usage of acid and hydrogen peroxide can be saved; the distilling return fluid can be repeatedly reused; and no distilling waste acid is generated.

Owner:KUNMING HUIQUAN HIGH PURITY SEMICONUCTING MATERIALS CO LTD

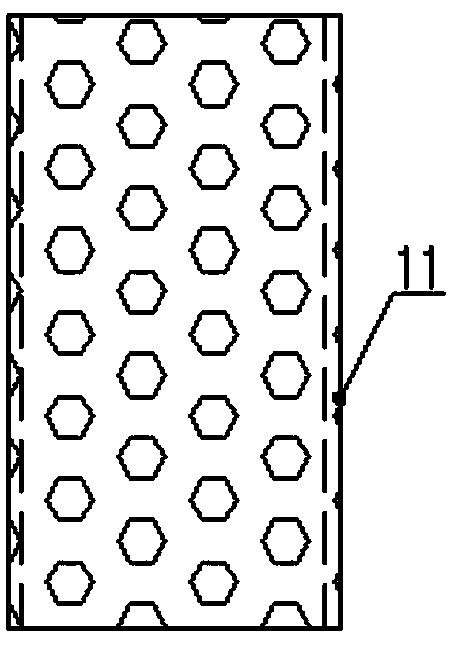

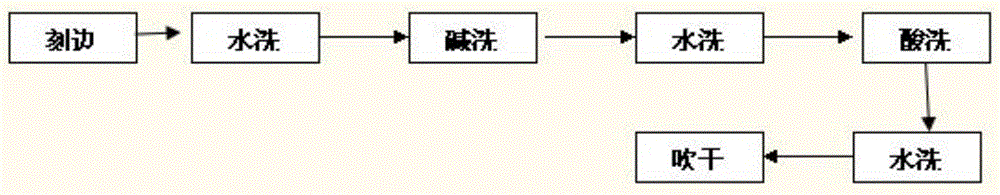

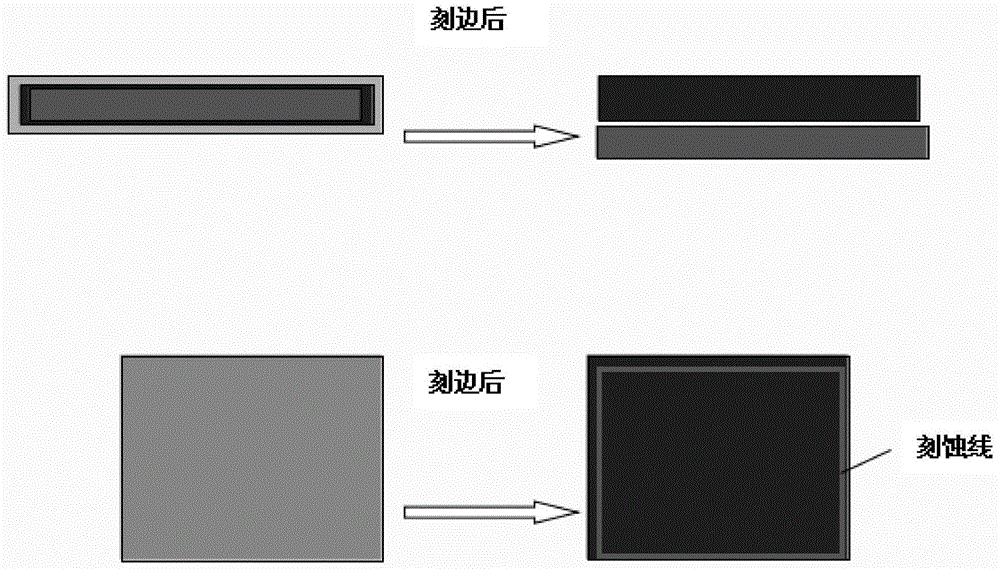

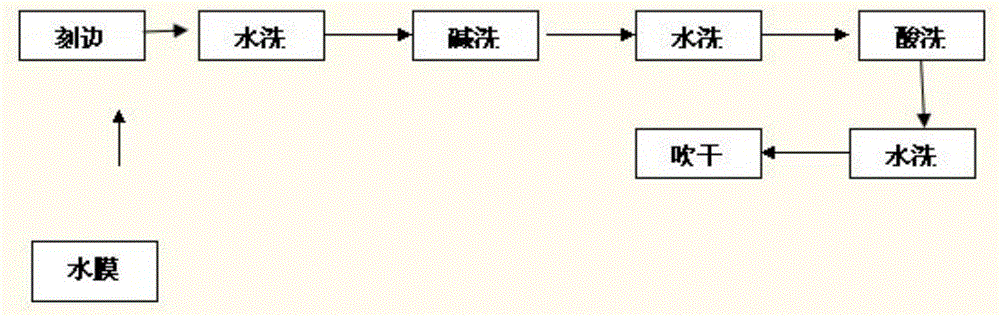

Novel crystalline silicon cell wet process edge etching technology

InactiveCN104900760AAvoid climbingEliminate etchingFinal product manufactureSemiconductor devicesChemical solutionEtching

The invention relates to a novel crystalline silicon cell wet process edge etching technology. The technology includes the following steps that: phosphosilicate glass (PSG) layers of edge corners of a silicon wafer are removed through utilizing HF; the concentration of mass percentage of the HF ranges from 2% to 5%; the treated surface of the silicon wafer is dried by hot air, and the temperature of the hot air ranges from 50 to 70 DEG C; edge etching is performed on the silicon wafer through utilizing mixed acid of HF and HNO3; the etched silicon wafer is washed in a water tank; the washed silicon wafer is arranged in an alkaline tank, so that porous silicon can be removed, and ammonium hydroxide of which the concentration of mass percentage ranges from 5% to 8% is adopted as alkali; and the silicon wafer which has been subjected to alkali treatment is arranged in the water tank so as to be washed; HF or mixed acid of HF / HCl, of which the mass percentage ranges from 2% to 5%, is utilized to remove the PSG; the volume ratio of the mixed acid of HF / HCl ranges from 1:2 to 4; the silicon wafer of which the PSG has been removed is arranged in the water tank so as to be washed; and the silicon wafer is dried by air. According to the novel crystalline silicon cell wet process edge etching technology of the invention, the PSG of the edge corners of the silicon wafer is removed at first innovatively, and therefore, chemical solutions can be prevented from climbing onto the front surface of the silicon wafer, and etching dents can be avoided.

Owner:RISEN ENERGY

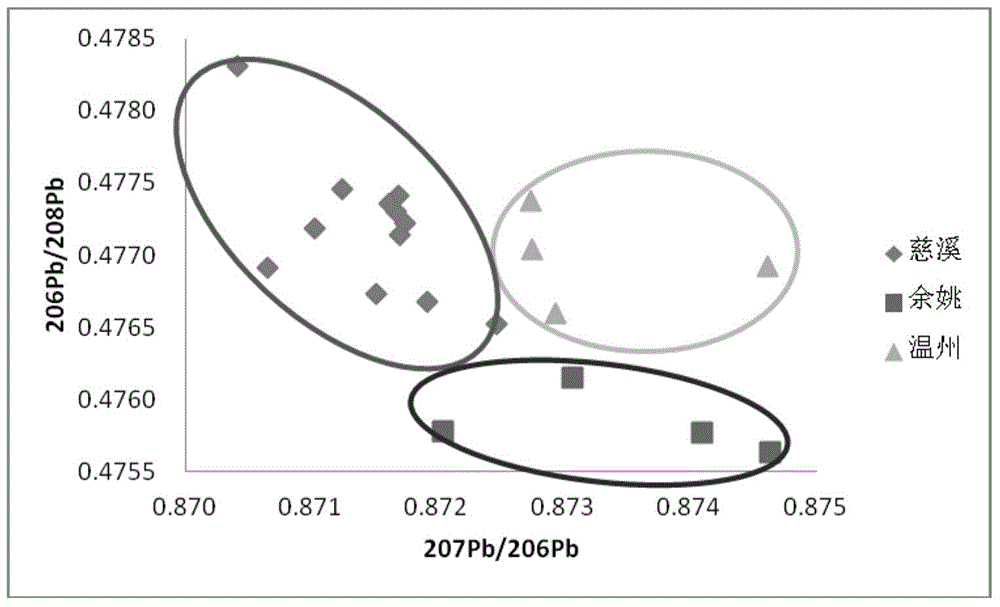

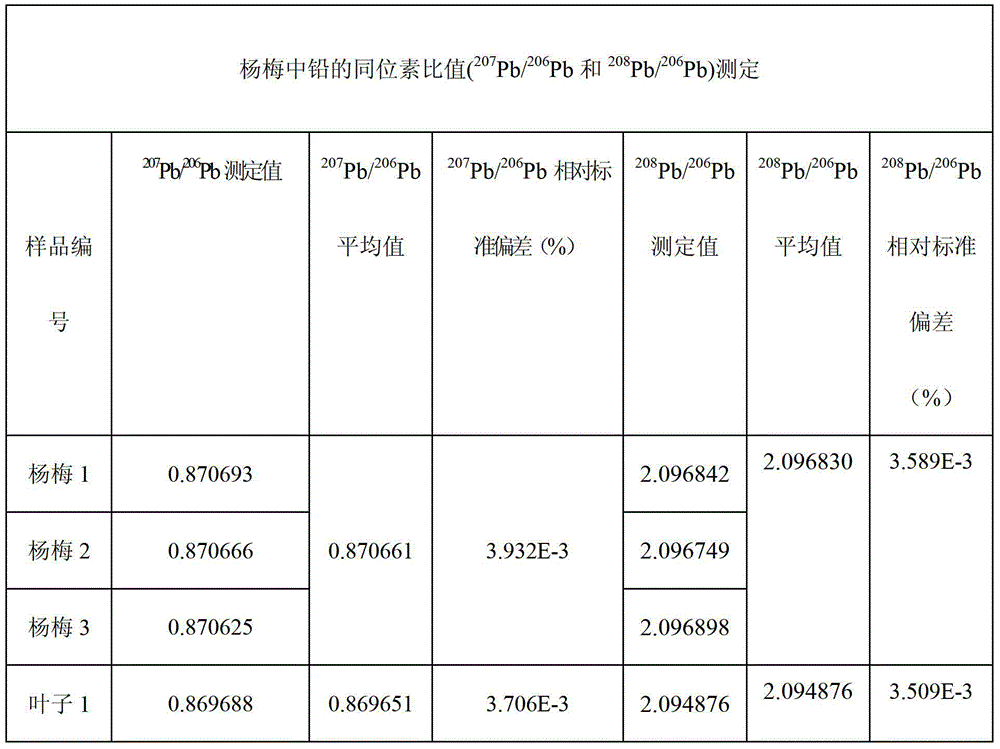

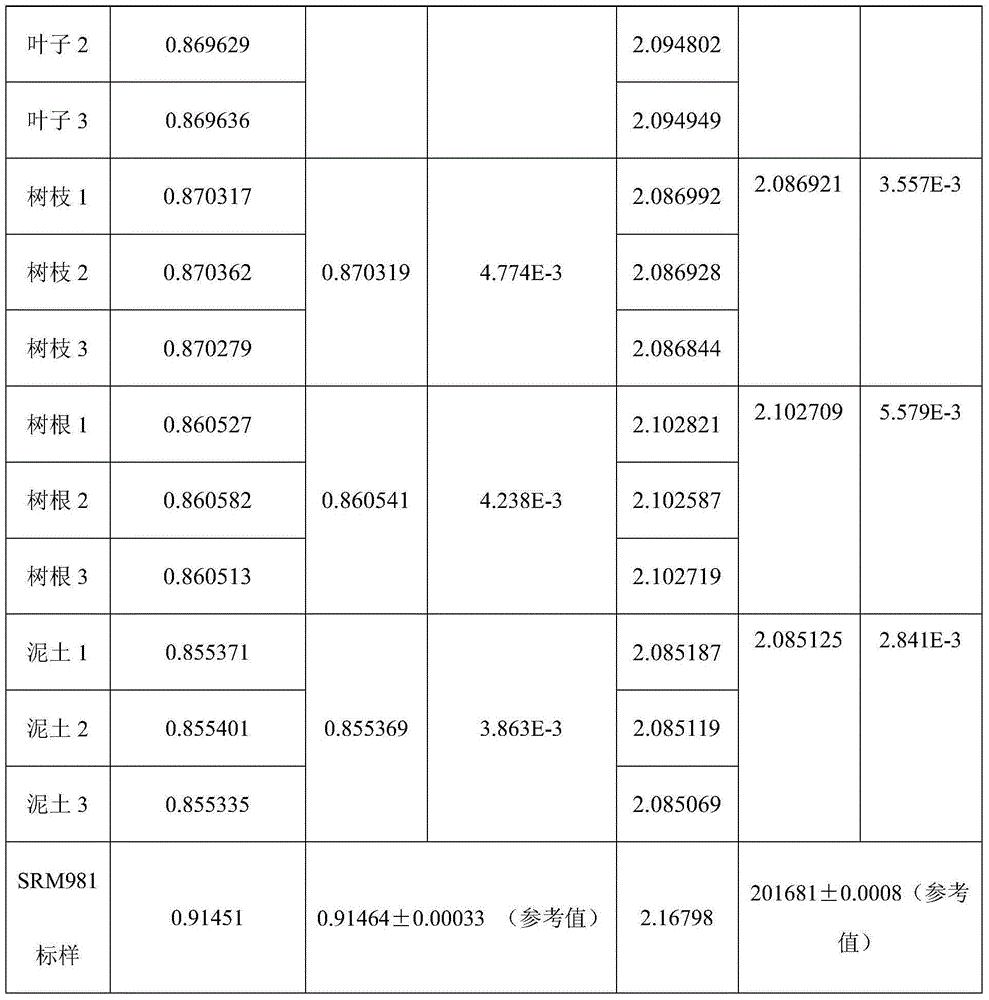

Method for determining ratio of lead isotopes in sample of different parts of waxberry tree and identifying origin of waxberry

ActiveCN105203622AEasy to separateHigh precisionMaterial analysis by electric/magnetic meansIsotopes of leadBiology

The invention discloses a method for determining a ratio of lead isotopes in a sample of different parts of a waxberry tree and identifying an origin of waxberry. The method comprises the following steps: measuring a sample of different parts of the waxberry tree, preprocessing the sample, digesting the sample by virtue of microwave, purifying the sample by utilizing SR resin-B resin, eluting to obtain a lead sample, and then detecting the lead sample by adopting a thermal surface ionization mass spectrometry to obtain a ratio of lead isotopes in the lead sample. A correlation distribution map can be drawn according to the ratio of the lead isotopes of the sample of the same part in different origins and can be used for identifying the origin situation of the waxberry tree sample of an unknown origin. The thermal surface ionization mass spectrometry is first used for rapidly determining the ratio of lead isotopes in the sample of different parts of the waxberry, a scientific, independent and invariable identify identification information can be provided for tracking the waxberry source, and the method is reliable and stable. Particularly for the products of a large-sized area, the difference can be effectively distinguished. The method is high in detection efficiency; moreover, the detection result is high in precision and good in effect.

Owner:INSPECTION & QUARANTINE TECH CENT OF NINGBO ENTRY EXIT INSPECTION & QUARANTINE BUREAU

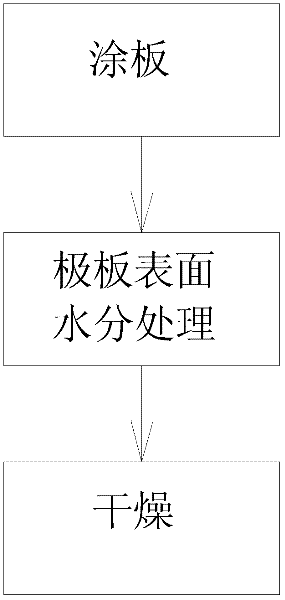

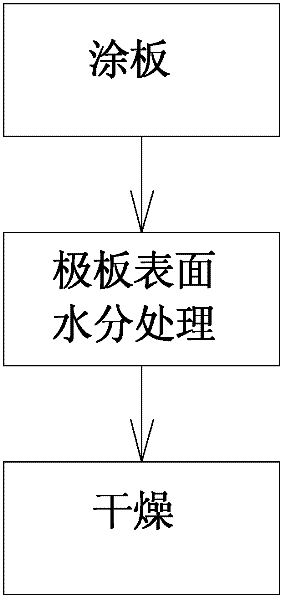

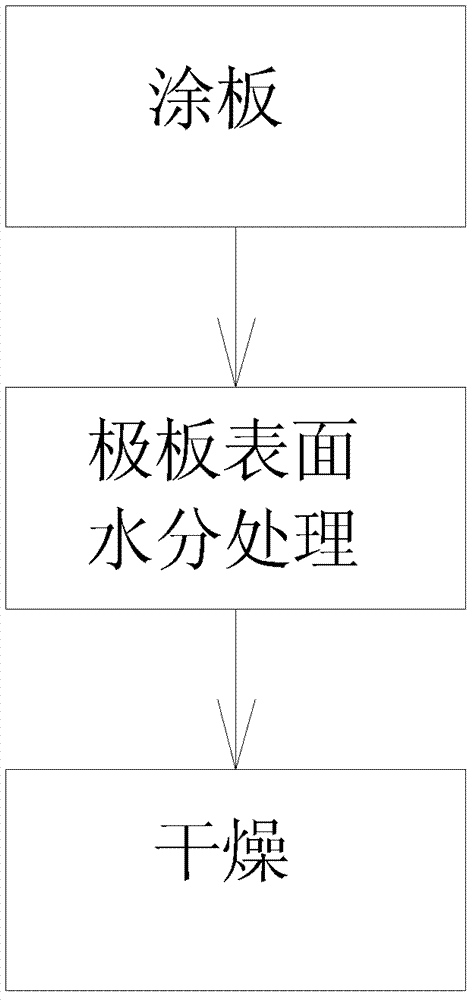

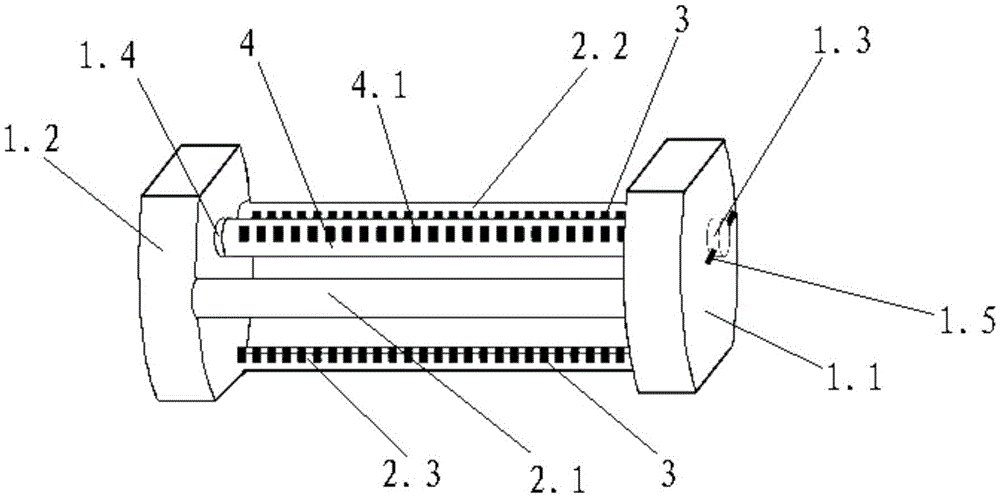

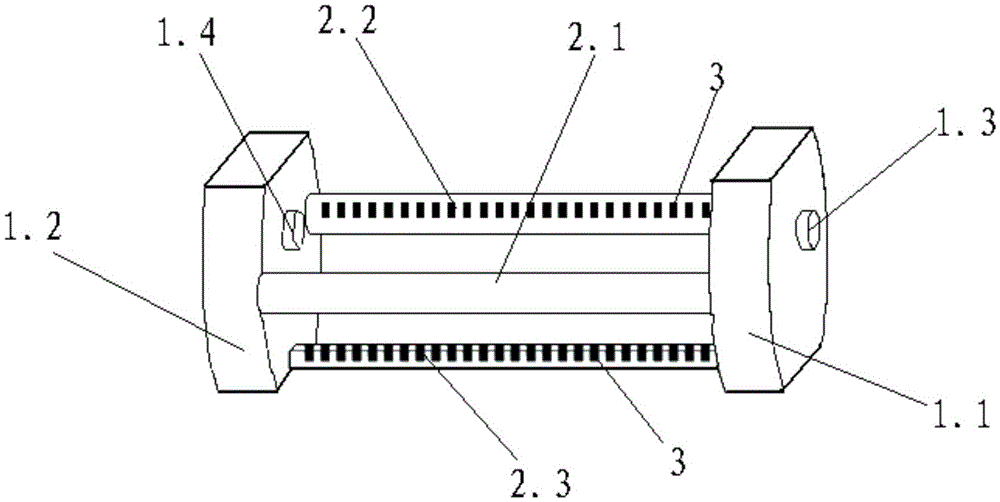

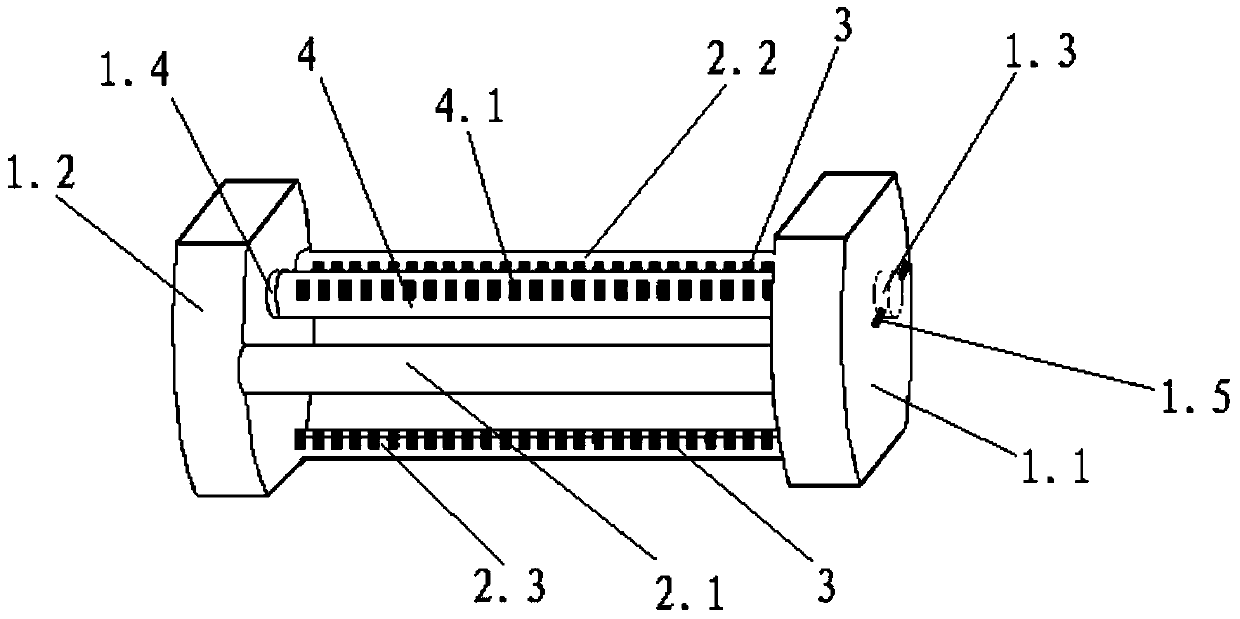

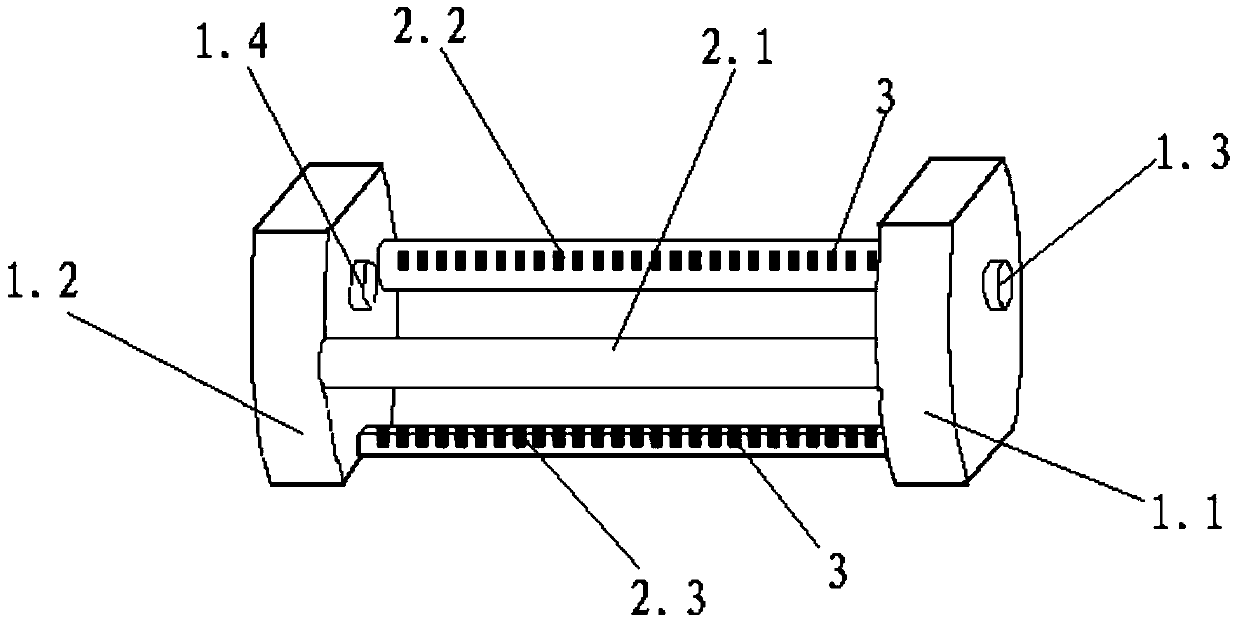

Polar plate treating method and compression roller assembly used for same

ActiveCN102646815AMoisture content meets the requirementsMoisture content requirementsLead-acid accumulator electrodesMoistureMaterials science

The invention relates to a polar plate treating method and a compression roller assembly used for the same. The polar plate treating method comprises the following steps of: step a, carrying out plate coating treatment on a polar plate; step b, absorbing water on the surface of the polar plate subjected to the plate coating treatment by utilizing a water-absorbing material to; and step c, carrying out drying treatment on the polar plate. According to the invention, after the plate is coated, the water-absorbing material is directly used for absorbing the water on the surface of the polar plate; and then, the polar plate is dried. The whole treating process can save acid pouring operation, so that not only can acid liquid be saved, but also the problem in the prior art that floating powder is easy to generate due to acid pouring is avoided. Furthermore, the moisture content of the polar plate machined by the method disclosed by the invention meets requirements.

Owner:ANHUI LEOCH POWER SUPPLY

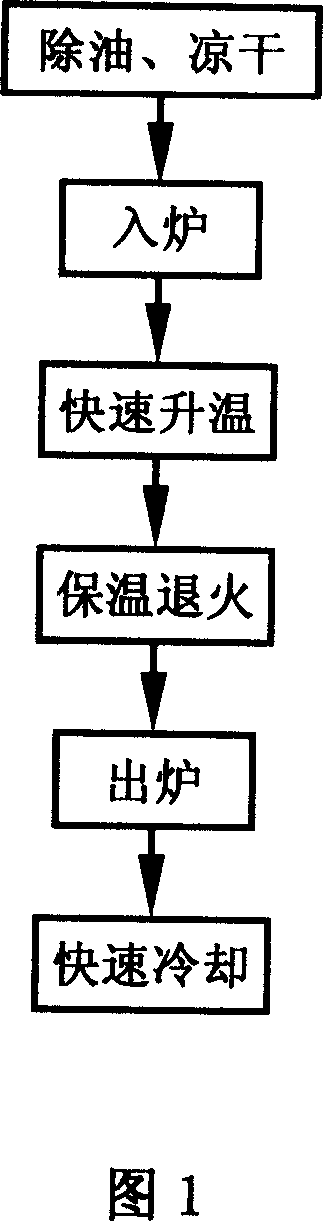

Quick annealing method for titanium seamless pipe

InactiveCN101086056AIncrease productivityReduce energy consumptionIncreasing energy efficiencyFurnace typesAutomatic controlIntermediate frequency

This invention discloses a method for annealing ti-seamless tubes. It comprises following steps: putting titanium tube into intermediate frequency induction annealing furnace orderly, heating to crystallization temperature rapidly when crossing intermediate frequency induction annealing furnace, restraining 'recovery' process, finishing recrystallization rapidly, cooling to room temperature fast, restraining ' grain growth' and high temperature oxidation. It only need several minutes for heating, thermal insulating and cooling for one titanium tube. It solves the technical problems of low production efficiency and high cost in background technology. The invention is characterized by automatic control, suitability for different length tubes annealing, mass or small production and excellent performance.

Owner:WESTERN TITANIUM TECH

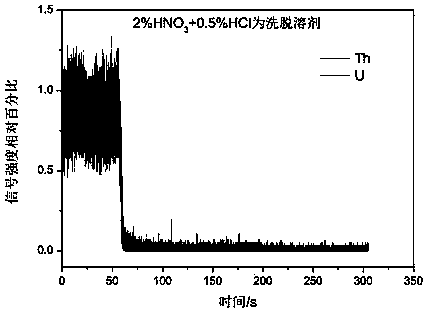

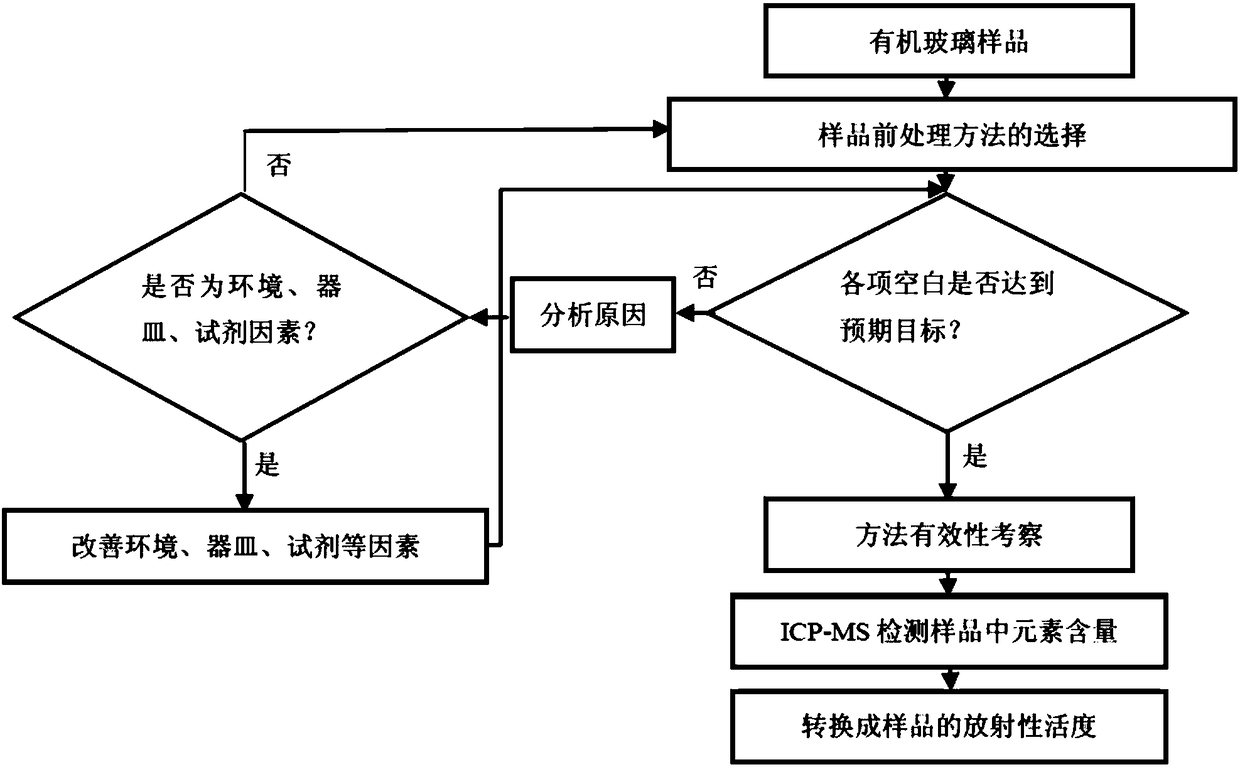

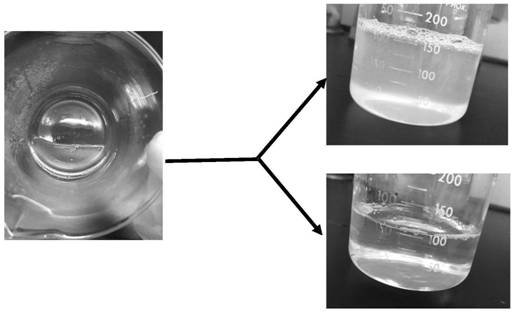

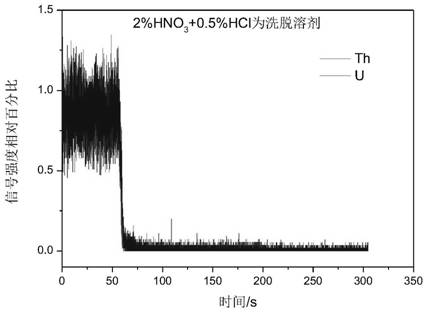

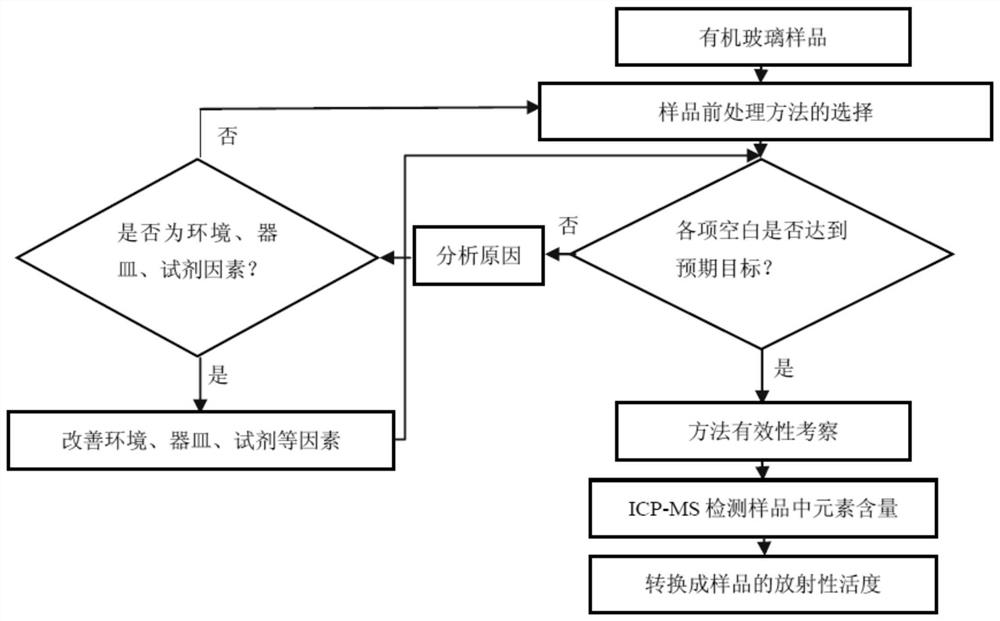

Method for detecting super trace radioactive background in polymer

ActiveCN108414607ALow detection limitImprove signal-to-noise ratioPreparing sample for investigationMaterial analysis by electric/magnetic meansTrace elementOrganic glass

The invention belongs to the field of analytical chemistry, and relates to a method for detecting super trace radioactive background in a polymer. The analytic method for measuring the super trace radioactive background by ICP-MS is established in a dry ashing pretreatment manner in order to realize the analysis of super trace elements in organic glass. The detection limit of the detection methodcan reach 1 pg / g or below; and additionally, the method can be simply, rapidly and accurately operated.

Owner:SUN YAT SEN UNIV

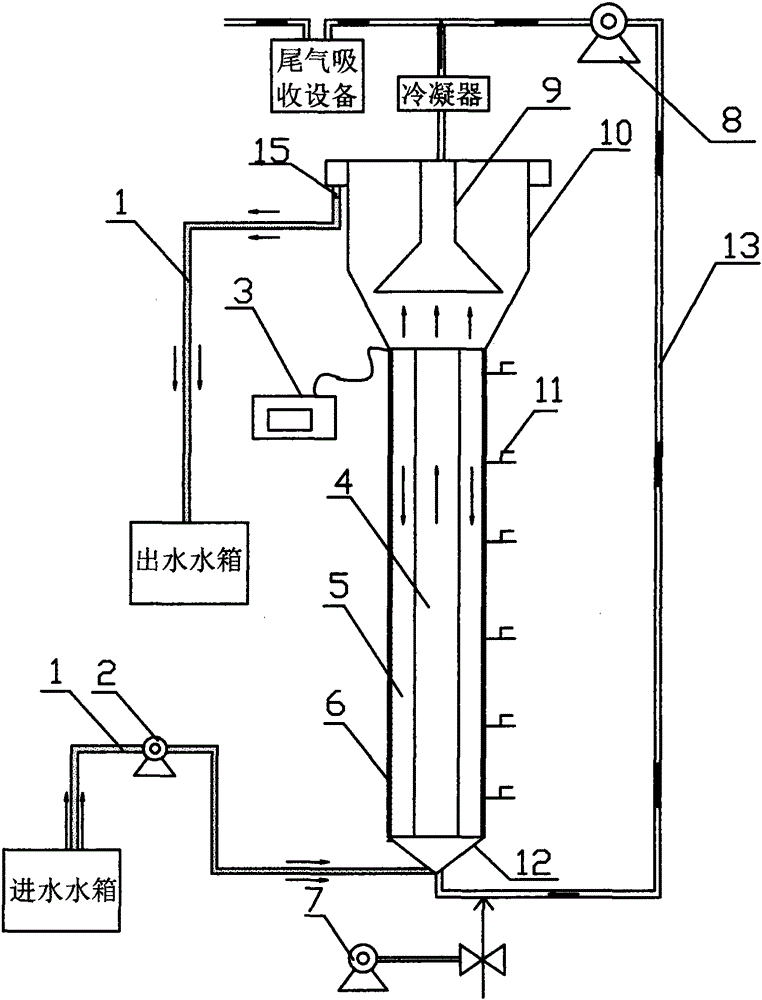

Biological treatment process and device for high-sulfur-containing and phenol-containing waste alkali liquid

ActiveCN102757130AEfficient removalIncrease concentrationWater/sewage treatmentBiological water/sewage treatmentChemical oxygen demandReaction temperature

The invention discloses a biological treatment process for high-sulfur-containing and phenol-containing waste alkali liquid. The process comprises the following steps of: diluting high-sulfur-containing and phenol-containing waste alkali liquid until the concentration of sulfide is not more than 7.0g / L, the concentration of the COD (chemical oxygen demand) is not more than 25g / L and the concentration of Na+ is not more than 0.8mol / L; regulating a pH value of the liquid to be not more than 9.5; and performing treatment process of three steps, namely sludge inoculation, starting of a reactor and treatment of waste alkali liquid, under the conditions that the reaction temperature is 20-35 DEG C, the dissolved oxygen is 3-7mg / L and the hydraulic retention time is 24-96 hours. The invention also discloses a biological treatment device for high-sulfur-containing and phenol-containing waste alkali liquid. The biological treatment process and the biological treatment device have the beneficial effects that the removal ratio of pollutants is high, the removal ratio of sulfide is over 95 percent, and the removal ratio of organic matters is up to 90 percent; the capability of treating the waste alkali liquid is greatly improved, and the waste alkali liquid of which the pH value is about 9.5 can be treated; the cost and pretreatment expenses are reduced; and the secondary pollution is not caused, and the reaction device is small in floor area and is easy to operate.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for cleaning and treating organic glass surface pollutants

InactiveCN109604245AImprove work performanceAvoid damageCleaning using toolsCleaning using liquidsHydrofluoric acidOrganic glass

The invention discloses a method for cleaning and treating organic glass surface pollutants. The method comprises the following steps that first, the organic glass surface pollutants are cleaned for afirst time by adopting pure water; second, organic glass cleaned in the first step is washed with a first cleaning agent prepared from isopropanol and a cleaning solution; third, the organic glass washed by the first cleaning agent is washed for a second time with pure water; fourth, the organic glass washed in the third step is washed again with a second cleaning agent prepared from nitric acid,hydrofluoric acid and water; and fifth, the organic glass washed in the fourth step is washed with the pure water and then dried. According to the method for cleaning and treating the organic glass surface pollutants, repeated cleaning operation steps are avoided, time is saved, cleaning raw materials such as acid liquor are saved, and the working effect of cleaning organic glass products is improved.

Owner:芜湖通潮精密机械股份有限公司

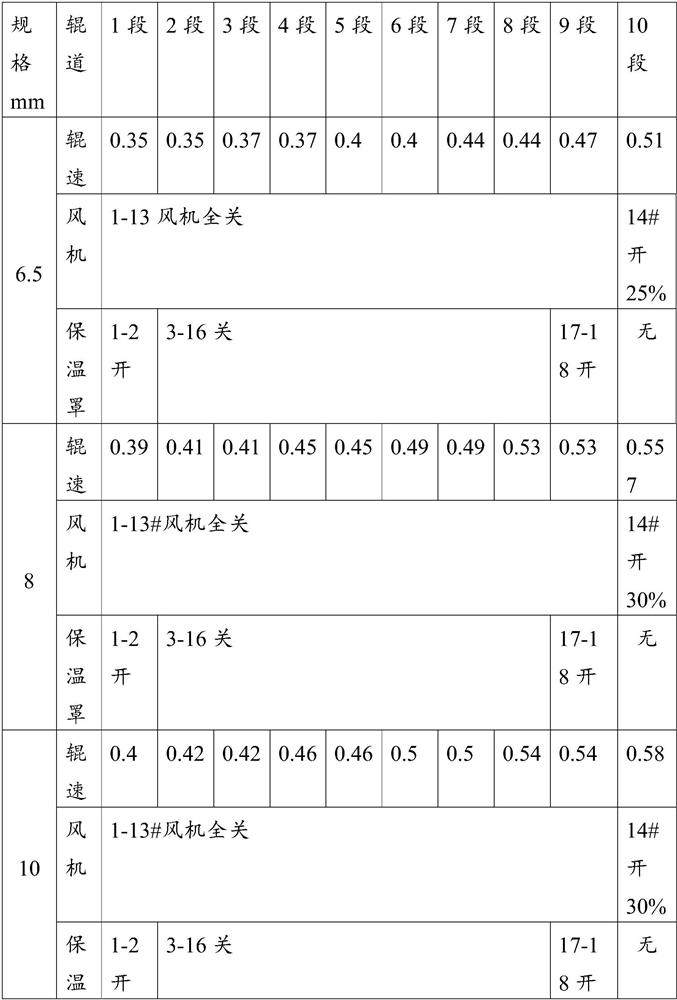

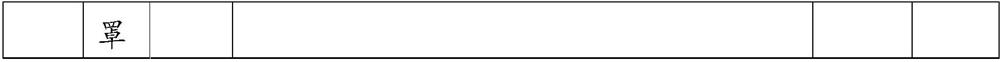

Easily-pickled low-carbon steel wire rod and control method of surface scale of easily-pickled low-carbon steel wire rod

ActiveCN112642859AThe overall thickness is thinReasonable thickness distributionTemperature control deviceMetal rolling arrangementsWire rodCarbon steel

The invention discloses an easily-pickled low-carbon steel wire rod and a control method for a surface scale of the easily-pickled low-carbon steel wire rod and relates to the technical field of steel rolling. The control method for the surface scale of the easily-pickled low-carbon steel wire rod includes the following steps of: step S1, rolling; step S2, discharging a wire at a temperature of 820 DEG C to 850 DEG C; and step S3, conducting a cooling step, specifically, slowly cooling the low-carbon steel wire rod obtained in the discharging step to a temperature of 580 DE C to 670 DEG C, then conducting quenching treatment to a temperature of 390 DEG C to 410 DEG C, and then conducting air cooling to the room temperature. Through reasonable matching of all the above steps, it is guaranteed that the finally-obtained iron oxide scale is relatively thin and is composed of three different phases (Fe3O4, FeO and Fe2O3) with specific thicknesses; all the phases are distributed in a layered mode, so that the iron oxide scale is compact and not cracked, also contains little Fe3O4, is beneficial for acid pickling; and meanwhile the tensile strength of the prepared easily-pickled low-carbon steel wire rod meets related requirements.

Owner:SGIS SONGSHAN CO LTD

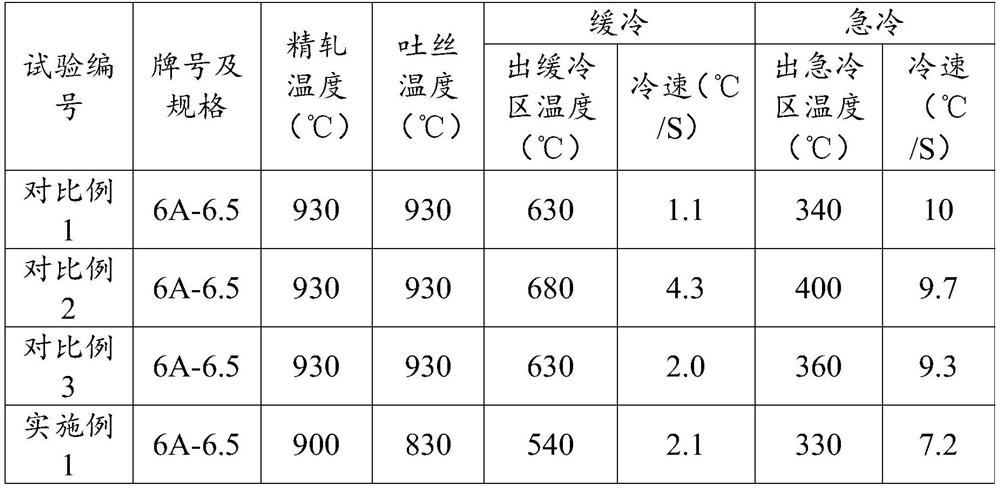

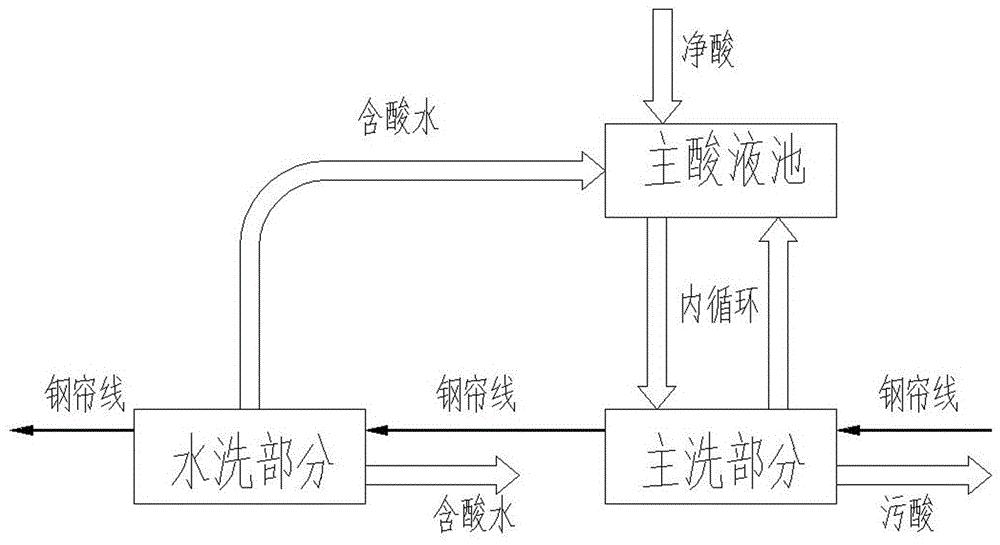

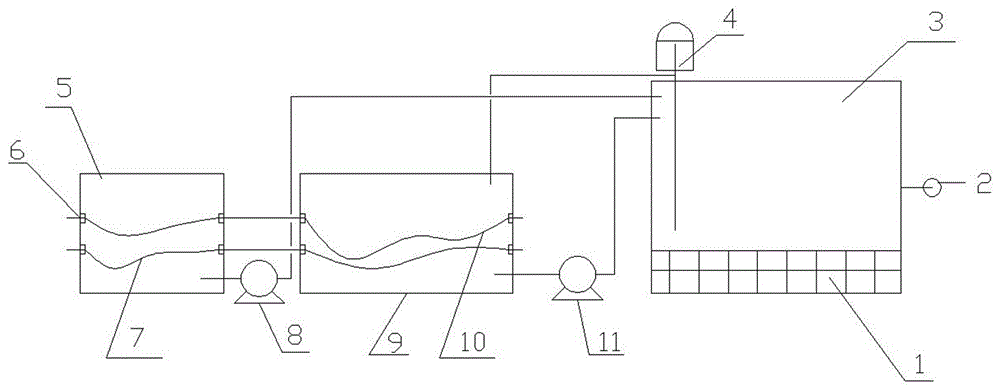

Steel cord cleaning process and device

The invention relates to a steel cord cleaning process, and the cleaning process comprises an acid pickling part and a washing part, wherein the steel cord is firstly cleaned by the acid pickling part and secondly cleaned by the washing part, acid-containing water in the washing part is circularly entered into the acid pickling part. The steel cord cleaning process has the advantages of excellent cleaning effect, simple process, and thorough cleaning, besides 20-30% of acid is saved and production efficiency is greatly improved.

Owner:HENAN HENGXING SCIENCE & TECHNOLOGY CO LTD

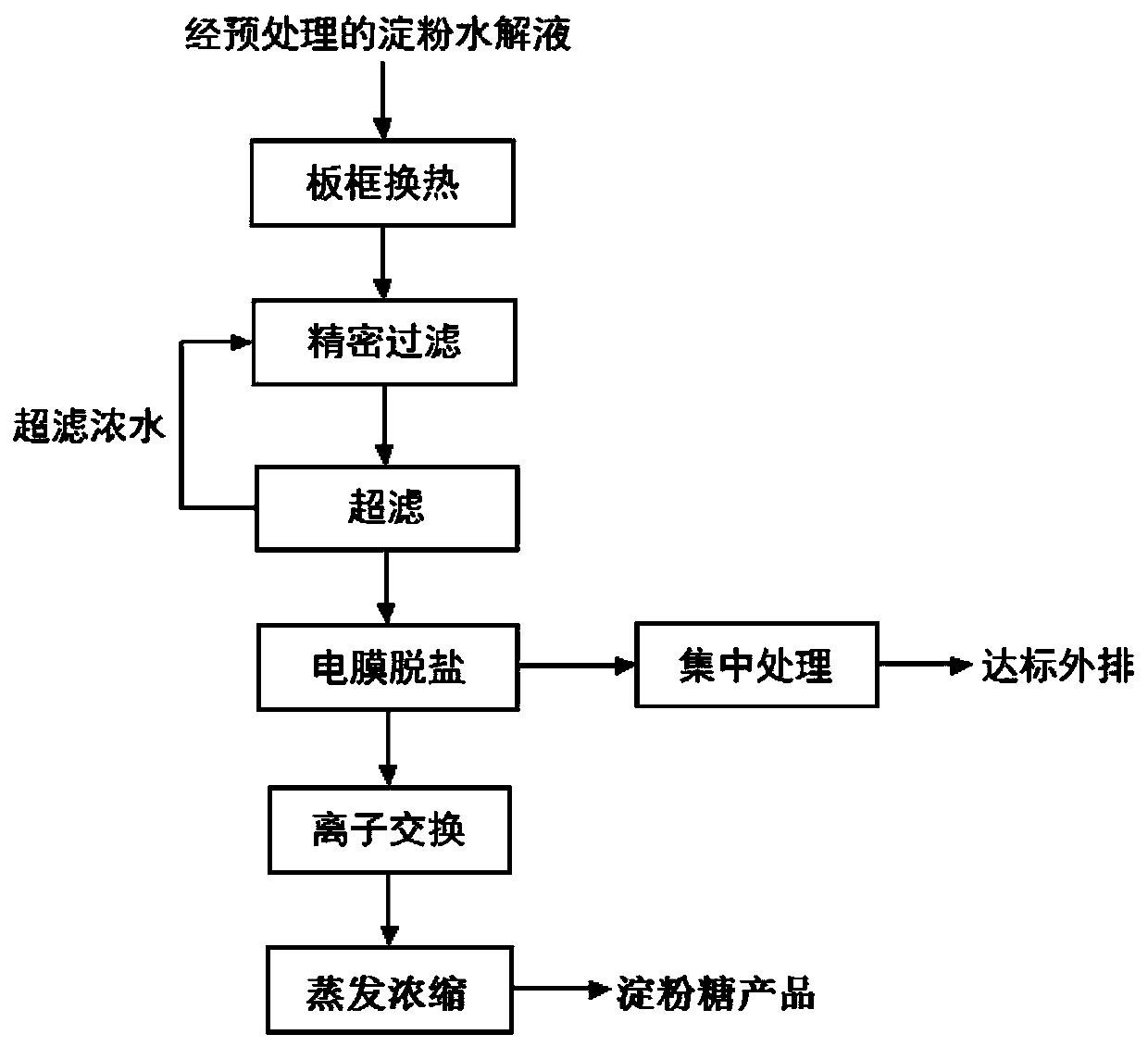

Combined process method applied to desalination of starch hydrolysate

PendingCN109761434AEfficient desalinationSolve the costMultistage water/sewage treatmentSaccharides productionSaline waterHydrolysate

The invention provides a combined process method applied to desalination of starch hydrolysate. The method comprises the following steps: successively carrying out precise filtration and ultrafiltration on the starch hydrolysate to obtain ultrafiltration fresh water and ultrafiltration concentrated water; carrying out electric membrane desalination on the obtained ultrafiltration fresh water to obtain primary desalinated starch hydrolysate and concentrated saline water; and carrying out ion exchange secondary desalination on the obtained primary desalinated starch hydrolysate to obtain deeplydesalinated starch hydrolysate. Through organic combination and synergistic effects of different desalination processes, especially electric membrane desalination enables the desalination rate of thestarch hydrolysate to reach 80% or above, and then ion exchange desalination is used for finally enabling the conductivity of the starch hydrolysate to be not higher than 5 mu S / cm; the method is capable of obviously slowing down membrane pollution, greatly prolonging the regeneration period of resin and reducing the acid and alkaline consumption and operation cost for regeneration of the resin, is applicable to desalination treatment of the starch hydrolysate from different sources, and is low in energy consumption, high in stability and wide in application range.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

High-temperature-resistant titanium alloy plate and annealing method thereof

InactiveCN107586998AImprove thermal stabilityImprove high temperature creep resistanceTitanium alloyHeating temperature

The invention discloses a high-temperature-resistant titanium alloy plate. A titanium alloy plate material is prepared from the following components in percentage by weight: 0.5 to 1.2 percent of aluminum, 3 to 5 percent of silicon, 0.2 to 0.5 percent of iron, 1.2 to 1.8 percent of nickel, 0.1 to 0.2 percent of carbon and the balance of titanium. A preparation process of the titanium alloy plate comprises the following steps: 1, mixing all the raw materials according to the formula amounts, feeding the mixture into a vertical type induction heating furnace, controlling heating temperature at 1,400 to 1,450 DEG C for smelting, and performing ingoting to form a titanium alloy ingot; 2, performing hot rolling on the titanium alloy ingot prepared in the step 1 to prepare a titanium alloy plateblank; 3, performing thermal treatment on the titanium alloy plate blank prepared in the step 2; 4, performing alkaline pickling on the titanium alloy plate subjected to the thermal treatment in thestep 3 to remove a surface oxide film, and mechanically grinding the titanium alloy plate till the surface coarseness is 0.5 to 1 [mu]m, thereby obtaining the titanium alloy plate. The high-temperature-resistant titanium alloy plate is good in thermal stability and high-temperature creep resistance. The invention further discloses a method of annealing the titanium alloy plate.

Owner:BAOJI YONGSHENGTAI TITANIUM IND

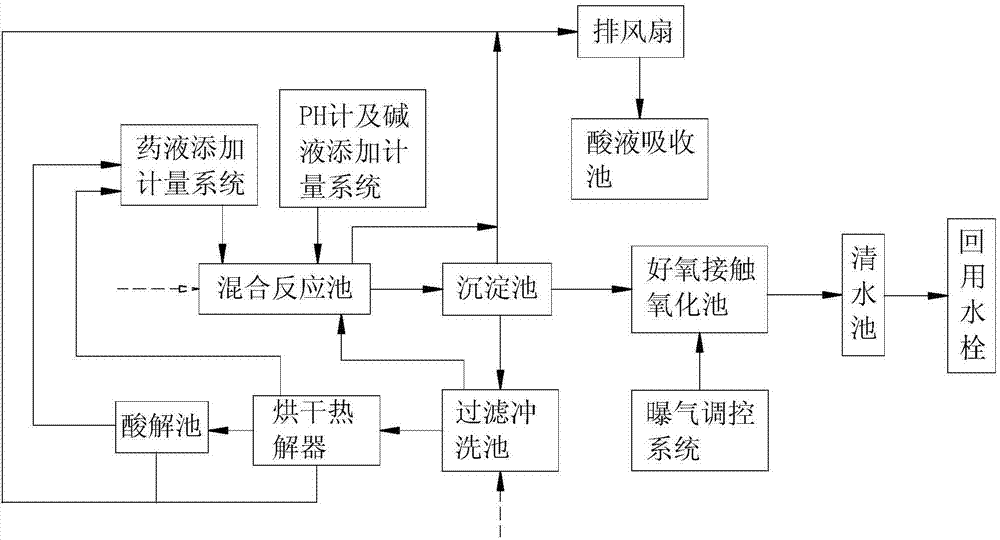

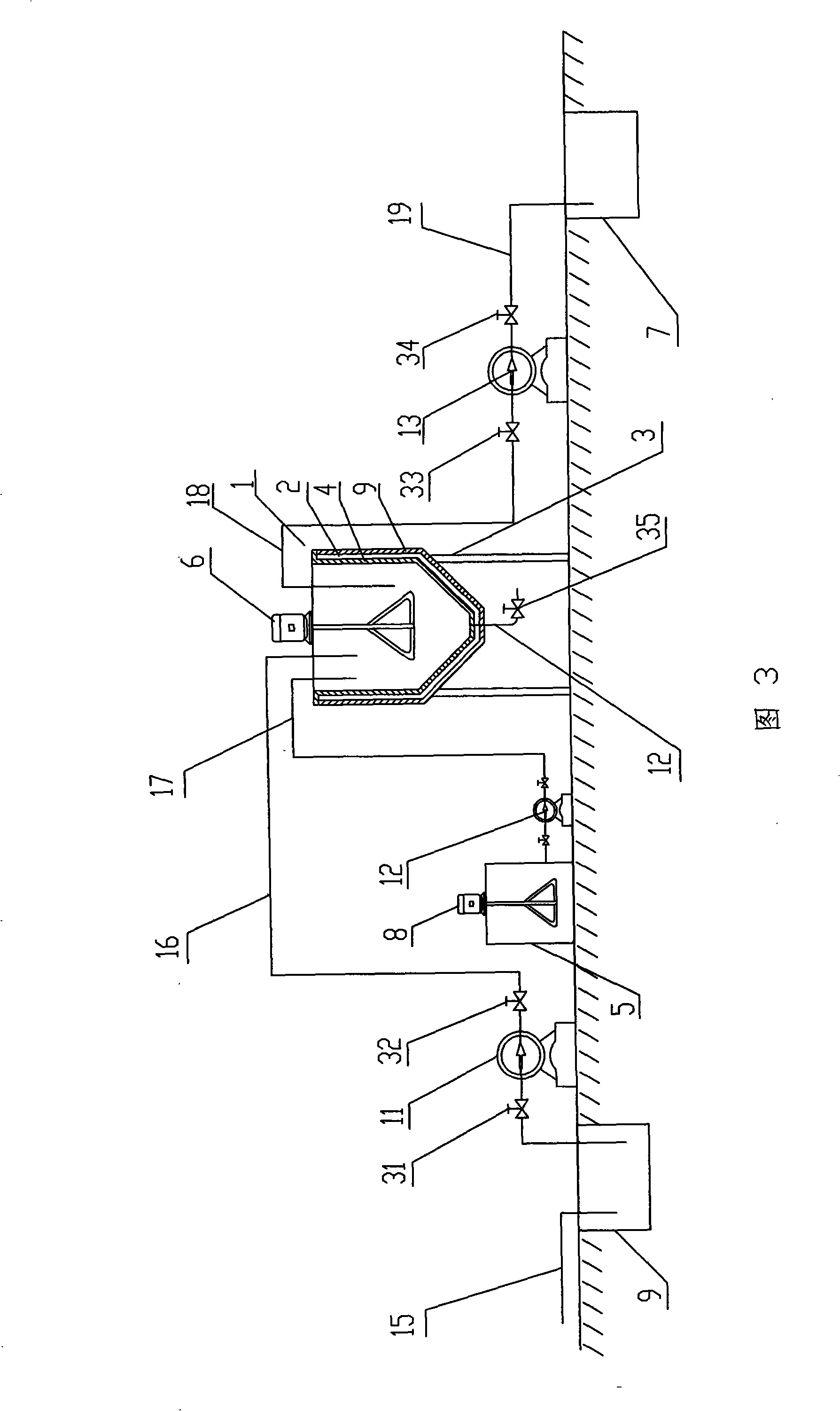

High-concentration ammonia nitrogen wastewater treatment method and system

InactiveCN103466829BAchieve recyclingAchieve reuseWater contaminantsMultistage water/sewage treatmentHigh concentrationPhosphate

The invention relates to the technical field of waste water treatment, in particular to a treatment method of high-concentration ammonia nitrogen waste water. The treatment method comprises the steps of adding alkaline liquor into the waste water, uniformly mixing, then adding fresh magnesium salt and phosphate liquor, settling, filtering, flushing and refiltering a settling product, drying and pyrolyzing the settling product, recovering a half of a pyrolyzed product to a mixing reaction tank, acidolyzing the other half of the pyrolyzed product continuously, recovering a solution after re-acidolysis to the mixing reaction tank, circulating for many times, then metering in the reaction tank, adding an appropriate amount of the magnesium salt and phosphate liquor, and allowing ammonia generated during treatment to react with an acidic solution to form ammonia salt. The invention further relates to a treatment system employing the method for treating the waste water. The treatment system comprises the mixing reaction tank, a settling tank, an aerobic catalytic oxidation tank, a filtering and flushing tank, a drying pyrolyzer, an acidolysis tank and an acidic solution absorption tank. The method realizes cyclic utilization of an agent, and saves the acidic solution. The treatment system is simple in structure and convenient to mount and operate.

Owner:江苏梅鑫环境科技有限公司

Process for producing protein feed by using alcohol full draff and stalk solid fermentation

InactiveCN1203774CEradicate degradationHigh nutritional valueFood processingAnimal feeding stuffFermentationMoisture

The present invention belongs to the fermented protein feed producing technology. Grain alcohol residue in 70-94 wt%, straw in 0.6-1.5 wt%, solidifying agent comprising wheat bran, urea and ammoniumsulfate are mixture to regulate the moisture content of grain alcohol residue of 40-60 %; and after further mixing with composite enzyme and composite bacteria, the mixed material is fermented at 25-35 deg.c and under anaerobic condition for 1-5 days to produce the protein feed. The present invention has the advantages of saving in energy source, no pollution and the high protein content up to 28 % in the produced feed.

Owner:TIANJIN UNIV

A biological treatment process and device for high-sulfur and phenol-containing waste lye

ActiveCN102757130BEfficient removalIncrease concentrationWater/sewage treatmentBiological water/sewage treatmentChemical oxygen demandReaction temperature

The invention discloses a biological treatment process for high-sulfur-containing and phenol-containing waste alkali liquid. The process comprises the following steps of: diluting high-sulfur-containing and phenol-containing waste alkali liquid until the concentration of sulfide is not more than 7.0g / L, the concentration of the COD (chemical oxygen demand) is not more than 25g / L and the concentration of Na+ is not more than 0.8mol / L; regulating a pH value of the liquid to be not more than 9.5; and performing treatment process of three steps, namely sludge inoculation, starting of a reactor and treatment of waste alkali liquid, under the conditions that the reaction temperature is 20-35 DEG C, the dissolved oxygen is 3-7mg / L and the hydraulic retention time is 24-96 hours. The invention also discloses a biological treatment device for high-sulfur-containing and phenol-containing waste alkali liquid. The biological treatment process and the biological treatment device have the beneficial effects that the removal ratio of pollutants is high, the removal ratio of sulfide is over 95 percent, and the removal ratio of organic matters is up to 90 percent; the capability of treating the waste alkali liquid is greatly improved, and the waste alkali liquid of which the pH value is about 9.5 can be treated; the cost and pretreatment expenses are reduced; and the secondary pollution is not caused, and the reaction device is small in floor area and is easy to operate.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

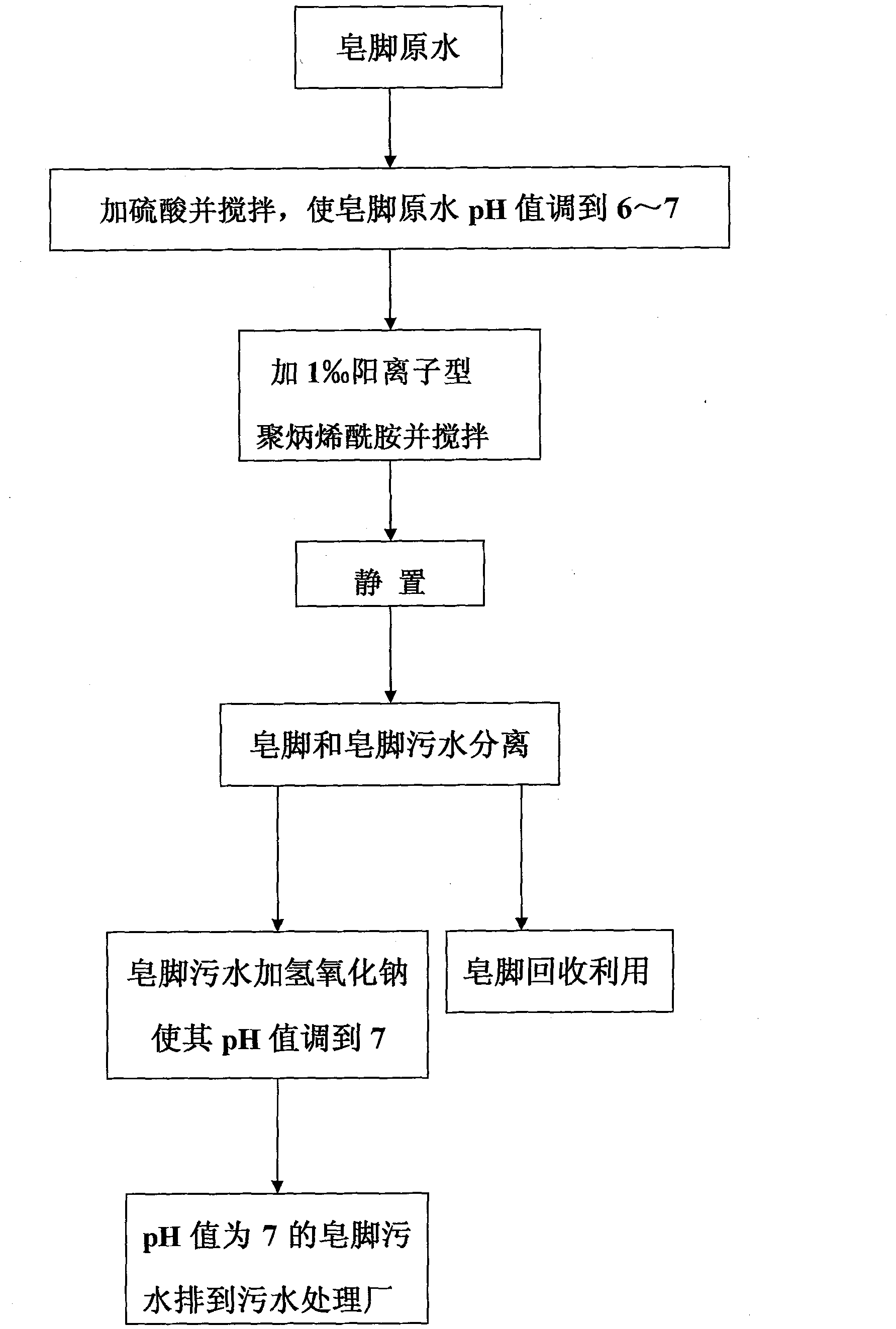

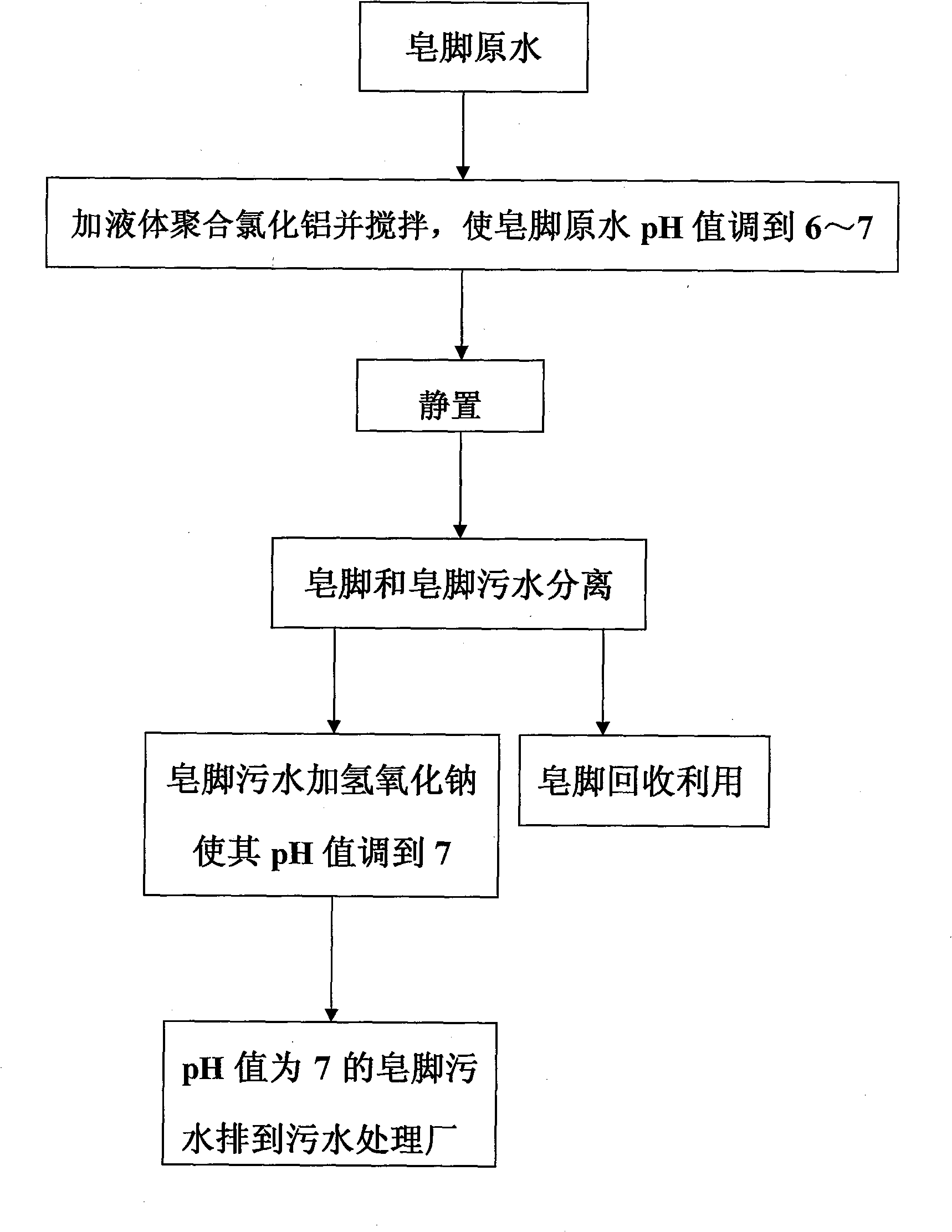

Method of separation of soap and water

InactiveCN101554542BReduce processing costsEfficient recyclingNon-miscible liquid separationAluminium chlorideScrew pump

The invention discloses a method of separation of soap and water, comprising the following steps of: using a screw pump to pump soapstock raw water to a heating and stirring tank; adding sulfuric acidto the heating and stirring tank till the pH value of the soapstock raw water is adjusted to be 6 to 7, and simultaneously starting stirring; adding 1 per thousand cationic-type polyacrylamide with the proportion of 35L in each ton of soapstock raw water; continuing stirring for 1 hour, standing for 4 hours and completing the layering of the soapstock and soapstock sewage; and pumping the upper layer of soapstock to a soapstock pool from the heating and stirring tank by using the screw pump and adjusting the pH value of the lower layer of soapstock sewage to be 7 by using sodium hydroxide andthen discharging the mixed solution to the sewage treatment plant. Or liquid polyaluminium chloride is used for replacing the sulfuric acid and the cationic-type polyacrylamide. The method has littleacid usage, low cost, good economic benefit, low treatment cost and easy treatment of separated soapstock sewage, and also can effectively recycle soapstock, improve economic benefit of enterprises and lead the soapstock resource to be utilized fully.

Owner:高建东

A steel cord cleaning process and device

Owner:HENAN HENGXING SCIENCE & TECHNOLOGY CO LTD

Degreasing cleaning method for inner wall of high-pressure oxygen pipeline

PendingCN112090878AImprove the effectPrevent blockage of high pressure oxygen pipelineHollow article cleaningCleaning using liquidsGas explosionChemistry

The invention provides a degreasing cleaning method for an inner wall of a high-pressure oxygen pipeline, and relates to the field of degreasing cleaning of pipelines. The degreasing cleaning method for the inner wall of the high-pressure oxygen pipeline comprises the steps: flushing, grease dissolution, acid washing, enzyme washing, detection and drying. By using a mixed flushing way of sand andwater, a large amount of oil grease attached with the inner wall of the high-pressure oxygen pipeline can be removed; and meanwhile, by using a gas explosion way, the effect of cleaning the sand can be improved, and blockage of the high-pressure oxygen pipeline caused by combination of the dropped oil grease and the sand during cleaning is also prevented; and meanwhile, in an impacting process ofthe sand, the inner wall of the high-pressure oxygen pipeline can be ground, impurities such as iron rust and welding slag can be removed, and acid liquid required by passivation is reduced.

Owner:陈广萍

Polar plate treating method and compression roller assembly used for same

ActiveCN102646815BMoisture content meets the requirementsMoisture content requirementsLead-acid accumulator electrodesState of artMoisture

The invention relates to a polar plate treating method and a compression roller assembly used for the same. The polar plate treating method comprises the following steps of: step a, carrying out plate coating treatment on a polar plate; step b, absorbing water on the surface of the polar plate subjected to the plate coating treatment by utilizing a water-absorbing material to; and step c, carrying out drying treatment on the polar plate. According to the invention, after the plate is coated, the water-absorbing material is directly used for absorbing the water on the surface of the polar plate; and then, the polar plate is dried. The whole treating process can save acid pouring operation, so that not only can acid liquid be saved, but also the problem in the prior art that floating powder is easy to generate due to acid pouring is avoided. Furthermore, the moisture content of the polar plate machined by the method disclosed by the invention meets requirements.

Owner:ANHUI LEOCH POWER SUPPLY

A jig for cleaning the insulation sheet of furnace tube equipment

ActiveCN103464414BExtended use timeShorten maintenance timeCleaning using liquidsMachine maintenanceTube furnace

The invention relates to a jig for cleaning furnace tube equipment heat insulation sheets. The jig comprises two supporting seats and three supporting rods, the supporting rods include a first supporting rod, a second supporting rod and a third supporting rod, two ends of the first supporting rod and two ends of the second supporting rod are correspondingly fixed to the vertical middles of two sides of the two supporting seats respectively, two ends of the third supporting rod are fixed to the vertical bottoms of the two supporting seats, and corresponding positions of the three supporting rods are respectively provided with one or a plurality of toothed clamp grooves. When cleaned, a plurality of furnace tube equipment heat insulation sheets can be placed into the toothed clamp grooves of the supporting rods and simultaneously cleaned, cleaning efficiency is improved, acid liquor is saved, the service time of the acid liquor is prolonged, machine maintenance time is shortened, and accordingly, energy production efficiency is improved.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

A detection method for measuring ultra-trace radioactive background of polymers

ActiveCN108414607BLow detection limitImprove signal-to-noise ratioPreparing sample for investigationMaterial analysis by electric/magnetic meansTrace elementOrganic glass

The invention belongs to the field of analytical chemistry, and relates to a method for detecting super trace radioactive background in a polymer. The analytic method for measuring the super trace radioactive background by ICP-MS is established in a dry ashing pretreatment manner in order to realize the analysis of super trace elements in organic glass. The detection limit of the detection methodcan reach 1 pg / g or below; and additionally, the method can be simply, rapidly and accurately operated.

Owner:SUN YAT SEN UNIV

Jig for cleaning furnace tube equipment heat insulation sheets

ActiveCN103464414AExtended use timeShorten maintenance timeCleaning using liquidsMachine maintenancePulp and paper industry

The invention relates to a jig for cleaning furnace tube equipment heat insulation sheets. The jig comprises two supporting seats and three supporting rods, the supporting rods include a first supporting rod, a second supporting rod and a third supporting rod, two ends of the first supporting rod and two ends of the second supporting rod are correspondingly fixed to the vertical middles of two sides of the two supporting seats respectively, two ends of the third supporting rod are fixed to the vertical bottoms of the two supporting seats, and corresponding positions of the three supporting rods are respectively provided with one or a plurality of toothed clamp grooves. When cleaned, a plurality of furnace tube equipment heat insulation sheets can be placed into the toothed clamp grooves of the supporting rods and simultaneously cleaned, cleaning efficiency is improved, acid liquor is saved, the service time of the acid liquor is prolonged, machine maintenance time is shortened, and accordingly, energy production efficiency is improved.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com