Patents

Literature

44results about How to "Avoid sliding in" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

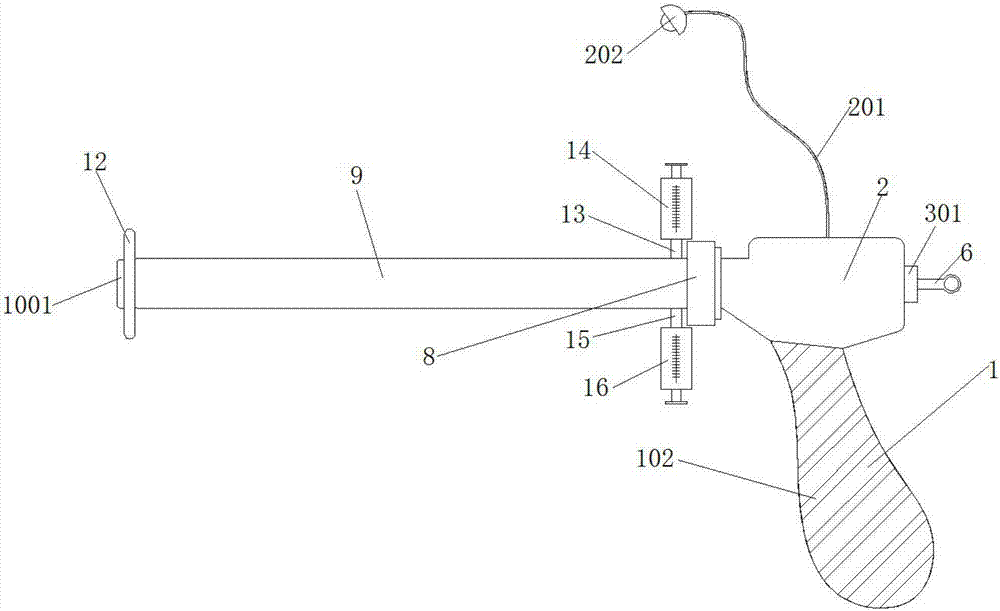

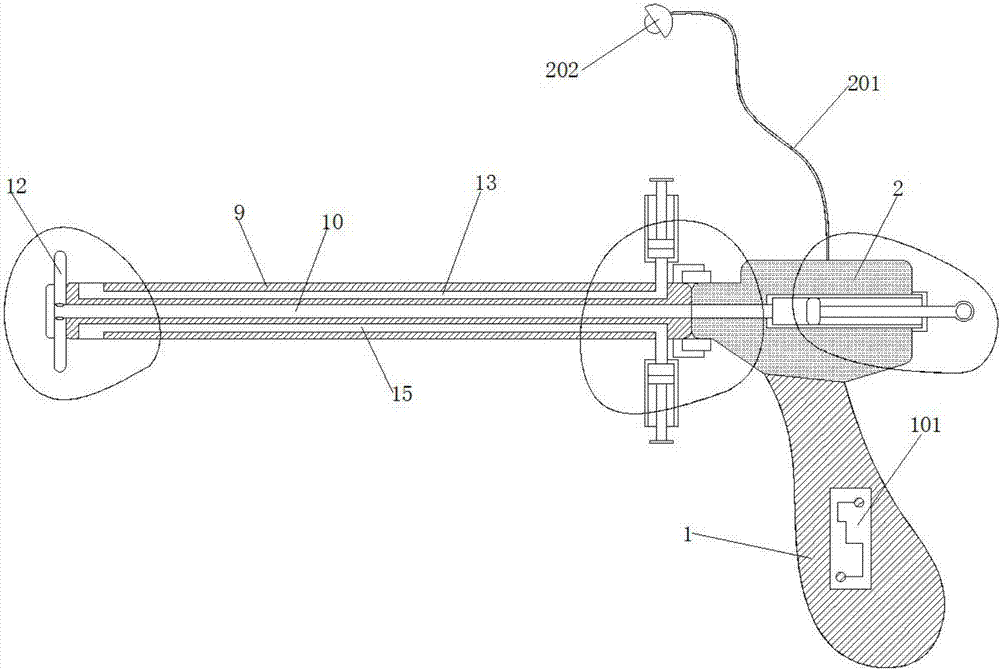

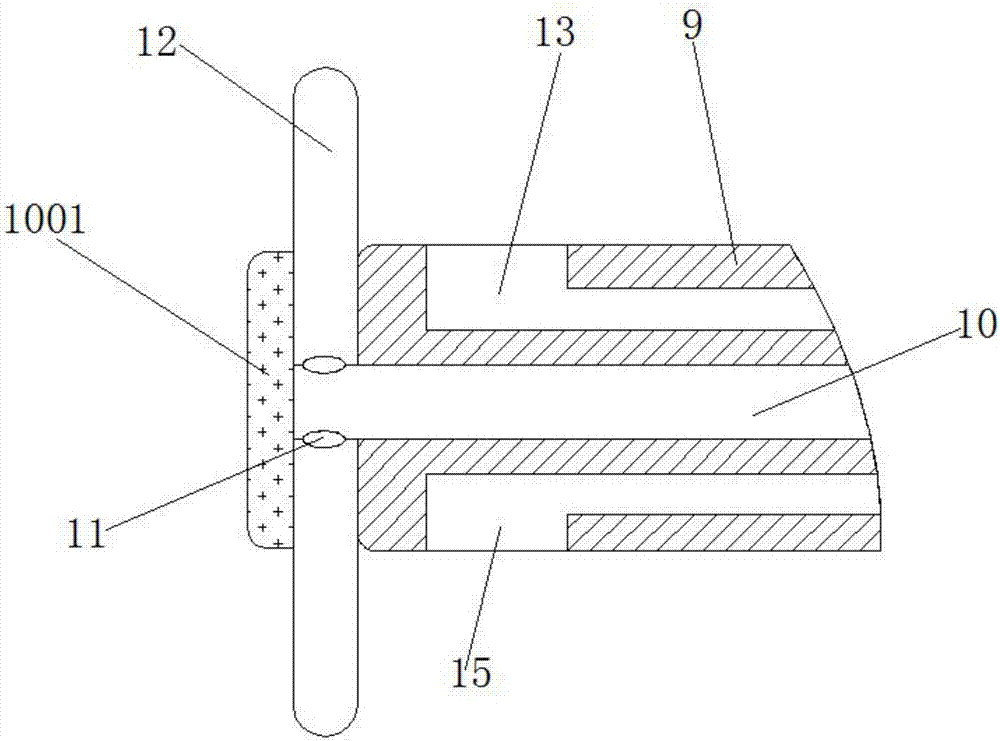

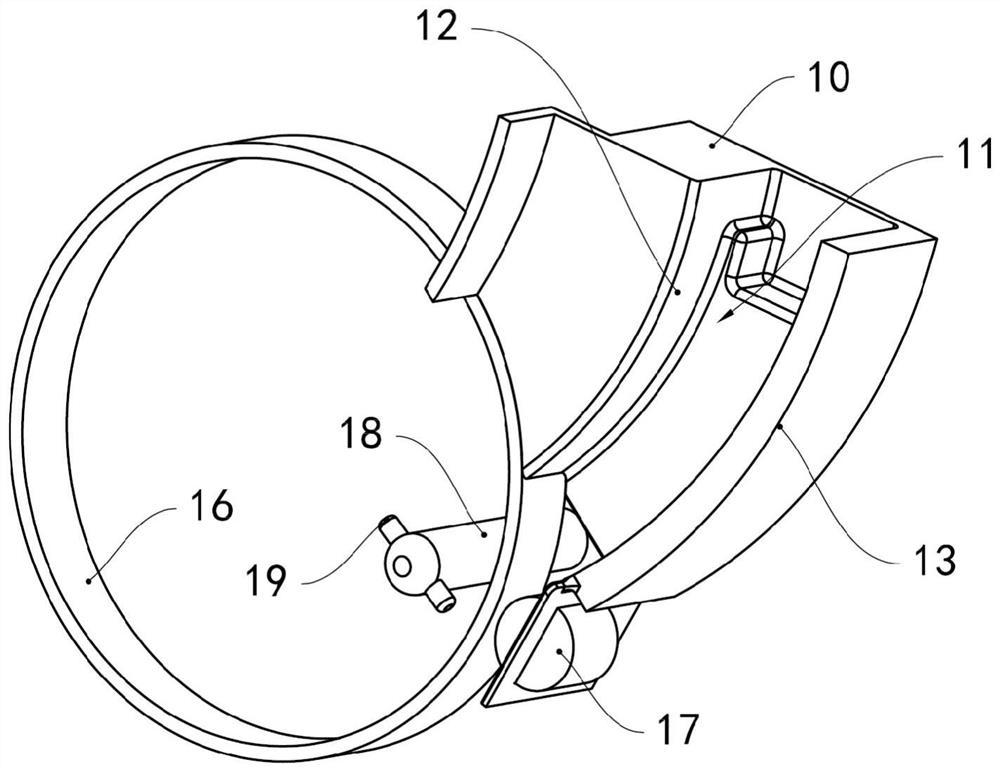

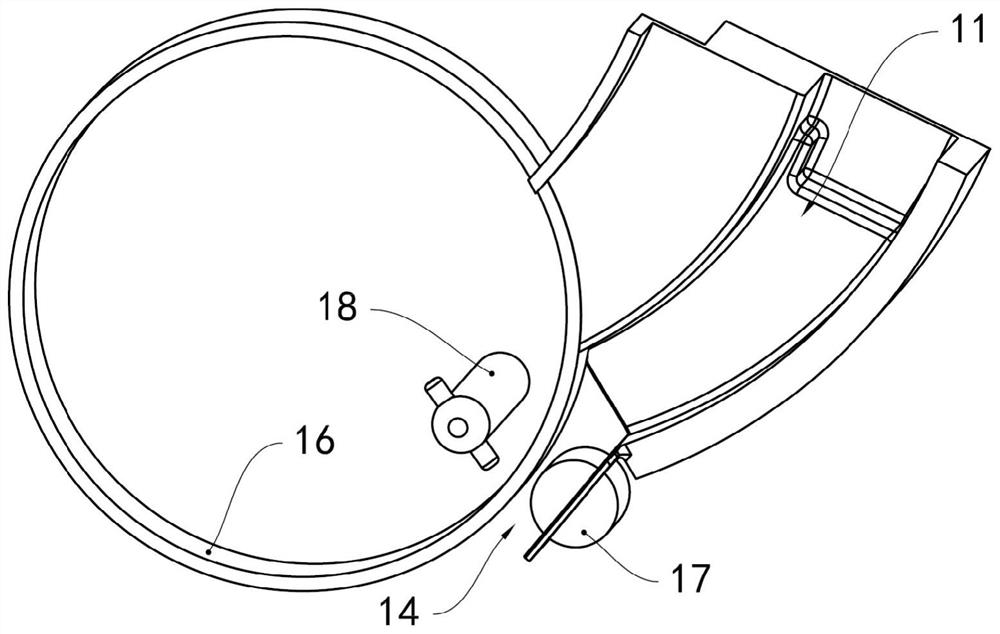

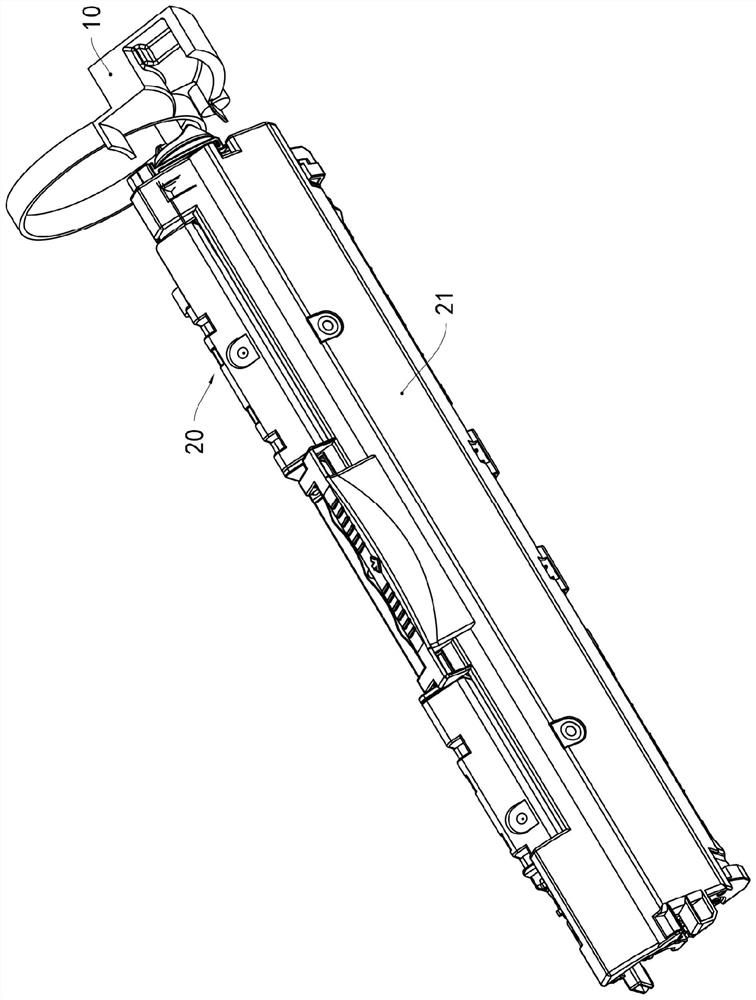

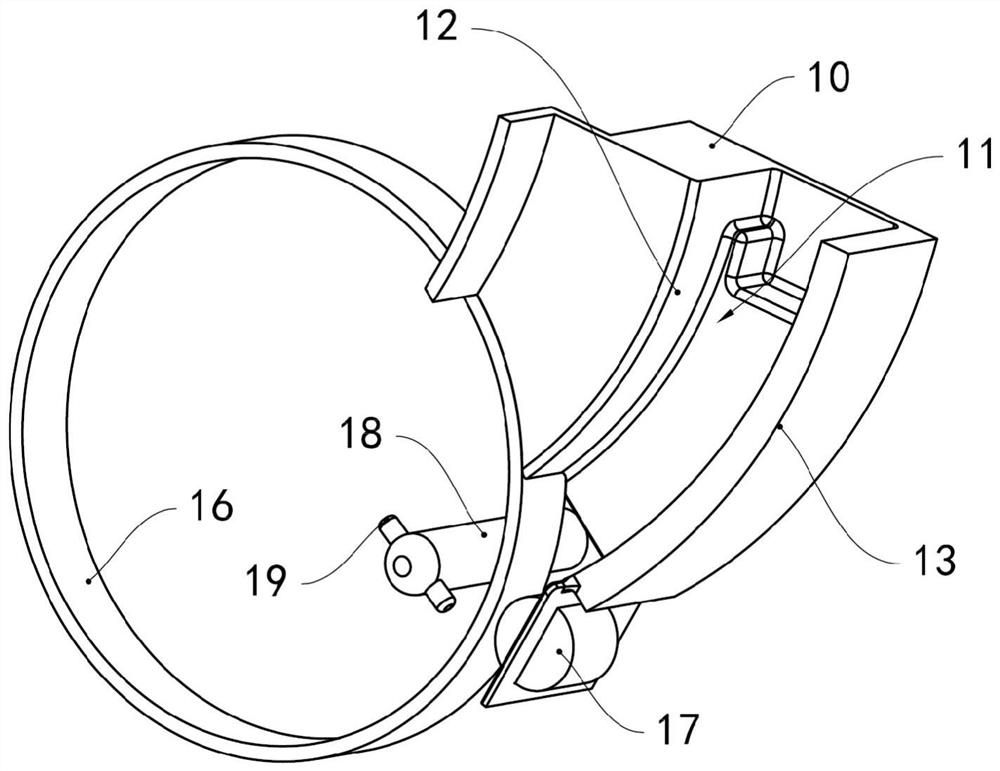

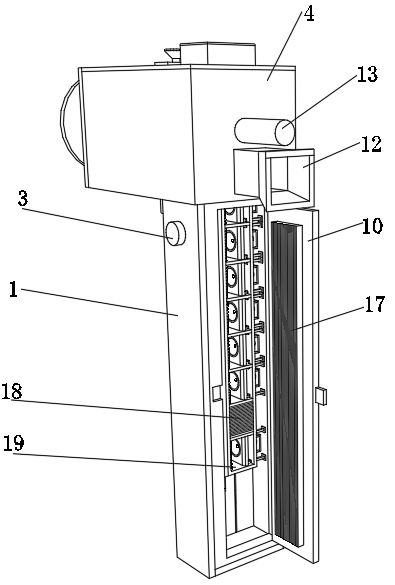

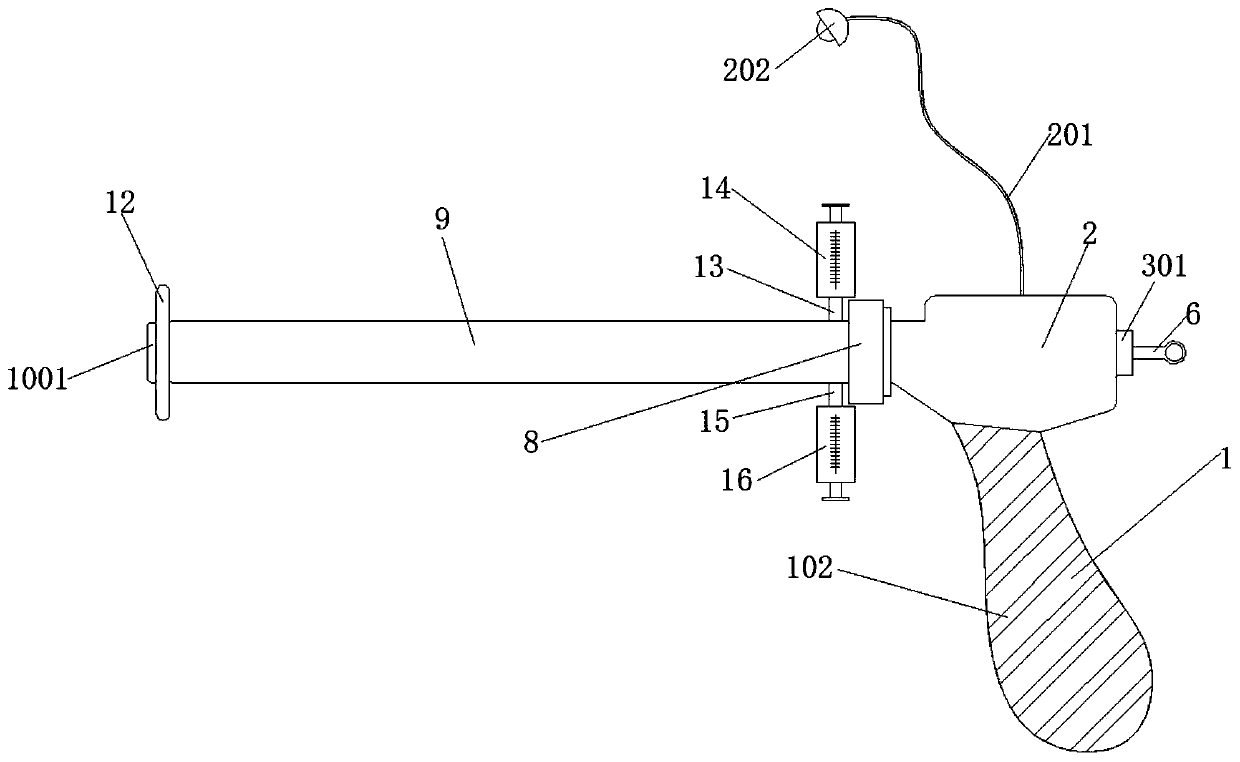

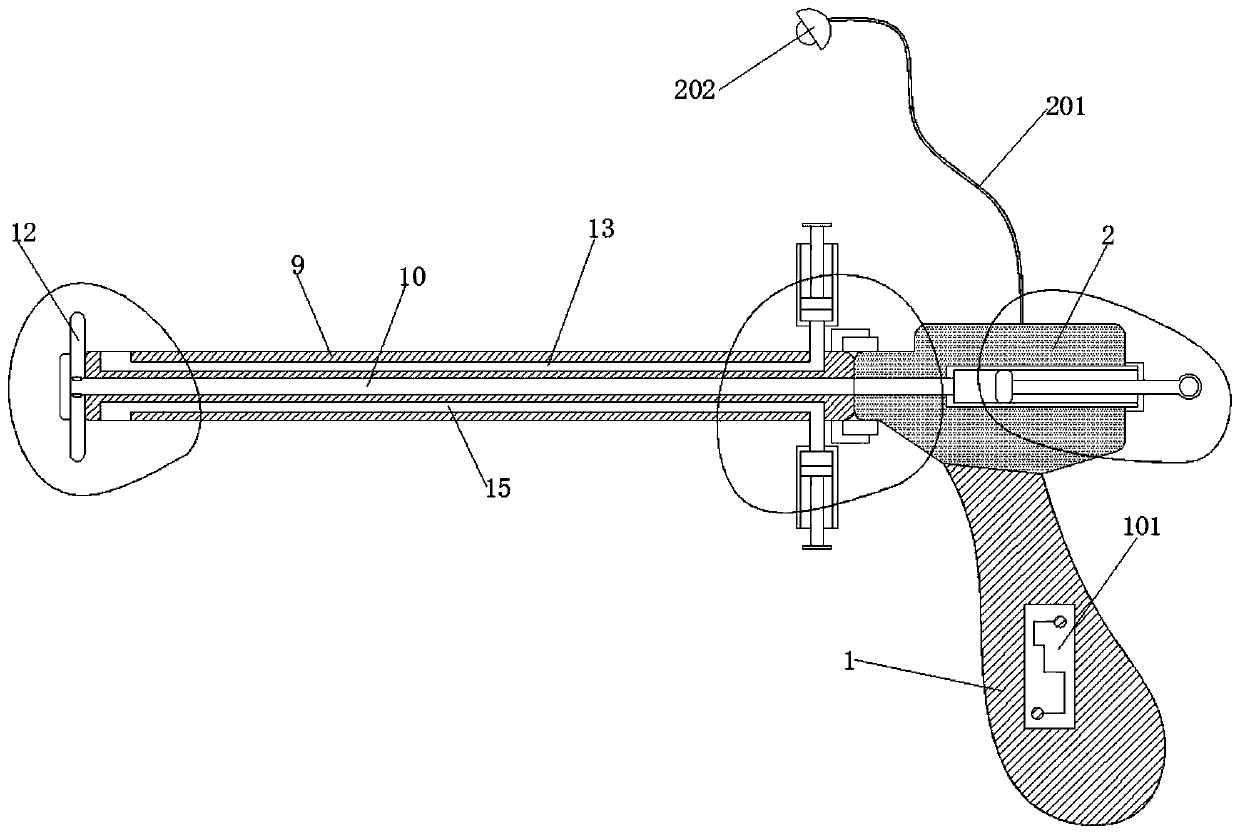

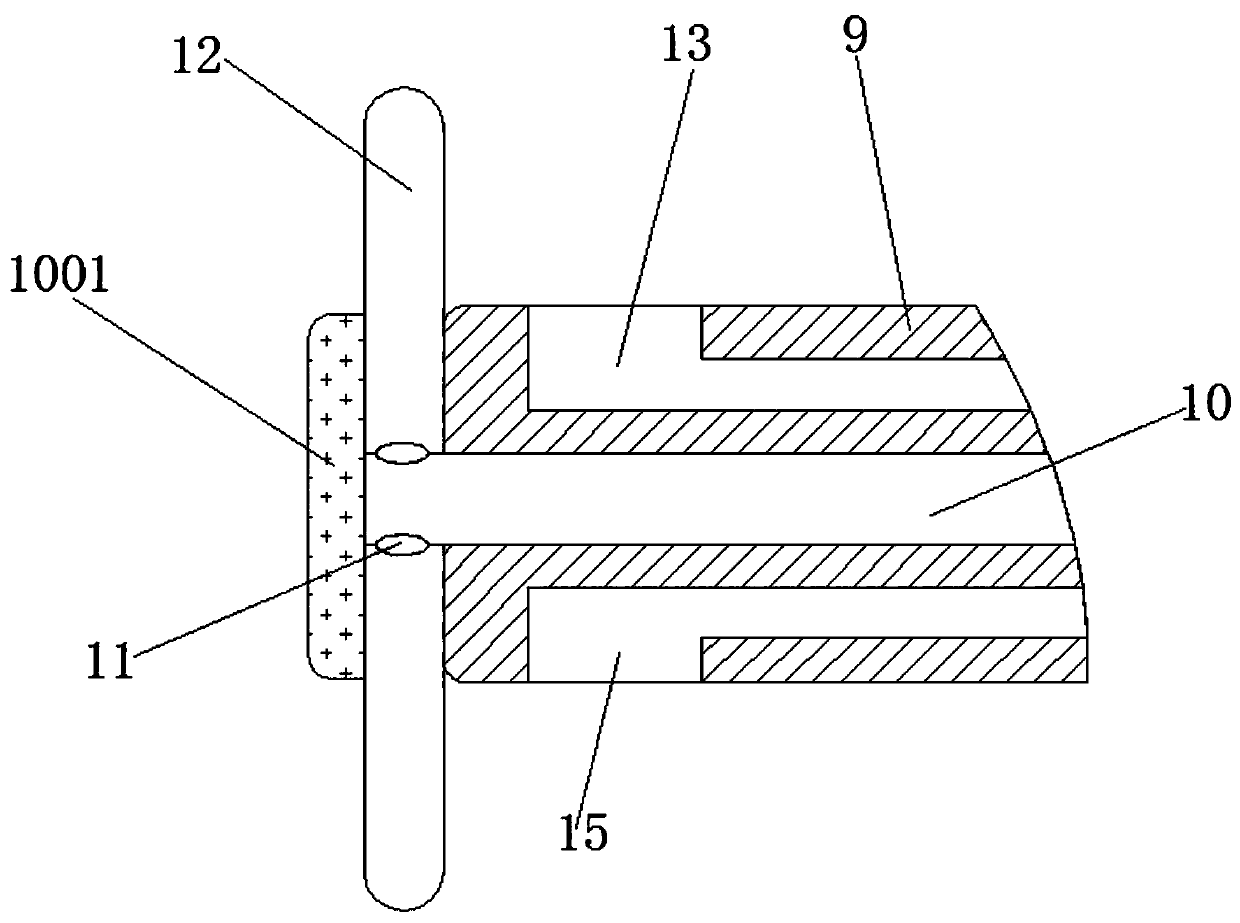

Ear canal cleaning device used for ear-nose-throat department

ActiveCN107411876AAchieve cleaningAchieve therapeutic effectEar treatmentOtoscopesOtolaryngology/ENTGas cylinder

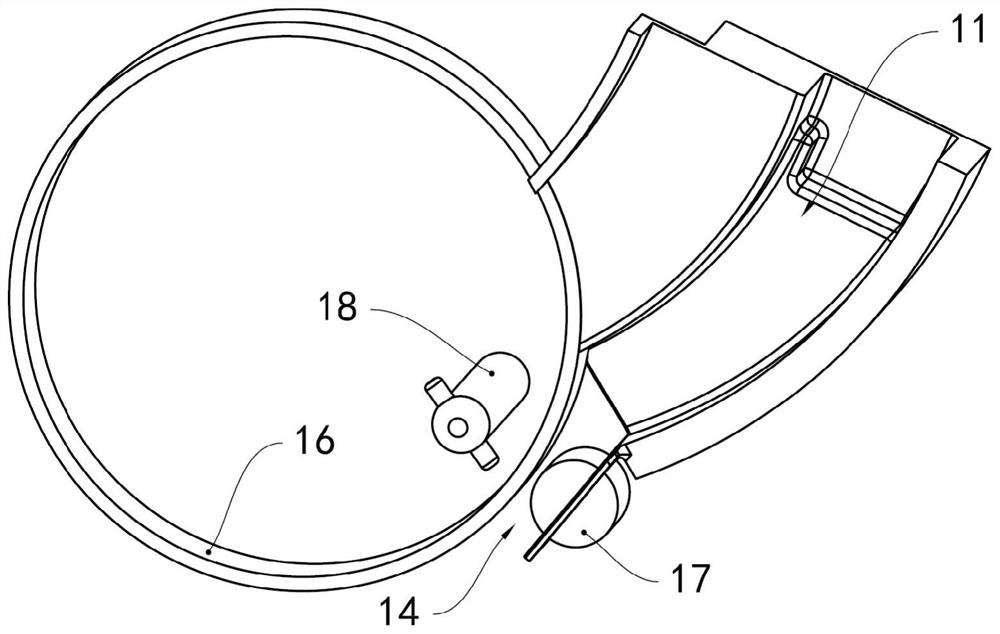

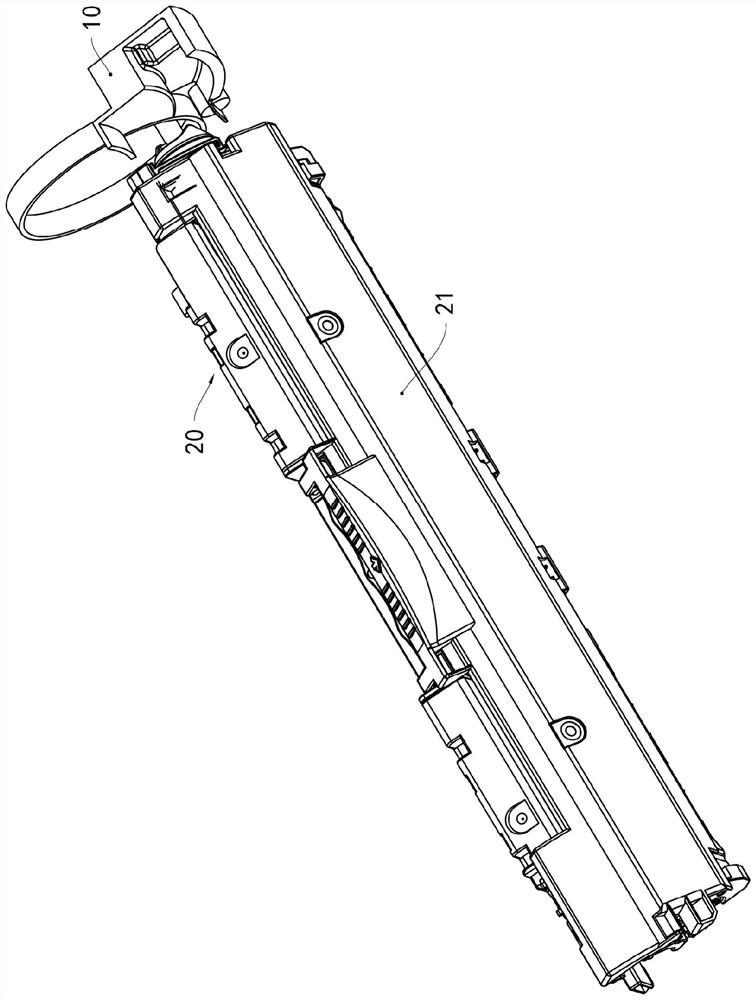

The invention discloses an ear canal cleaning device used for an ear-nose-throat department. The ear canal cleaning device used for the ear-nose-throat department comprises a handle, a fixing base, a gas cylinder, a gas injecting hole, a piston, a pushing rod, a fixing sleeve, a screw sleeve, a inserting barrel, an air injecting pipe, a leaking hole, an air cushion, a first flowing pipe, a first syringe, a second flowing pipe and a second syringe. The ear canal cleaning device used for the ear-nose-throat department is ingenious in structure and powerful in function; by using the device, firstly, ear wax foreign matters in an ear canal of a patient can be suck out of the ear canal, and secondly, according to the illness state of the patient, corresponding medicine liquid can be injected into the ear canal of the patient, and targeted treatment is conducted on the patient, and finally depth in the ear canal of the patient can be blocked through simple operation, and the medicine liquid and the ear wax foreign matters are effectively prevented from slipping into the depth of the ear canal of the patient in the operation process, so that cleaning for the ear canal of the patient is improved greatly, and operation of health care workers is facilitated.

Owner:杨晓蓉

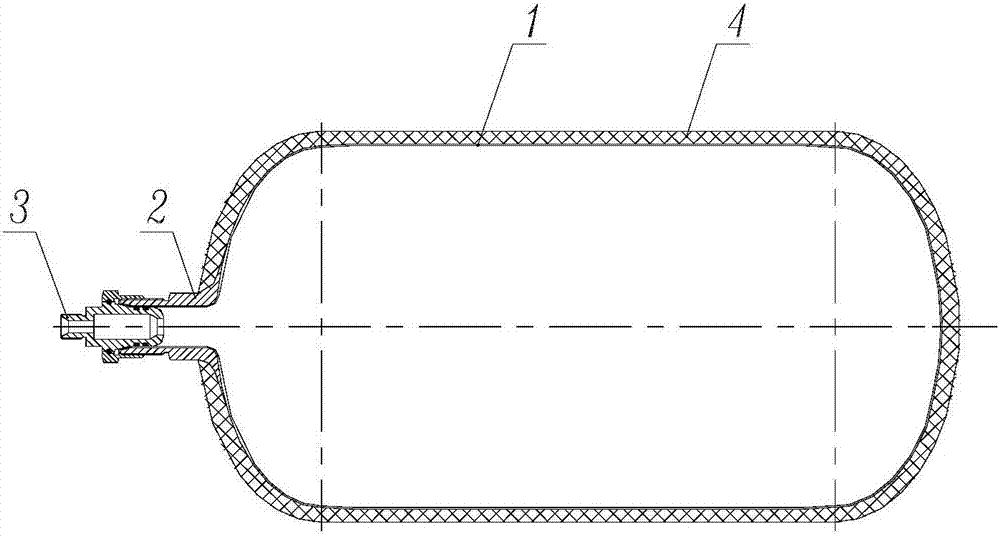

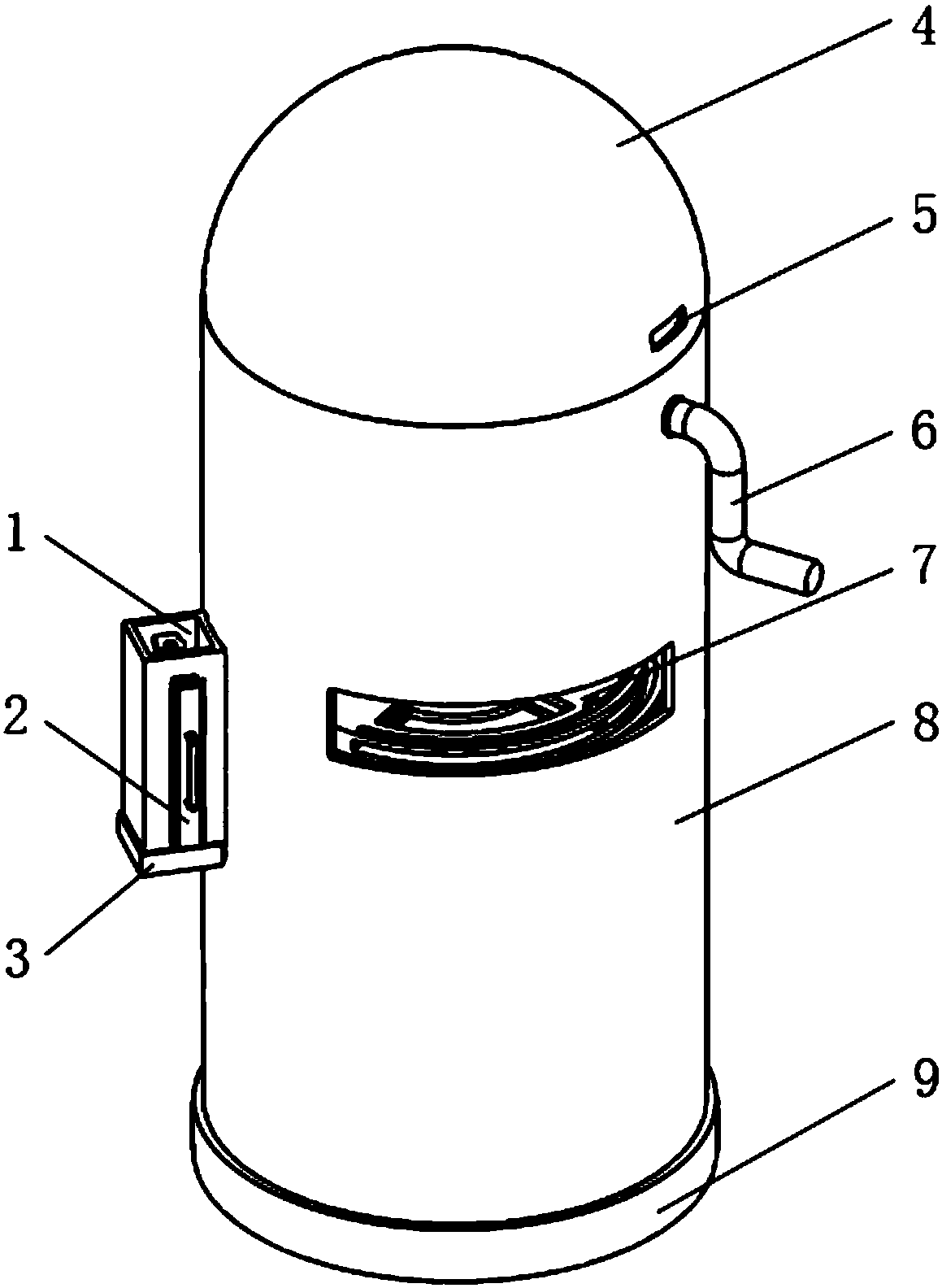

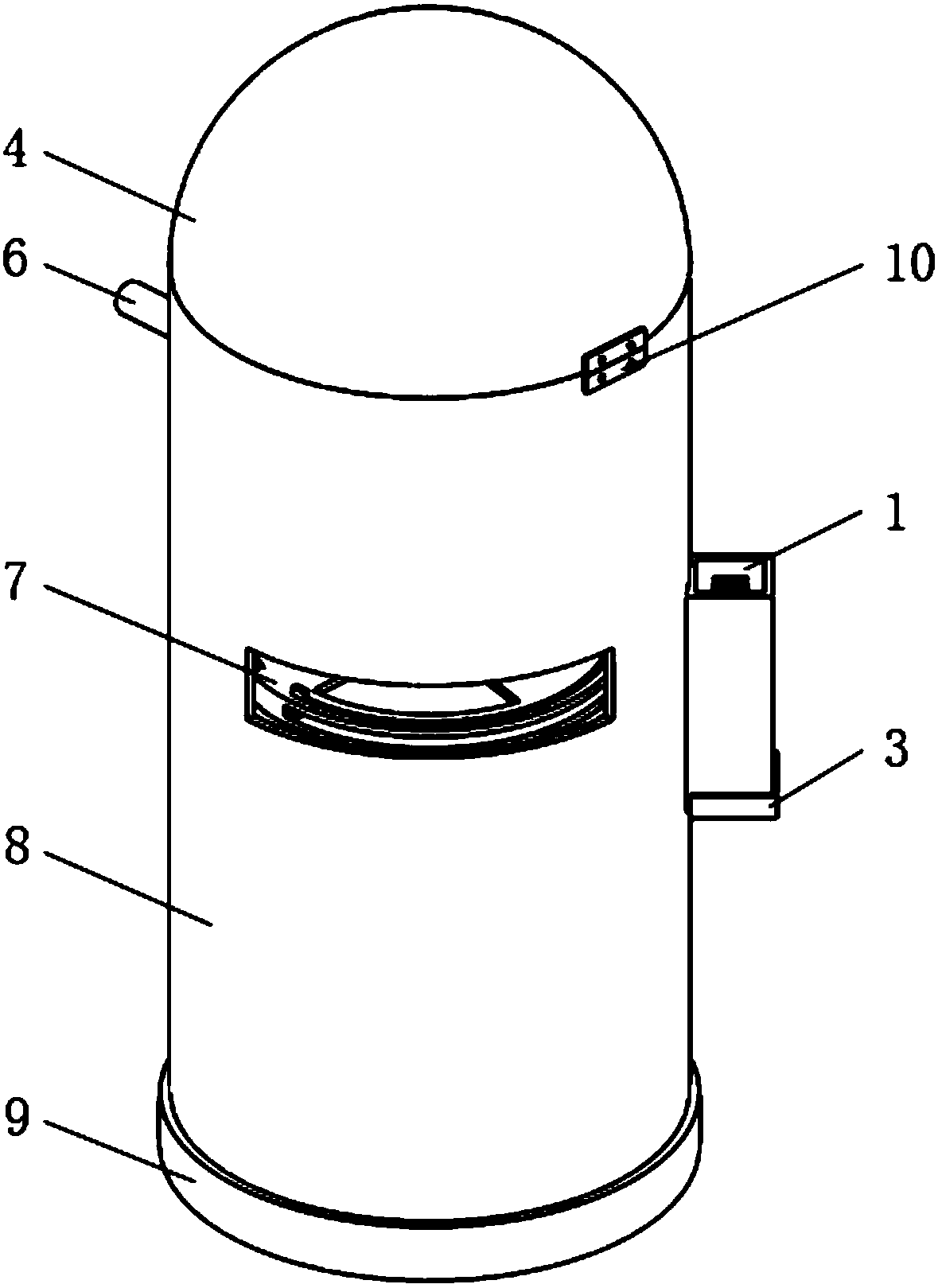

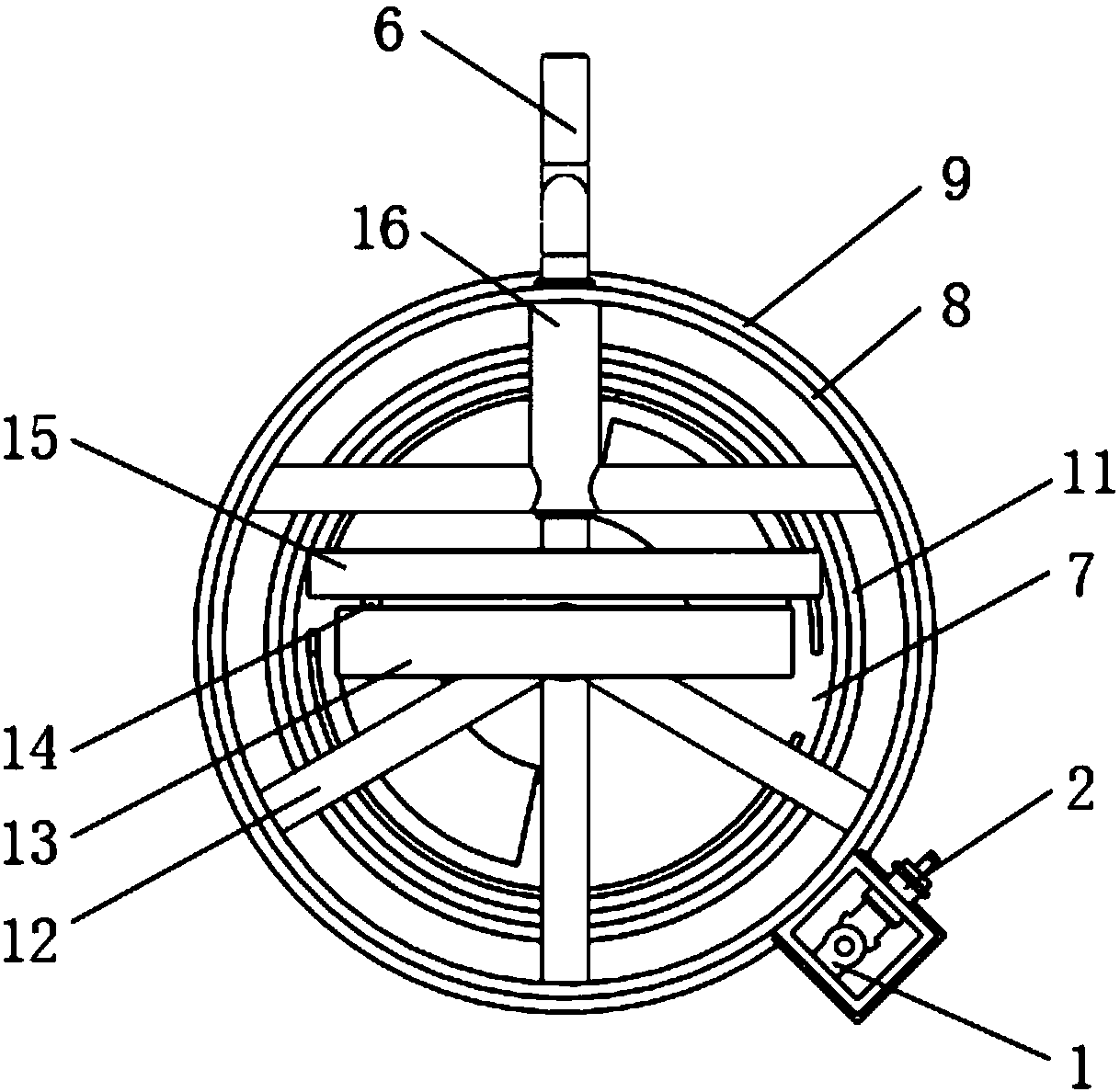

Low-weight long-service-life composite material hydrogen cylinder and manufacturing method thereof

ActiveCN106979455AImprove the safety of useWork lessVessel mounting detailsVessel manufacturingFiberCarbon fibers

The invention relates to the technical field of machines, in particular to a low-weight long-service-life composite material hydrogen cylinder. The hydrogen cylinder comprises a hydrogen cylinder body. The hydrogen cylinder body comprises a bottle main body. The bottle main body is made of carbon fibers. The inner wall of the bottle main body is provided with an inner container which is made of a nonmetal elastic material, and the inner container can be replaced repeatedly. According to the low-weight long-service-life composite material hydrogen cylinder, by optimizing a traditional hydrogen cylinder structure, the working fatigue frequency of the cylinder is effectively increased, and the service life of the cylinder is effectively prolonged; and meanwhile, the weight of the cylinder is lowered, production cost is low, and manufacturing cycle is short. Due to the fact that the inner container is made of the nonmetal elastic material, if the hydrogen cylinder is exploded, no metal scraps can be produced, and the using safety of the hydrogen cylinder is quite high.

Owner:上海瀚氢动力科技有限公司

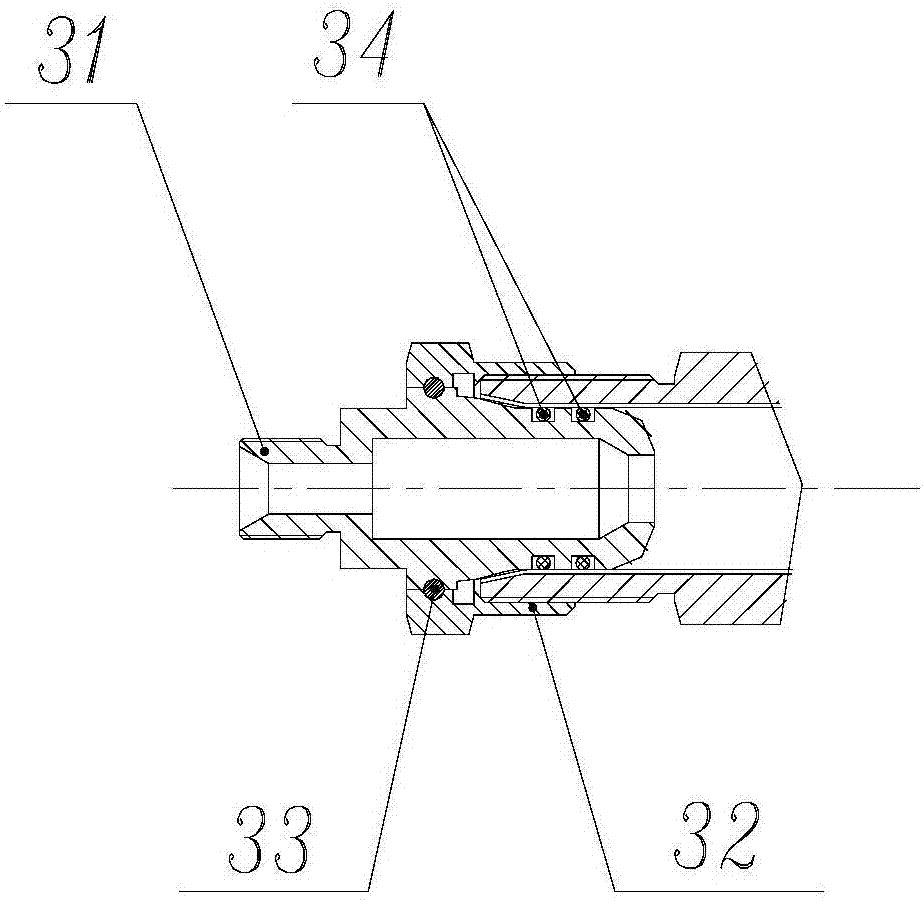

Hydraulic micro-rotation safety joint for downhole tubular column

PendingCN109138857AAchieve dropReduce the binding forceDrilling rodsDrilling casingsUpper jointSteel ball

The invention relates to a hydraulic micro-rotation safety joint for a downhole tubular column. The hydraulic micro-rotation safety joint comprises an upper joint and a lower joint, wherein central holes of the two joints share the same axis and are communicated mutually. A cylinder extending upwardly is arranged at the upper end of the lower joint. A sliding sleeve that can slide axially along the inner wall of the cylinder is installed in the inner cavity of the cylinder, wherein the central hole of the sliding sleeve is reduced gradually from top to bottom; a ball base in a horn shape is arranged at the lower end of the sliding sleeve; the ball base is provided with a matched steel ball for turning off the ball base; and the mouth of the lower end of the ball base is communicated with the central hole formed in the lower joint. The outer wall of the lower end of the sliding sleeve is fixed on the cylinder by a shearing pin. The e lower part of the upper joint is inserted into the cylinder and is embedded with the inner wall of the cylinder after rotation; and the lower end of the upper joint is plugged with the upper end of the sliding sleeve by a spline. An upper joint outer step is arranged at the middle part of the upper joint and is pressed on the upper port of the cylinder, wherein the diameter of the part under the upper joint outer step is reduced gradually. The innercavity of the cylinder is reduced gradually from top to bottom. The safety joint is operated conveniently and is protected from being affected by the friction of the tubular column and the well deviation; and the disconnection success rate is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

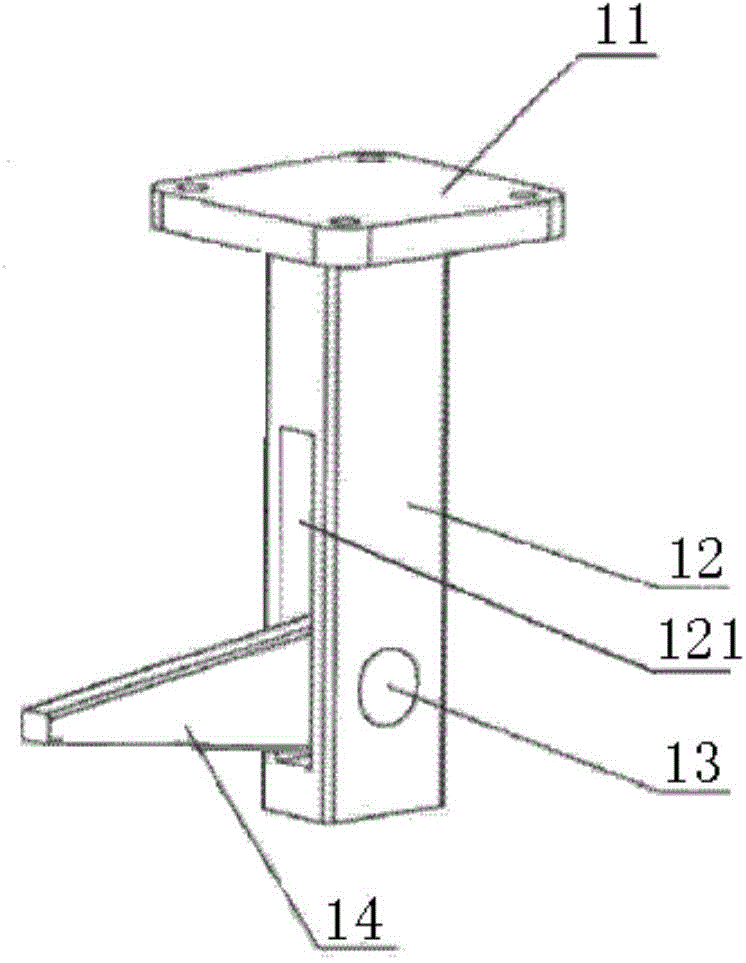

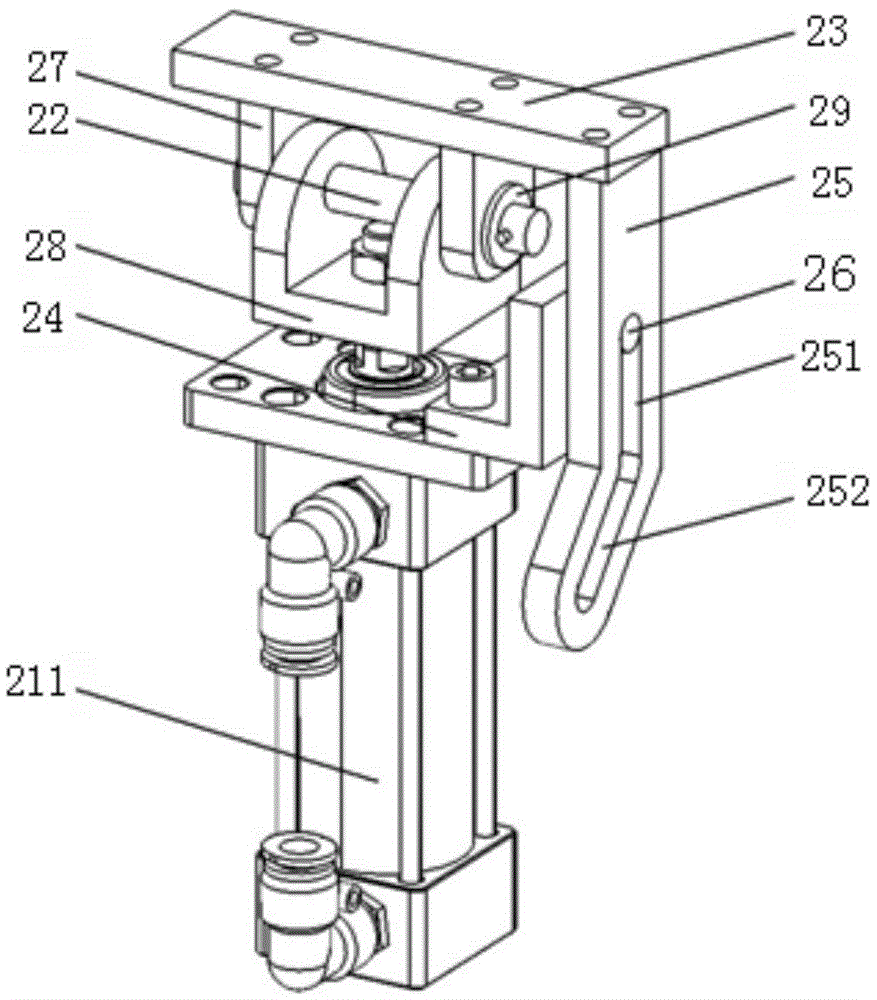

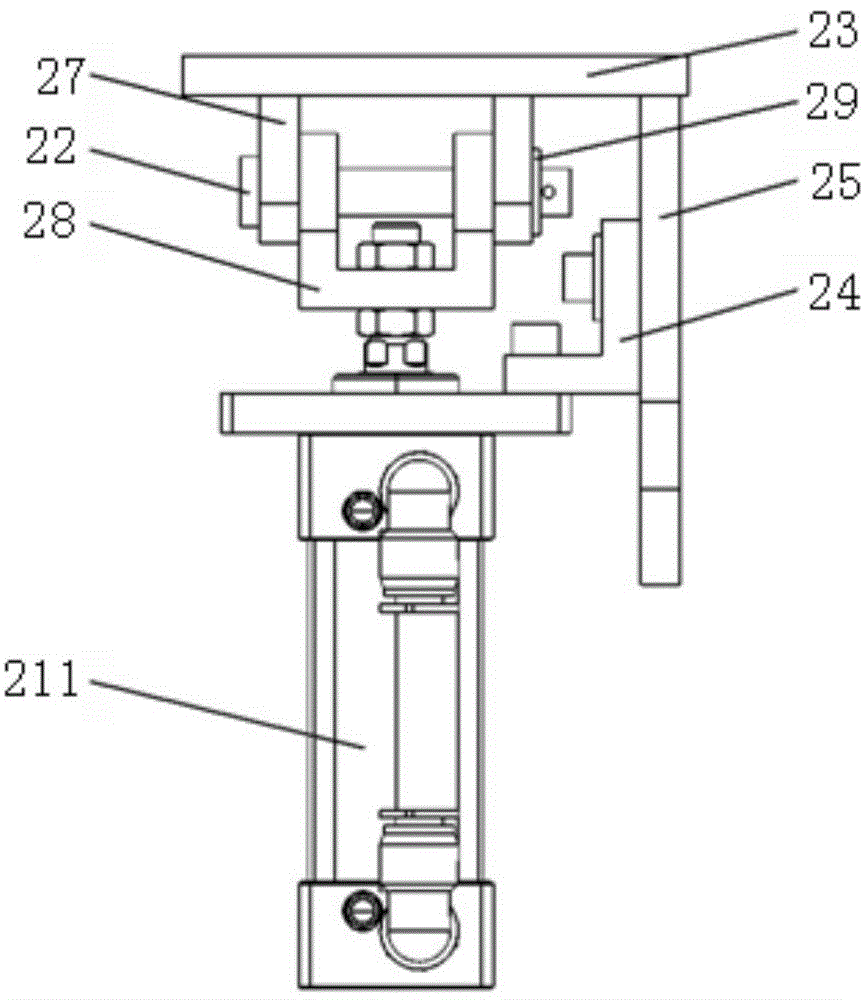

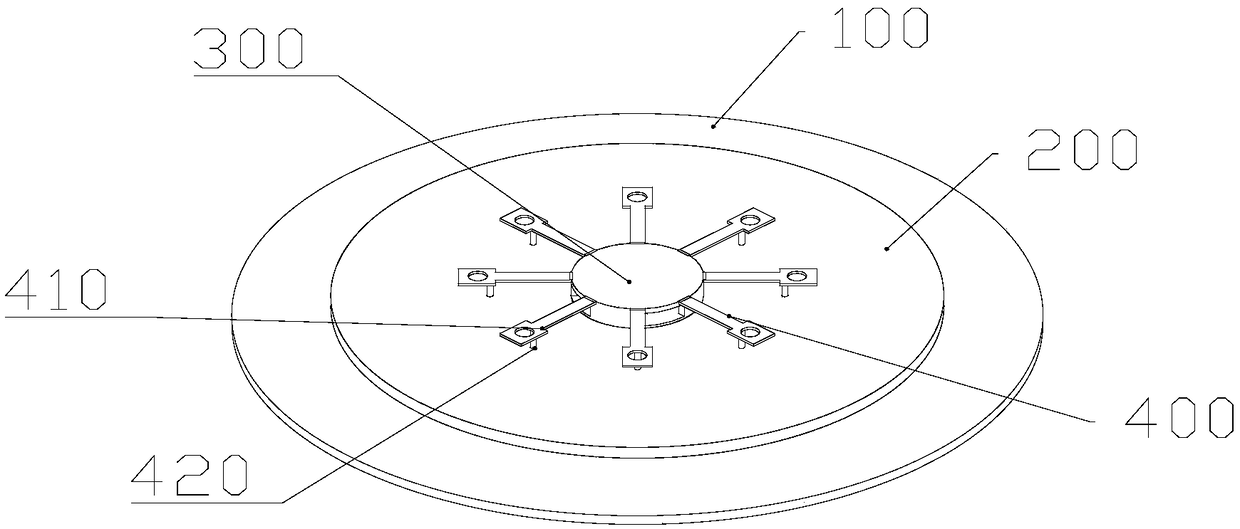

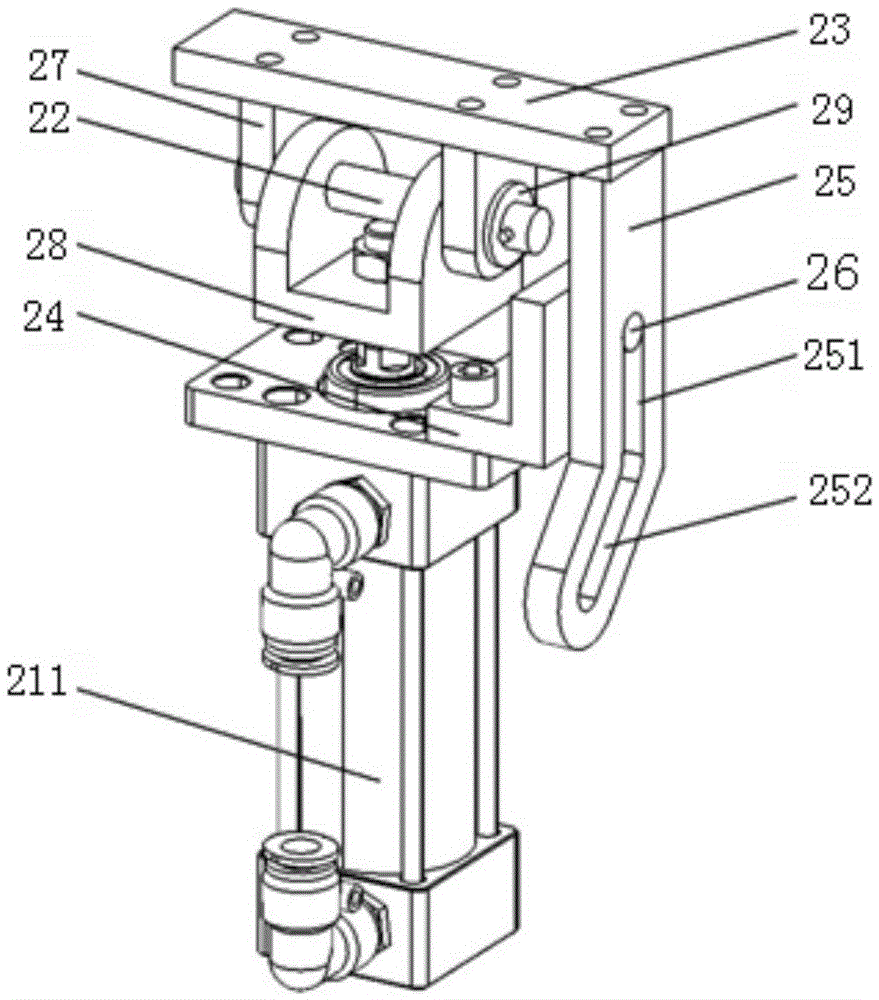

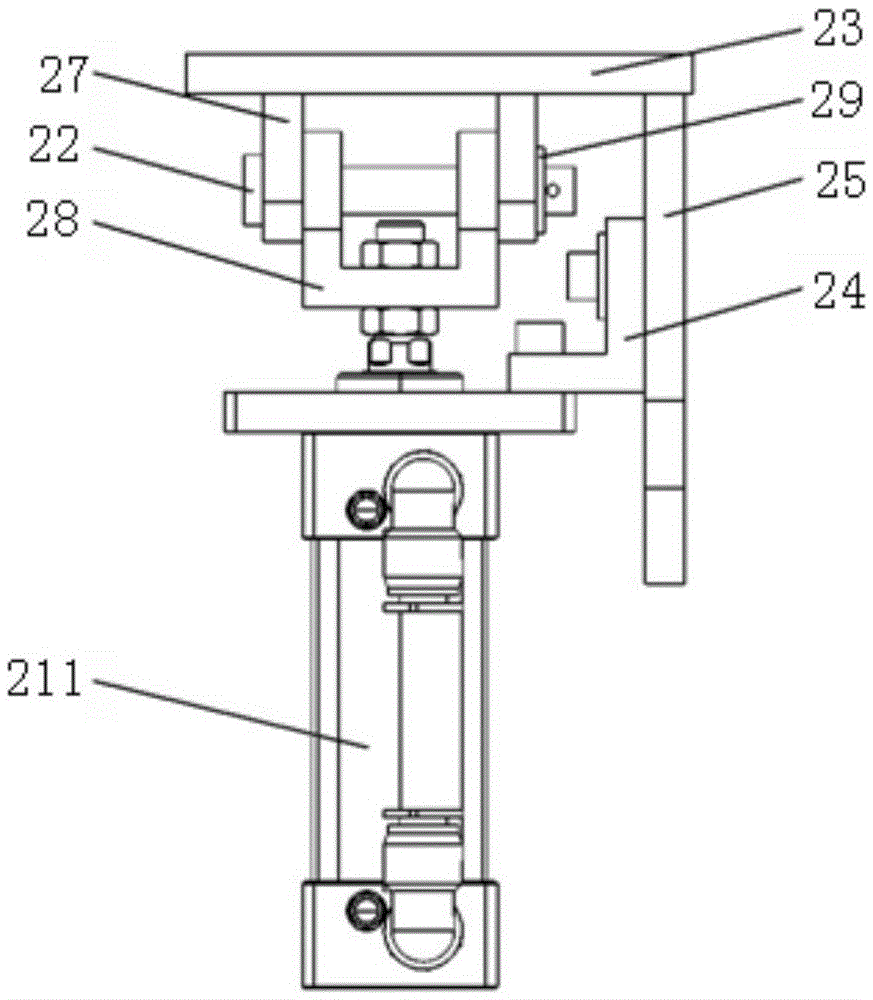

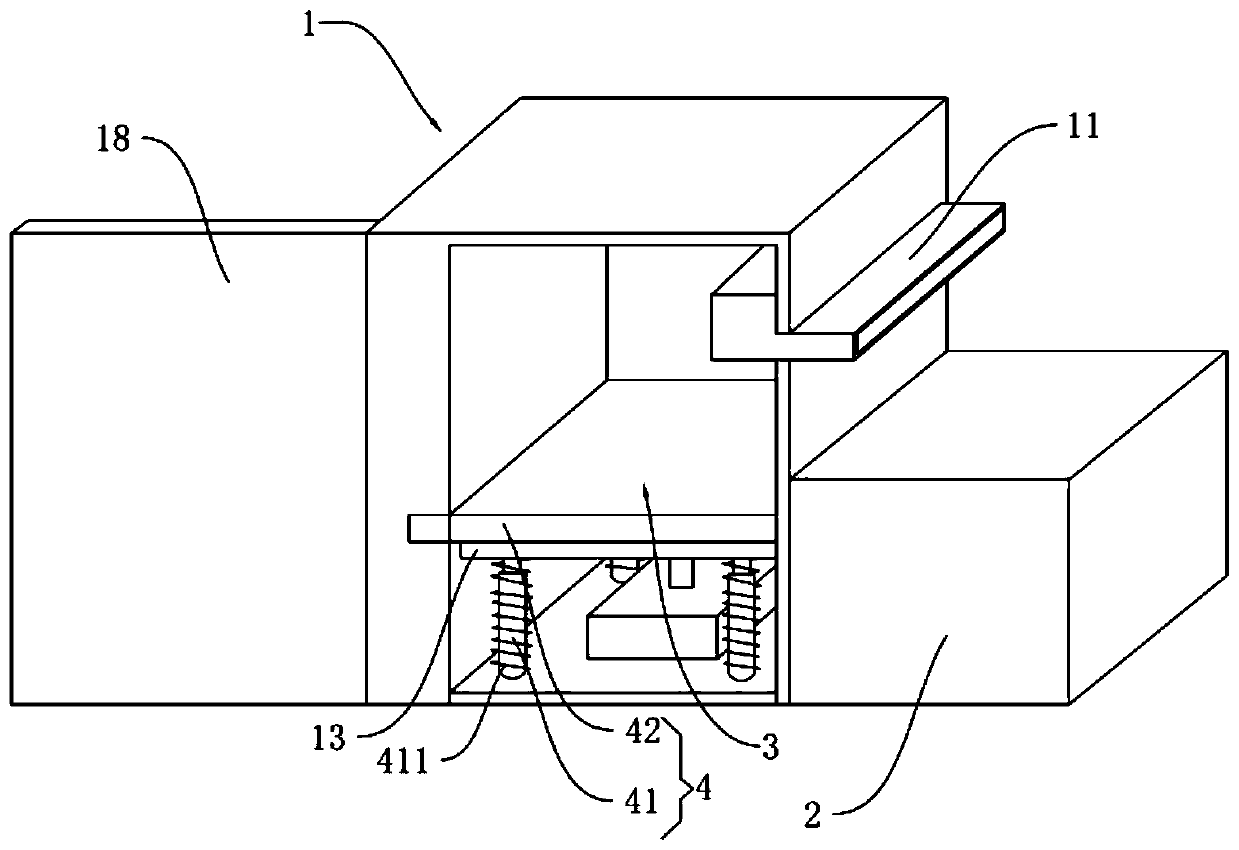

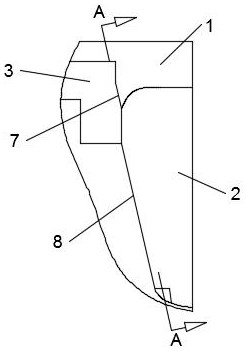

Stamping mold and waste ejection mechanism thereof

The invention discloses a stamping mold and a waste ejection mechanism thereof. The waste ejection mechanism comprises a cylinder of which a fixed end is arranged on a lower die holder, wherein a telescopic end of the cylinder is provided with an ejection plate through a rotating shaft in a rotating manner; the rotating shaft is arranged perpendicular to the axial direction of the cylinder; when the cylinder is at an extension limit position, the ejection plate rotates around the rotating shaft to a state back on to a mold body; one end of the ejection plate is provided with a guide plate which is provided with a guide groove; the fixed end is provided with a guide block which is in slide guide fit with the guide groove; the plane where the guide stroke of the guide groove is positioned is parallel to the axial direction of the cylinder and perpendicular to the axial direction of the rotating shaft; the guide groove comprises an upper guide groove and a lower guide groove which is communicated with the upper guide groove; the slide guide direction of the upper guide groove is parallel to the axial direction of the cylinder; the lower guide groove and the upper guide groove are at a preset angle; the lower guide groove gets away from the mold body gradually in the extension direction away from the upper guide groove. Thus, ejection stroke and discharge direction of waste can be excellently controlled through the arrangement of the guide structure.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

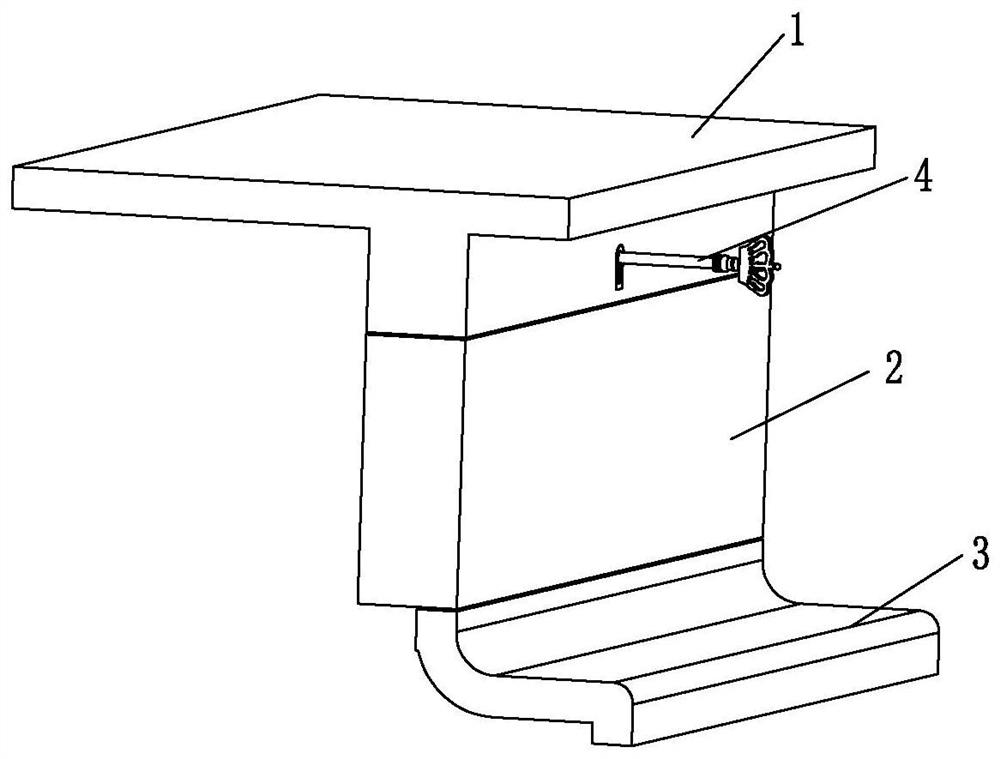

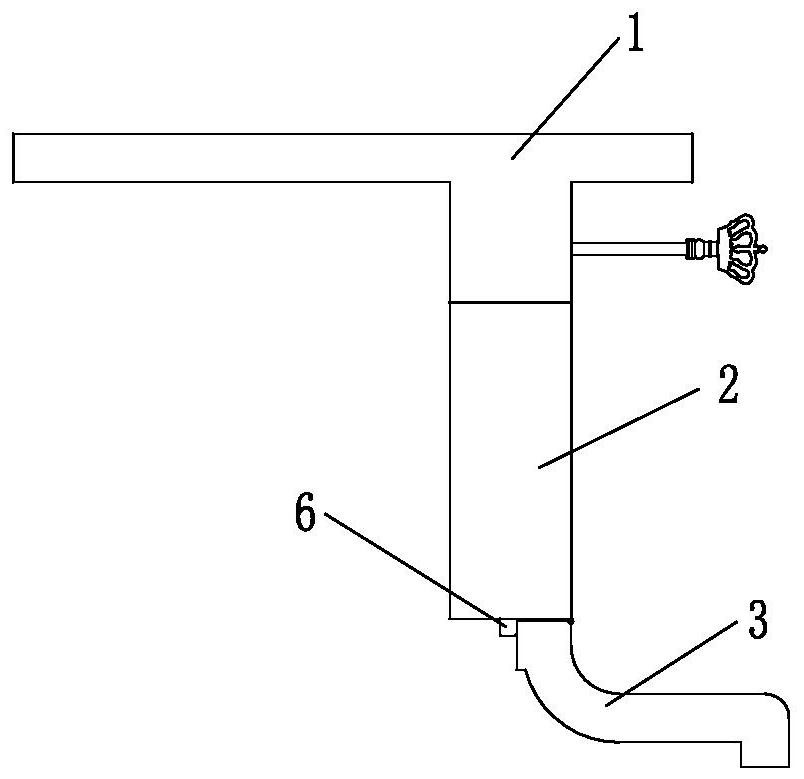

Dining table convenient to clean

The invention relates to dining tables, in particular to a dining table convenient to clean. The dining table comprises a table plate, a rotary plate pivoted to the upper end surface of the table plate, a cleaning mechanism and auxiliary placement racks, wherein the cleaning mechanism comprises a cleaning casing, a base, a bowl and dish conveying channel, a waste conveying channel and a bowl and dish storage barrel, the cleaning casing is fixed in the middle of the upper end surface of the rotary plate, an inlet allowing entering of bowls and dishes is formed in the side wall of the cleaning casing, a cleaning brush and a push rod are fixed on the cleaning casing, the rotary plate is provided with a through hole formed in the cleaning casing, the base is located in the through hole and fixed on the table plate, a waste port is formed in the middle of the base and communicated with the waste conveying channel, and a bowl and dish outlet is formed in the outer side of the base and communicated with the bowl and dish conveying channel. The dining table capable of facilitating fast dish removal is provided to solve the problem that the dish removal rate is too low for the conventionaldining table.

Owner:重庆展成家俱制造有限公司

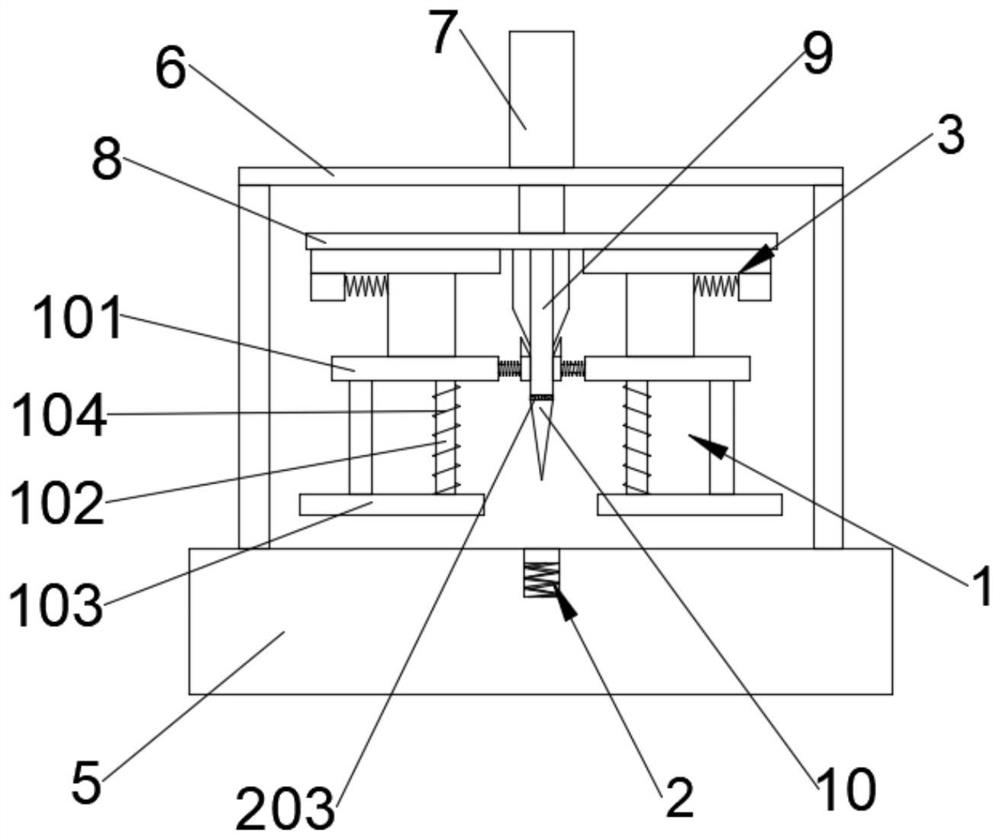

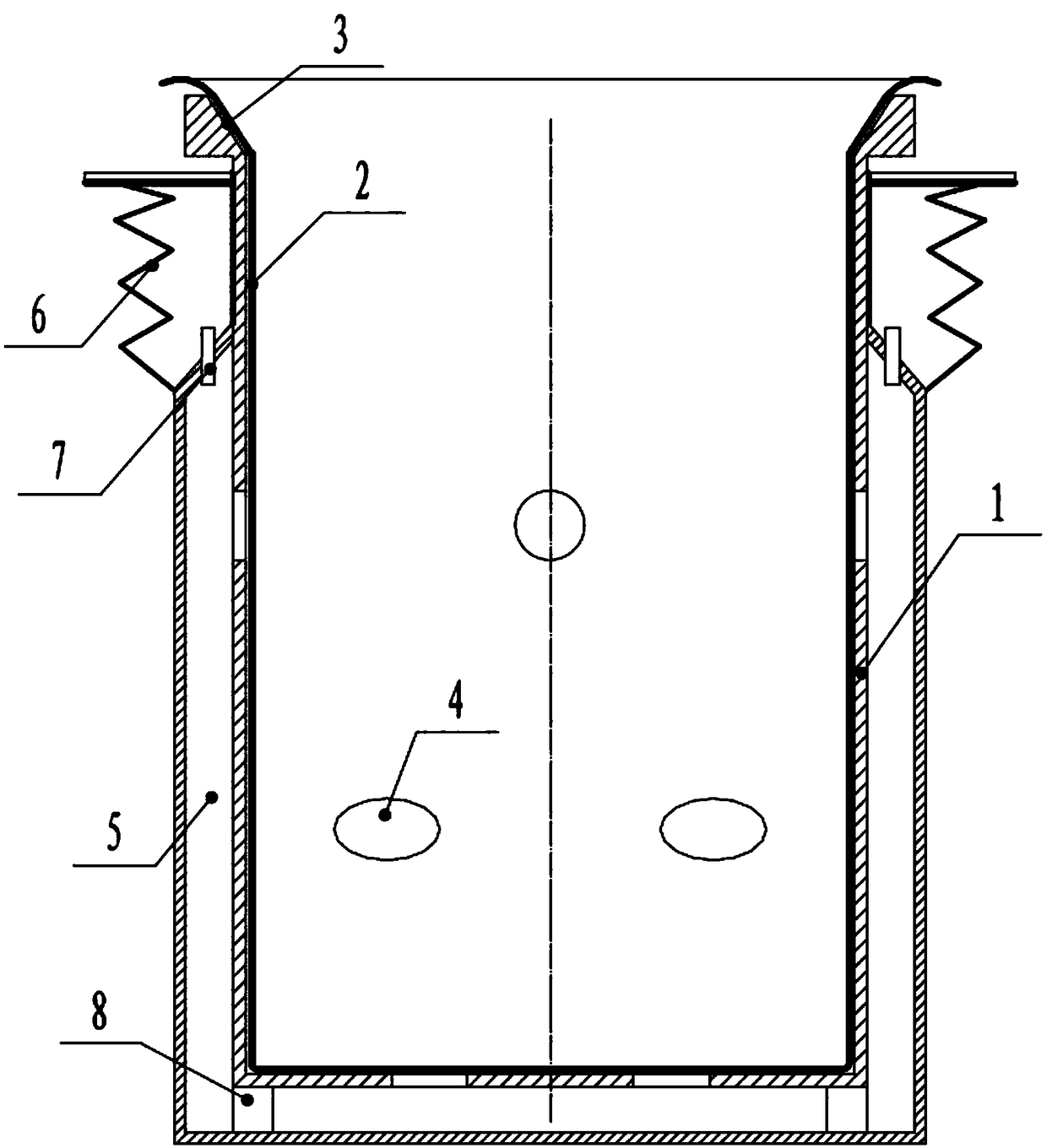

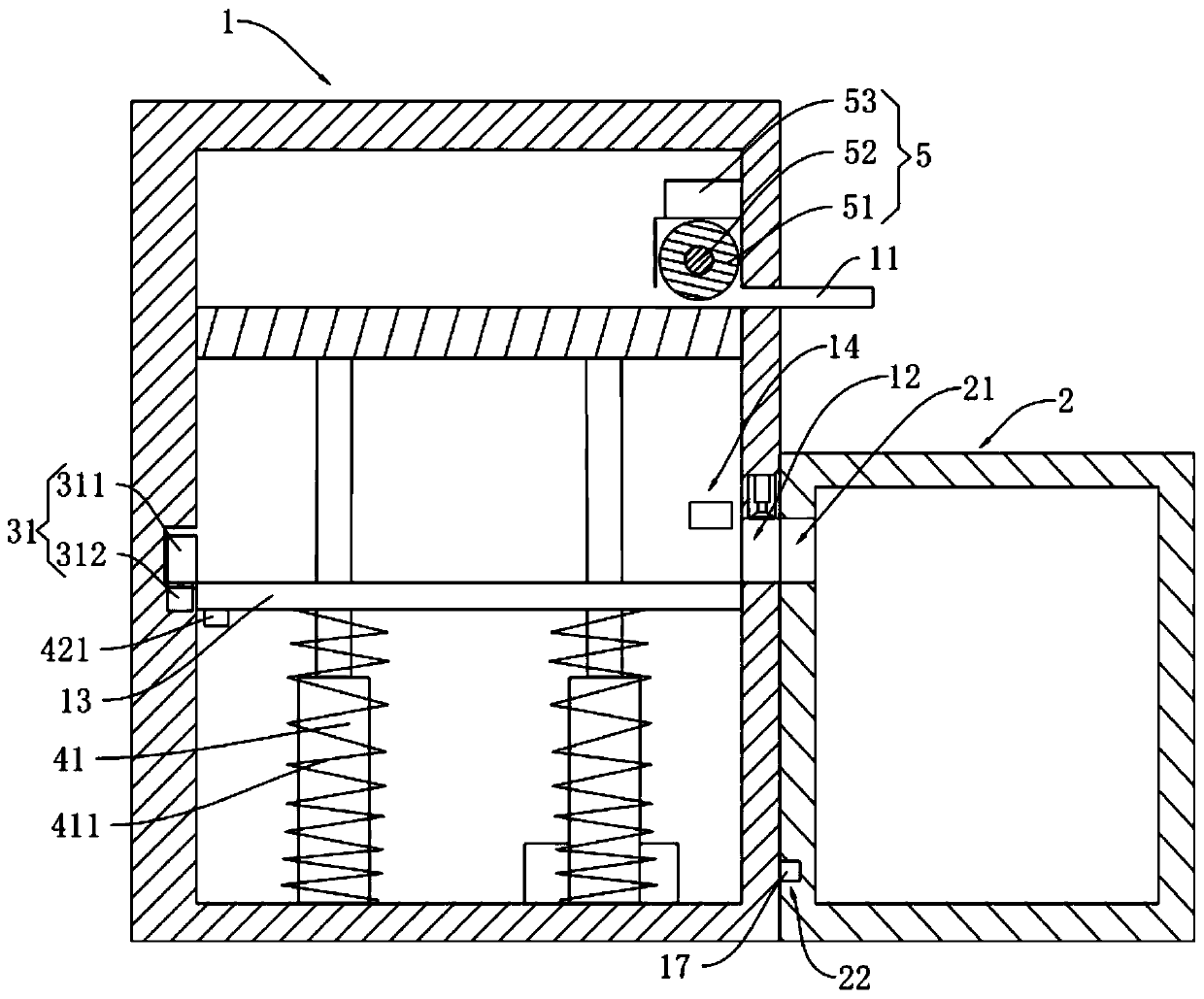

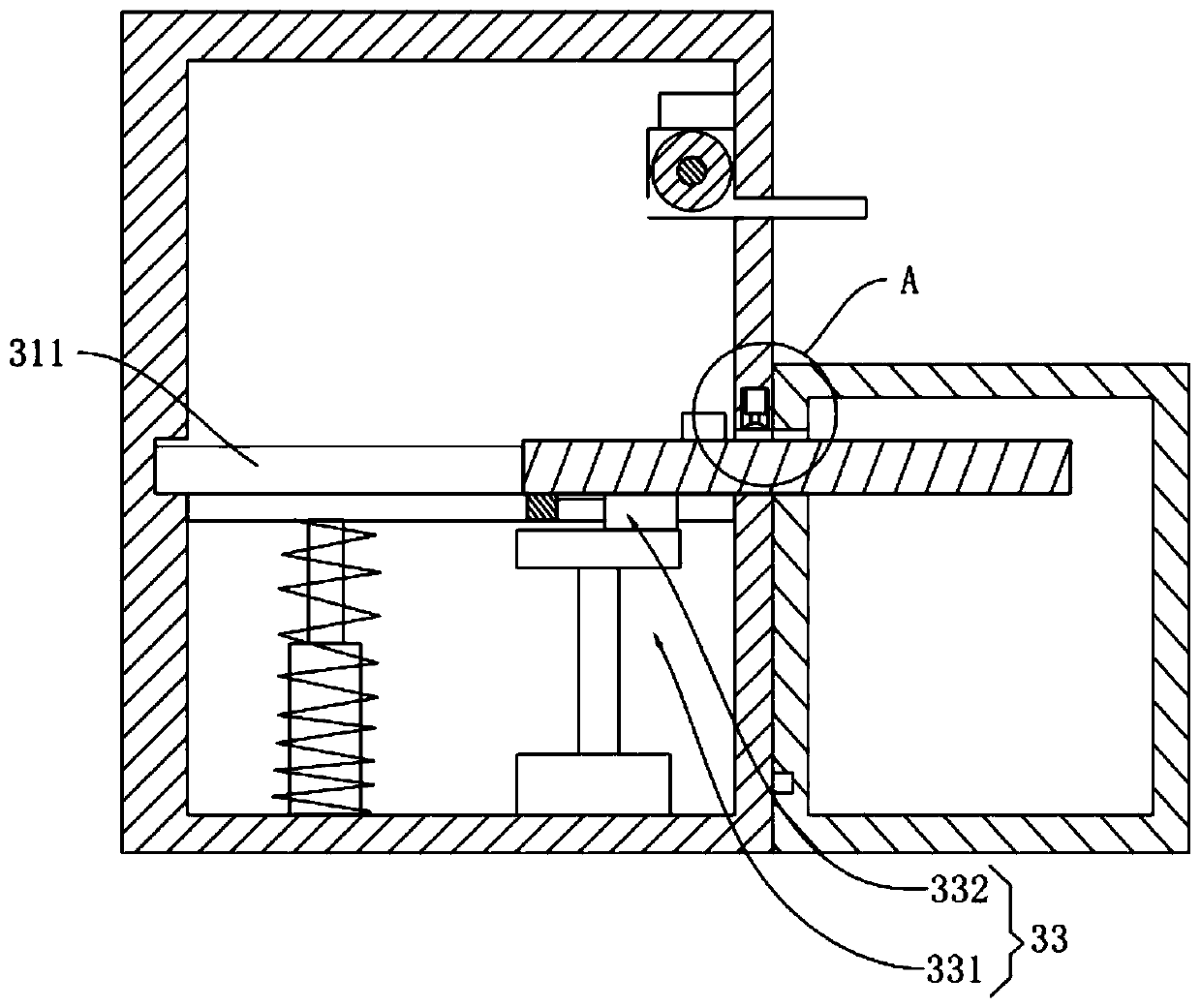

Hog house cement dropping board demolding device

ActiveCN111660418ASave energyNot easy to get hurtDischarging arrangementAnimal housingElectric machineryStructural engineering

The invention relates to a demolding device, in particular to a hog house cement dropping board demolding device. The hog house cement dropping board demolding device is provided and is time-saving and labor-saving, and is not prone to causing injury. According to the technical scheme, the hog house cement dropping board demolding device comprises a base, baffles and a mounting frame, wherein a placing mechanism is arranged on one side of the base, the baffles are arranged on two sides of the top of the base, the mounting frame is arranged at the top of the base and close to the positions of the baffles, and a rotating mechanism is connected between left sides and right sides of the tops of the mounting frame and the base. A motor, a first rotating shaft, a bearing seat, a rotating block and the like are arranged to cooperate with one another, so that a bearing plate is rotated, penetrates through a rectangular groove, makes contact with a hog house cement dropping board and drives thehog house cement dropping board to rotate clockwise to be turned, turning is achieved without manual work, physical strength can be saved, and people are not prone to being injured in the process ofturning and demolding of the hog house cement dropping board.

Owner:义乌市巨界机械设备有限公司

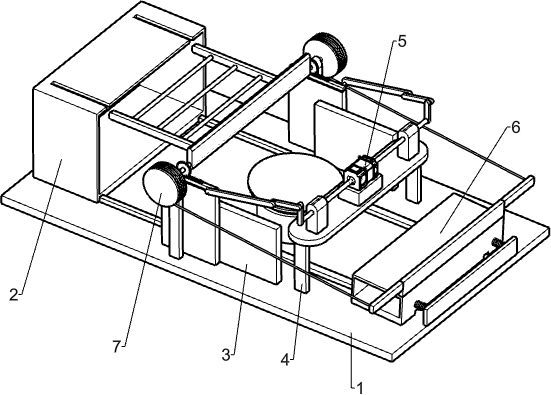

Pressing and cutting integrated melt-blown cloth splitting machine

InactiveCN113059600AEasy to fixGuaranteed accuracySevering textilesMetal working apparatusStructural engineeringKnife holder

The embodiment of the invention discloses a pressing and cutting integrated melt-blown cloth splitting machine, which comprises a base and a fixed plate arranged on the base in parallel; the fixed plate is fixed to the base through a support; a driving air cylinder is arranged on the fixed plate; an output end of the driving air cylinder vertically penetrates through the fixed plate downwards and is connected with a driving plate; a cutter frame is arranged in the center of the bottom end of the driving plate; a cutter is vertically connected to the bottom of the cutter frame; pressing components are arranged at the two ends of the driving plate respectively; the pressing components on the two sides are symmetrically arranged on the two sides of the cutter; each pressing component comprises a pressing base plate horizontally connected with the driving plate; a pressing rod vertically penetrates through the pressing base plate; the lower end of the pressing rod is connected with a horizontal pressing plate; a pressing buffer spring is arranged between the driving plate and the pressing plate; and the pressing buffer spring is sleeved on the outside of the pressing rod. The splitting accuracy of melt-blown cloth can be well guaranteed, and the finished product quality of the melt-blown cloth is improved.

Owner:安徽伟源兴盛实业有限公司

Novel garbage can

The invention discloses a novel garbage can. The novel garbage can comprises a barrel body with an opening at the upper end and a garbage bag, wherein the garbage bag is detachably arranged in the garbage can, two-sided adhesives for sealing connection are arranged on the outer side of the sealing opening of the garbage bag, through holes are formed in the periphery and the bottom of the barrel body, gas collecting cavities are formed outside the through holes, the air collecting cavities are connected with sealing telescopic cavity sleeves through pipelines, and the sealing telescopic cavitysleeves sleeve outside the upper end of the barrel body. According to the novel garbage can, the two-sided adhesives are arranged on the outer sides of the sealing part of the garbage bag, so that thegarbage bag can be fixed in the garbage can, and the bag opening of the garbage bag is prevented from slipping into the garbage can caused by wind blowing, and the thrown garbage can completely fallinto the garbage can, so that the cleaning is convenient and fast, the garbage can be prevented from being cleaned, and time and labor are saved; after the sealing telescopic cavities sleeves are usedfor stretching, negative pressure is generated in the air collecting cavities, so that the garbage bag can be tightly attached to the inner wall of the garbage can, the garbage capacity is greatly improved, the waste capacity of the garbage bag caused by the deformation of the garbage bag can be effectively avoided, and the operation is convenient and rapid; and the novel garbage can also has thecharacteristics of being simple in structure and low in cost.

Owner:GUIZHOU UNIV

Ward garbage can with compression function

InactiveCN108438622AEasy to moveIncreased landing stabilityRefuse receptaclesInterference fitEngineering

The invention relates to a garbage can, in particular to the ward garbage can with a compression function, and belongs to the technical field of environmental protection devices. The ward garbage cancomprises a fixing seat, a pressing head, a tray, a bending shaft, a lower pressing plate, an outer can, a supporting seat, an inner can, a first supporting frame, a horizontal sliding way, a connecting shaft, a rotating disc, a second supporting frame, a pressing rod, a square sliding block and the like; and the pressing head is inserted into the fixing seat, the tray is buckled at the lower endof the fixing seat, the lower end of the outer can is inserted into the supporting seat, the bending shaft penetrates through the outer can and the second supporting frame to be fixedly connected withthe rotating disc, one end of the connecting shaft is fixedly connected with the rotating disc, the other end of the connecting shaft is connected with the square sliding block in a rotatable mode, the upper end of the pressing rod is fixedly connected with the horizontal sliding way, the lower end of the pressing rod penetrates through the first supporting frame to be fixedly connected with theupper end surface of the lower pressing plate, and the lower end of the inner can is inserted into the supporting seat and is in interference fit with the supporting seat. The ward garbage can has thebeneficial effects that the basic requirements of collecting garbage can be met, and moreover, the ward garbage can also has the functions of being convenient to move and capable of compressing the garbage and bending toothpicks.

Owner:李如意

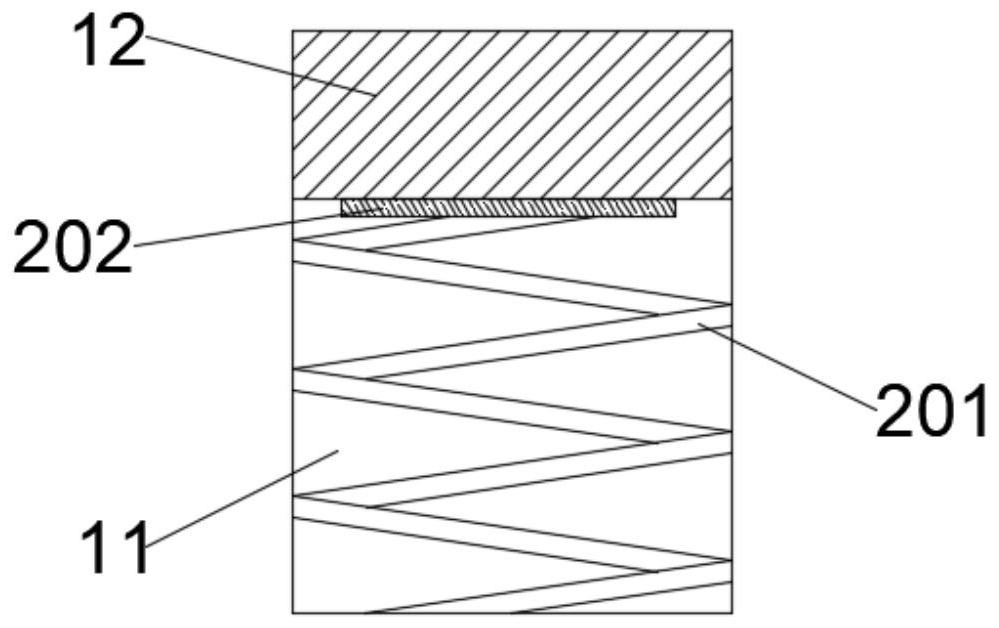

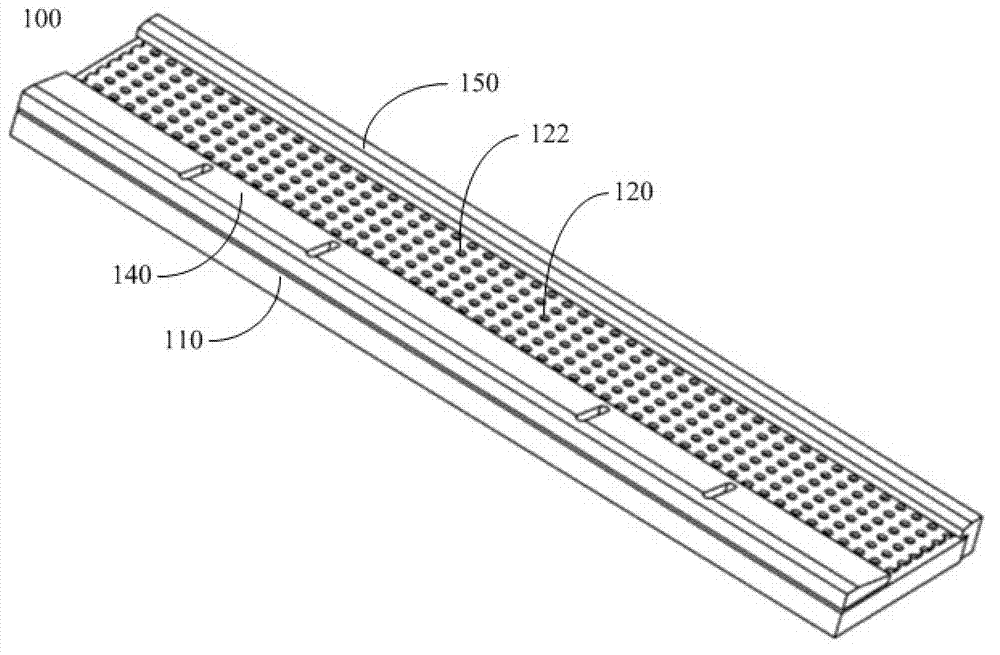

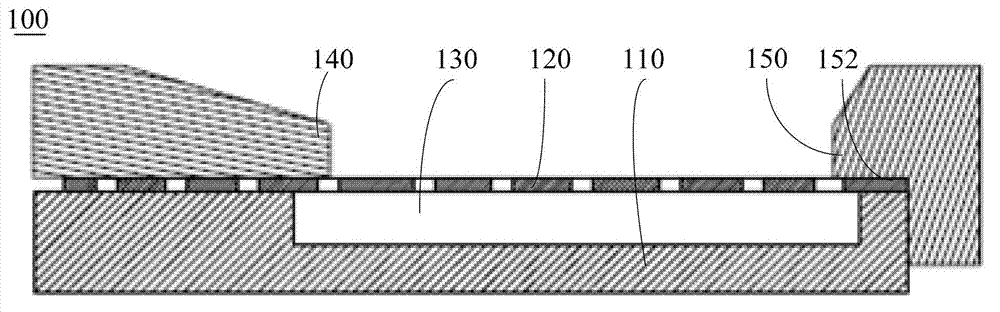

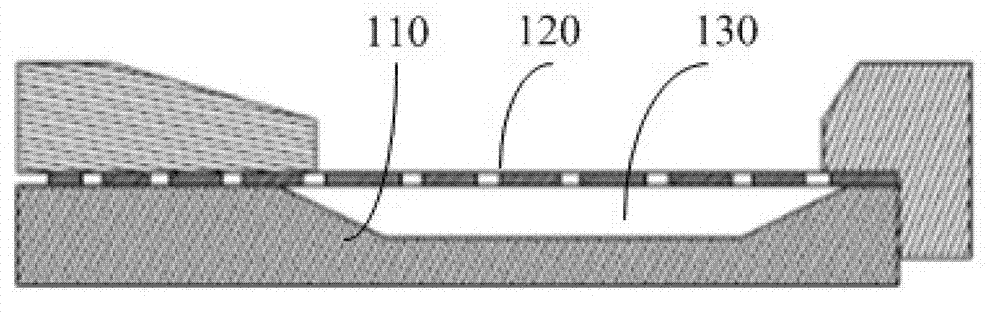

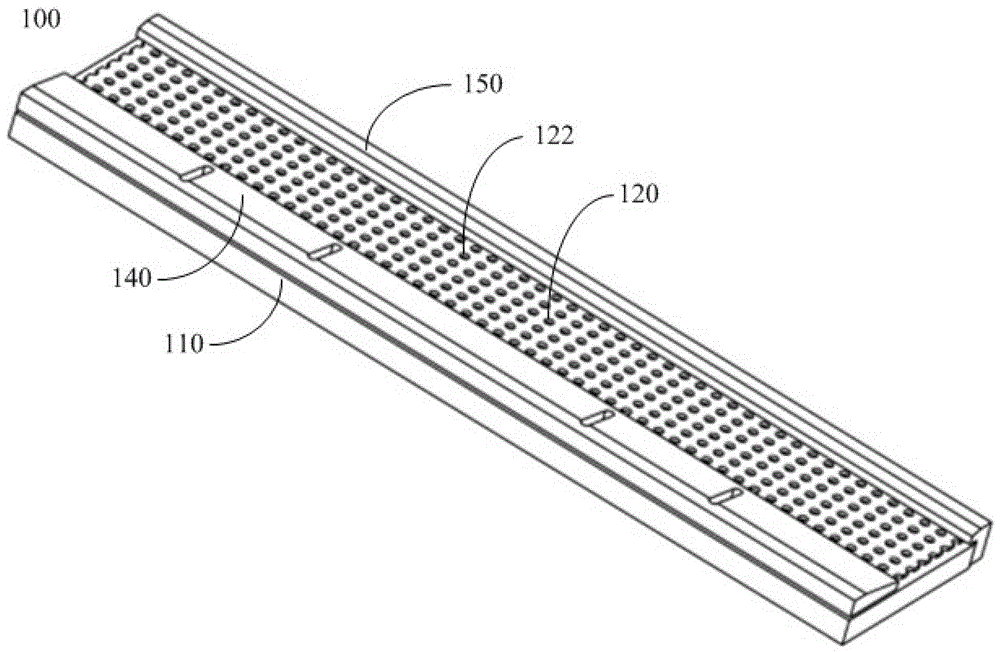

Semi-automatic winding machine dedusting guide rail

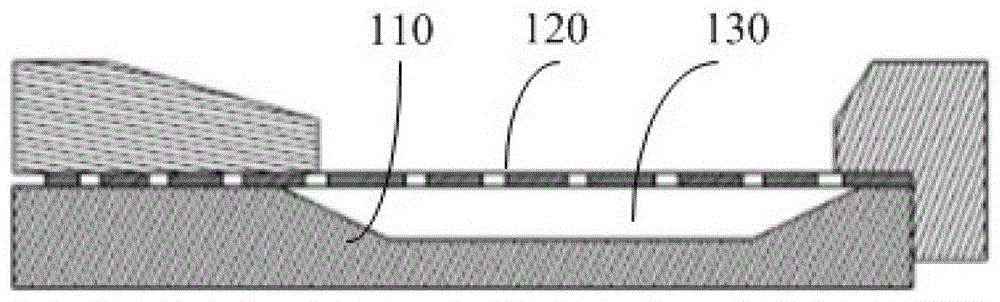

InactiveCN103928710AGuaranteed Chance of ClearingAvoid sliding inAssembling battery machinesFinal product manufactureWinding machineSemi automatic

The invention relates to a semi-automatic winding machine dedusting guide rail, which comprises a bottom plate and a mesh plate. The mesh plate is mounted on the bottom plate, and is evenly provided with a plurality of meshes. The bottom plate is provided with a material storage groove, the opening of which is over against the mesh plate, and the material storage groove is used for collecting dust particles. The mesh plate is mounted on the bottom plate, and when an anode flake and a cathode flake are transferred by the dedusting guide rail, dust on the anode flake and the cathode flake and chips or metal particles and other particles generated in the production process can be separated through mutual friction with the mesh plate, enter the meshes through the gravity of the particles themselves, and fall into the material storage groove over against the mesh plate along the meshes, so that dust and other particles can be effectively prevented from sliding into a winding mechanism along the guide rail. Thus, the battery assembly defective rate is reduced, and also battery short circuit, over heat or explosion and other hazards are effectively reduced.

Owner:深圳市朗能电池有限公司

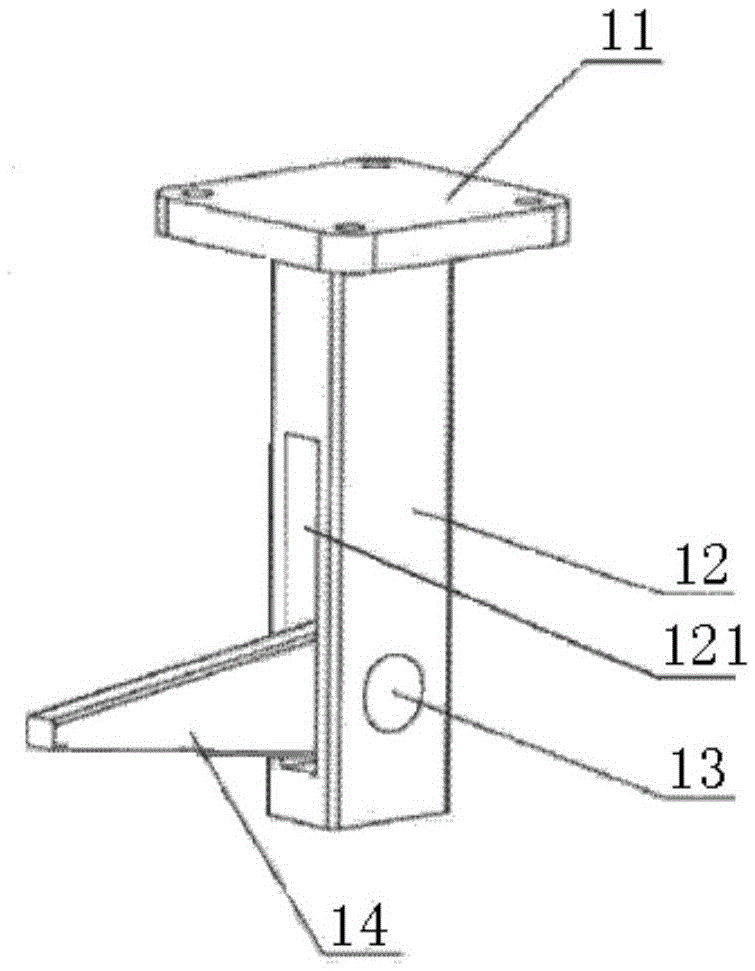

Rotary mounting seat, fixing structure of auxiliary instrument board and automobile

ActiveCN113511268AAvoid sliding inSlip preventionSuperstructure subunitsStructural engineeringMechanical engineering

The invention discloses a rotary mounting seat, a fixing structure of an auxiliary instrument board and an automobile, the rotary mounting seat is used for being fixed on a mounting bracket, the rotary mounting seat comprises a mounting part, a rotating part and a first limiting structure, the mounting part is provided with a first end and a second end which are oppositely arranged, and the first end is used for mounting a screw; the rotating part is arranged at the second end; the first limiting structure is arranged on the peripheral side of the rotating part, and the first limiting structure is used for being located on the side, back to the mounting part, of the mounting hole after the rotating part is inserted into the mounting hole of the mounting bracket in a posture, and after the mounting part rotates in the first hour hand direction, the first limiting structure is in abutting fit with the hole edge of the side, back to the mounting part, of the hole wall of the mounting hole. According to the arrangement, the rotary mounting seat is simple in fixing mode and firm in fixation.

Owner:DONGFENG LIUZHOU MOTOR

Dust removal guide rail for semi-automatic winding machine

InactiveCN103928710BGuaranteed Chance of ClearingAvoid sliding inAssembling battery machinesFinal product manufactureWinding machineTreatment fever

A dust removal guide rail for a semi-automatic winding machine, comprising a bottom plate and a mesh plate, the mesh plate is installed on the bottom plate, a plurality of mesh holes are evenly opened on the mesh plate, and a storage space is opened on the bottom plate A hopper, the opening of the hopper is facing the mesh plate, and the hopper is used for collecting dust particles. By installing a mesh plate on the bottom plate, when the positive electrode sheet and the negative electrode sheet are conveyed through the dust removal guide rail, the dust on the positive electrode sheet and the negative electrode sheet, as well as debris or metal particles in the production process, pass through the interaction between the mesh plate and the negative electrode sheet. Friction and separation, the particles enter the mesh through their own gravity, and fall into the storage tank facing the mesh plate along the mesh, effectively preventing dust and other particles from sliding into the winding mechanism along the guide rail. Thereby reducing the bad rate of battery assembly, and effectively reducing the risk of battery short circuit, heating or explosion.

Owner:深圳市朗能电池有限公司

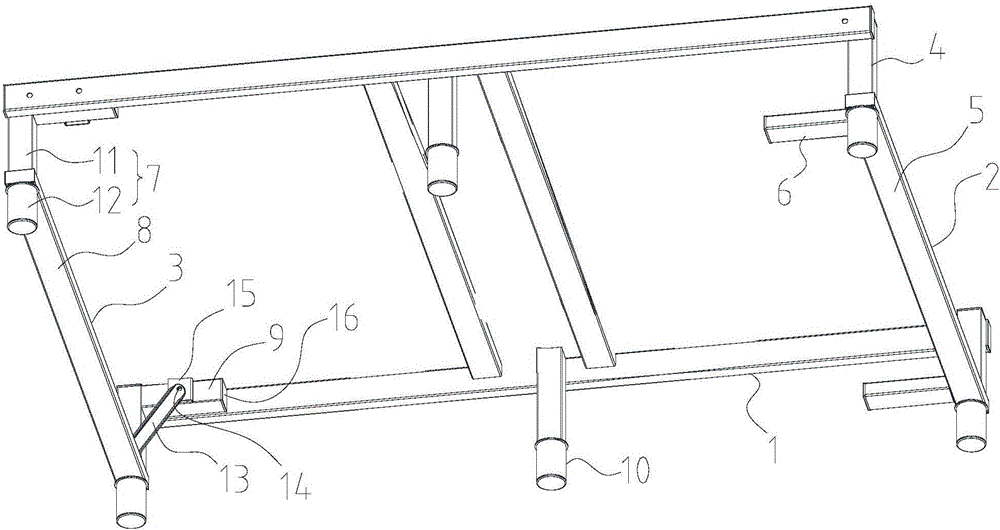

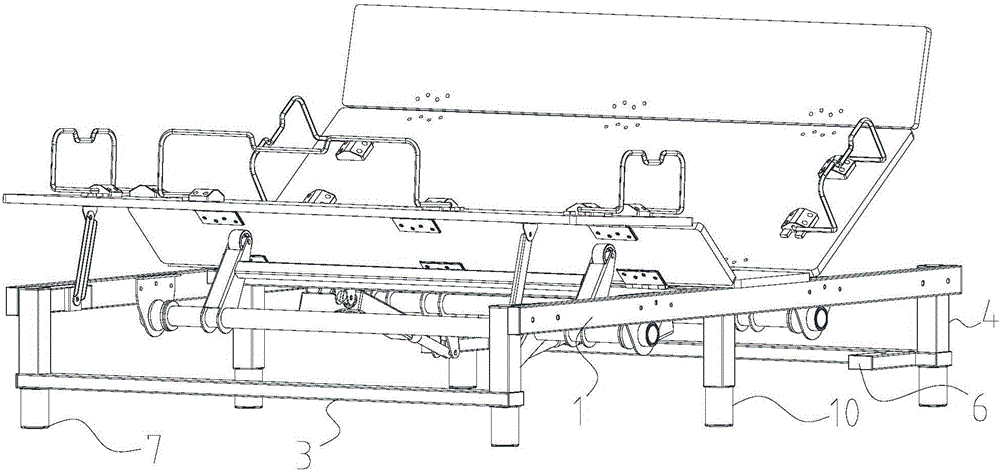

Under frame for electric bed

The invention relates to an under frame for an electric bed, which solves the defect that the electric bed in the prior art is short in service life. The under frame for the electric bed is characterized in that a connecting rod for connecting two front upright posts is arranged between the two front upright posts; the vertical distance between the connecting rod and the ground is less than the vertical distance between the connecting rod and cross rods. After assembling is completed, the connecting rod has the function of preventing an object from sliding in the under frame, i.e., the object cannot enter the under frame due to the blocking of the connecting rod, so that the object is prevented from colliding with a driving device in the under frame, and the service life of the driving device is prolonged; the connecting rod is provided with a blocking rod, the blocking rod is simultaneously vertical to the connecting rod and the front upright posts, the blocking rod stretches from the connecting rod to the direction of a rear-end support, the blocking rod can be used for preventing the object from entering the under frame from the side surface of the under frame, and the service life of the driving device is further prolonged.

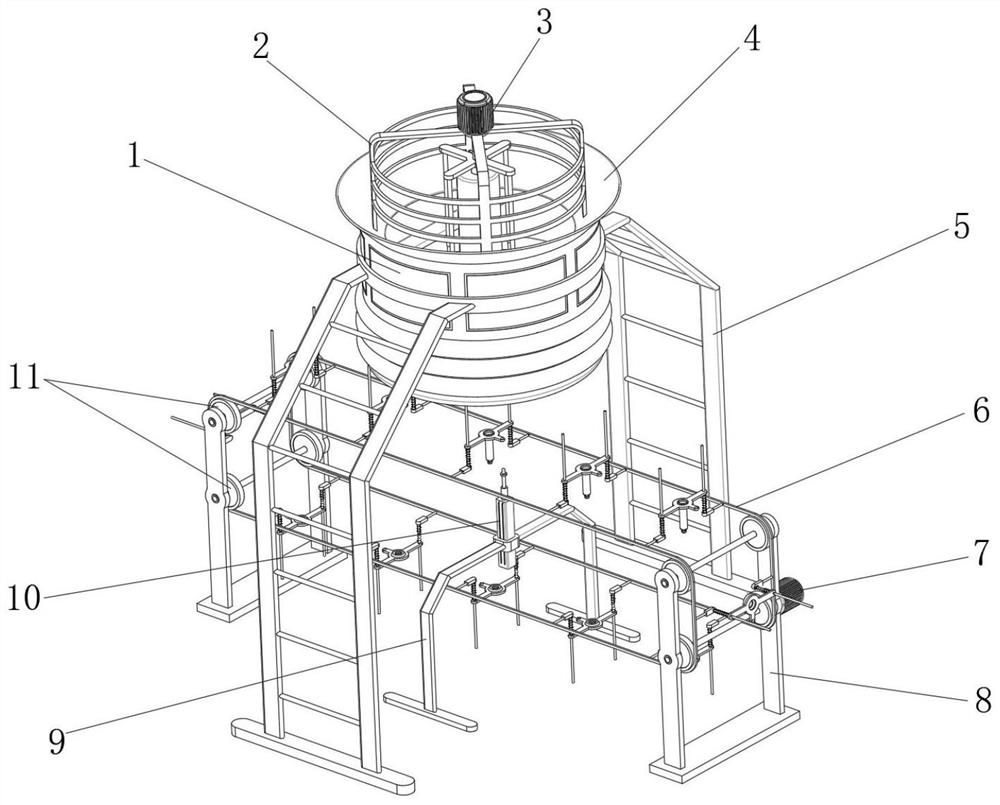

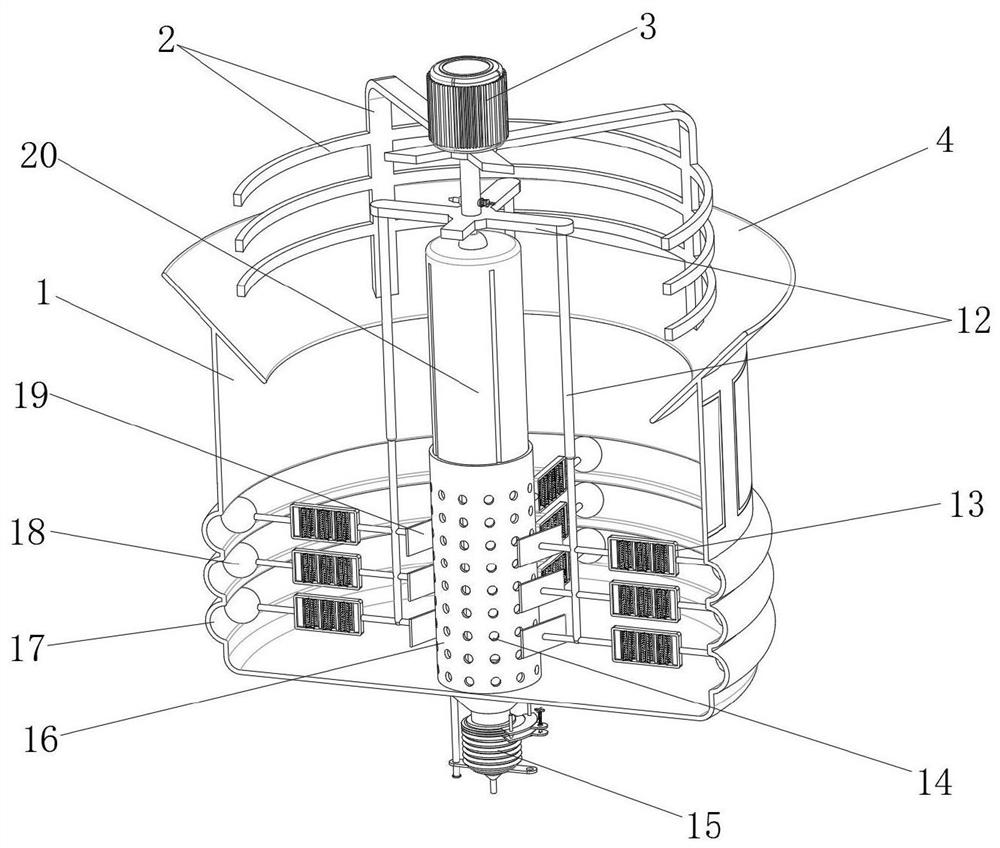

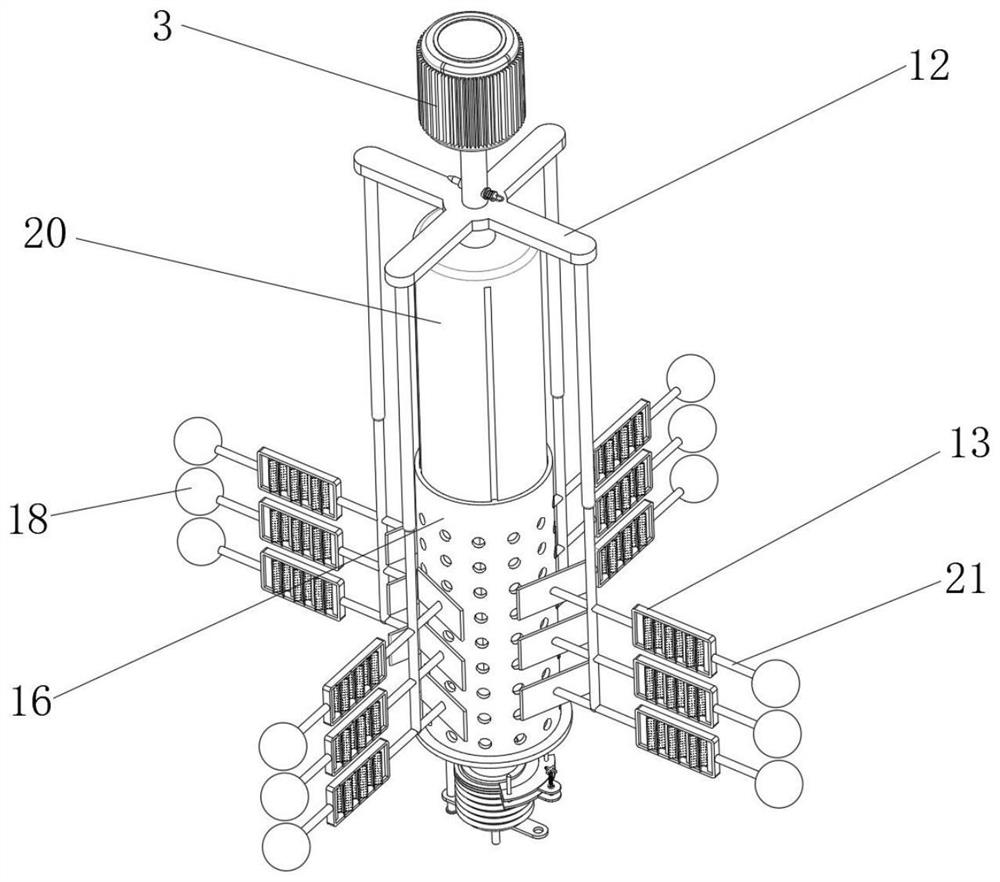

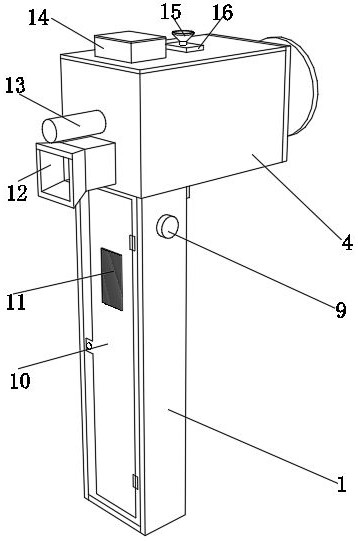

Nasal allergen blocking ointment formula and production equipment thereof

PendingCN114834659ATo achieve the purpose of fillingChange volumeRotary stirring mixersWrapper twisting/gatheringWhite petrolatumGlycerol

The invention discloses a nasal allergen blocking ointment formula and production equipment thereof, and relates to the technical field of nasal anti-allergic ointment. Ointment products of different specifications are prepared in order to facilitate filling; the equipment comprises a preparation tank and a conveying mechanism, a stirring mechanism is arranged in the preparation tank, a filling mechanism is arranged at the bottom of the preparation tank, and the preparation tank is mounted above the conveying mechanism through a first mounting frame; the ointment is prepared from the following raw materials in parts by weight: 65-80 parts of white vaseline, 6.5-8 parts of glycerol monostearate and glycerol distearate, 4-6.5 parts of liquid paraffin, 3-7 parts of PEG40 hydrogenated castor oil, 1-3 parts of menthol and 1-1.5 parts of wool fat. During filling, the carrying frame and the ointment container are jacked up through the jacking mechanism, the bottom end of the filling pipe is inserted into the ointment container, the extrusion plate continues to be jacked upwards, then the elastic bag is extruded, medicine in the elastic bag is extruded into the ointment container, and the purpose of filling is achieved.

Owner:娄飞

A stamping die and its waste material ejection mechanism

The invention discloses a stamping mold and a waste ejection mechanism thereof. The waste ejection mechanism comprises a cylinder of which a fixed end is arranged on a lower die holder, wherein a telescopic end of the cylinder is provided with an ejection plate through a rotating shaft in a rotating manner; the rotating shaft is arranged perpendicular to the axial direction of the cylinder; when the cylinder is at an extension limit position, the ejection plate rotates around the rotating shaft to a state back on to a mold body; one end of the ejection plate is provided with a guide plate which is provided with a guide groove; the fixed end is provided with a guide block which is in slide guide fit with the guide groove; the plane where the guide stroke of the guide groove is positioned is parallel to the axial direction of the cylinder and perpendicular to the axial direction of the rotating shaft; the guide groove comprises an upper guide groove and a lower guide groove which is communicated with the upper guide groove; the slide guide direction of the upper guide groove is parallel to the axial direction of the cylinder; the lower guide groove and the upper guide groove are at a preset angle; the lower guide groove gets away from the mold body gradually in the extension direction away from the upper guide groove. Thus, ejection stroke and discharge direction of waste can be excellently controlled through the arrangement of the guide structure.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

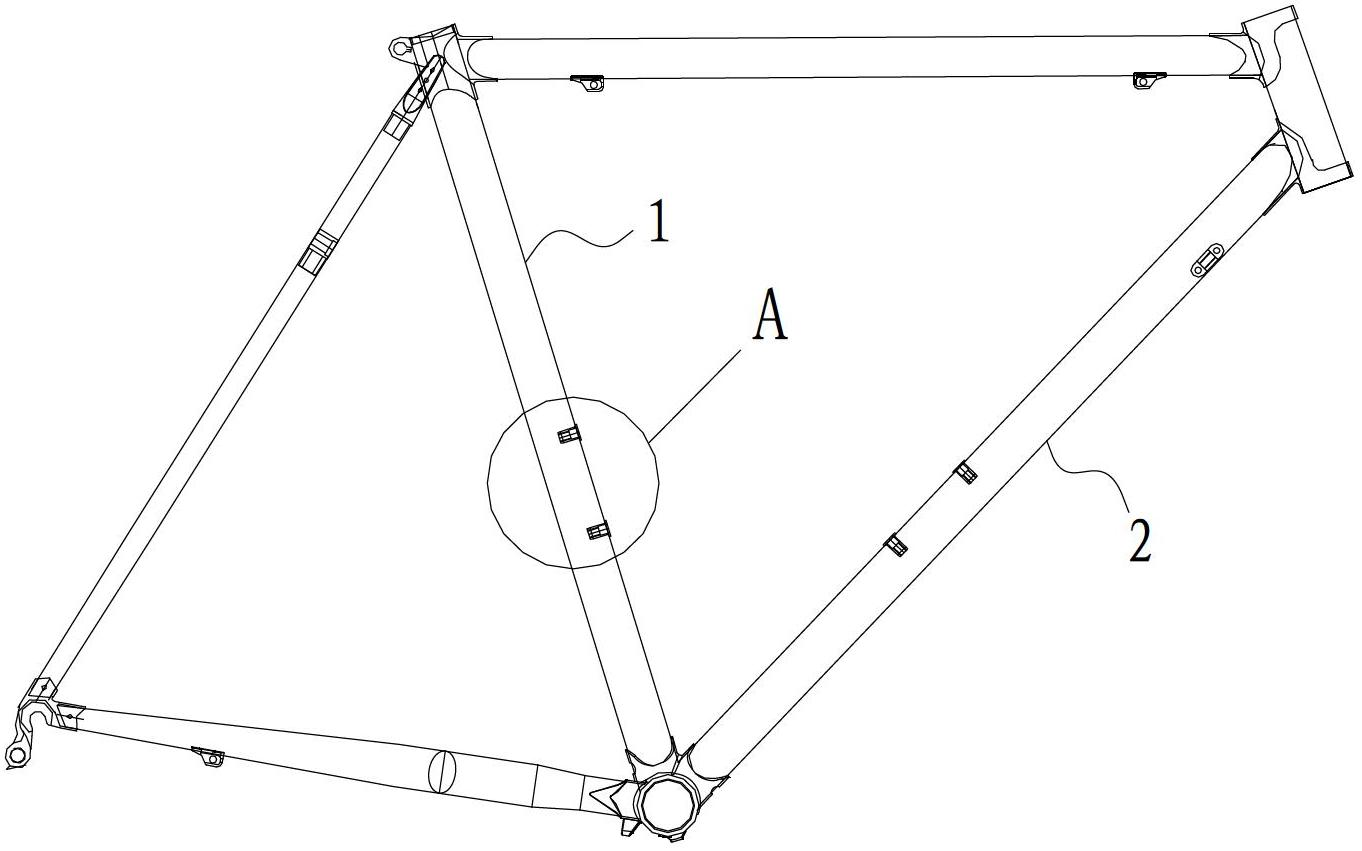

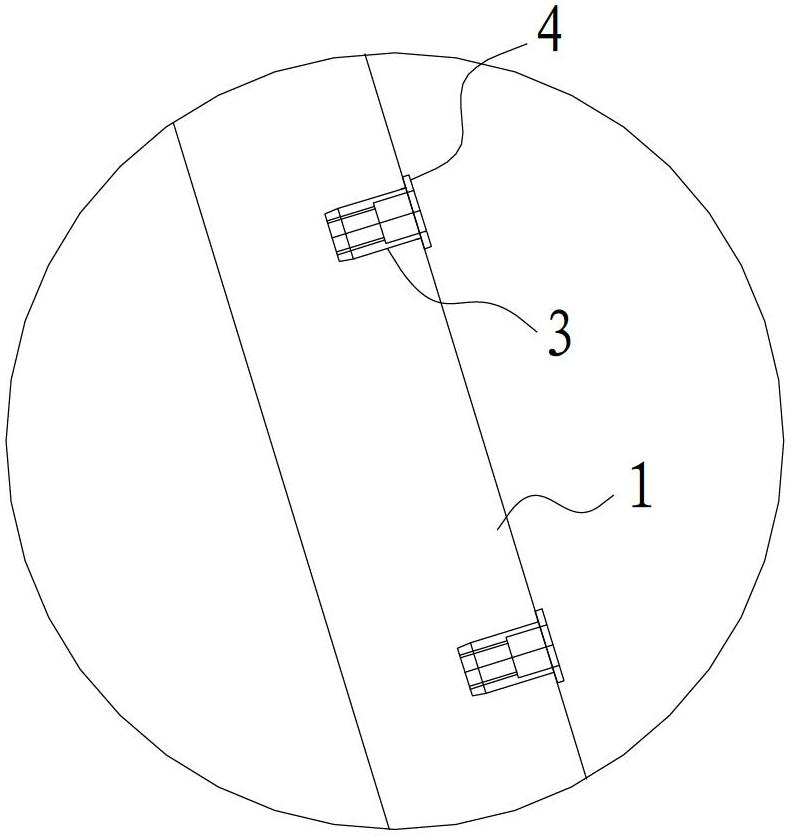

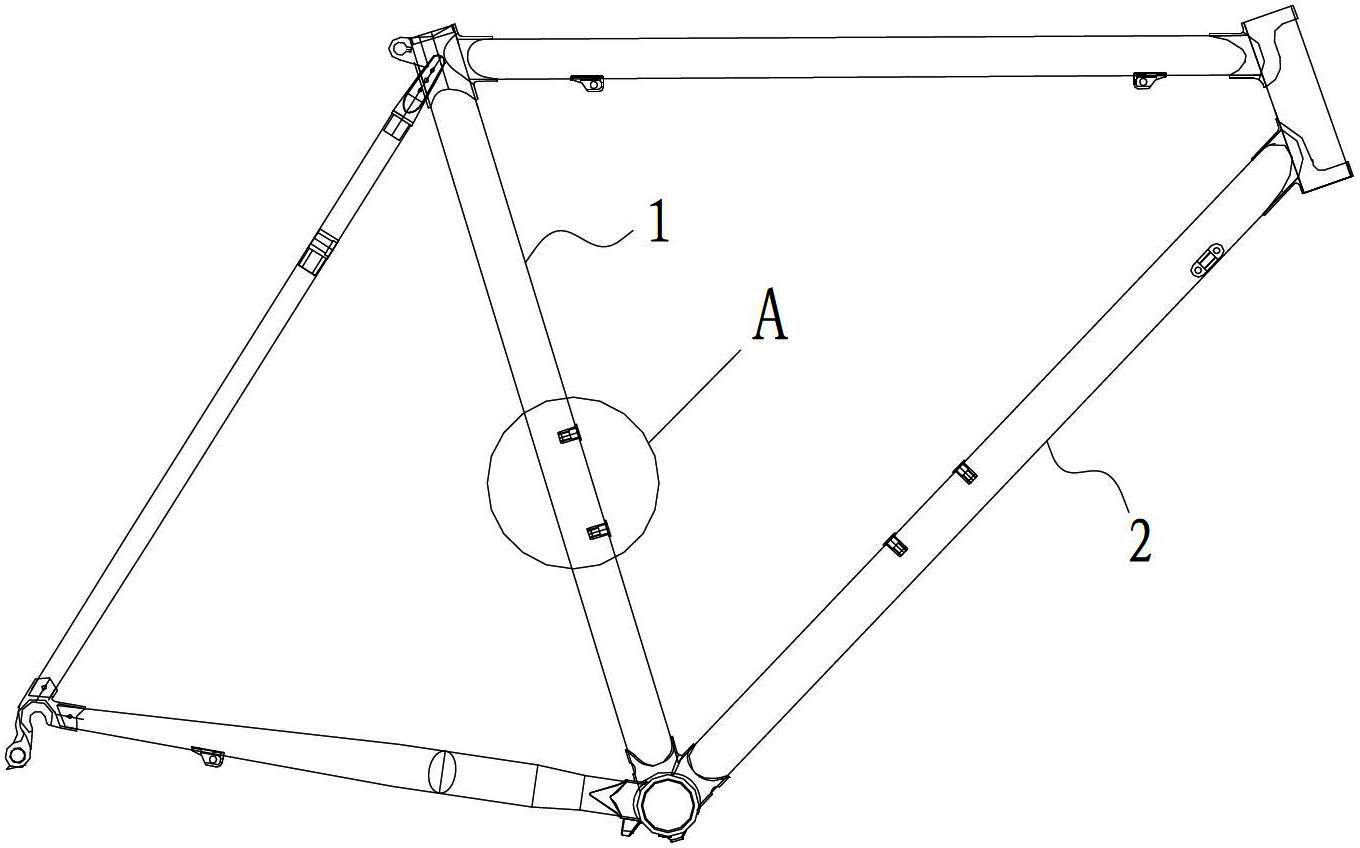

Bicycle frame embodied with installation sleeve

The invention relates to a bicycle frame embodied with an installation sleeve, comprising an inclined beam and a vertical beam, wherein the inclined beam and / or the vertical beam is provided with a radial installation hole, and an inclined beam installation sleeve is coaxially and fixedly installed in the installation hole. The installation sleeve is coaxially provided with an internal thread. The bicycle frame is made of chrome molybdenum steel, so that the machinability and the impact absorption are good; and the bicycle frame can be easily welded compared with the bicycle frame made of titanium or aluminum, and can be designed into various shapes. In addition, the bicycle frame made of the chrome molybdenum steel does not need heat treatment after being welded, so that the large heat treatment equipment is not needed.

Owner:天津恒腾自行车有限公司

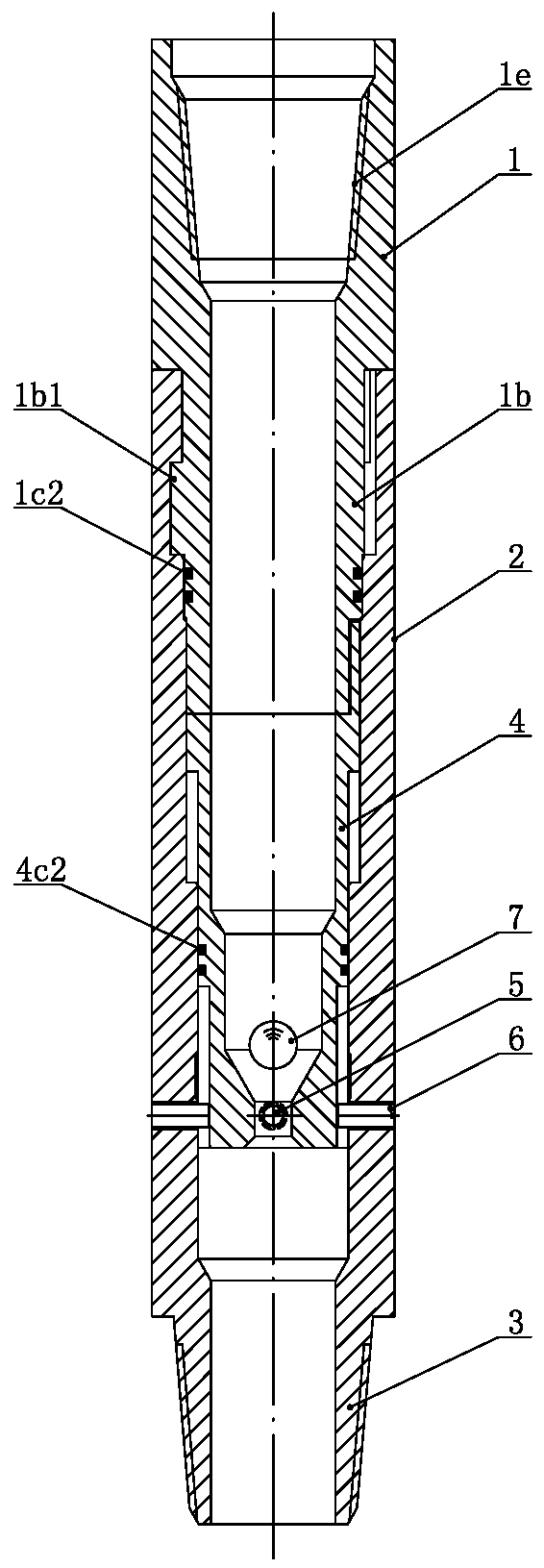

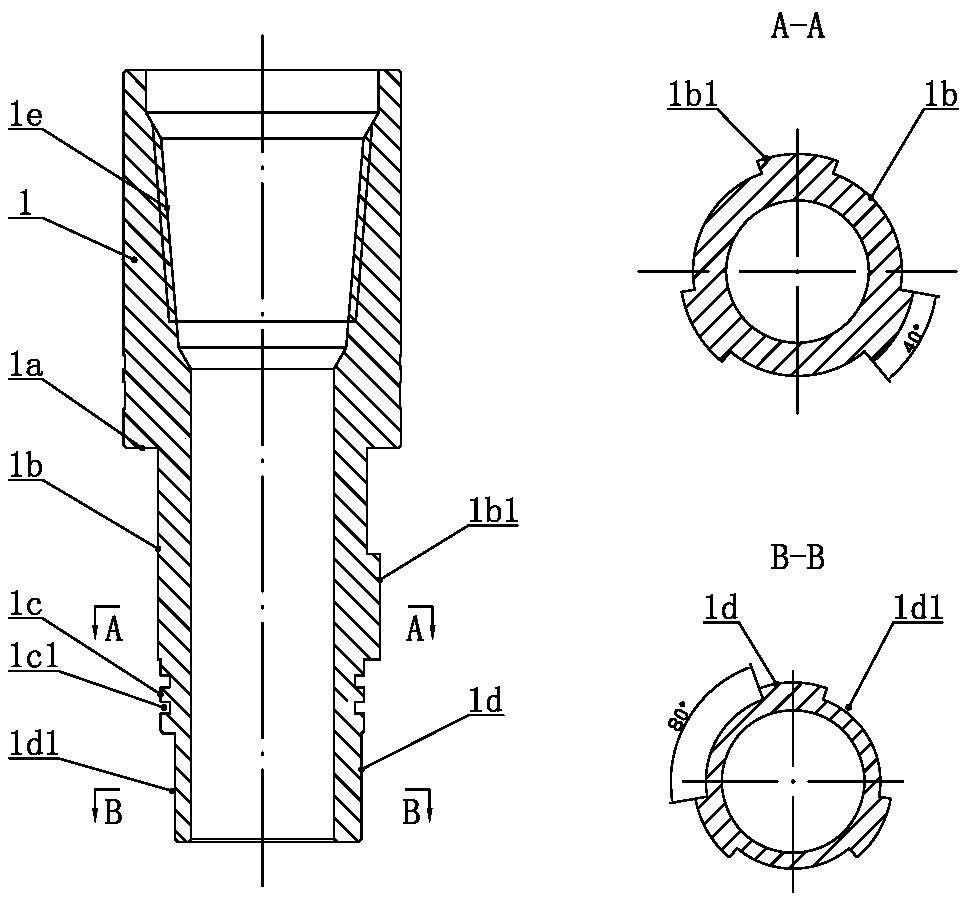

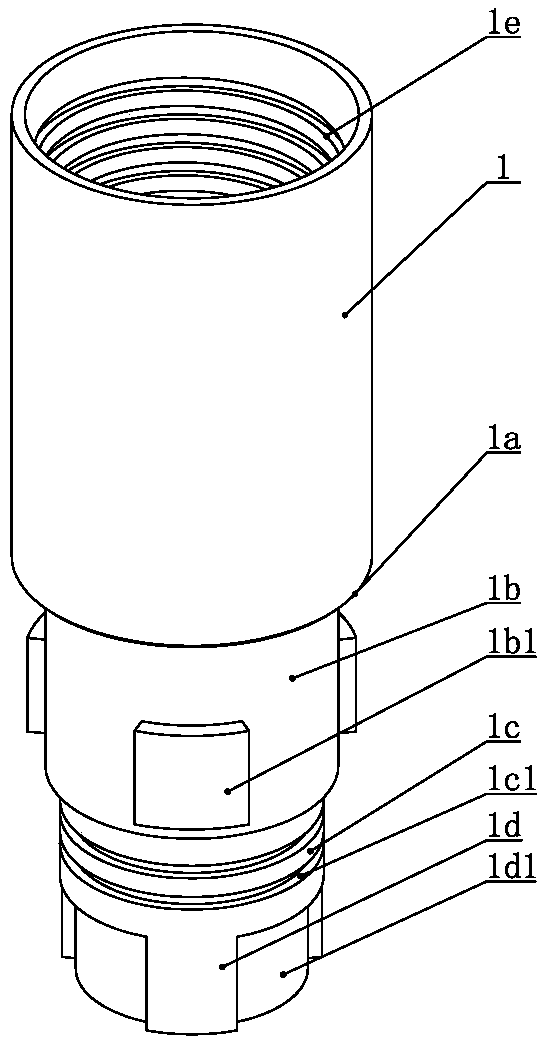

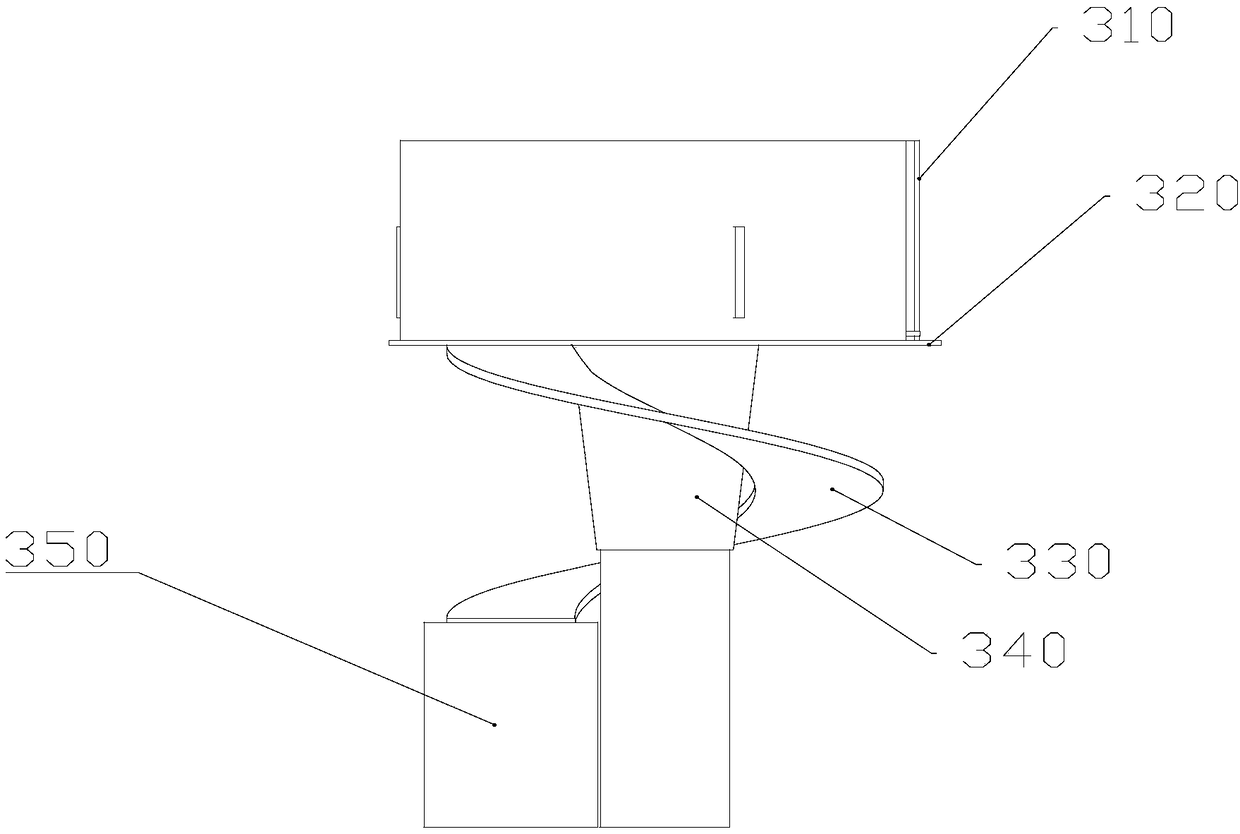

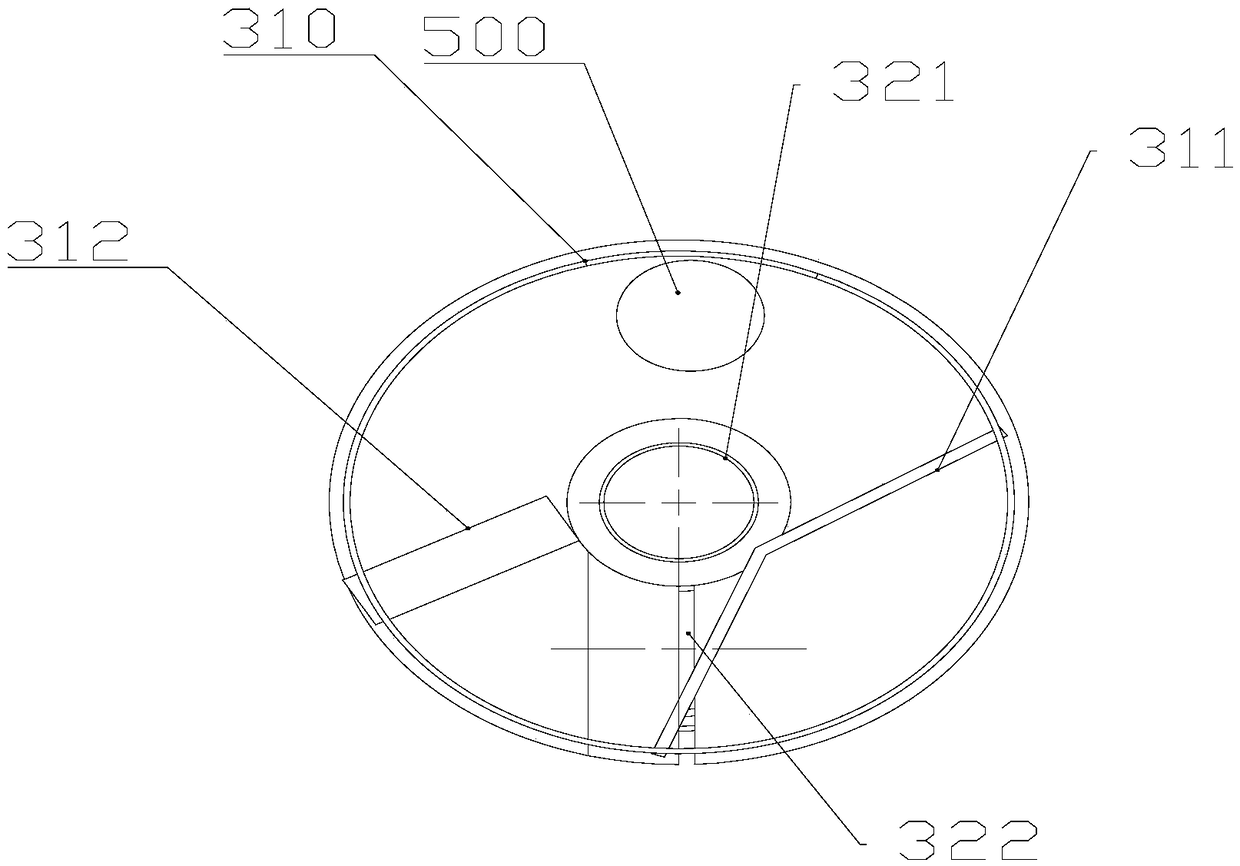

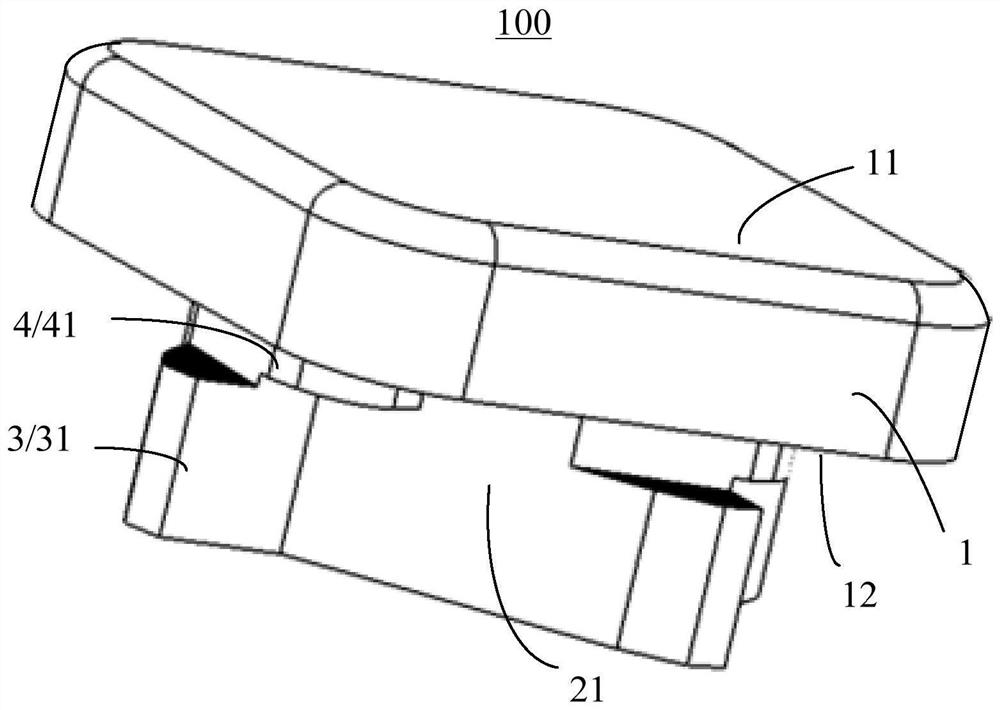

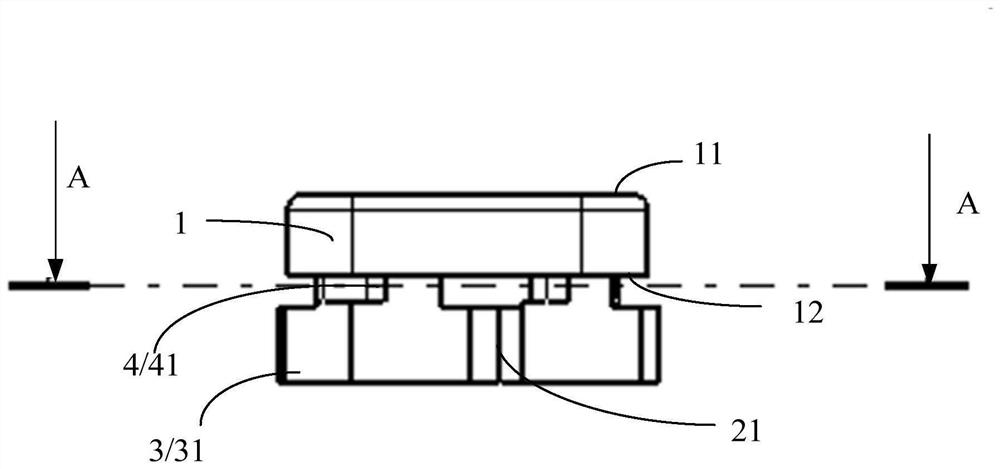

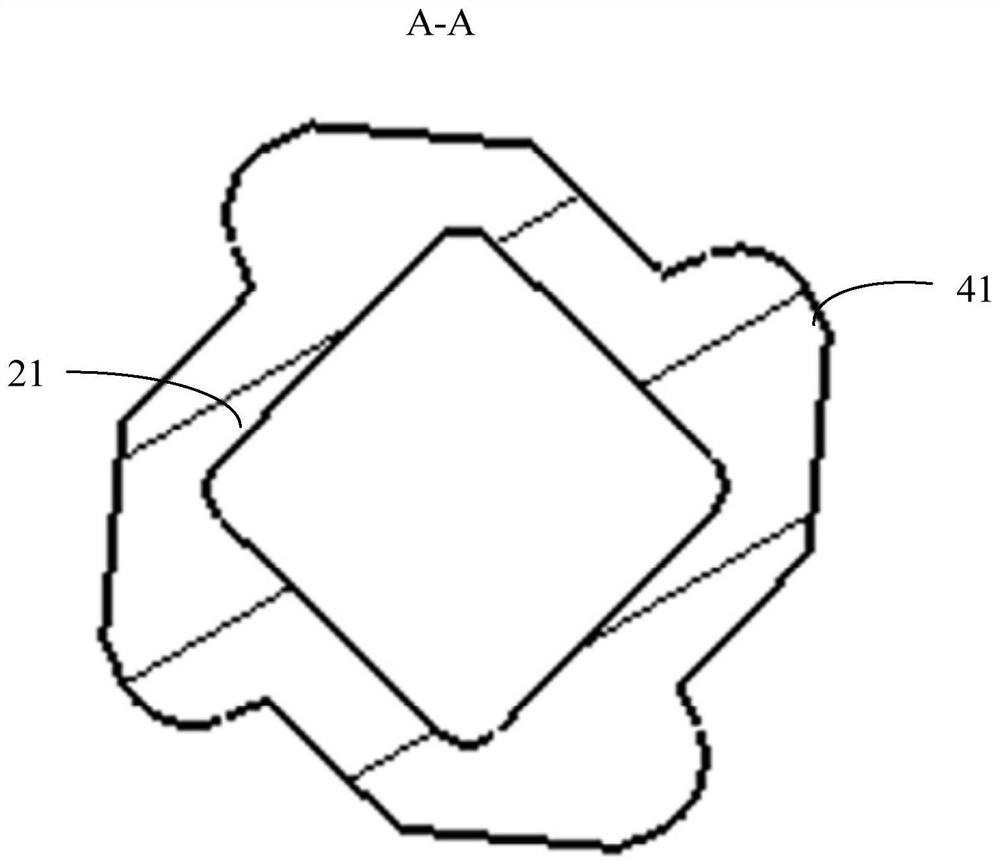

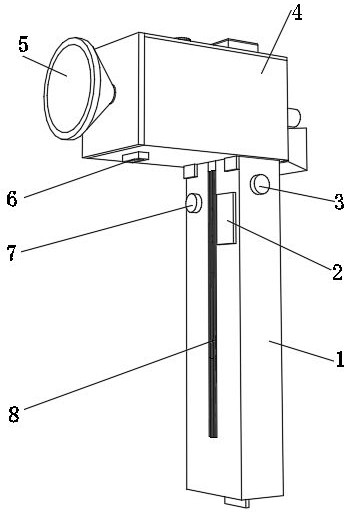

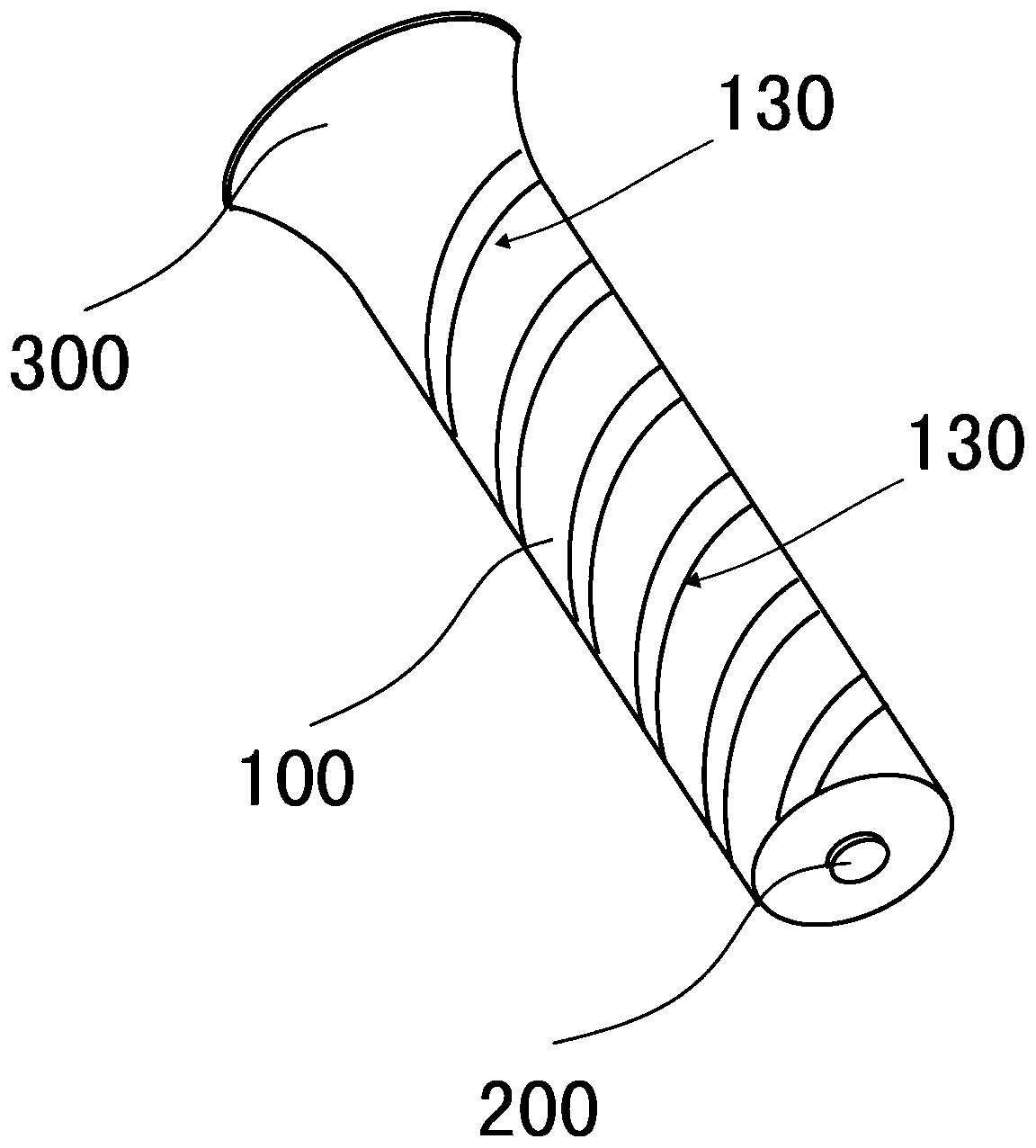

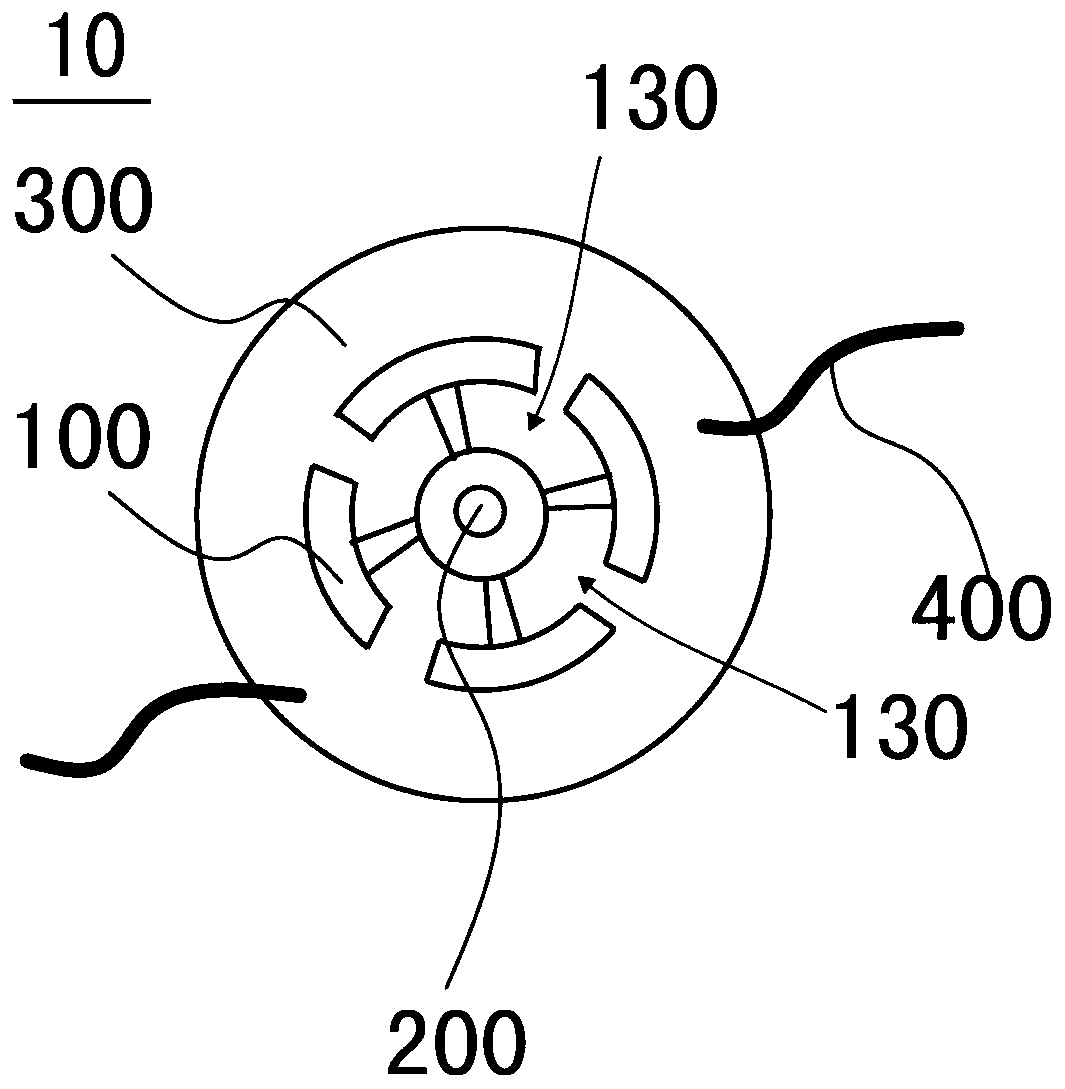

Driving force transmission assembly, rotating member, toner cartridge and electronic imaging equipment

PendingCN113156789AAvoid sliding inEasy to installElectrography/magnetographyGear wheelElectronic imaging

The invention provides a driving force transmission assembly, a rotating member, a toner cartridge and electronic imaging equipment. The driving force transmission assembly comprises a driving force receiving piece and a driving gear. The driving force receiving piece is provided with a rod body and a driving force receiving part located at one end of the rod body, and the rod body is inserted into the driving gear and drives the driving gear to rotate. The rod body is sleeved with a reset piece installed in the driving gear, and the rod body is further provided with a limiting piece. The end face, away from the driving gear, of the driving force receiving part is an outer end face, and driving force receiving teeth extending outwards are arranged on the outer end face. The end face, close to the driving gear, of the driving force receiving part is an inner end face, the diameter of the inner end face is larger than that of the outer end face, a guiding face is formed between the inner end face and the outer end face, and the diameter of the inner end face is larger than the gap size of the bottom of a guiding groove of the electronic imaging equipment. The rotating member comprises a barrel and the driving force transmission assembly. The toner cartridge is provided with the rotating member. According to the invention, smooth mounting of the toner cartridge can be ensured.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

Driving force transmission assembly, rotating member, toner cartridge and electronic imaging equipment

The invention provides a driving force transmission assembly, a rotating member, a toner cartridge and electronic imaging equipment. The driving force transmission assembly comprises a driving force receiving piece and a driving gear. The driving force receiving piece is provided with a rod body and a driving force receiving part located at one end of the rod body; and the rod body is inserted into the driving gear and drives the driving gear to rotate. A mounting frame is arranged in the driving gear, and a body of the mounting frame is arranged at the end, close to the driving force receiving part, of the driving gear. An abutting piece is arranged on the rod body, and a reset piece is arranged between the abutting piece and the body of the mounting frame. The driving force receiving part is engaged with a driving shaft, and at least one of the driving force receiving part and the driving shaft contains a magnetic material. The rotating member comprises a barrel and the driving force transmission assembly. The toner cartridge is provided with the rotating member. The electronic imaging equipment is provided with the toner cartridge. According to the invention, smooth mounting of the toner cartridge can be ensured.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

Safe atomization medicine inhaler for patients with cardiovascular and cerebrovascular diseases

PendingCN113750328ADosing is convenientDressing change at convenienceMedical atomisersDiseaseMedical equipment

The invention discloses a safe atomization medicine inhaler for patients with cardiovascular and cerebrovascular diseases, and relates to the technical field of medical equipment. The problems that tablets cannot be ground into medicine powder quickly, and all the medicine powder cannot be mixed with water and sprayed out are solved. The safe atomization medicine inhaler specifically comprises a protective shell; a medicine storage frame is slidably connected to the inner wall of the protective shell; a plurality of rectangular through grooves are formed in the outer wall of one side of the medicine storage frame; a medicine clamping mechanism is arranged on the inner wall of the medicine storage frame; a rack plate is fixed to the outer wall of one side of the medicine storage frame; a stepping motor is fixed to the inner wall of the protective shell; an output shaft of the stepping motor is connected with a gear through a coupler; the gear and the rack plate are in meshed connection; and a mounting box is fixed to the outer wall of the top of the protective shell. By arranging an arc-shaped push plate and a grinding box, tablets can be pushed by the arc-shaped push plate all the time to pass through the grinding box to be ground; the ground tablets are pushed into a stirring box to be stirred; liquid medicine can be sprayed out through a spraying pump after stirring is finished; and the whole spraying manufacturing process can be completed within several seconds.

Owner:杜唯

Ear canal cleaning device for ENT

ActiveCN107411876BAchieve cleaningAchieve therapeutic effectEar treatmentOtoscopesNoseBiomedical engineering

The invention discloses an ear canal cleaning device used for an ear-nose-throat department. The ear canal cleaning device used for the ear-nose-throat department comprises a handle, a fixing base, a gas cylinder, a gas injecting hole, a piston, a pushing rod, a fixing sleeve, a screw sleeve, a inserting barrel, an air injecting pipe, a leaking hole, an air cushion, a first flowing pipe, a first syringe, a second flowing pipe and a second syringe. The ear canal cleaning device used for the ear-nose-throat department is ingenious in structure and powerful in function; by using the device, firstly, ear wax foreign matters in an ear canal of a patient can be suck out of the ear canal, and secondly, according to the illness state of the patient, corresponding medicine liquid can be injected into the ear canal of the patient, and targeted treatment is conducted on the patient, and finally depth in the ear canal of the patient can be blocked through simple operation, and the medicine liquid and the ear wax foreign matters are effectively prevented from slipping into the depth of the ear canal of the patient in the operation process, so that cleaning for the ear canal of the patient is improved greatly, and operation of health care workers is facilitated.

Owner:杨晓蓉

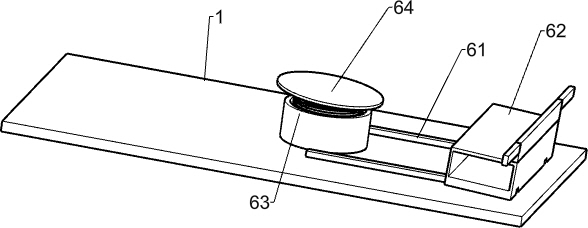

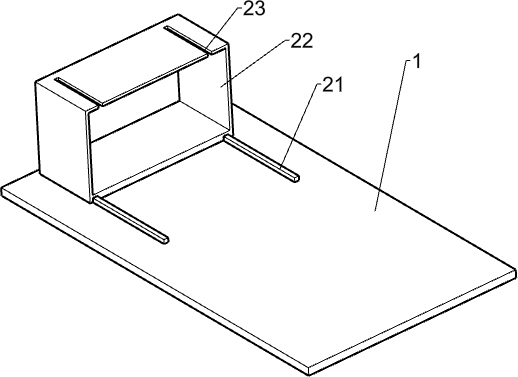

An auxiliary decision-making conference system

ActiveCN110969752BImprove efficiencyAvoid lossVoting apparatusProcess engineeringIndustrial engineering

The invention relates to the technical field of conferences, in particular to an auxiliary decision conference system. The system comprises a collecting device, a storage device and a transportation mechanism, a paper inlet is formed in one side of the collecting device, a scanner capable of scanning characters on paper is arranged at the paper inlet, the scanner is electrically connected with anexternal computer, and a paper outlet is formed in the position, close to the bottom, of the collecting device; the storage device is located on one side of the collecting device, and an object inletis formed in one side of the storage device and corresponds to the paper outlet. The conveying mechanism is located in the collecting device and can convey paper from the interior of the collecting device to the interior of the storage device through the paper outlet and the object inlet. After voting is finished, written votes are directly and sequentially put into the paper inlet, the votes arescanned by the scanner at the paper inlet and then input into the external computer for statistics, manual statistics is not needed, and the conference decision making efficiency is improved.

Owner:ZHUHAI DAHENGQIN TECH DEV CO LTD

Drainage device

PendingCN111166944AImprove drainage effectReduce the chance of infectionMedical devicesIntravenous devicesFecesPostoperative recovery

The invention discloses a drainage device. The drainage device comprises a first draining part and a second draining part, wherein the first draining part is of a cylindrical structure; two ends of the first draining part is respectively provided with a first end face and a second end face; a draining slot is formed in the outer circumference of the first draining part, and is opened in the firstend face; and the second draining part has a hollow tubular structure with two opening ends, and runs through the first draining part in the direction from the first end face to the second end face. The drainage device has a good draining effect and can effectively shorten the recovery cycle after an operation. According to the drainage device, hematodes exudate around an anus wound is guided to enter the draining slot through the first draining part and is drained out; and the second end face is a closed end face, and faeces can only be drained out through the second draining part and cannotenter the draining slot, so that the exudate of the anus wound can be separated from the faeces in rectums due to the first draining part and the second draining part, and the infection probability ofanus wounds can be reduced.

Owner:GUANGZHOU WOMEN AND CHILDRENS MEDICAL CENTER

A piano lock mechanism

ActiveCN110984715BDoes not destroy the integrity of the appearanceAvoid being touchedKeysPianoEngineering

Owner:NINGBO SIHAI PIANO

Piano lock mechanism

ActiveCN110984715ADoes not destroy the integrity of the appearanceAvoid being touchedKeysPianoEngineering

The invention discloses a piano lock mechanism. The piano lock mechanism includes a lock head structure embedded in a front top cover (1), a lock seat structure arranged in a lock door stop (2) and akey assembly. In a locked state, a spring bolt of the lock head structure protrudes out, and is embedded in a positioning hole of the lock seat structure and performs positioning in an up and down mode, a latch of the lock seat structure protrudes downward out of the bottom of the lock door stop (2) to abut against the back surface of a piano key cover (3), and the piano key cover (3) positions along a rotation axis; in a unlocked state, the spring bolt of the lock head structure is retracted into the lock head structure away from a lock hole of the lock seat structure, the latch of the lock seat structure is retracted upward into the lock door stop (2), and the piano key cover (3) swings along the rotation axis; and the key assembly is used for being inserted into the lock hole of the lock head structure and driving the lock head structure to protrude or retract. The built-in type of the piano lock mechanism is not prone to being touched, and the piano lock mechanism is simple in structure and good in reliability, and ensures the integrity of the entire piano.

Owner:NINGBO SIHAI PIANO

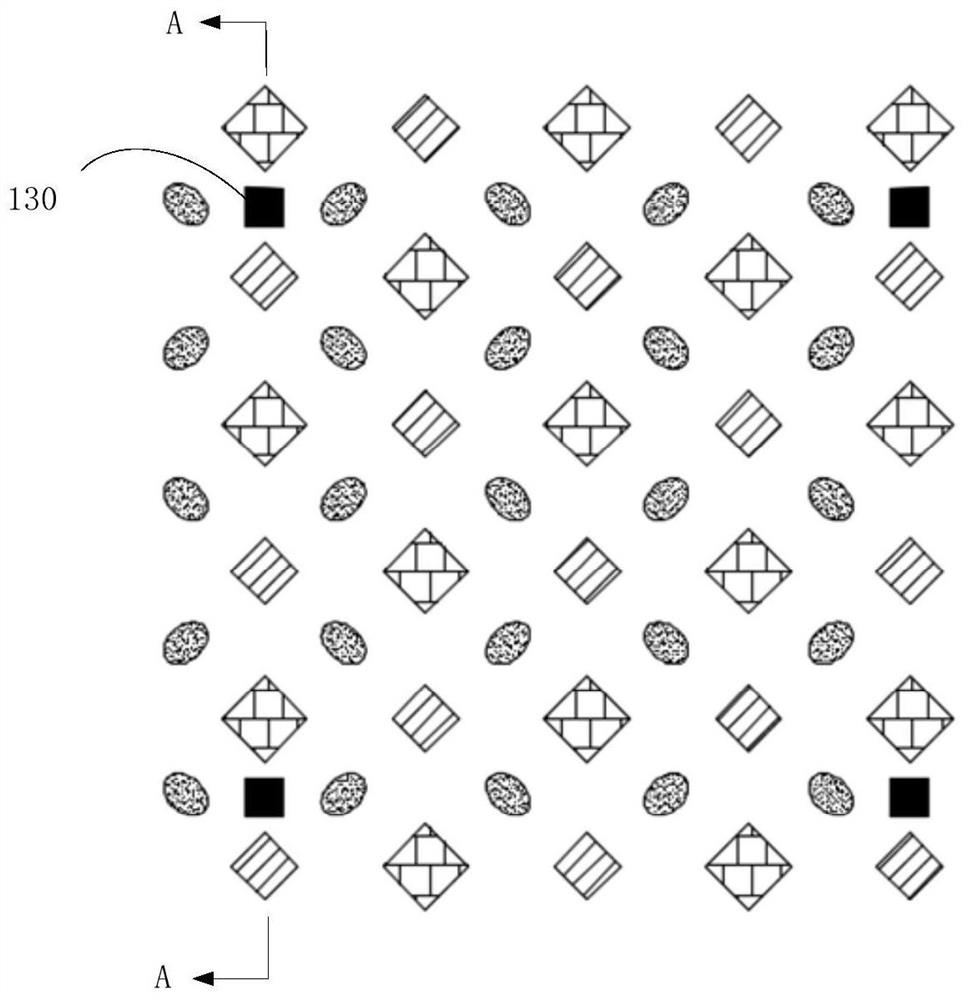

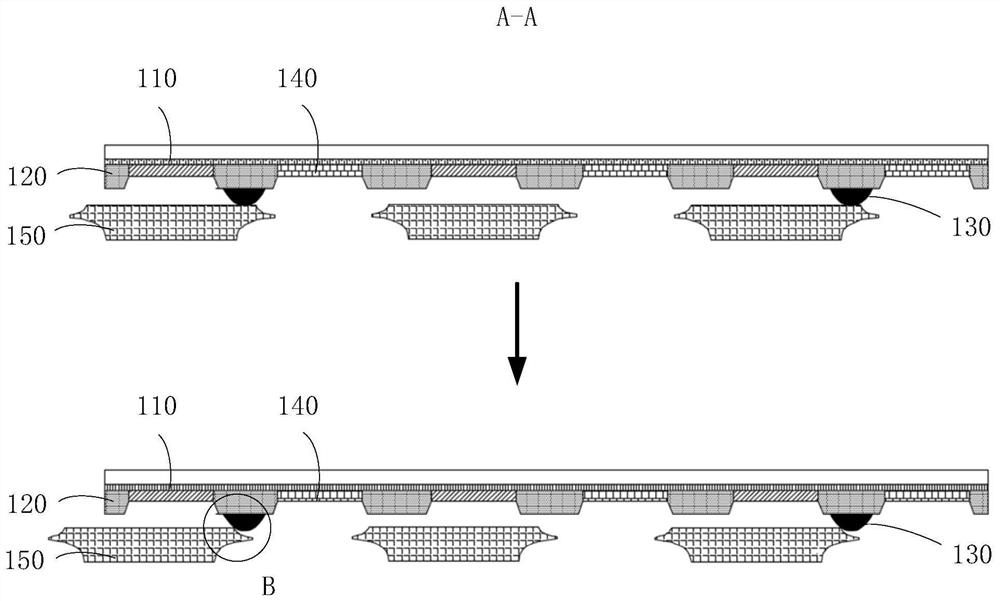

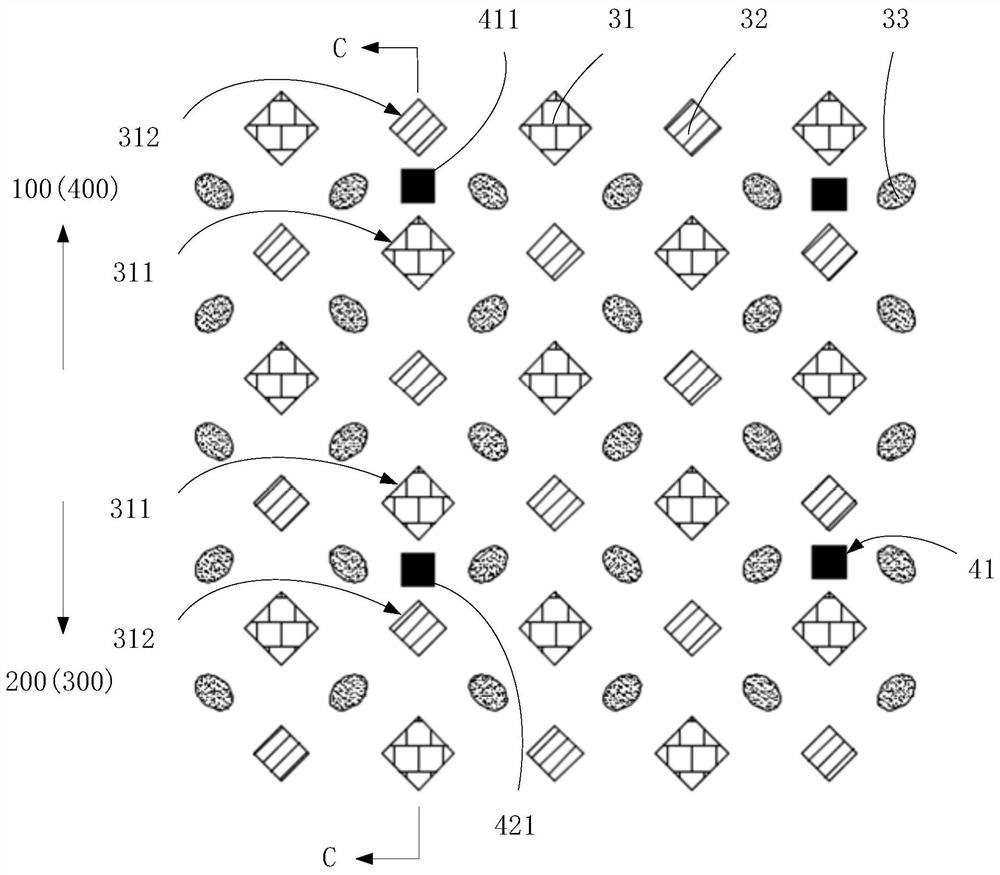

Display panel

ActiveCN113540197AAvoid scratchesAvoid package failureSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The embodiment of the invention discloses a display panel. According to the display panel, a plurality of first shock insulator columns are distributed according to a first preset rule, so that the first shock insulator columns are in one-to-one correspondence with adjacent first sub-pixel openings, and the first sub-pixel openings are formed in at least two directions around the adjacent first shock insulator columns; in other words, the first shock insulator columns are arranged in different directions of the first sub-pixel openings, and the positions of the pixel openings correspond to the positions of the openings of the mask plate, so that when the mask plate is staggered, all the first shock insulator columns are prevented from sliding into the opening positions of the mask plate at the same time, and when one shock insulator column slides into the opening position of the mask plate, the other shock insulator column can play a supporting role, so that the shock insulator column sliding into the opening position of the mask plate is prevented from being scratched, the probability of generating fine particles is further reduced, and packaging failure or abnormal display of the display panel is avoided.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

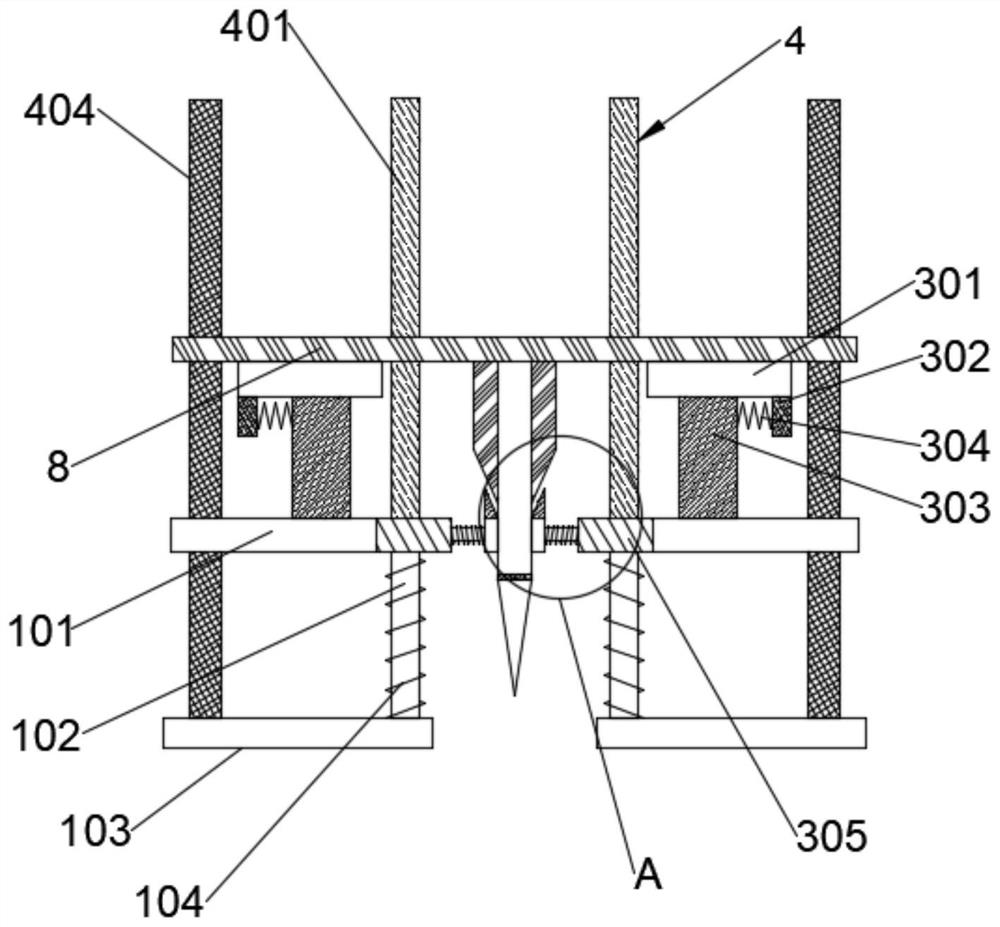

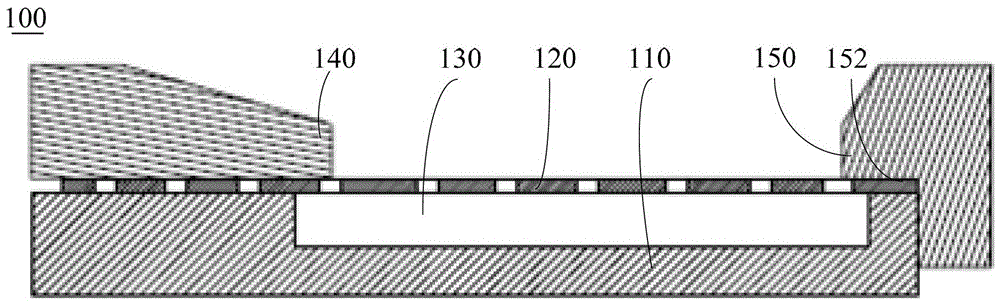

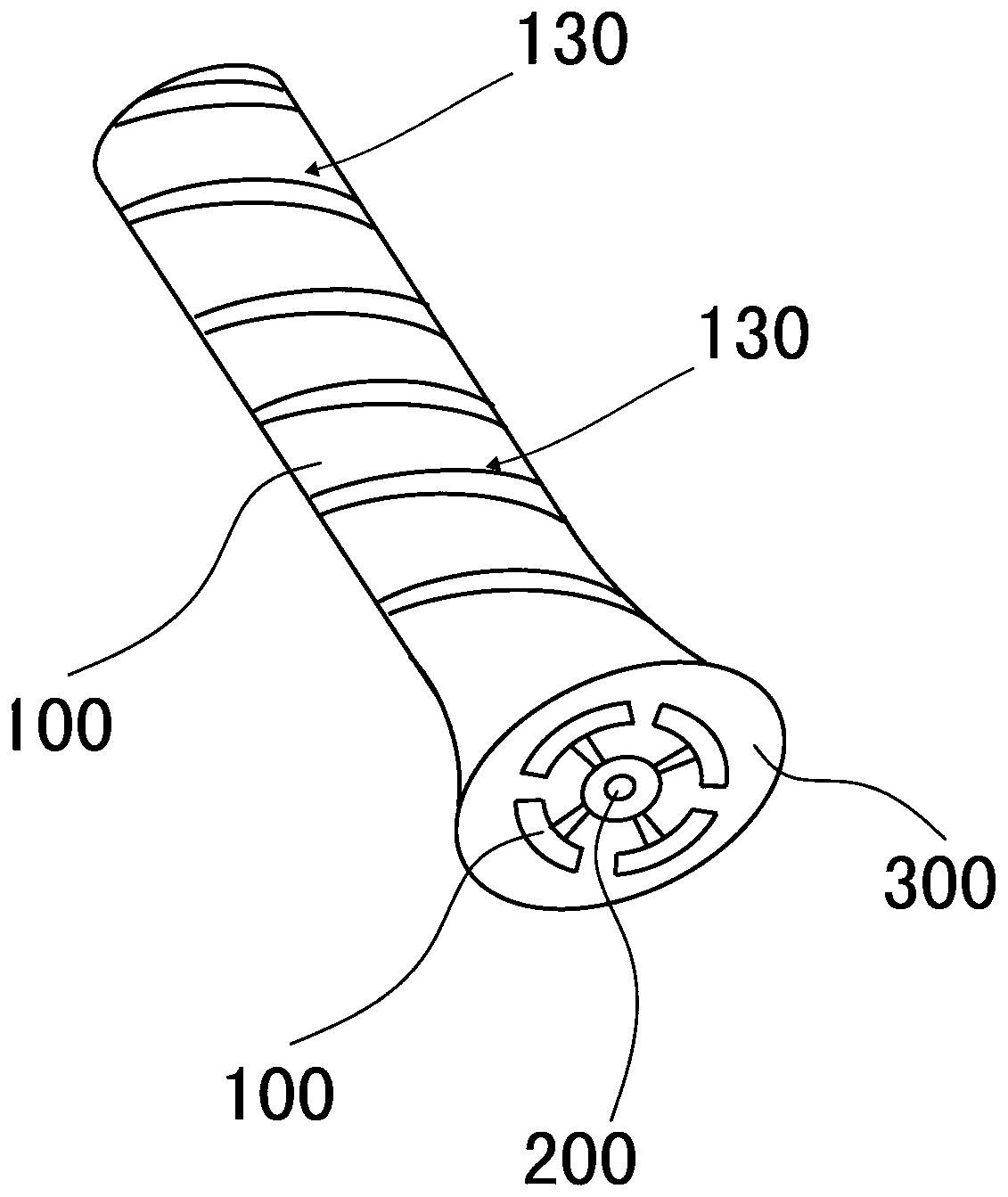

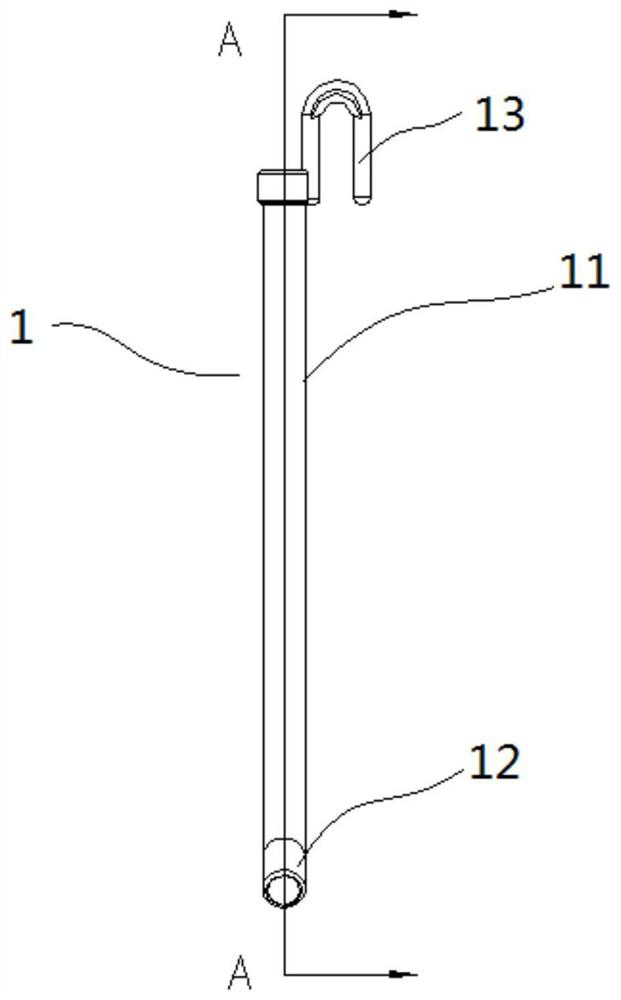

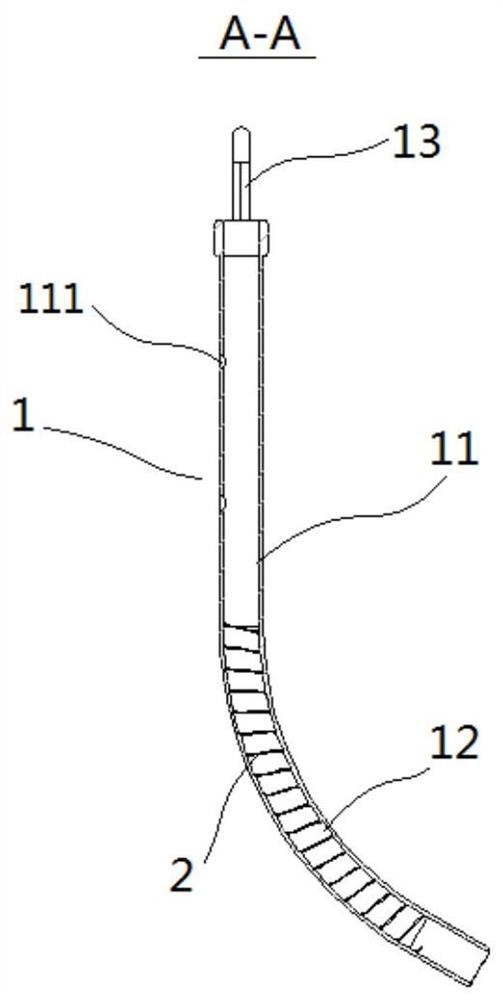

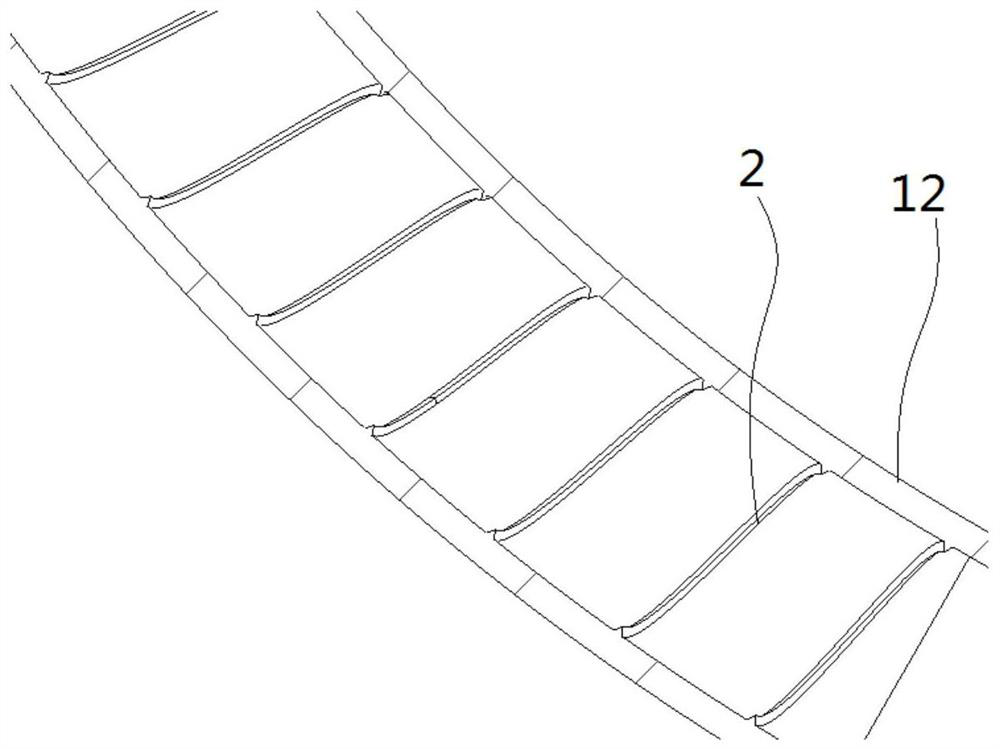

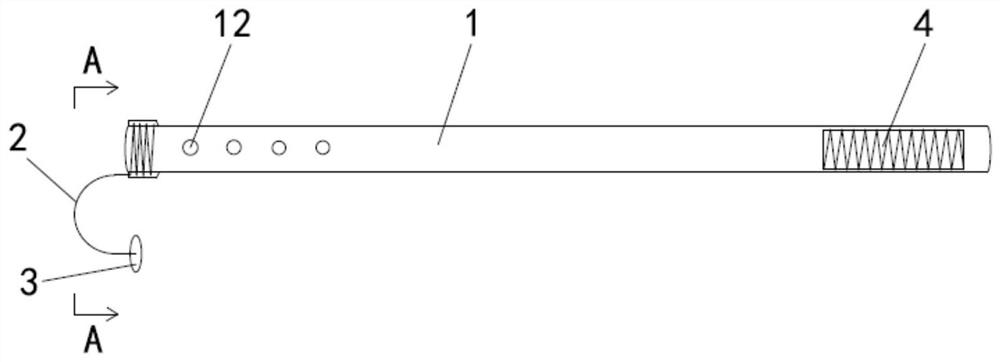

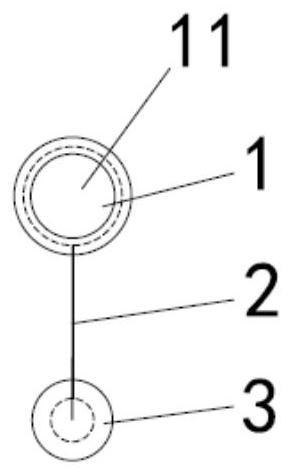

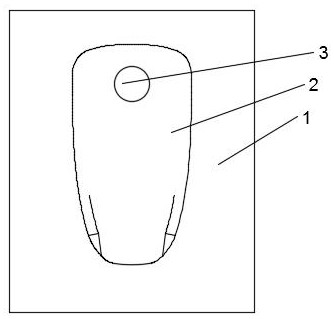

Anti-suffocation pharyngeal catheter device and manufacturing mold of catheter device

PendingCN111803772ANo distortion problemGuaranteed unobstructedTracheal tubesStentsSurgical riskNasal passages

The invention discloses an anti-suffocation pharyngeal catheter device and a manufacturing mold of the catheter device. The catheter device is a flexible catheter (1), the flexible catheter (1) comprises a flexible straight tube portion (11) and an arc-shaped tube portion (12), the arc-shaped tube portion (12) is located at the front end of the straight tube portion (11), and the radian of the arc-shaped tube portion (12) is consistent with the radian of human soft palate; when the flexible catheter (1) extends from human lower nasal passage into the pharynx, the arc-shaped tube portion (12) is placed in the pharynx supports the collapsed part of the pharyngeal polyp; and at the same time, the manufacturing mold of the flexible catheter device is also disclosed. The device can be insertedinto the pharynx from the nostril before a general anesthesia operation of a patient, and even if the patient has pharyngeal polyp collapse during the operation, the breathing can also be kept unobstructed because of the enhanced support of the arc-shaped tube portion, thus avoiding the surgical risk and trauma of tube cutting.

Owner:安徽朔源医疗器械有限公司

Anti-suffocation pharyngeal catheter device and application thereof

PendingCN111603647AKeep breathingFreedom from Trauma and Surgical RisksTracheal tubesStentsNasopharyngeal airwayPharynx

The invention discloses an anti-suffocation pharyngeal catheter device and application thereof. The anti-suffocation pharyngeal catheter device structurally comprises a nasopharyngeal airway and an expander, wherein the nasopharyngeal airway is made of a medical silicone material capable of being bent freely; the expander is arranged in the portion, close to the rear end, of the nasopharyngeal airway; and the length of the nasopharyngeal airway can allow the nasopharyngeal airway to penetrate into the human pharynx from the nostrils. The dilator plays a role in supporting and prevents the pharyngeal polyp from collapsing to extrude the nasopharyngeal airway to reduce or close the nasopharyngeal airway channel. The device can be inserted into the pharynx from the nostrils before the generalanesthesia operation of a patient, even if the polyp of the pharynx collapses during the operation of the patient, the patient can breathe smoothly due to the support of the expander, and the operation risk and trauma of tube cutting are avoided.

Owner:安徽朔源医疗器械有限公司

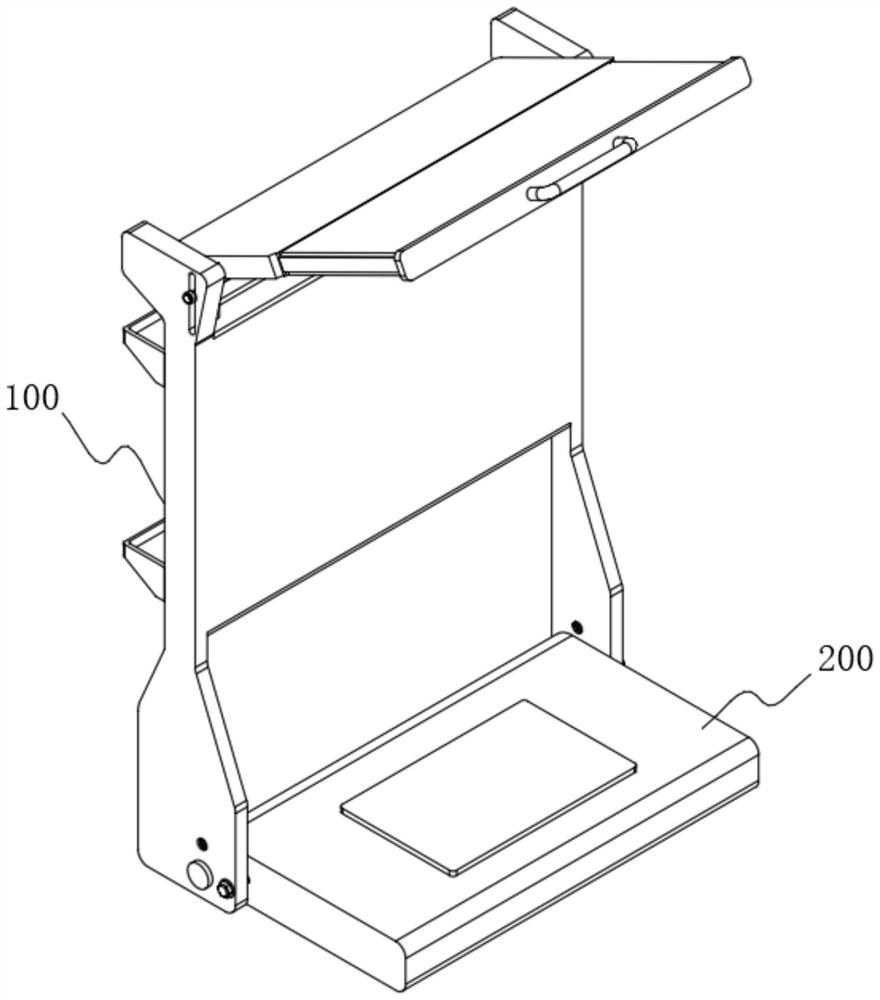

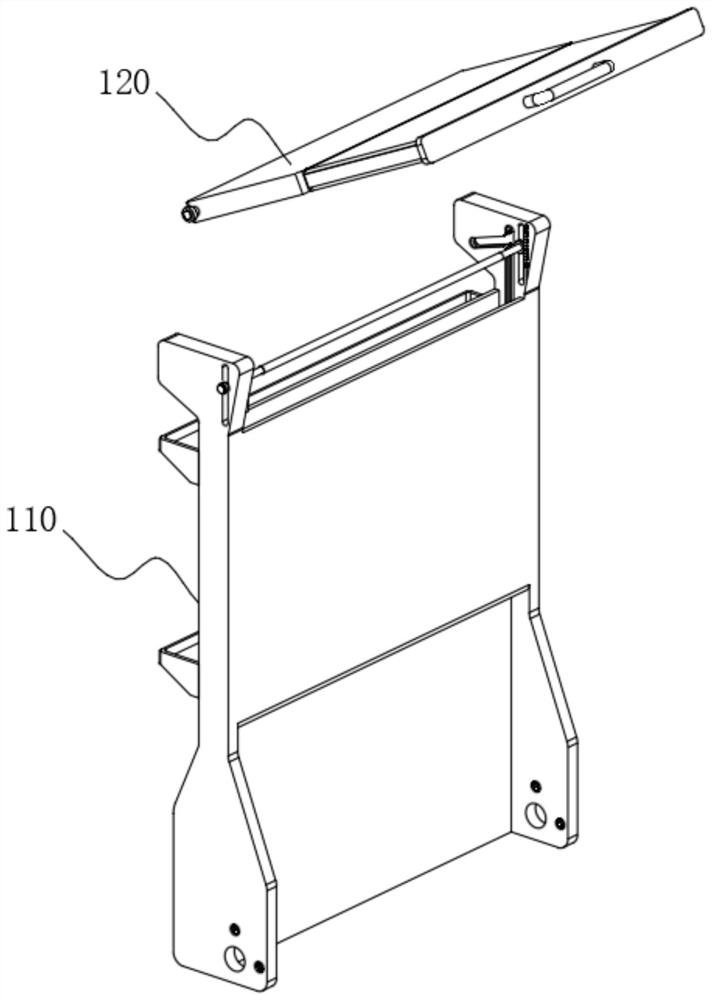

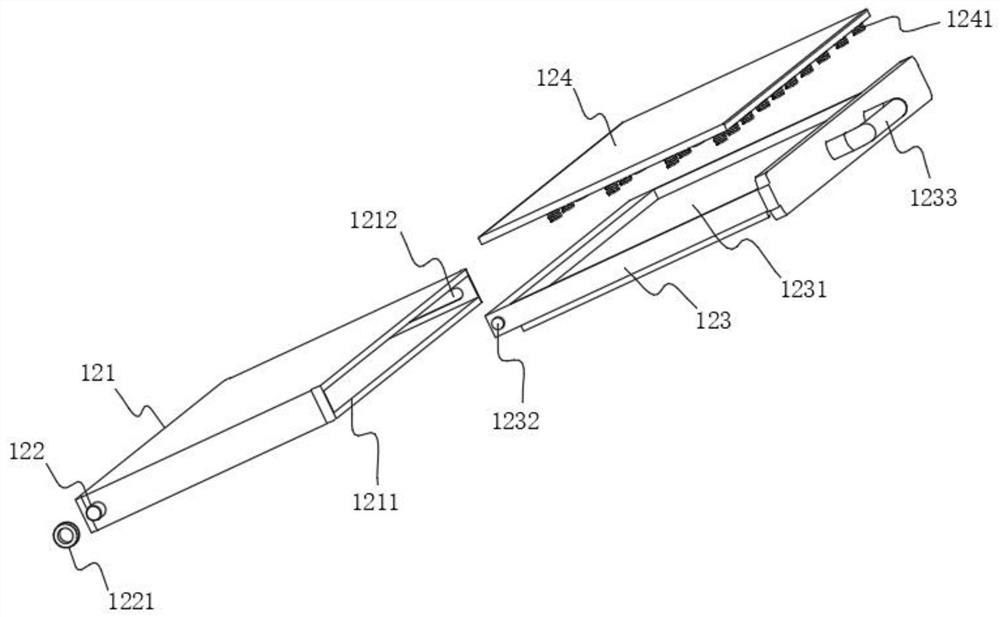

A kind of canopy for charging pile installed in retractable and foldable way

ActiveCN112721682BSolve the problem of reducing the irradiation area of solar panelsAvoid damageCharging stationsGeneral water supply conservationStructural engineeringMechanical engineering

The present invention relates to the technical field of charging piles, in particular to a canopy for charging piles that is retracted and folded. It includes an overturned fluid blocking device and an overturning plate arranged at the bottom of the overturned fluid blocking device to support it. In the present invention, rainwater is blocked by the resistance effect of the storage plate, so as to prevent the rainwater from directly contacting the charging column at the bottom thereof, thereby preventing the solar panel installed outside the solar panel from being damaged due to water ingress, so as to prevent the solar panel for the charging pile from raining. In addition, it is stored through the storage cavity to save the occupied area of the storage board, and at the same time, there is no shelter on the top of the charging pile after storage, so as to provide enough irradiation area for the solar panels installed outside it, and then Solve the problem that the general rain shelter reduces the irradiation area of the solar panel.

Owner:国网安徽省电力有限公司定远县供电公司

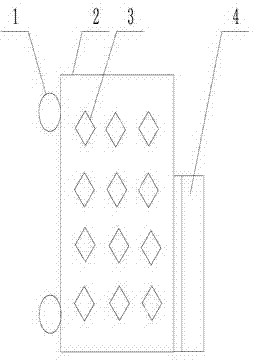

Vehicle brake pedal device

InactiveCN104724087AWith anti-slip effectNot easy to missFoot actuated initiationsAnti-theft devicesEngineeringVehicle brake

The invention discloses a vehicle brake pedal device which comprises a pedal body. Rhombus convex anti-skid stripes are distributed on the top of the pedal body, the left side of the pedal body is provided with a hanging ring, the right side of the pedal body is provided with a guide plate whose section is L-shaped, and the plane of the top of the guide plate and that of the pedal body are located on the same plane. The vehicle brake pedal device is simple in structure, easy to realize, and capable of having the anti-skid and theft-proof functions due to the arrangement of the hanging ring and the rhombus convex anti-skid stripes, solving the problems that the feet of a driver skids into the space below the brake pedal when stepping on the brake and the vehicle cannot stop in time and improving the safety during driving.

Owner:李学军

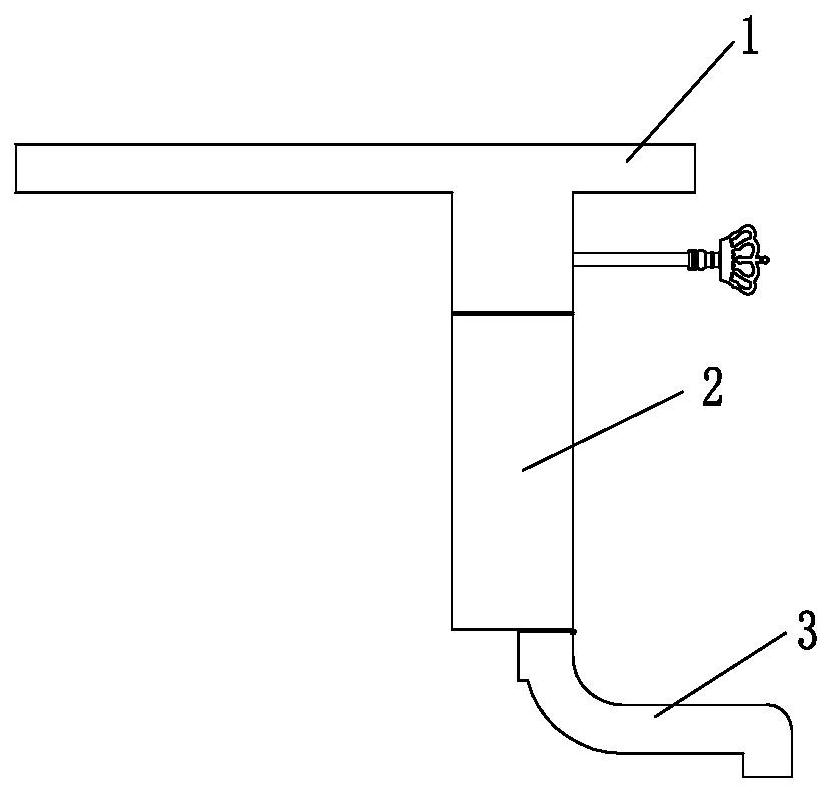

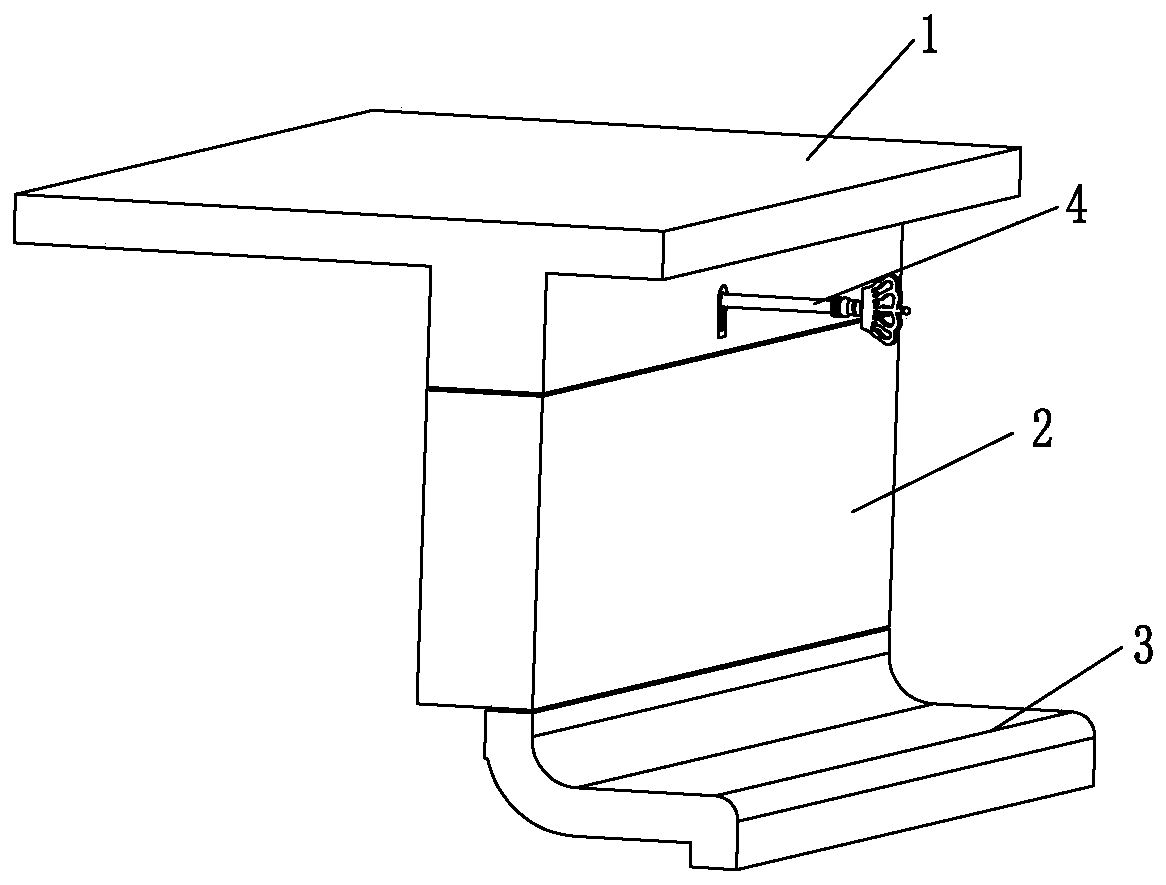

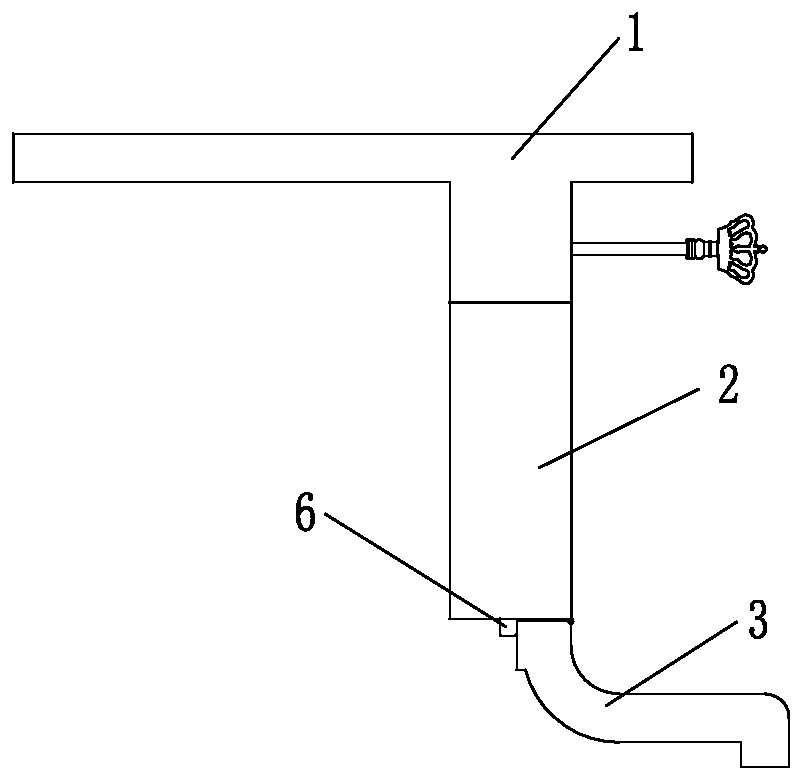

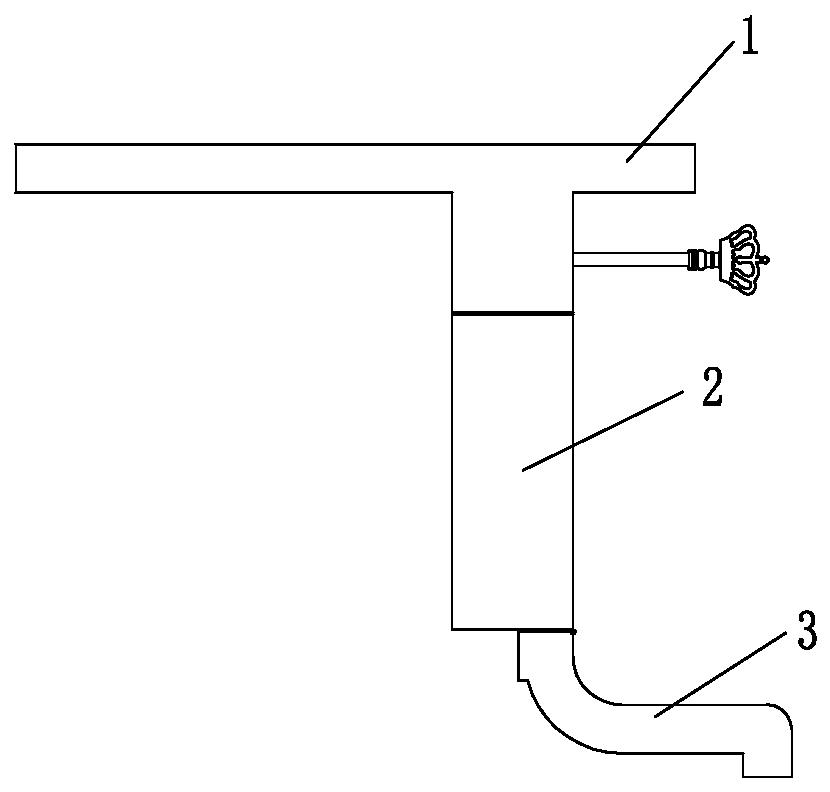

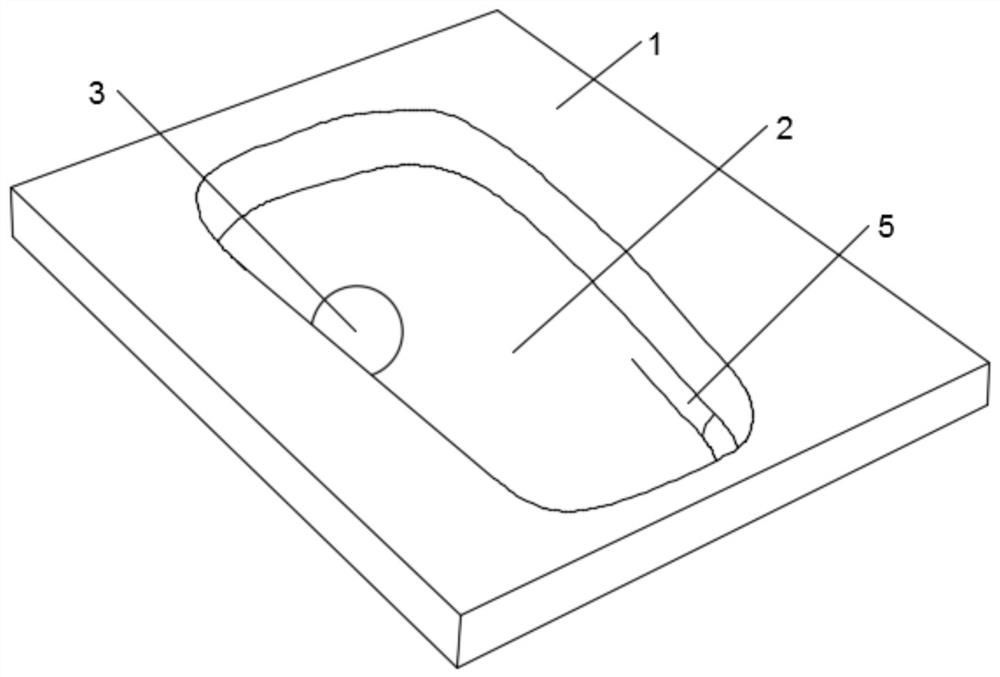

Squatting pan

PendingCN113374048AAvoid sliding inRush in easilyWater closetsFlushing devicesEngineeringMechanical engineering

The invention relates to the technical field of squatting pans, in particular to a squatting pan which comprises a squatting pan body and further comprises an excrement cavity formed in the squatting pan body and a sewage draining hole formed in one end of the squatting pan body, wherein the sewage draining hole is communicated with the excrement cavity; large washing holes evenly formed in the end, away from the sewage discharging hole, of the squatting pan body in a communicating mode, wherein the large washing holes are all communicated with the excrement cavity; washing water guiding holes evenly and symmetrically formed in the two sides of the end, away from the sewage discharging hole, of the squatting pan body, wherein the washing water guiding holes are all communicated with the squatting pan body; and drainage grooves uniformly and symmetrically formed in two sides of one end, far away from the sewage discharging holes, of the squatting pan body. According to the invention, the squatting pan is provided with the large washing holes and the washing water guide holes, so sufficient strength and speeds can be realized when water flushes the excrement cavities and the water sprayed from the large washing holes and the washing water guide holes can form higher water coverage. Therefore, the excrement in the excrement cavity can be flushed into the pollution discharge hole.

Owner:开平金牌洁具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com