Novel crystalline silicon cell wet process edge etching technology

A technology of crystalline silicon battery and wet method, which is applied in the direction of circuit, electrical components, sustainable manufacturing/processing, etc., can solve the problems of easy dripping of water, waste of acid, high leakage ratio, etc., to eliminate etching and save energy consumption Acid, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

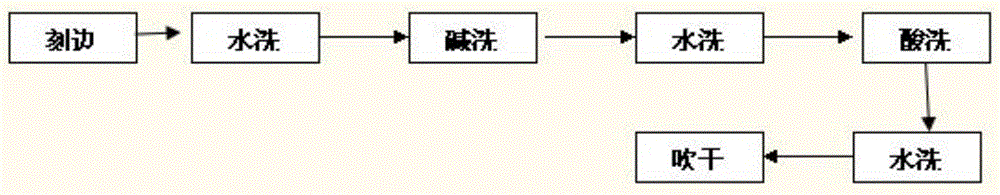

Method used

Image

Examples

Embodiment

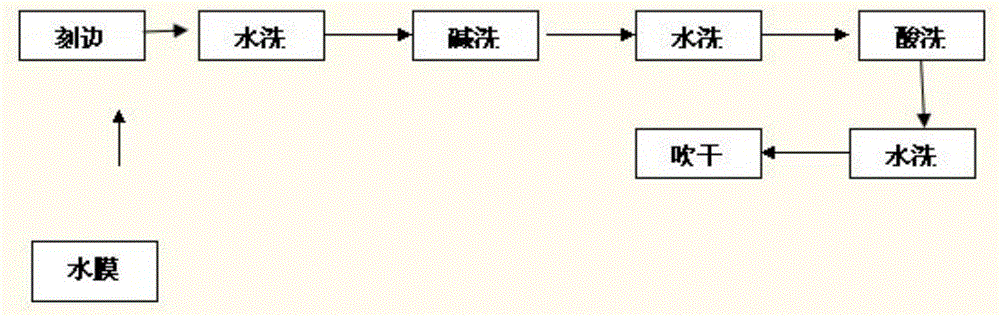

[0038] (1) Use HF to remove the PSG layer at the corner of the silicon wafer at room temperature by means of capillary roller carrying liquid or "floating on water"; the mass percentage concentration of HF is 3%, and the roller speed of the capillary roller is 2.5m / min;

[0039] Principle: When HF removes the corner PSG, it will climb to the upper surface along the PSG layer, remove the PSG layer on the edge, and the surface of the silicon wafer after HF treatment is hydrophobic;

[0040] (2) dry the silicon chip surface after step (1) by air knife or hot air knife, the temperature of hot air knife is 60°-65°; the speed of roller is 2.5m / min;

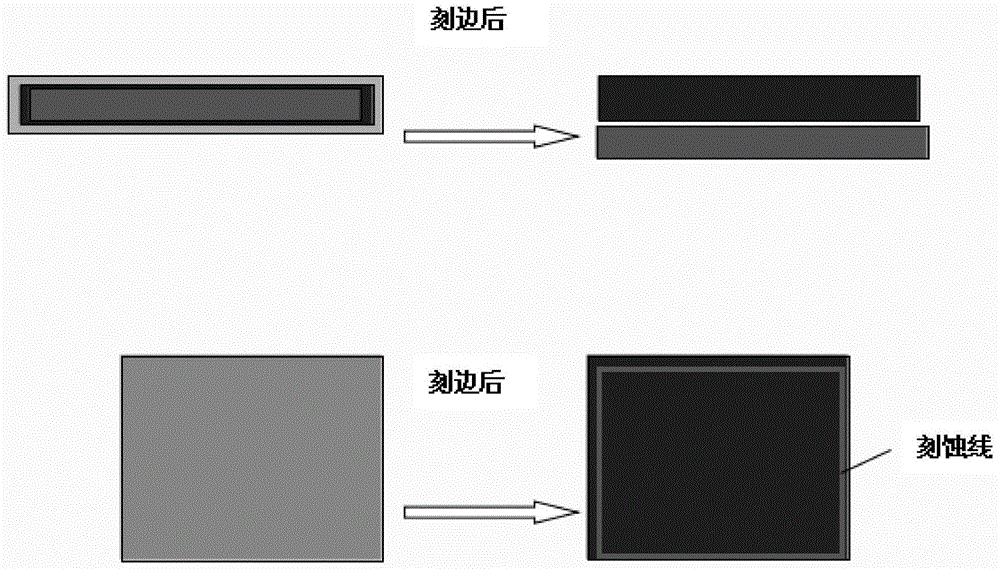

[0041] (3) Use HF / HNO3 mixed acid to edge the silicon wafer dried in step (2) by means of capillary roller with liquid or "floating on water"; wherein the volume ratio of HF / HNO3 is 1:3, and the edge cutting speed is 2.4 m / min;

[0042] Principle: Since the edge of the PN junction layer of the silicon wafer treated with HF is hydrophob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com