Exhaust type extruding single screw

A single-screw, exhaust-type technology, applied in the field of extruder parts, can solve the problems of adding hot air drying equipment, reducing production efficiency, increasing equipment costs, etc., to save drying time, improve production efficiency, and improve conveying capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

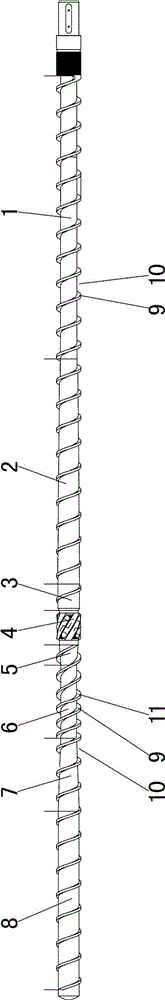

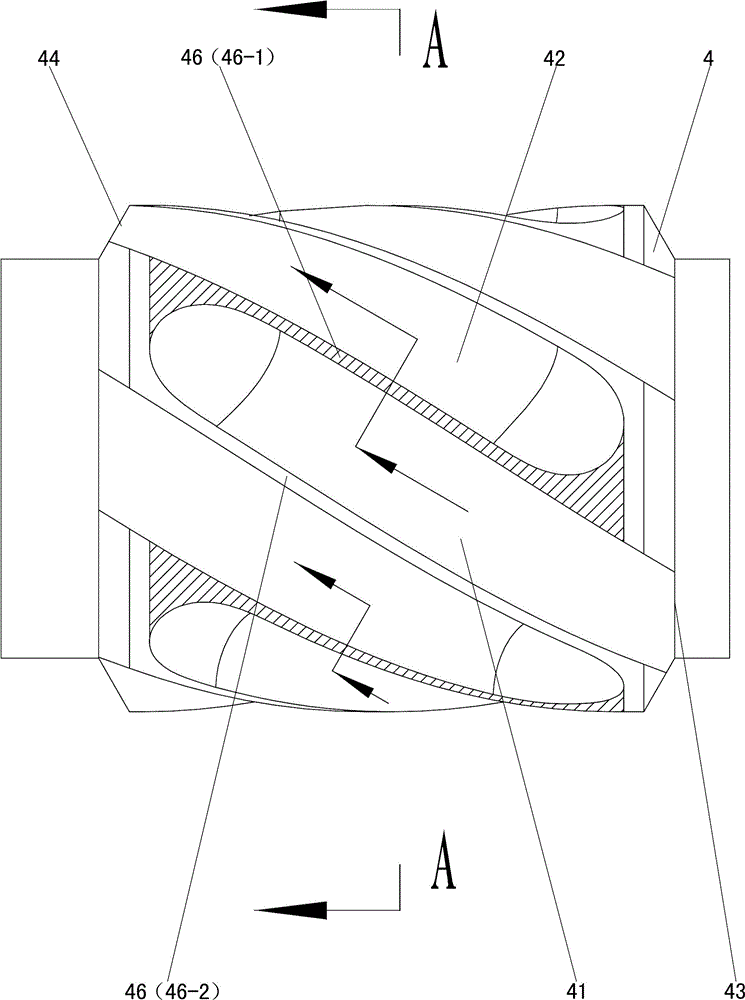

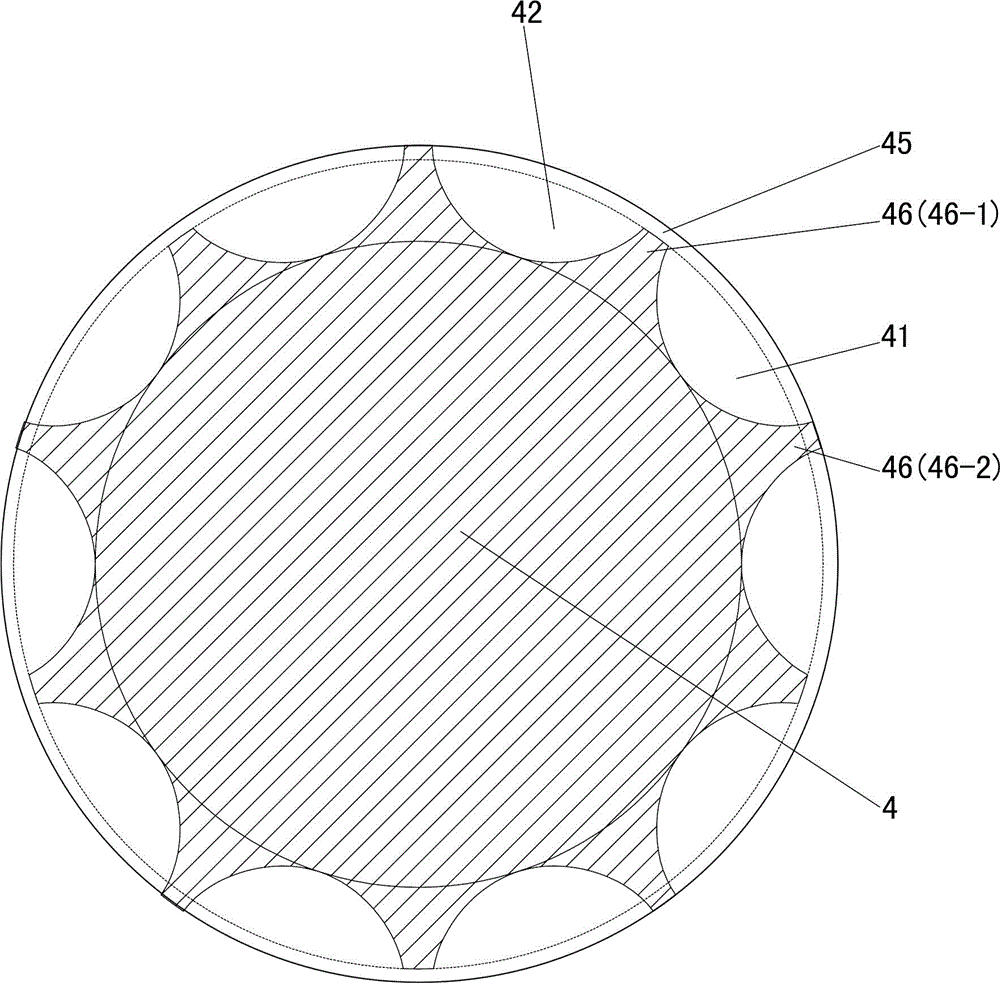

[0021] Such as figure 1 As shown, this exhaust type extrusion single screw includes feed section 1, first compression section 2, first metering section 3, mixing section 4, decompression section 5, exhaust section 6, first Two compression sections 7 and a second metering section 8 .

[0022] The feed section 1, the first compression section 2 and the first metering section 3 are all provided with a main screw thread 9, and the screw groove depth (the depth of the screw groove 10) of the main screw thread 9 on the first compression section 2 decreases gradually from front to back . The flight width and the screw groove depth of the main flight 9 of each part on the feed section 1 are consistent, and the flight width and the screw groove depth of the main flight 9 of each part on the first metering section 3 are also consistent; the first metering The groove depth of the main flight 9 on section 3 is smaller than the groove depth of the main flight 9 on feed section 1 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com