Power transmission line composite insulator repairing support and working method thereof

A technology of composite insulators and maintenance brackets, which is applied to overhead lines/cable equipment, etc., can solve problems such as affecting maintenance operations, increasing maintenance costs, and secondary damage to maintenance equipment, optimizing maintenance operations, improving construction safety, and ensuring The effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

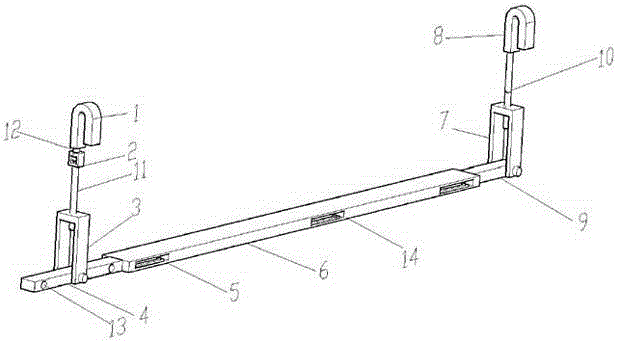

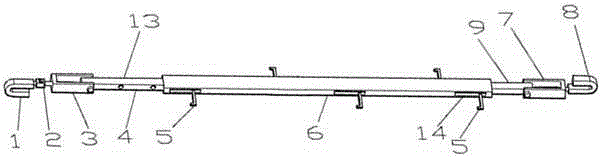

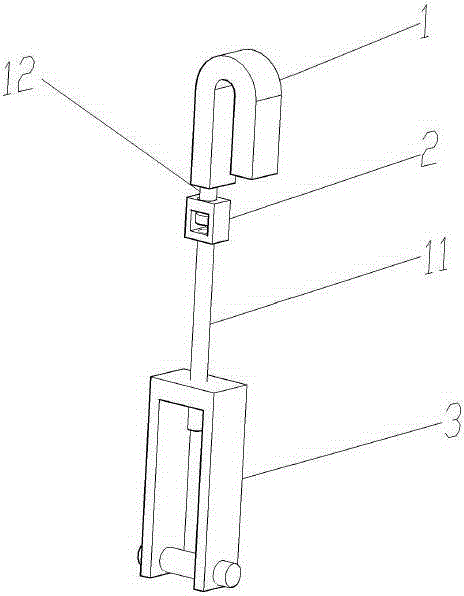

[0034] Figure 1-3 The maintenance support for composite insulators of power transmission lines includes a supporting body 6 for supporting maintenance personnel. Articulated connections. One end of the supporting body 6 is provided with an adjusting connector 4 extending along the length direction of the supporting body, and one of the suspension mechanisms is connected to the adjusting connector 4 as a first suspension mechanism. The other end of the supporting body 6 is provided with a connecting piece 9 extending along the length direction of the supporting body, and another suspension mechanism is connected to the connecting piece 9 as a second suspension mechanism.

[0035] Two side walls of the supporting body 6 are provided with several grooves 14 respectively, and the grooves are provided with embedded foot nails 5 . Each embedded foot nail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com