Absorption tower for denitrating flue gas by using bleaching effluent and denitrating method thereof

An absorption tower and flue gas technology, applied in the field of absorption towers, can solve problems such as high operating costs and secondary pollution, and achieve the effects of improving economic benefits, prolonging contact time, and reducing chemical oxygen consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

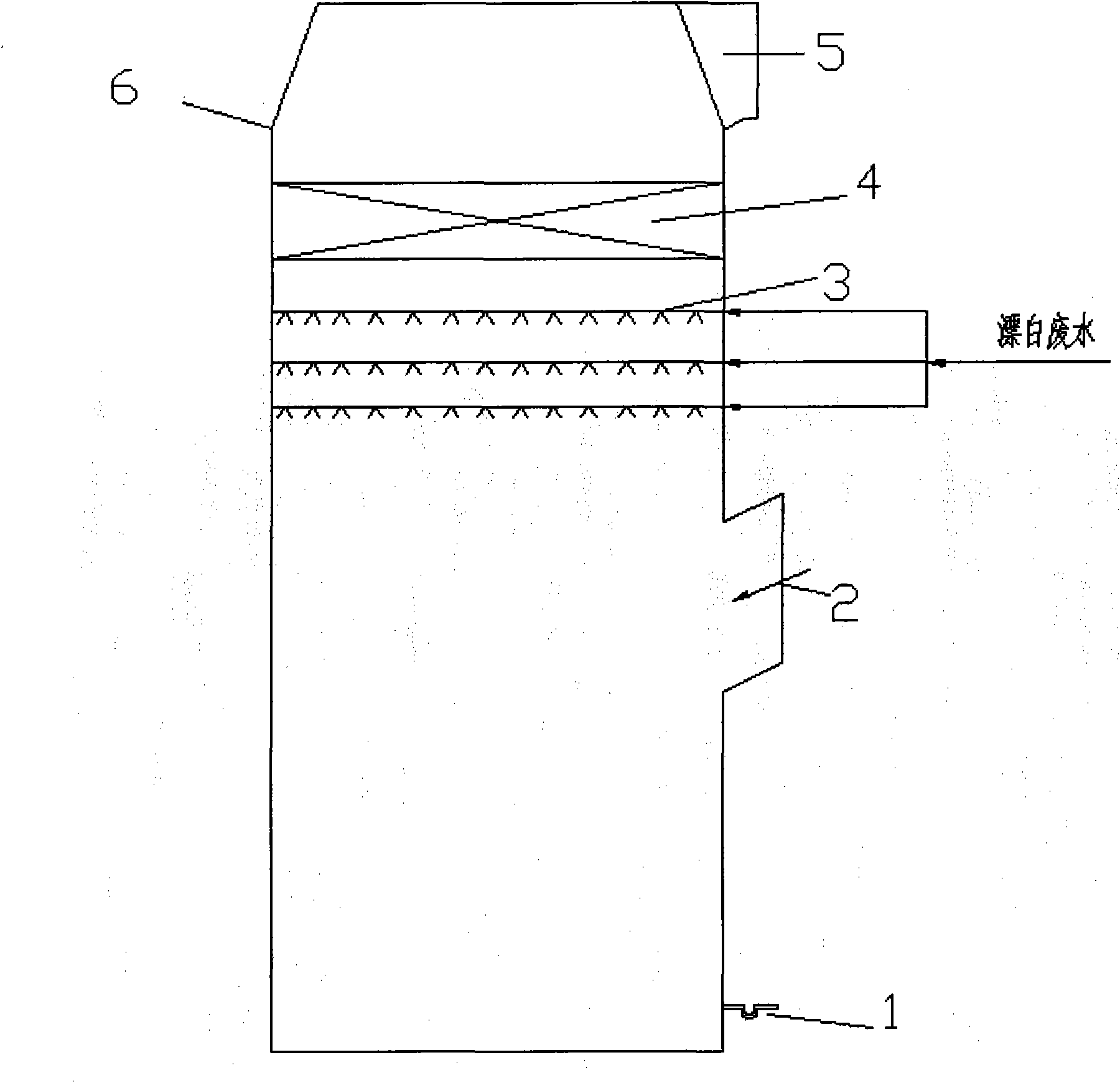

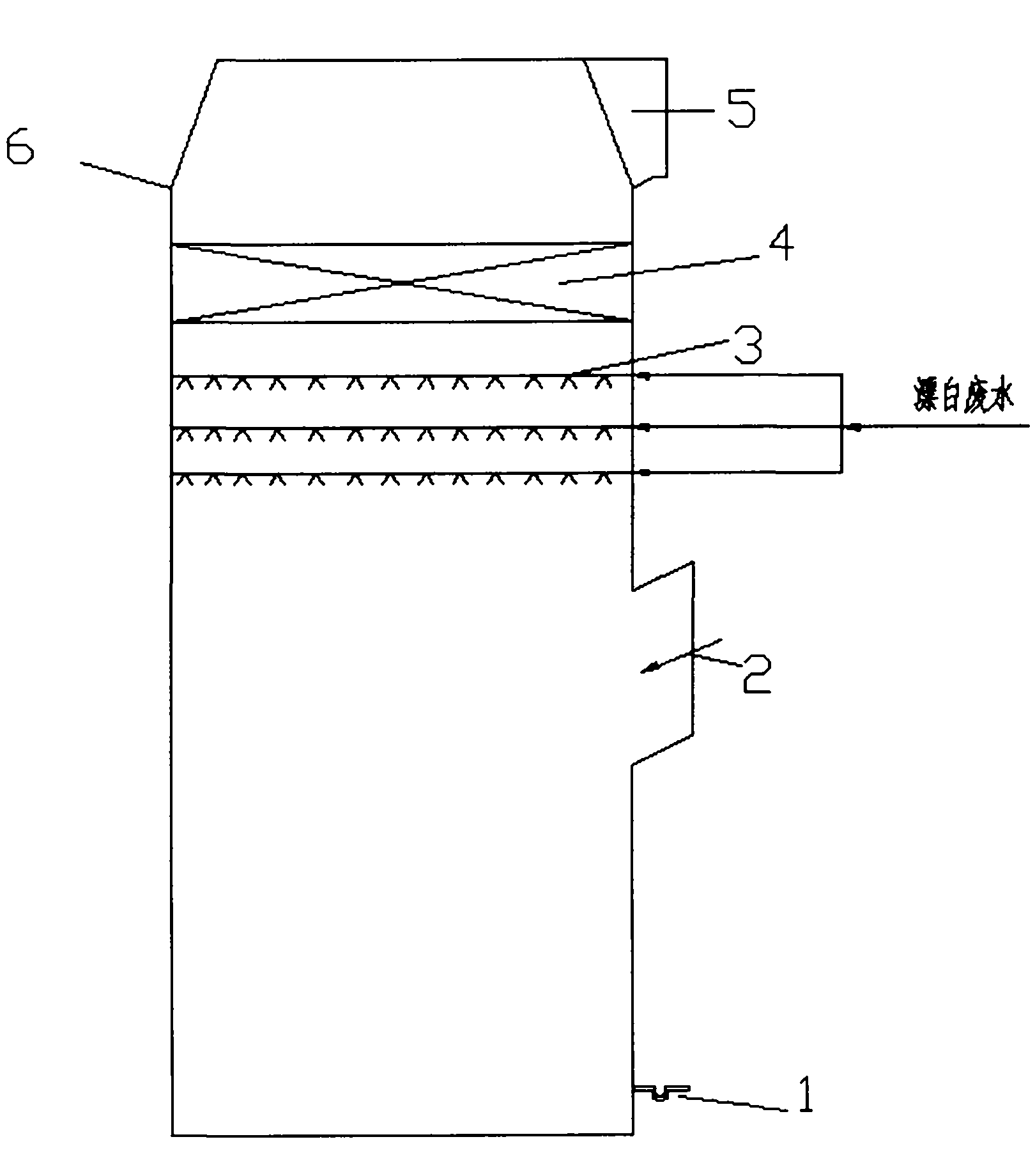

[0034] like figure 1 Absorption tower for flue gas denitrification with bleaching wastewater as shown

[0035] An absorption tower for flue gas denitrification by bleaching wastewater, comprising an absorption tower 6, and the desulfurization tower 6 includes a flue gas inlet 2, a flue gas outlet 5, an overflow port 1, a slurry spray area 3, and a demister area 4;

[0036] The flue gas outlet 5 is opened on the top of the absorption tower 6, and an overflow port 1 is opened on the side of the bottom of the absorption tower;

[0037] The inclination angle between the flue gas inlet 2 and the horizontal plane is 10-20°;

[0038] The overflow port is a U-shaped liquid outlet channel;

[0039] The slurry spraying area 3 is provided with 3 layers of staggered bleaching wastewater spraying layers; the spraying layer is provided with a spray pipe and a number of nozzles connected thereto;

[0040] The upper demister section 4 of the absorption tower 6 can remove liquid droplets i...

Embodiment 2

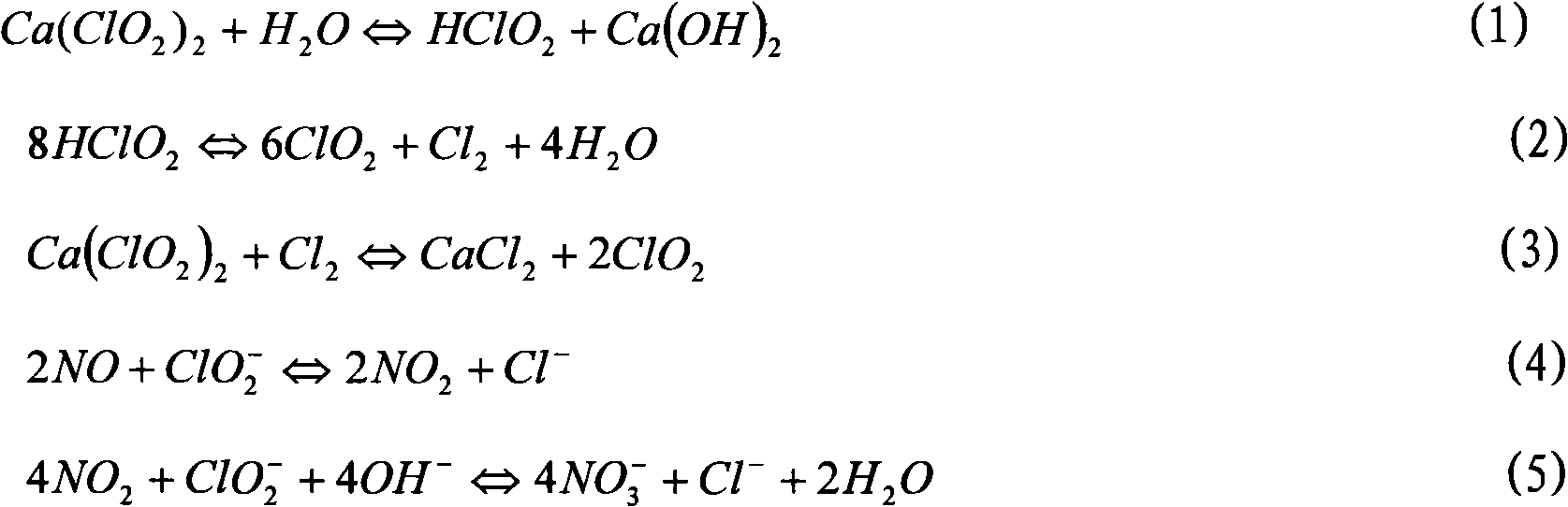

[0042] The bleaching wastewater flue gas denitrification device of the present invention is used for denitrification.

[0043] The flue gas discharged from the boiler, in which the NO concentration is 1339mg / m 3 , after the dust is removed by the electrostatic precipitator, the flue gas flow rate is selected to be 6785m through the booster fan 3 / h is sent into the absorption tower 6 through the flue gas inlet 2 of the absorption tower 6, and passes through the spray area 5 arranged staggeredly above the absorption tower 6, and the bleaching wastewater flows at a flow rate of 67.85m 3 / h is continuously transported to the spray area 3, sprayed out through the nozzle, and contacts with the flue gas countercurrently, thereby completing the denitrification. The reacted absorption liquid falls into the bottom of the absorption tower 6, and then is discharged through the overflow port 1 and sent to the waste water treatment device. At the flue gas outlet 5, the testo 350XL flue g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com