A jig for cleaning the insulation sheet of furnace tube equipment

A technology of heat preservation sheet and cleaning furnace, which is applied in the directions of cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc. Effectiveness of uptime, increased productivity, and reduced maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

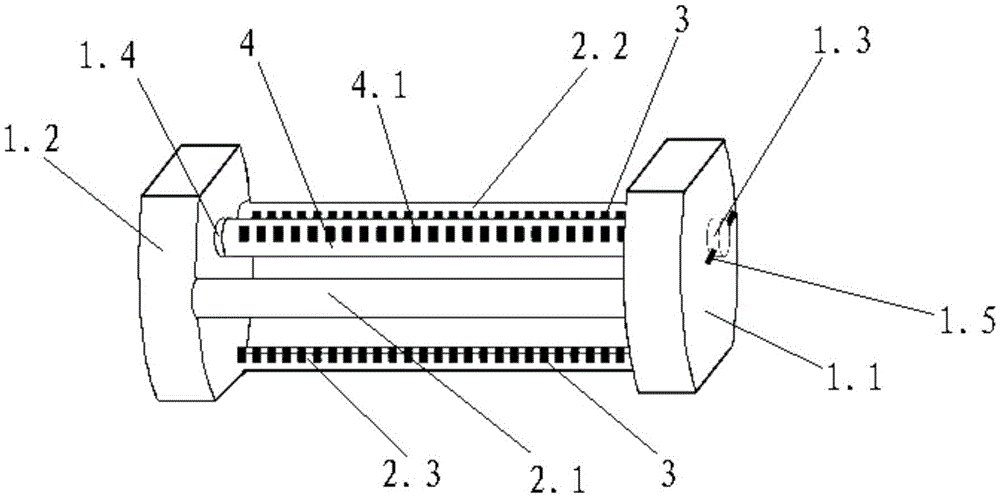

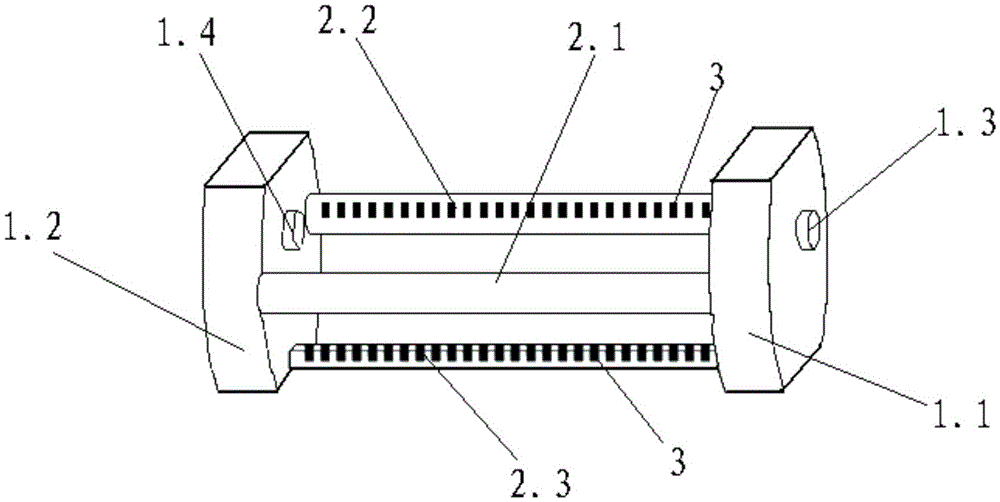

[0018] Such as figure 1 As shown, a jig for cleaning the insulation sheet of furnace tube equipment includes a support seat and a support rod. There are two support seats, which are respectively the first support seat 1.1 and the second support seat 1.2. There are three rods, which are respectively the first support rod 2.1, the second support rod 2.2, and the third support rod 2.3. The first support, 2.1, and the second support rod 2.2 are all cylindrical support rods, and the third support The rod 2.3 is a square support rod, and the two ends of the first support rod 2.1 and the second support rod 2.2 are respectively fixed at the vertical middle positions on both sides of the first support base 1.1 and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com