Hog house cement dropping board demolding device

A demoulding device, cement technology, applied in unloading devices, animal houses, manufacturing tools, etc., can solve the problems of easy injury, time-consuming and labor-intensive, and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

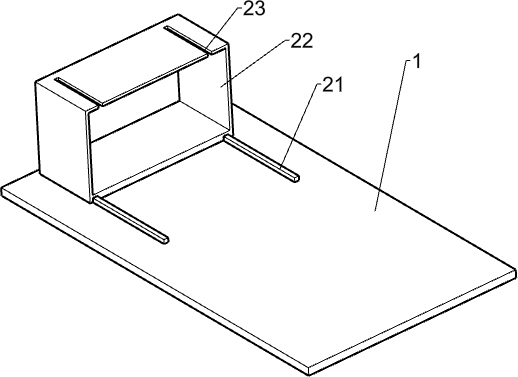

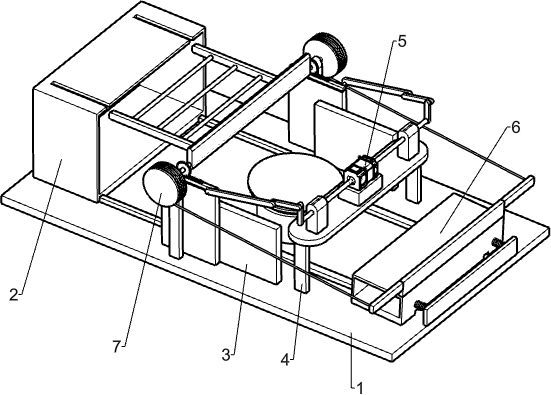

[0024] A demoulding device for pig house cement manure board, such as figure 1 As shown, it includes a base 1, a placement mechanism 2, a baffle 3, a mounting frame 4, and a rotating mechanism 5. The placement mechanism 2 is slidably connected to the left side of the top of the base 1, and baffles 3 are provided on both the front and rear sides of the top, middle , The top right side of the base 1 is provided with a mounting frame 4, and the mounting frame 4 is located on the right side of the baffle 3, a rotating mechanism 5 is connected between the mounting frame 4 and the top left and right of the base 1, and the rotating mechanism 5 is located on the right of the placing mechanism 2. On the other hand, when the pig house concrete manure board needs to be demolded, the staff first places the pig house cement manure board that needs to be demolded on the placement mechanism 2, and then pushes the placement mechanism 2 to the right by hand to drive the cement manure board toward...

Embodiment 2

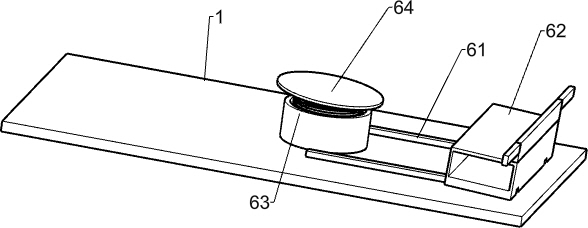

[0028] On the basis of Example 1, such as Figure 4 As shown, a buffer mechanism 6 is also included. The top right side of the base 1 is provided with a buffer mechanism 6. The buffer mechanism 6 includes a third slide rail 61, a collecting plate 62, a circular frame 63 and an inclined plate 64. The top right side of the base 1 The front and rear third slide rails 61 are provided with a collecting plate 62 slidably connected between the front and rear third slide rails 61, a circular frame 63 is provided in the middle of the top of the base 1, and the circular frame 63 is located inside the front and rear baffles 3, The inner wall of the circular frame 63 is connected with an inclined plate 64 through a spring. When the demoulded pig house concrete manure board falls down on the inclined plate 64 under the action of gravity, the inclined plate 64 moves downward by gravity, so that the spring is Compressed, it has a certain buffering effect on the fallen pig house cement manure b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com