Polar plate treating method and compression roller assembly used for same

A pole plate treatment and pole plate technology, applied in the direction of lead-acid battery electrodes, etc., can solve the problems of polluting the workshop environment, easy to fall off, battery short circuit, etc., and achieve the effect of saving acid and reducing moisture content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

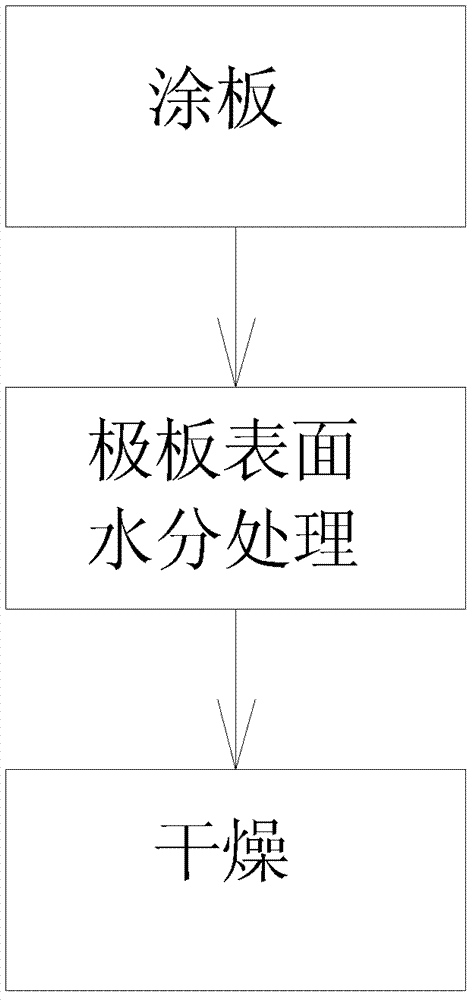

[0023] Please refer to figure 1 , in the present embodiment, a kind of plate treatment method comprises the steps:

[0024] Step a, carrying out plate-coating treatment on the pole plate;

[0025] In this step, the plate coating treatment can adopt the plate coating operation in the prior art.

[0026] Step b, using a water-absorbing material to absorb the moisture on the surface of the coated plate;

[0027] Specifically, this step may be: passing the plate-coated pole plate over a pressure roller, and winding the water-absorbing material on the pressure roller. The role of the water-absorbing material is to absorb the moisture on the surface of the plate, which has the following characteristics: 1. The material is soft, easy to wrap around the pressure roller, and will not crush the plate; 2. Does not contain iron, manganese, copper, chlorine Equally variable ionic components will not pollute the plate; 3. It has a good water absorption effect. For example, absorbent cot...

Embodiment 2

[0034] In this example, the pressure roller assembly used in step b of the electrode plate treatment method described in Embodiment 1 includes a pressure roller and a water-absorbing material wound on the pressure roller. The water-absorbing material is mainly used to absorb moisture on the surface of the electrode plate, which is convenient for subsequent drying treatment. The role of the water-absorbing material is to absorb the moisture on the surface of the plate, which has the following characteristics: 1. The material is soft, easy to wrap around the pressure roller, and will not crush the plate; 2. Does not contain iron, manganese, copper, chlorine Equally variable ionic components will not pollute the plate; 3. It has a good water absorption effect. For example, the water-absorbing material can be absorbent cotton yarn, etc., wherein the absorbent cotton yarn is usually replaced within a certain time of normal operation to ensure the drying of the absorbent cotton yarn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com