Patents

Literature

51results about How to "Avoid package failure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

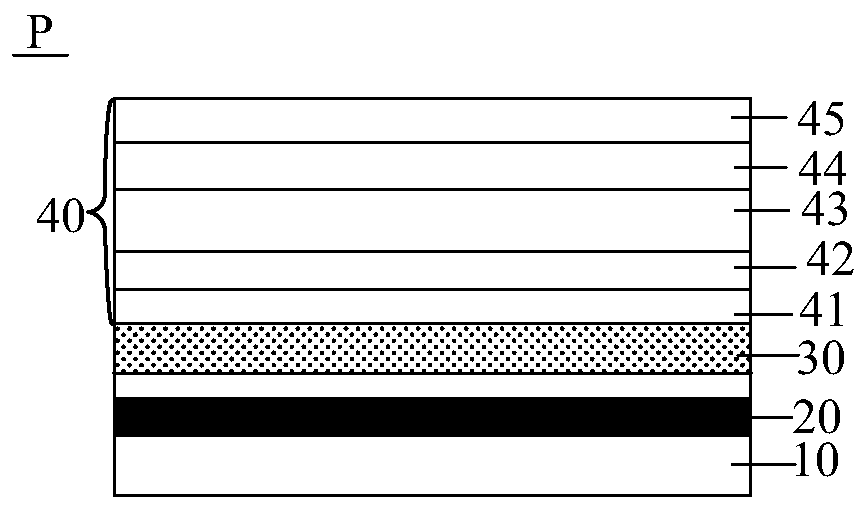

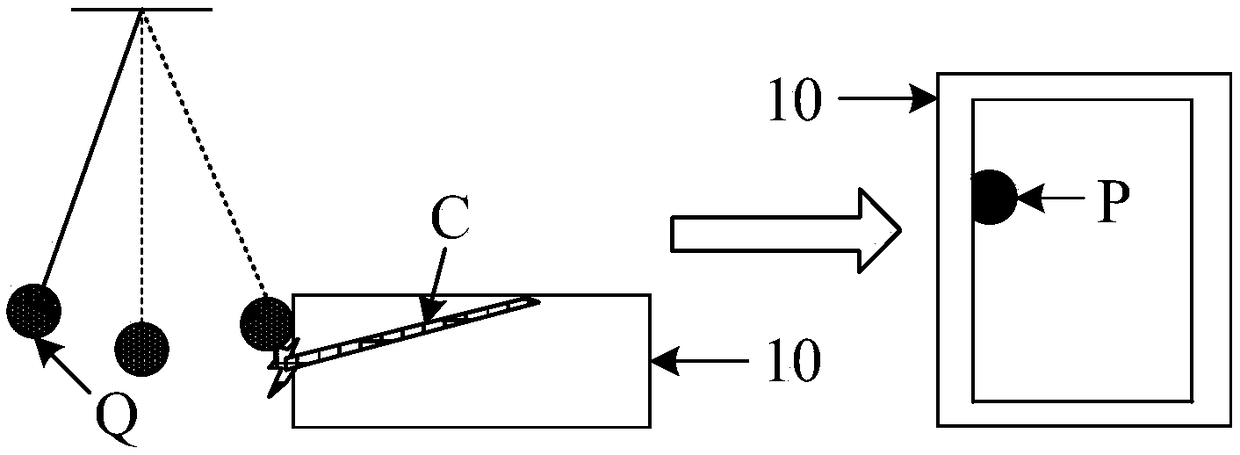

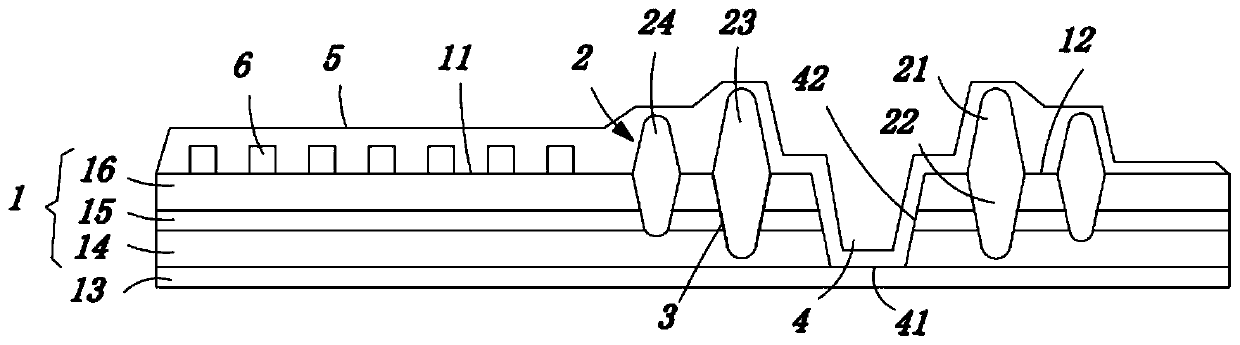

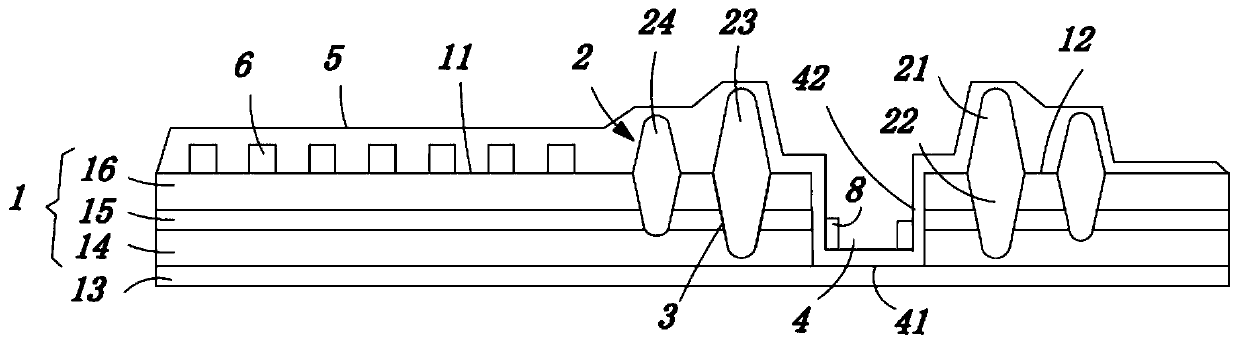

Display panel and display device

ActiveCN109659444AImprove bending resistanceFlexibleSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

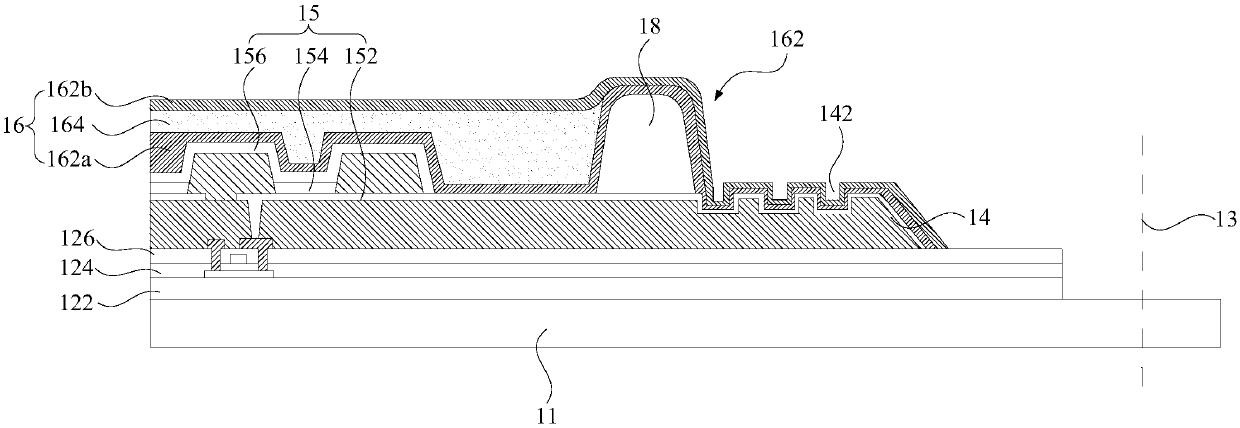

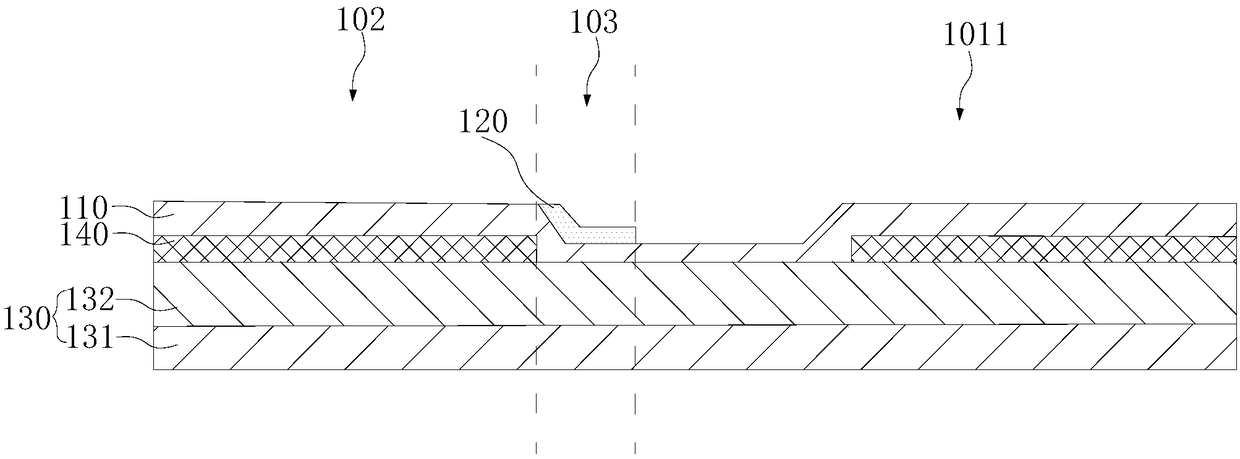

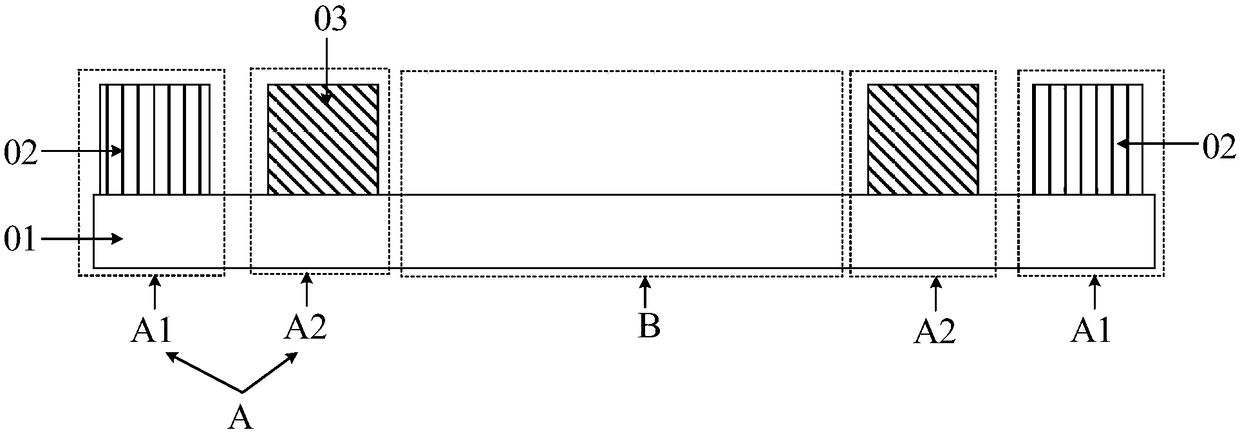

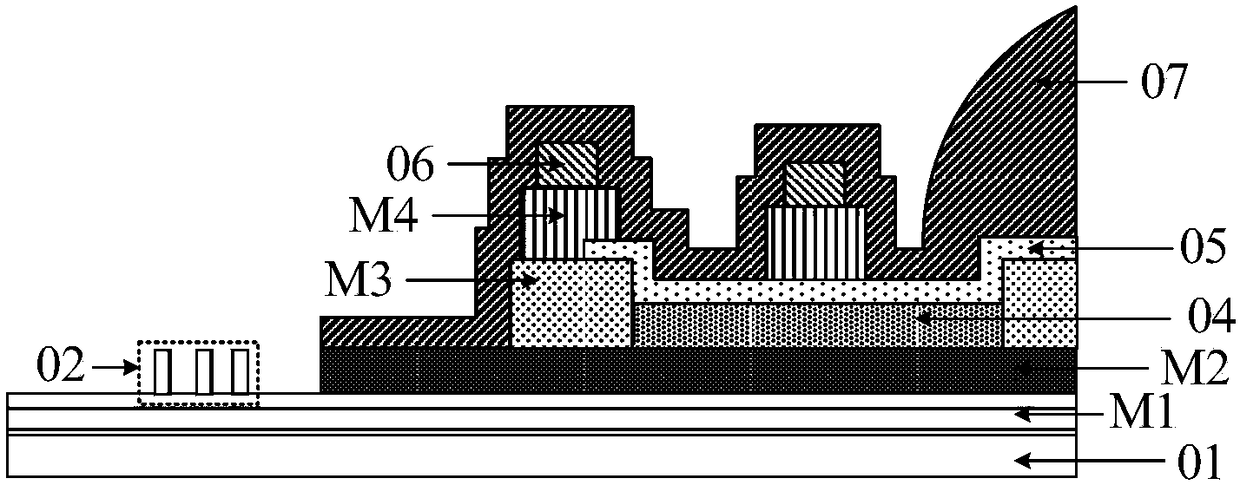

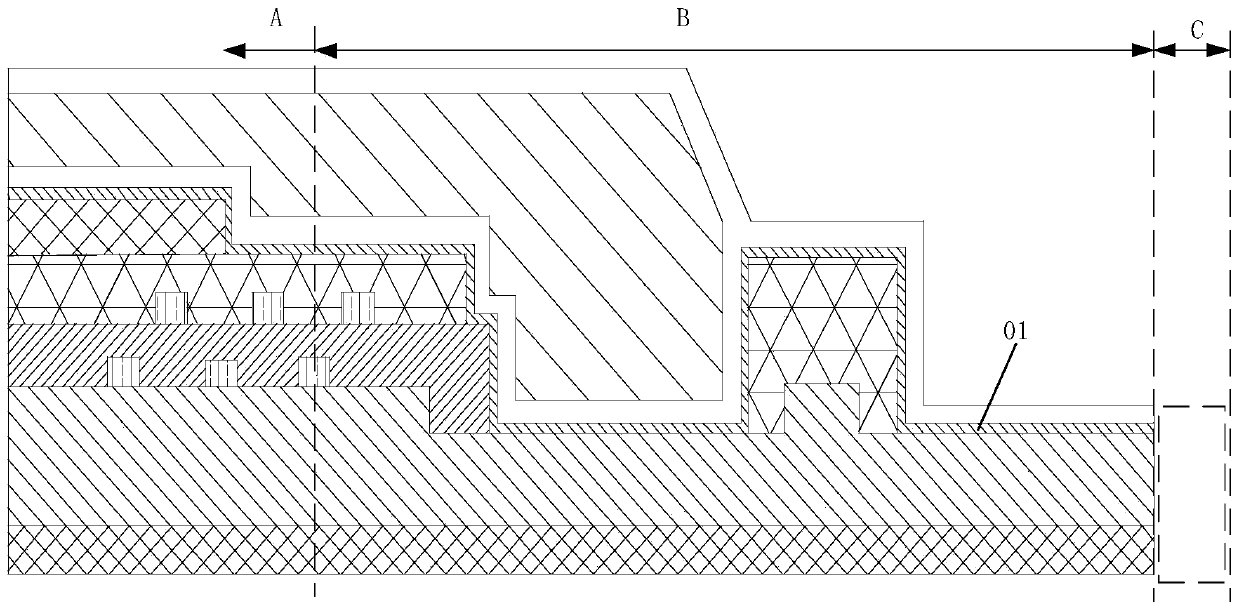

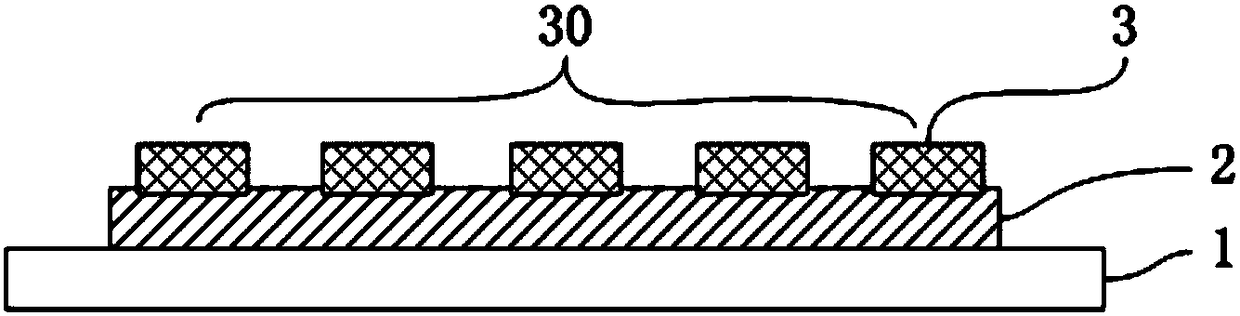

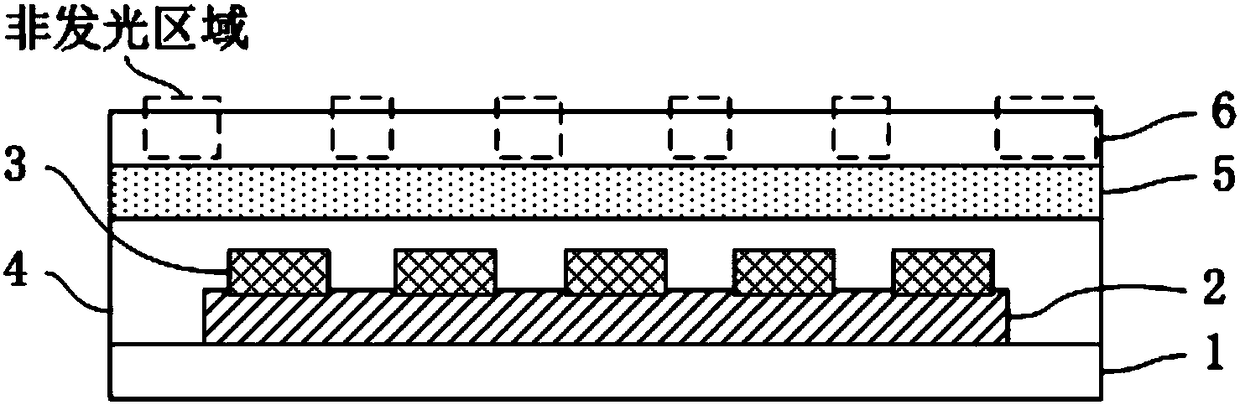

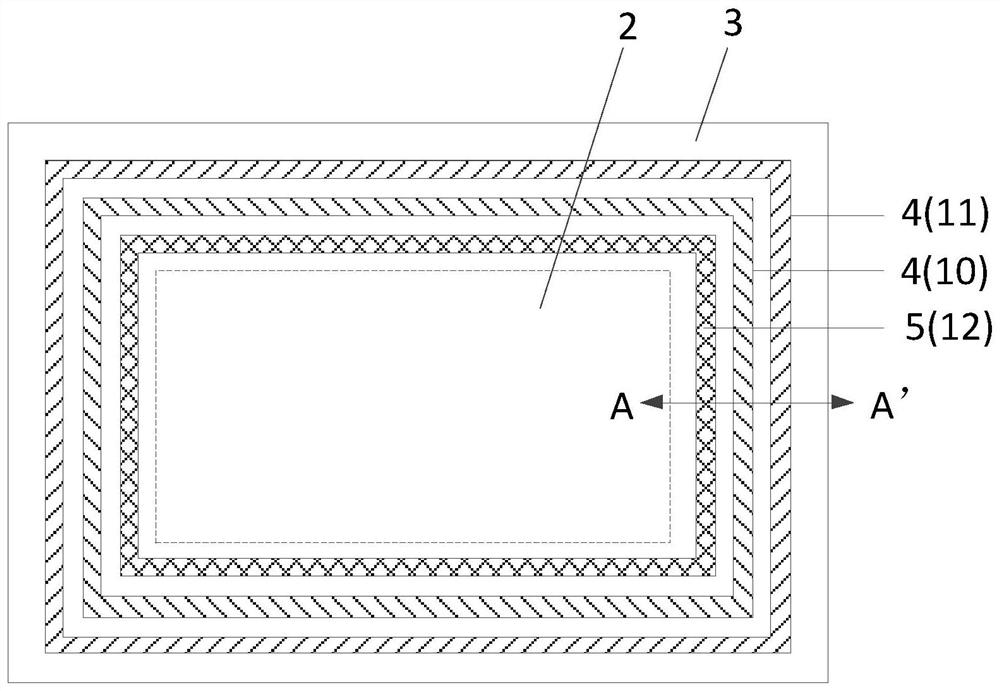

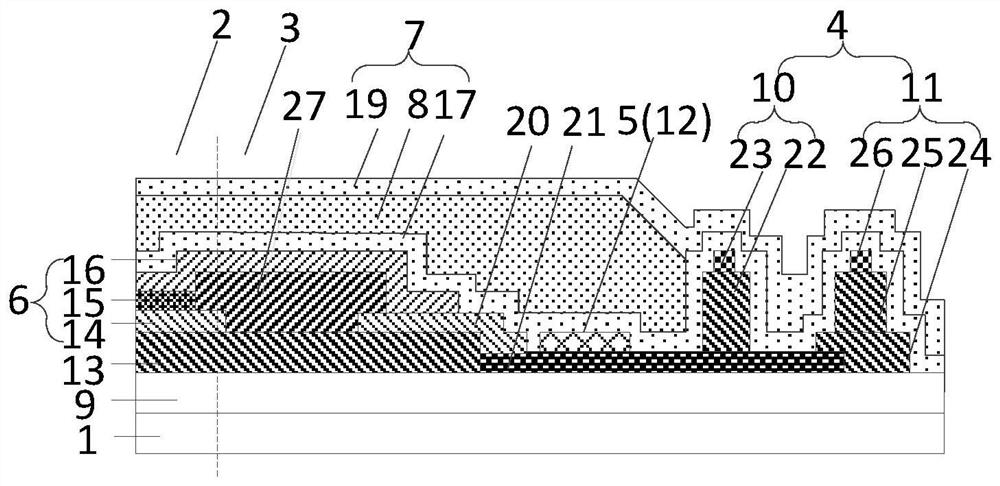

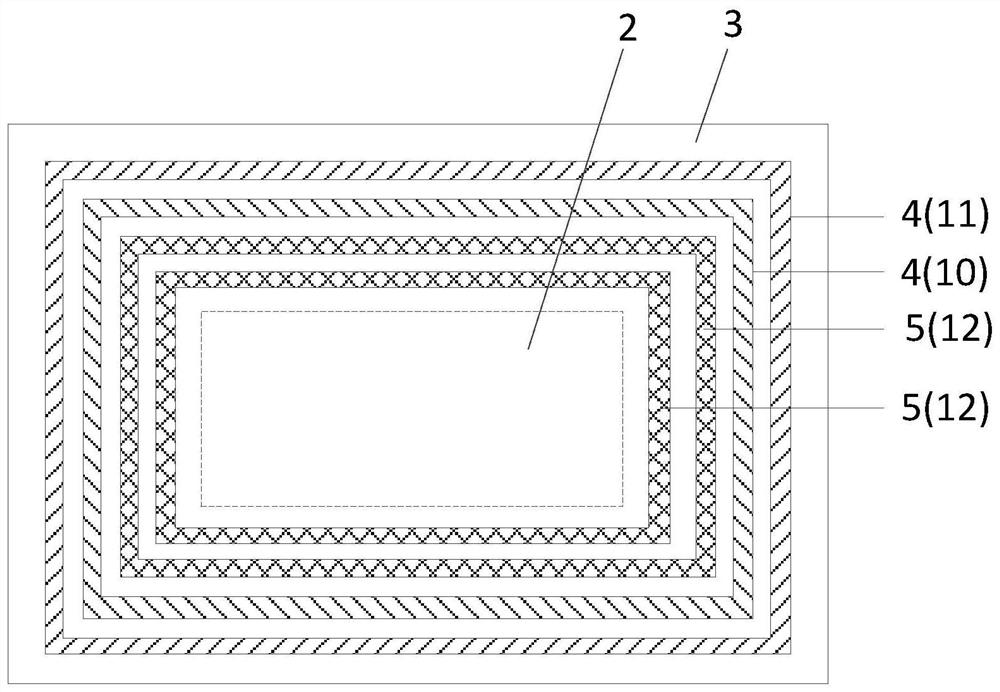

The present invention relates to a display panel. The display panel comprises a substrate, a planarization layer, a light-emitting element and a package structure. The substrate has a display area anda non-display area; the planarization layer is disposed on the substrate to form a planarization surface; the light-emitting element is disposed on the planarization layer; the package structure is disposed on the light-emitting element and the planarization layer; the package structure includes a plurality of inorganic encapsulation film layers; the planarization layer includes a central portioncovering the display area and is extended to the peripheral portion of the non-display area; and the inorganic encapsulation film layers are configured to be in contact with the peripheral portion ofthe planarization layer at the non-display area. The planarization layer has a certain flexibility, can have an effect on releasing of stress and can facilitate reduction of the stress of the inorganic encapsulation film layers of the package structure at the package boundary so as to effectively prevent the inorganic encapsulation film layers from generating cracks, improve the package reliability of the package structure and improve the anti-bending performance of the display panel. The present invention further provides a display device.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

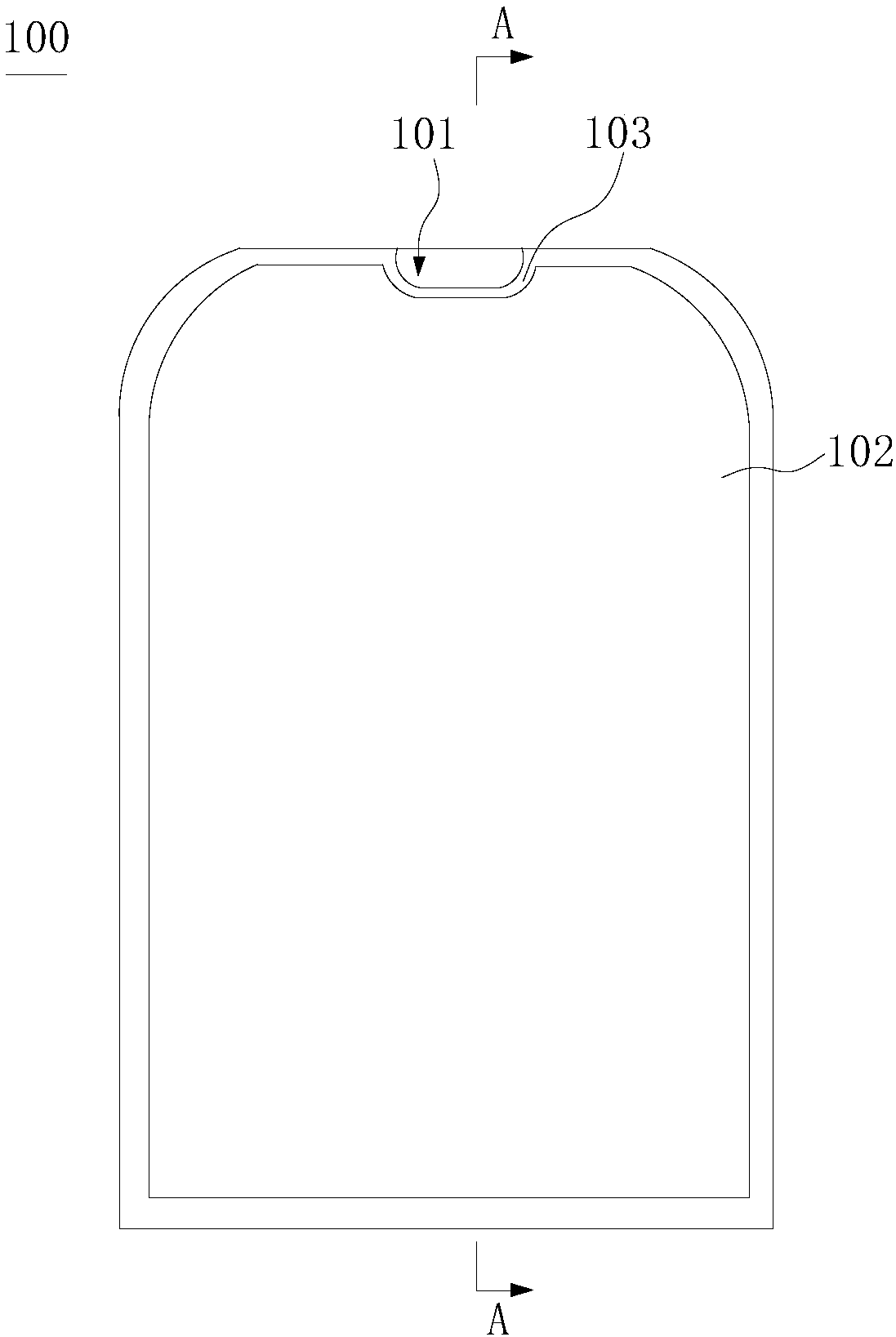

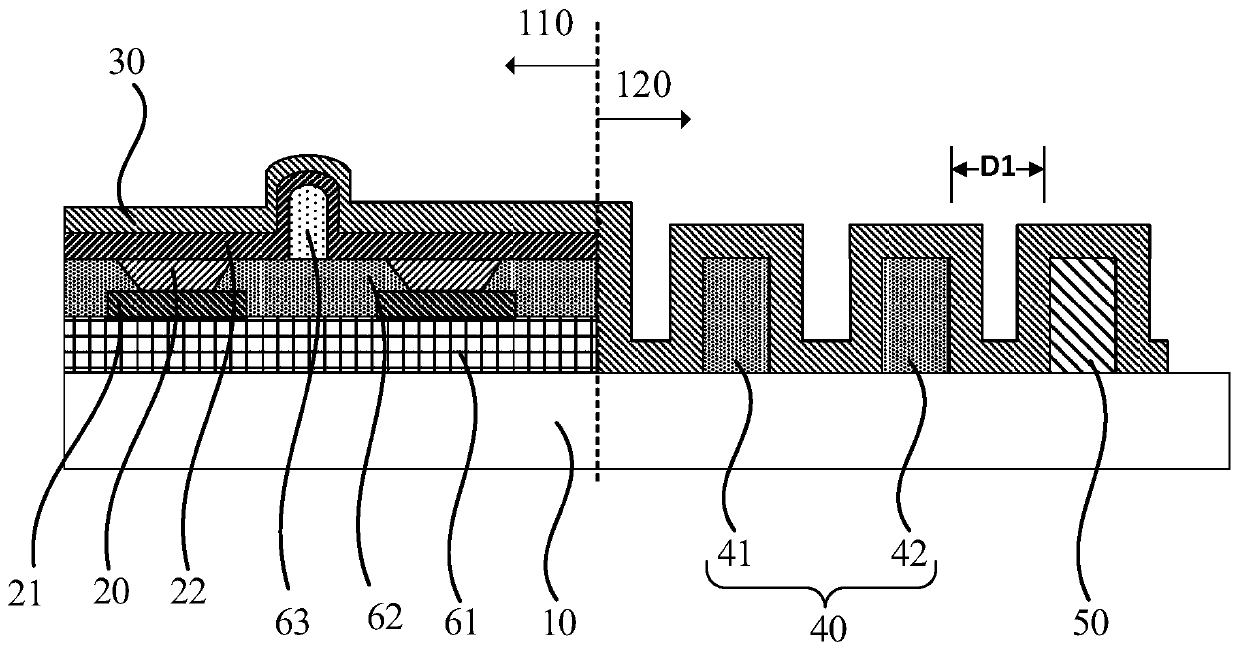

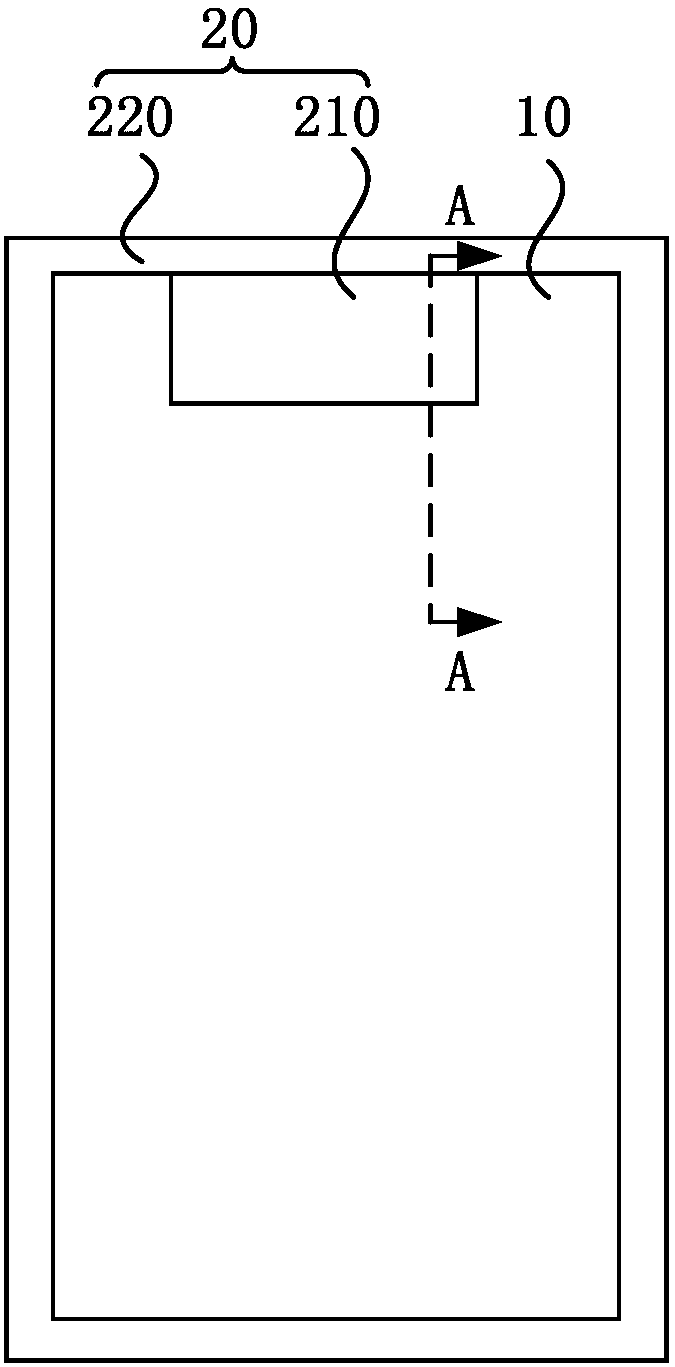

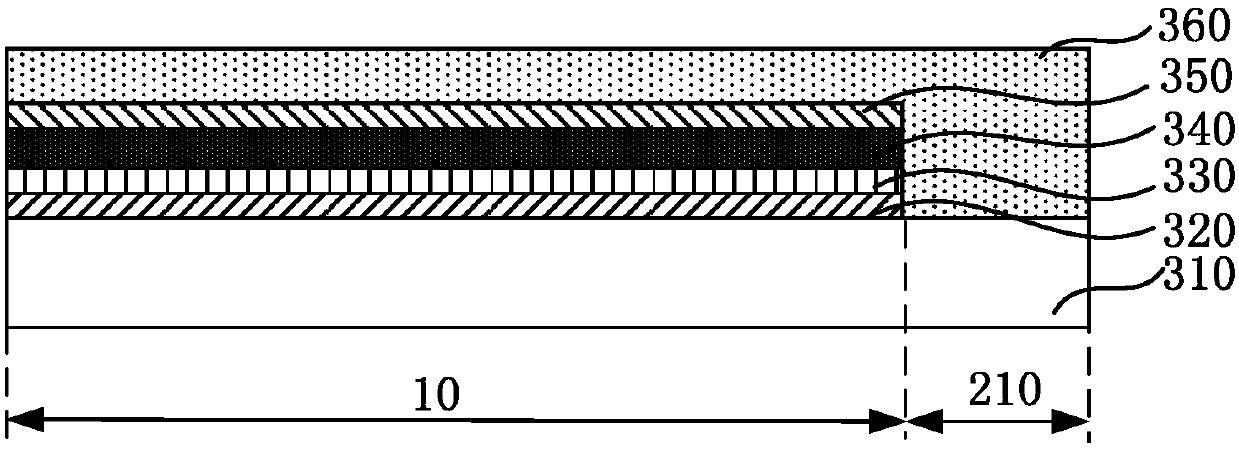

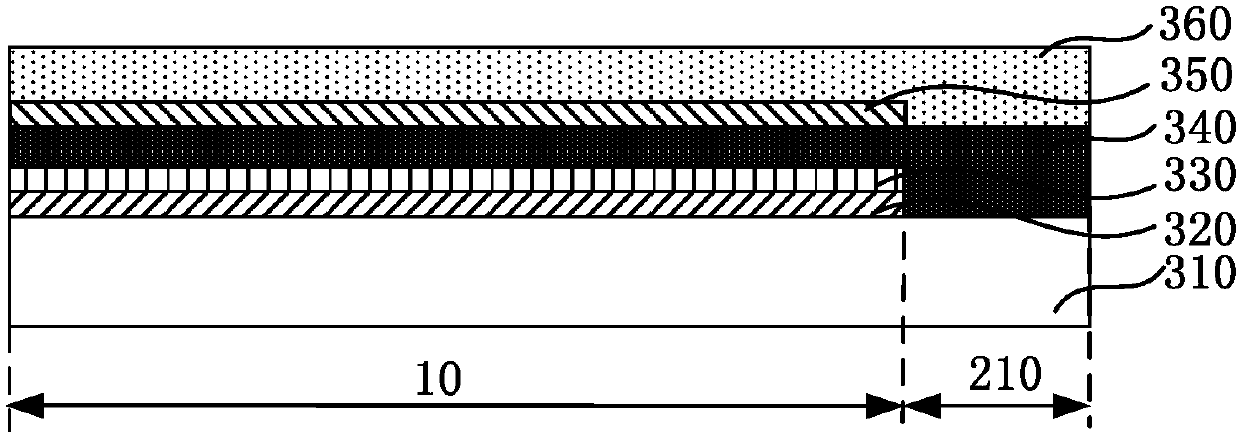

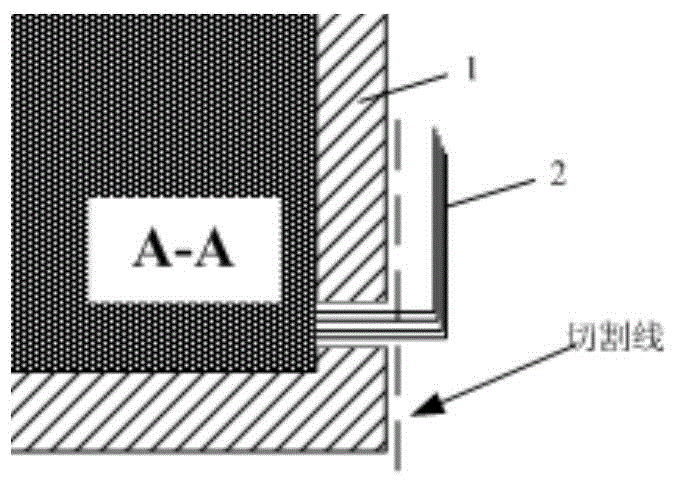

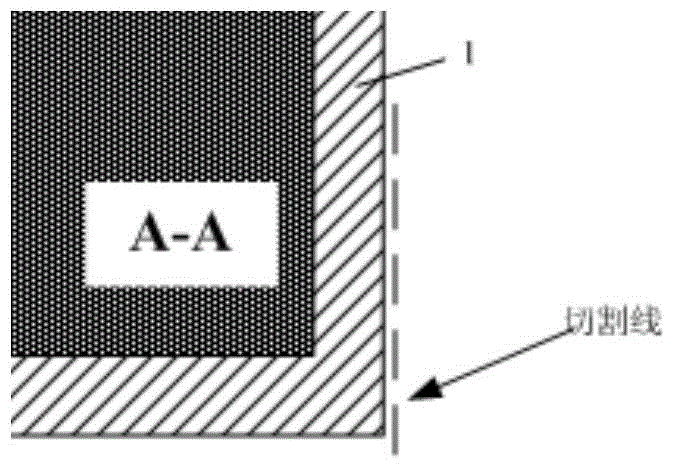

Display panel, manufacture method thereof and display terminal

ActiveCN108417733AImprove production yieldAvoid damageSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLaser cutting

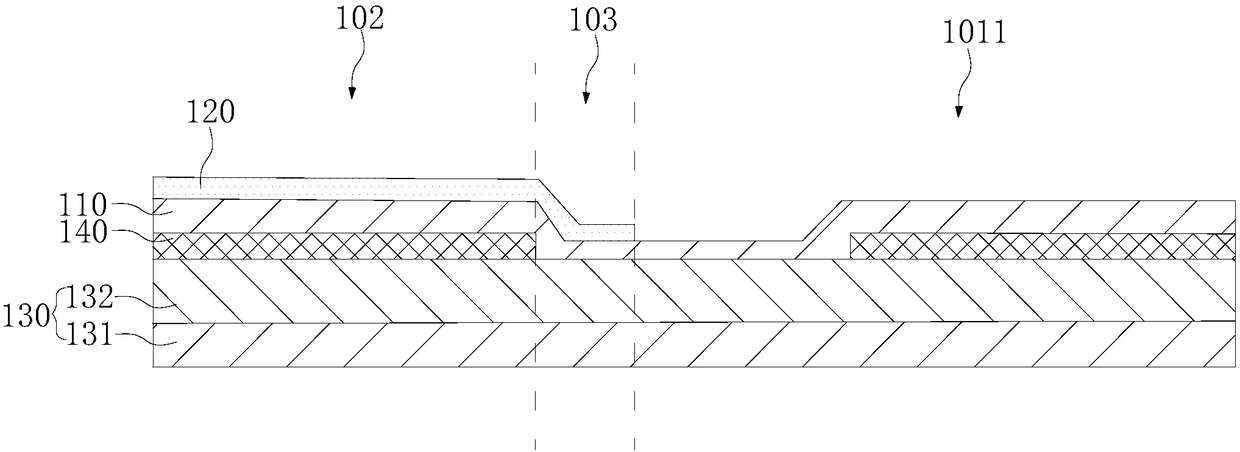

The invention discloses a display panel, a manufacture method thereof and a display terminal. The display panel is provided with a notch and includes a display region; the notch is positioned outsidethe display region; the display panel also includes a film packaging structure and a heat-insulating film layer; the film packaging structure at least covers the display region; the heat-insulating film layer is arranged on the display panel with the film packaging structure and is close to the notch. The display panel is provided with the heat-insulating film layer on the film packaging structureclose to the notch, and therefore, during the process of forming the notch by laser cutting, the heat-insulating film layer can prevent laser heat from being transmitted to the film packaging structure and the display region, damage to the film packaging structure and display region pixels due to laser cutting heat is further decreased, packaging failure caused by the damage is avoided, the damage problem is avoided for the film and substrate, and packaging reliability and display panel yield are increased.

Owner:YUNGU GUAN TECH CO LTD

Display panel, preparation method thereof and display device

ActiveCN109742133AReduce depositionInhibit sheddingSolid-state devicesSemiconductor/solid-state device manufacturingPunchingEvaporation

The invention relates to the technical field of a display device and particularly relates to a display panel, a preparation method thereof and the display device. The display panel comprises a base plate, wherein the base plate comprises a display area and a non-display area. A plurality of organic electroluminescent structures are set in the display area. At least one blocking dam and a punchingarea are set in the non-display area. The blocking dam is set between the display area and the punching area. At least one sunken part is set on a side wall of the blocking dam. The sunken part is setat one side of the blocking dam adjacent to the punching area. According to the display panel, the preparation method thereof and the display device, the at least one sunken part is set on the side wall of the blocking dam, an organic material deposited on the side wall of the blocking dam when evaporation is carried out is reduced, and packaging failure resulting from particle fall-off due to heat radiation when laser punching is carried out is avoided.

Owner:YUNGU GUAN TECH CO LTD

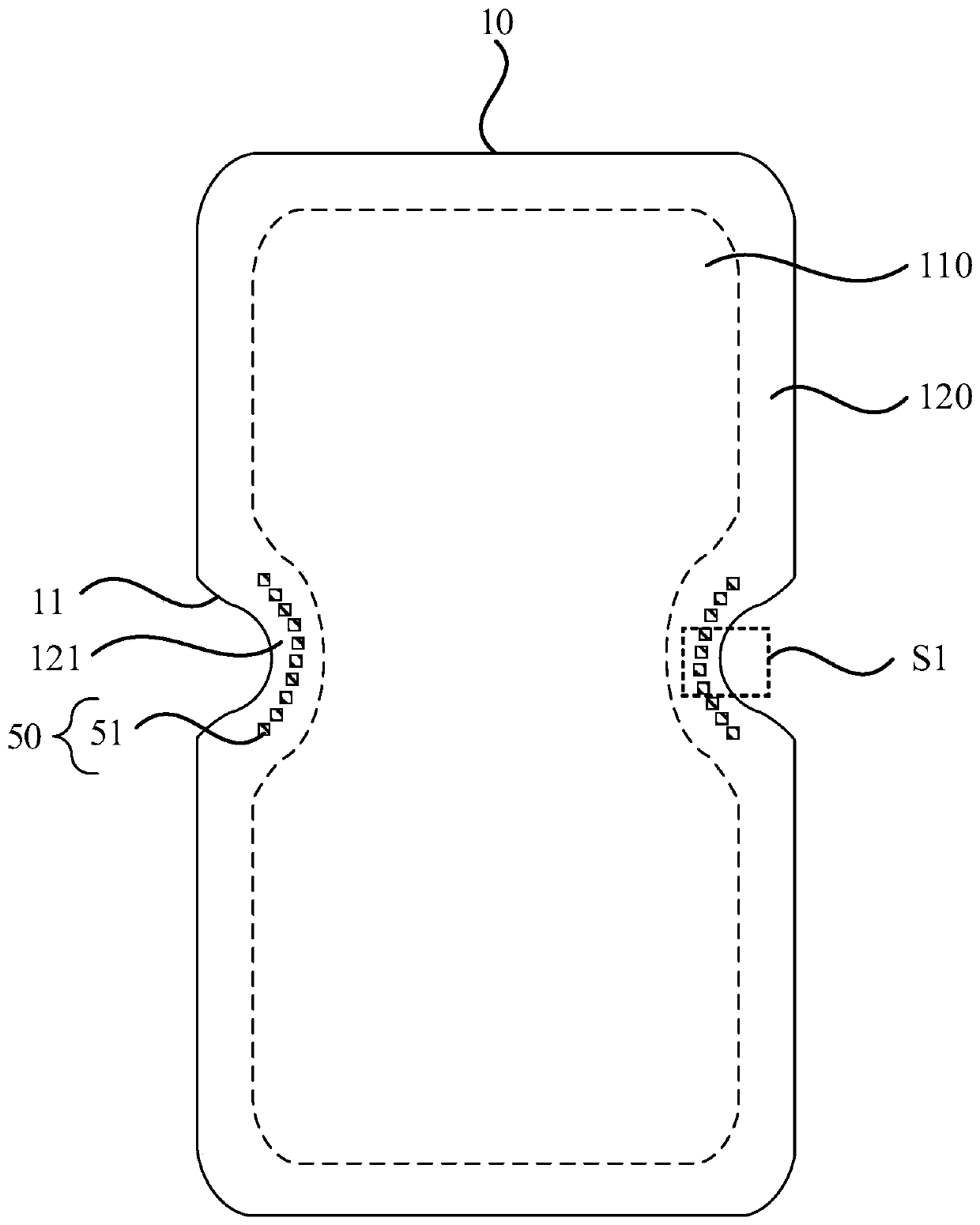

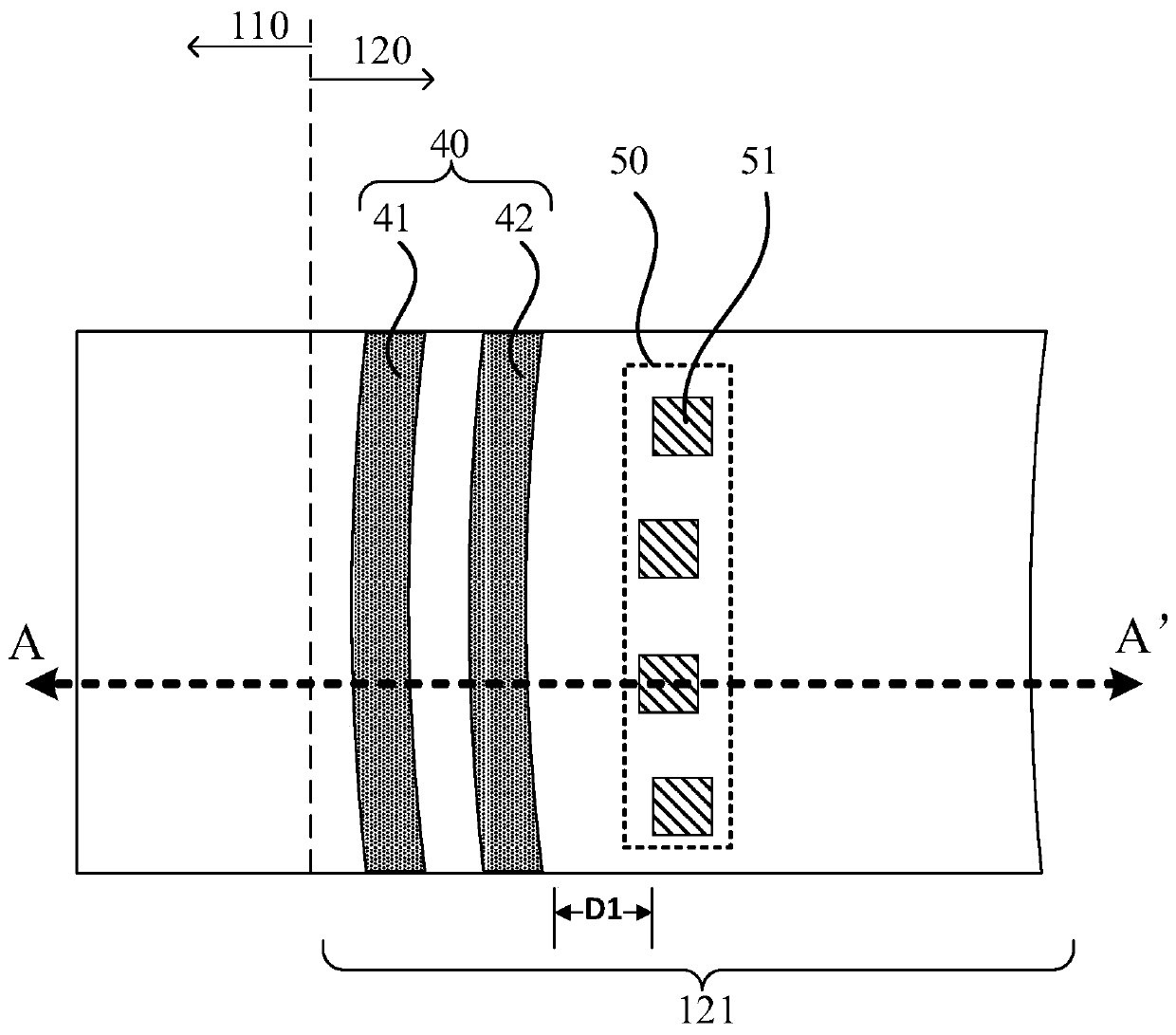

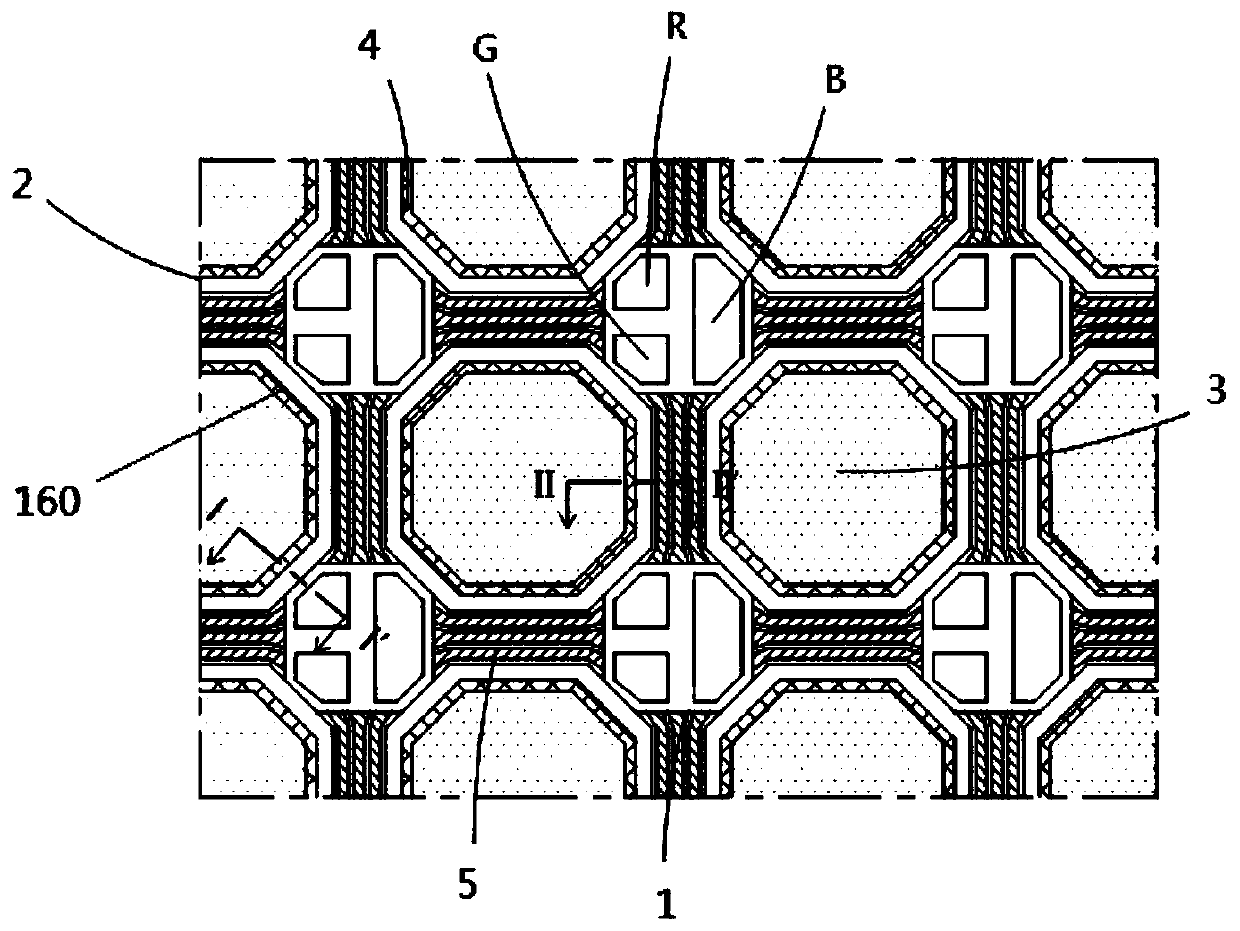

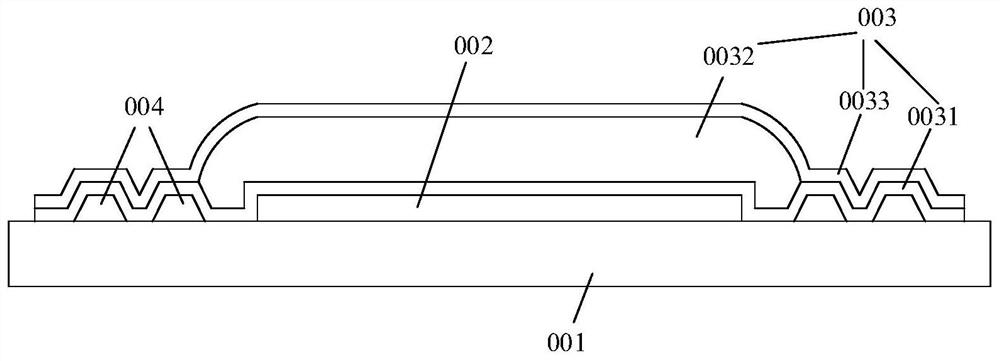

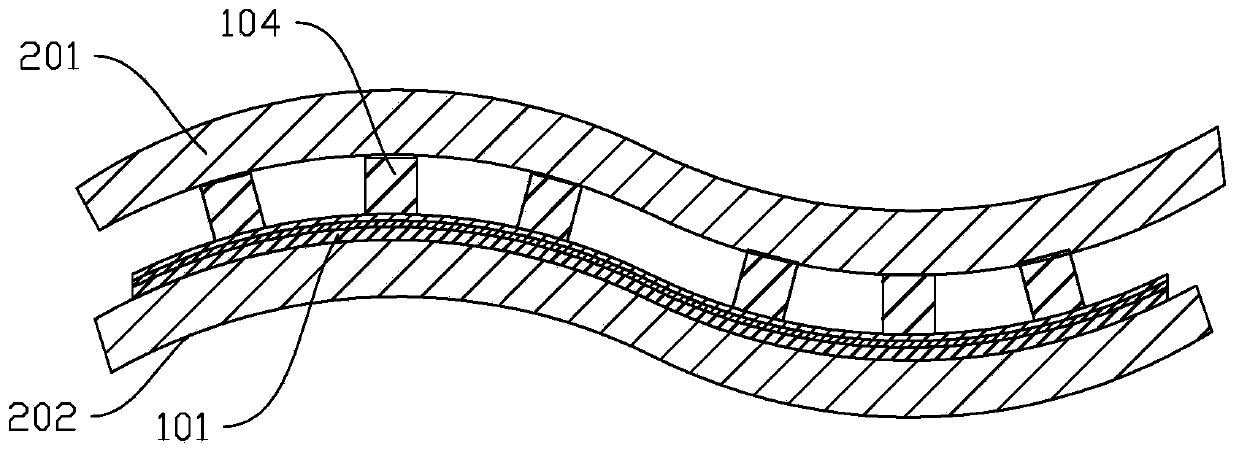

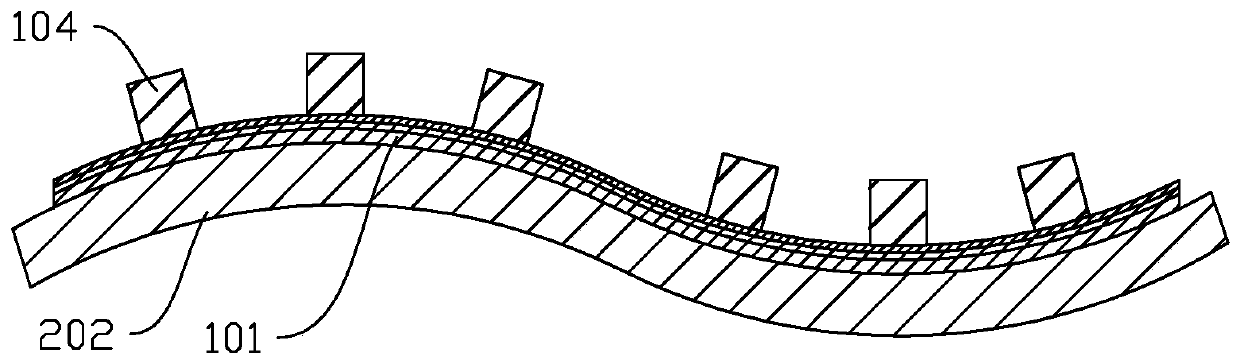

Flexible display substrate and flexible display device

ActiveCN109830614AImprove reliabilityAvoid package failureSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringFlexible display

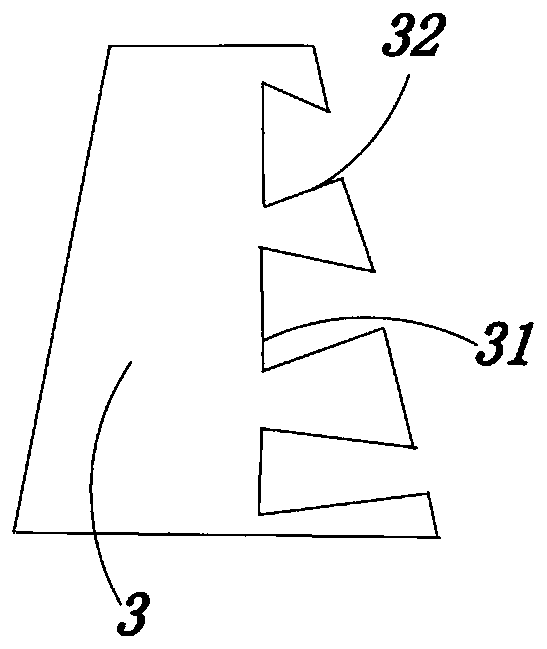

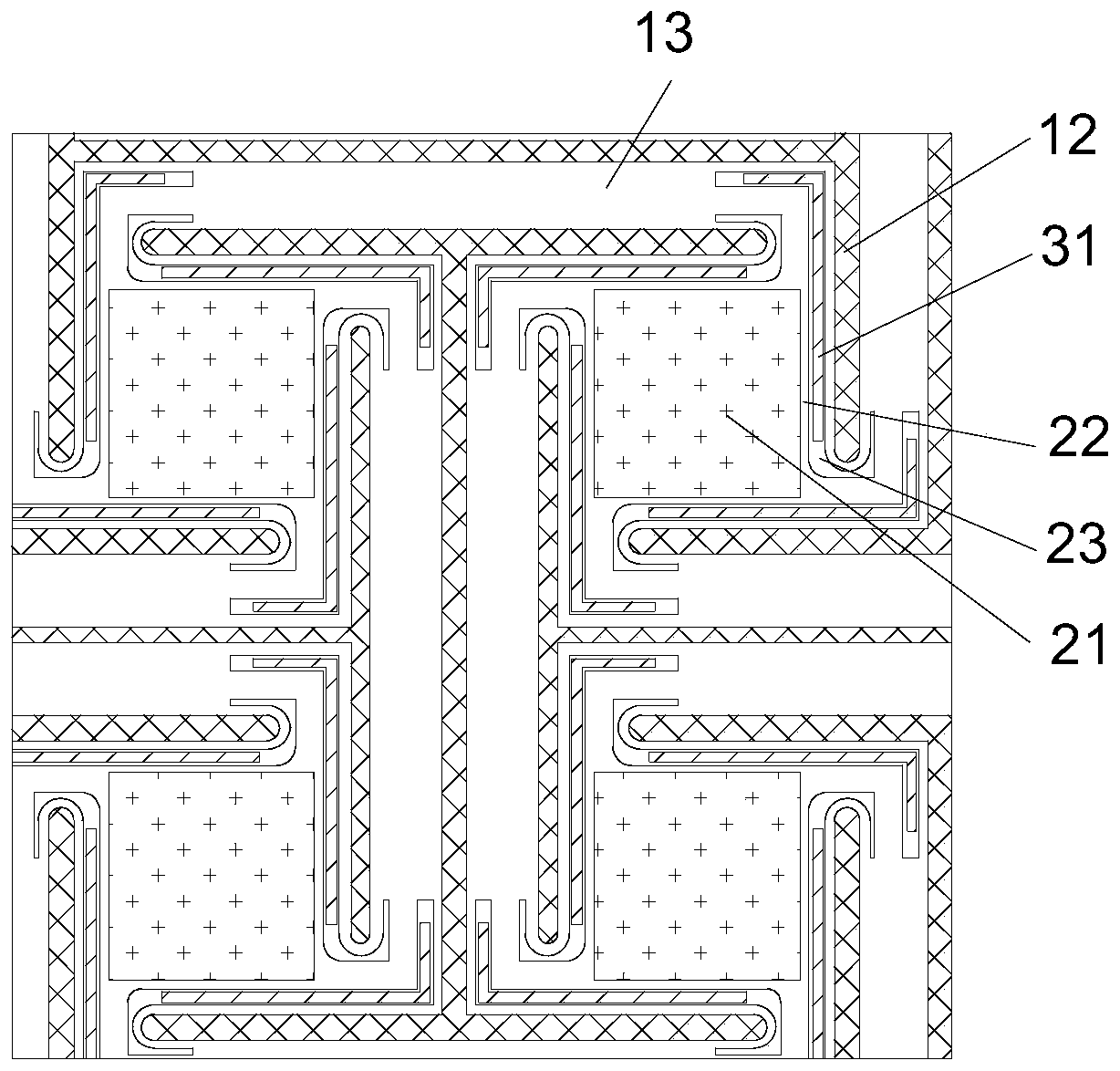

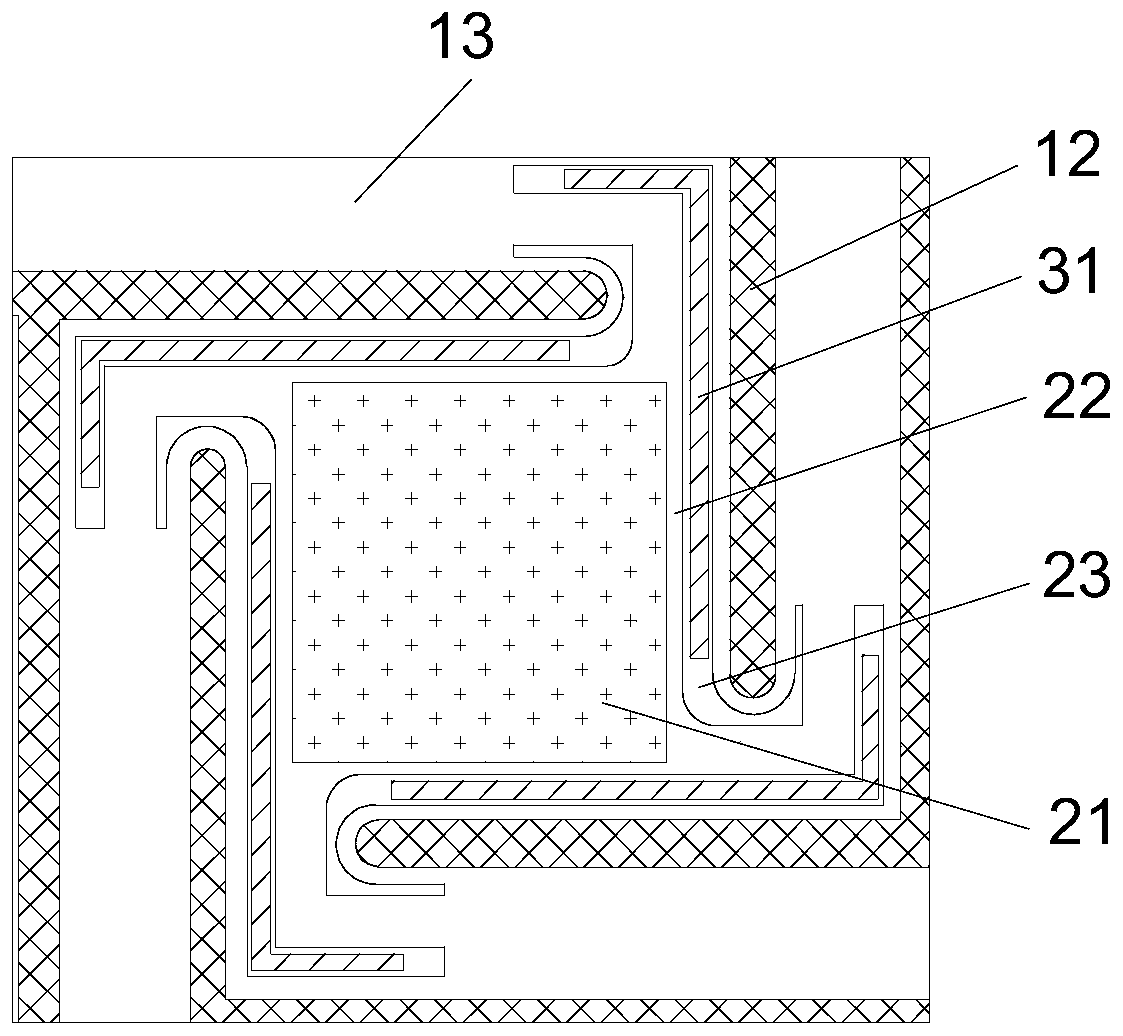

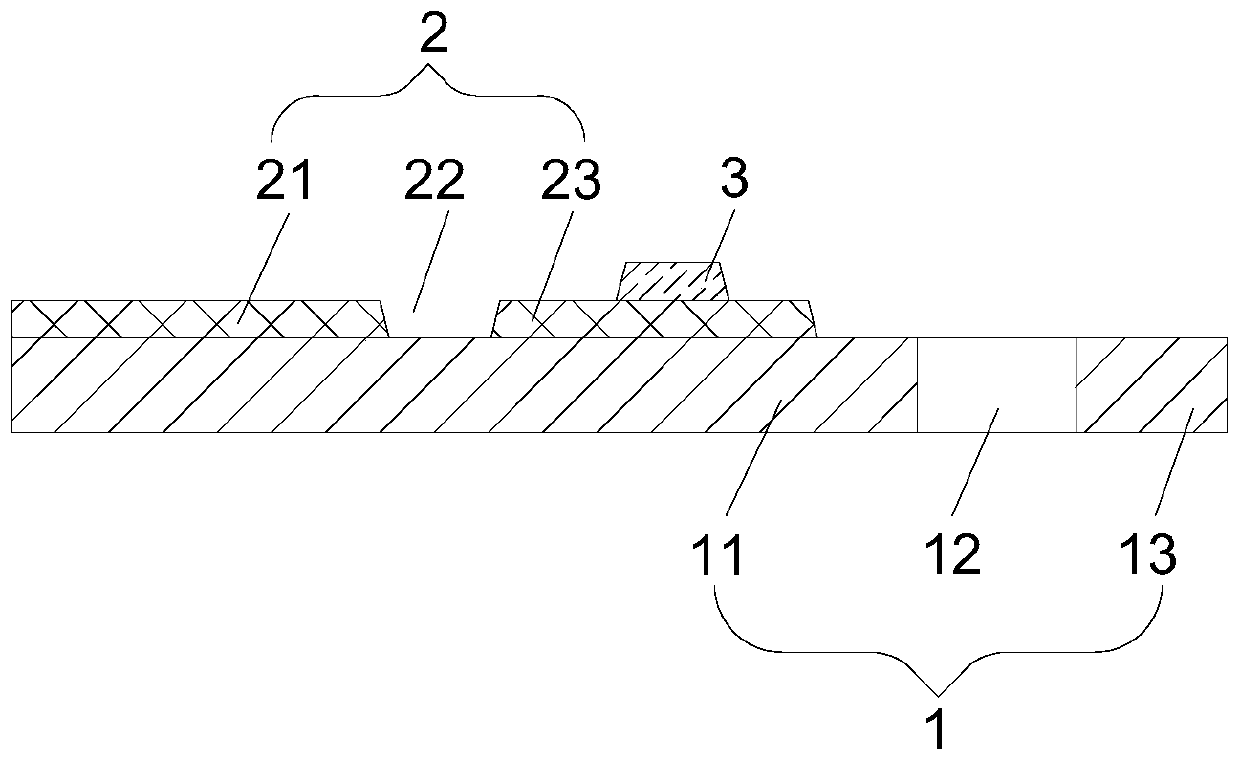

The present disclosure relates to a flexible display substrate and a flexible display device. The flexible display substrate includes a flexible substrate and a pixel layer. The flexible substrate includes a plurality of opening regions and a plurality of island regions and bridge regions divided by the plurality of the opening regions. The pixel layer includes a plurality of display units which are disposed in the respective island regions one to one. Each of the display units is provided with a first groove. The first groove divides the display unit into a display portion and a dam portion.At least a part of the dam portion is located between the display portion and the bridge region adjacent to the display portion. The flexible display substrate provided by the present disclosure can improve the product packaging reliability.

Owner:BOE TECH GRP CO LTD

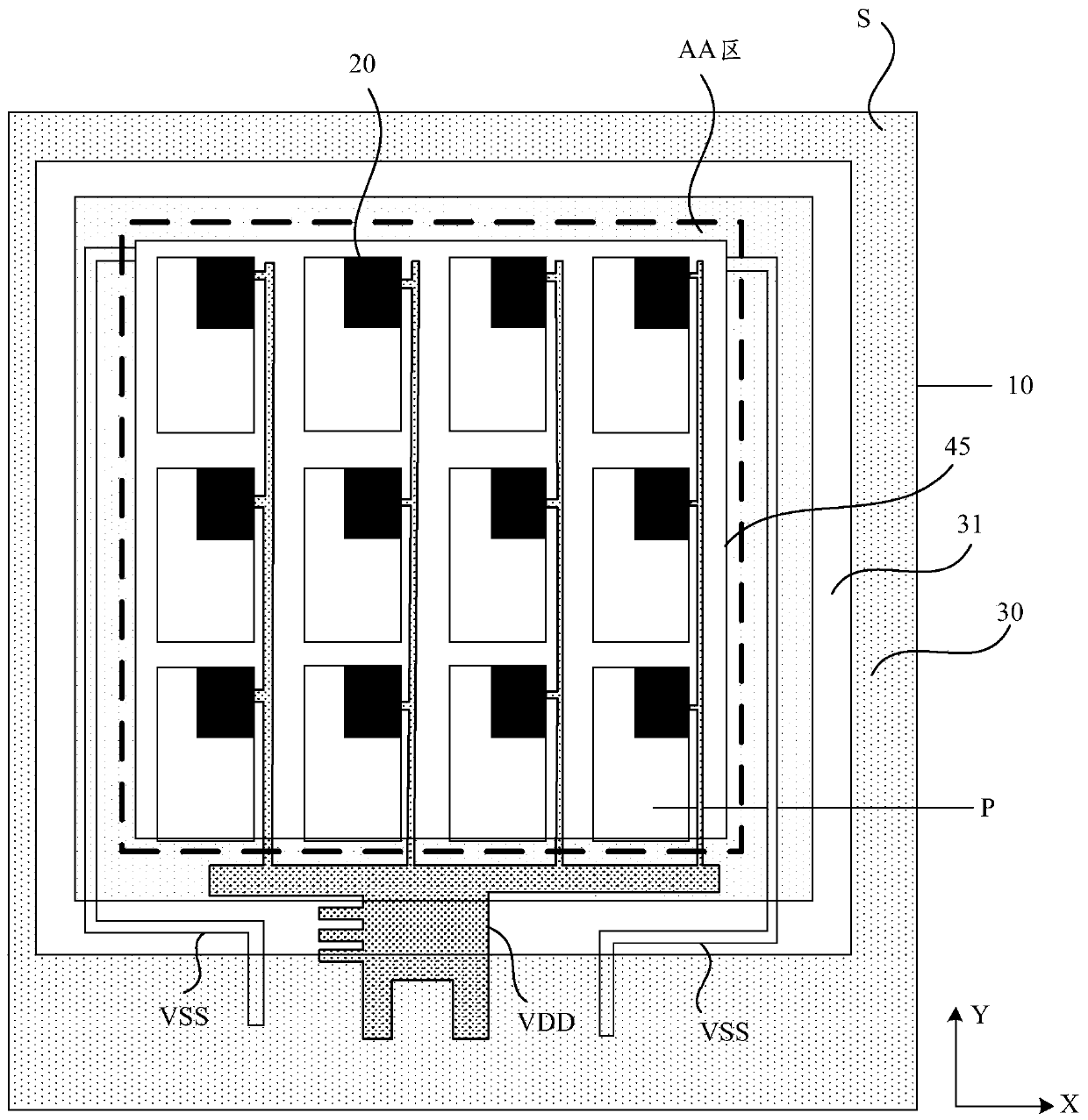

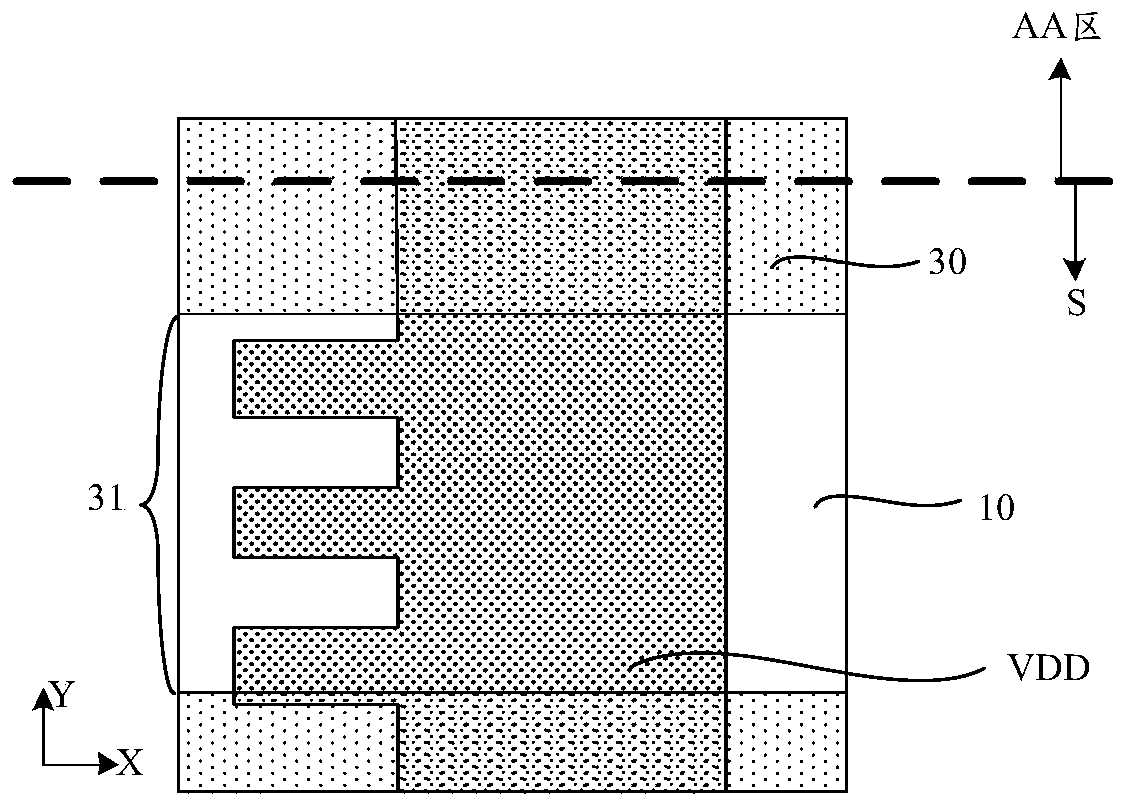

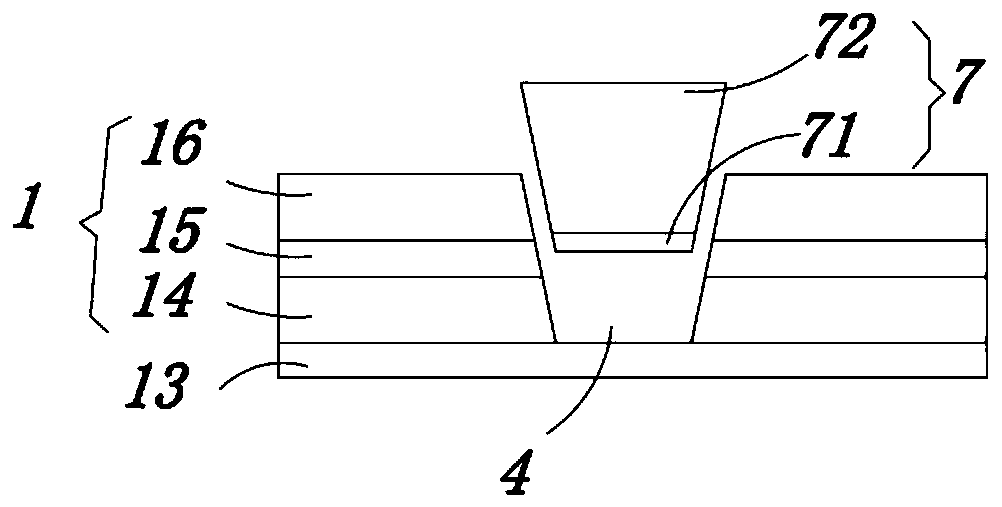

Display panel and display device

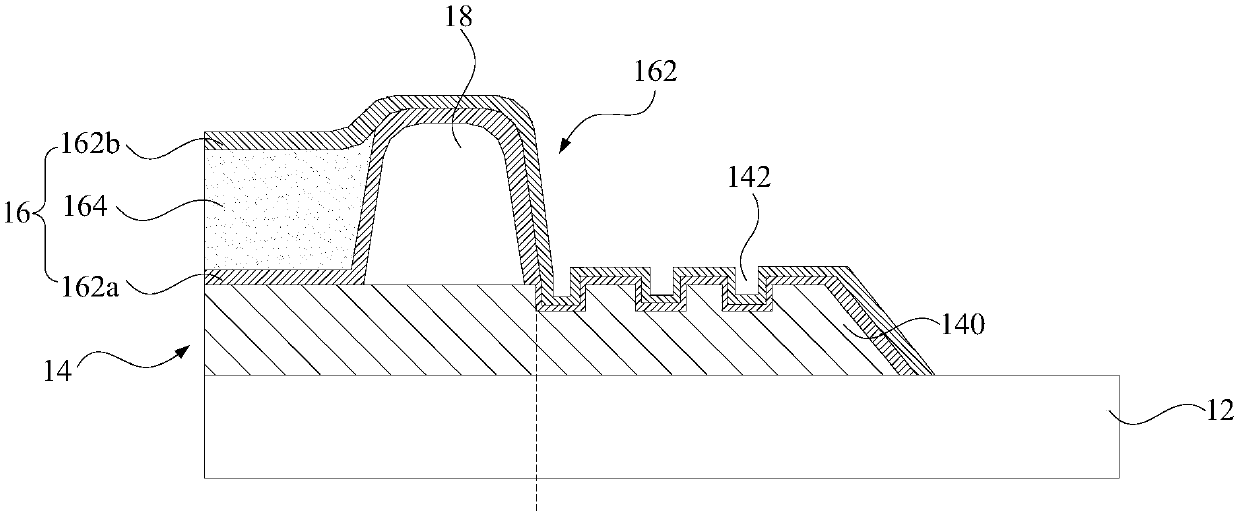

ActiveCN110767731AReduce erosionIncrease side lengthSolid-state devicesSemiconductor devicesDisplay deviceHemt circuits

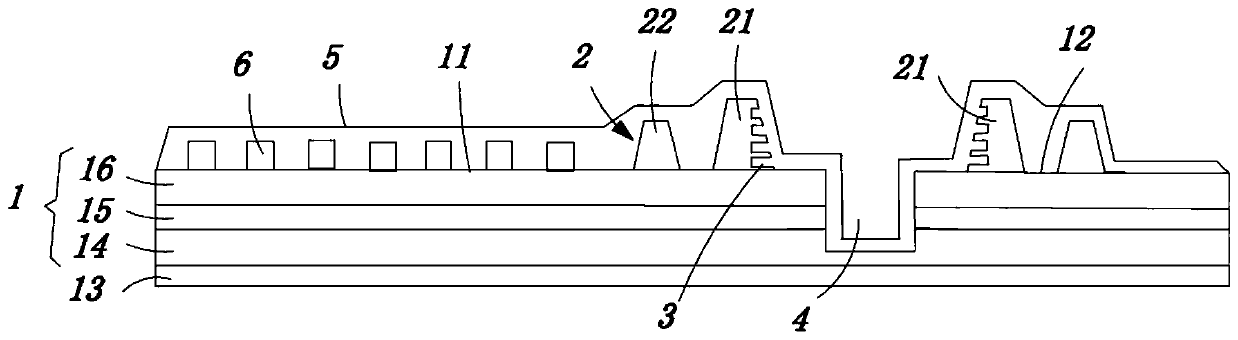

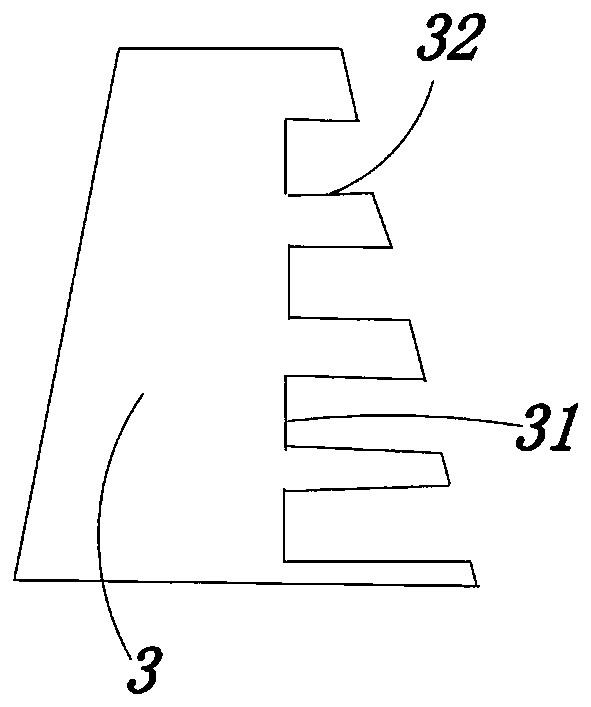

The embodiment of the invention provides a display panel and a display device, which relate to the technical field of display and can improve the problem that external water and oxygen invade a display area. The display panel is provided with a display area and a peripheral area. The display panel comprises a substrate, a pixel driving circuit arranged on the substrate and located in a display area, and a flat layer arranged on the side, away from the substrate, of the pixel driving circuit, and the flat layer is further located in the peripheral area. The display panel further comprises a signal line electrically connected with the pixel driving circuit, the signal line comprises a power line used for providing power signals for the pixel driving circuit, and the power line extends into the peripheral area. The flat layer is provided with a slot in the peripheral area, and the slot surrounds the display area by a circle. In the thickness direction of the substrate, the slot penetratesthrough the flat layer to expose the power line, and at least one side surface, exposed by the slot, of the power line is of a comb tooth structure.

Owner:BOE TECH GRP CO LTD +1

Display substrate and manufacturing method and display device thereof

PendingCN108508643AImprove yieldGood qualitySolid-state devicesNon-linear opticsDuctilityMetallic materials

The invention discloses a display substrate and a manufacturing method and a display device thereof, and belongs to the technical field of display. The provided display substrate comprises a substratum substrate and an obstructing structure arranged on the substratum substrate. It is due to the fact that the provided obstructing structure is made from metal materials with higher hardness, better ductility and stronger impact resistance, the obstructing structure is located at a non-display area of the substratum substrate, and a gap is reserved between the obstructing structure and a packagingarea, the obstructing structure can effectively avoid the problems that a split of the edge of the display substrate extends to the packaging area so as to cause packaging failure, and moisture or oxygen entering an effective display area causes the GDS phenomenon appearing on the display substrate. The yield of the display substrate is higher, and the quality is better.

Owner:BOE TECH GRP CO LTD +1

Organic light-emitting display panel and display device

ActiveCN110211998AReduce stressImprove water and oxygen resistanceSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention provides an organic light-emitting display panel and a display device. The organic light-emitting display panel comprises a substrate, an organic light-emitting structure layer, a thin film packaging layer, at least one retaining wall and at least one protective device, wherein the substrate comprises a display area, a non-display area, at least one special-shaped edge located in thenon-display area and at least one special-shaped area corresponding to the at least one special-shaped edge; the special-shaped area is an area in the non-display area adjacent to the special-shapededge on the substrate; the organic light-emitting structure layer is located on one side of the substrate and located in the display area; the thin film packaging layer is located on one side, far away from the substrate, of the organic light-emitting structure layer; the thin-film packaging layer comprises at least one inorganic layer; the inorganic layers in the thin film packaging layer cover the organic light-emitting structure layer in the display area and extend to cover part of the substrate in the non-display area; the at least one retaining wall is located in the non-display area; theinorganic layers cover the at least one retaining wall; and the at least one protective device is located in the special-shaped area and is located on one side, far away from the display area, of theat least one retaining wall. The water and oxygen resistance of the thin film packaging layer can be improved, so that the occurrence of package failure can be prevented.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

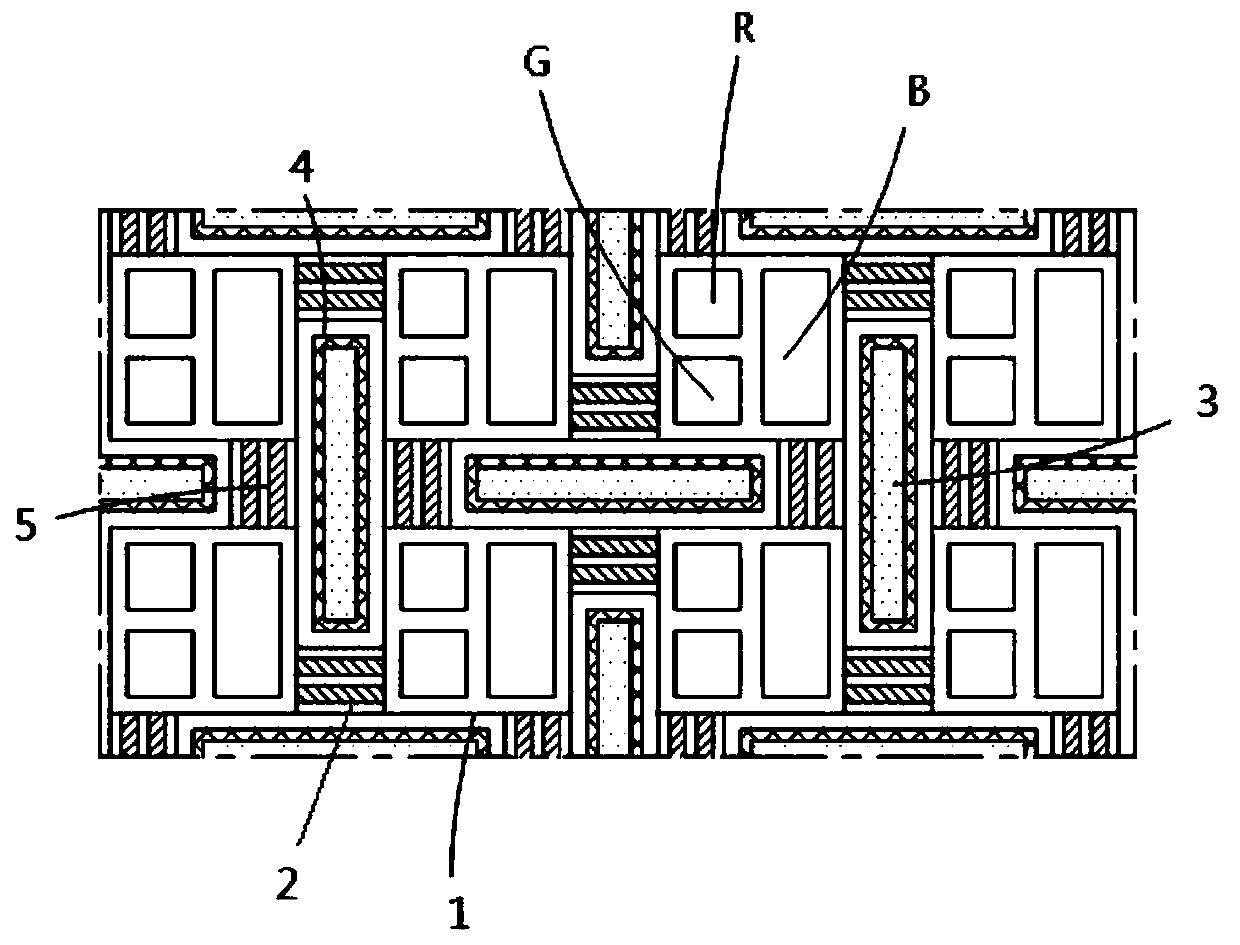

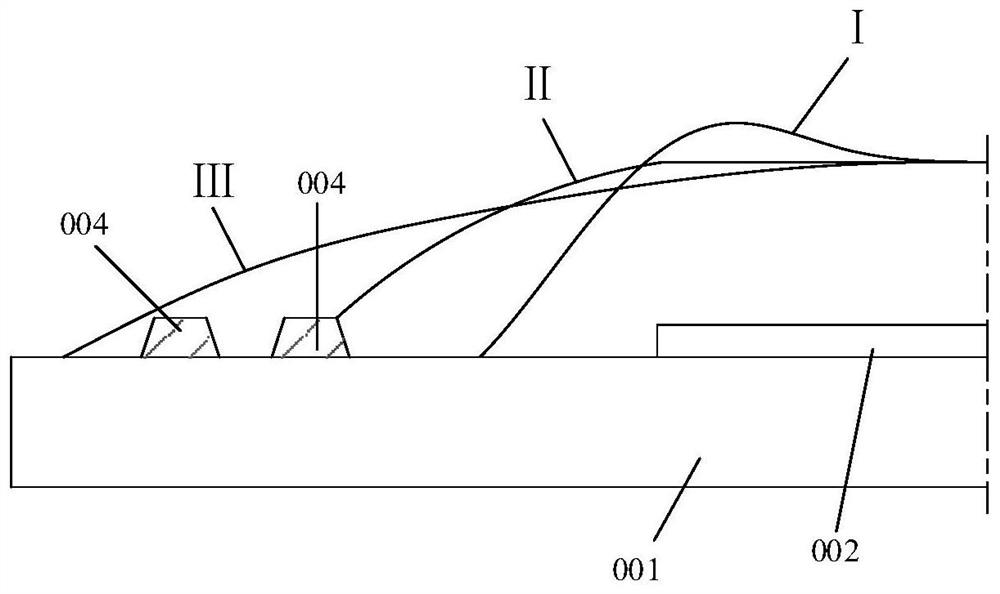

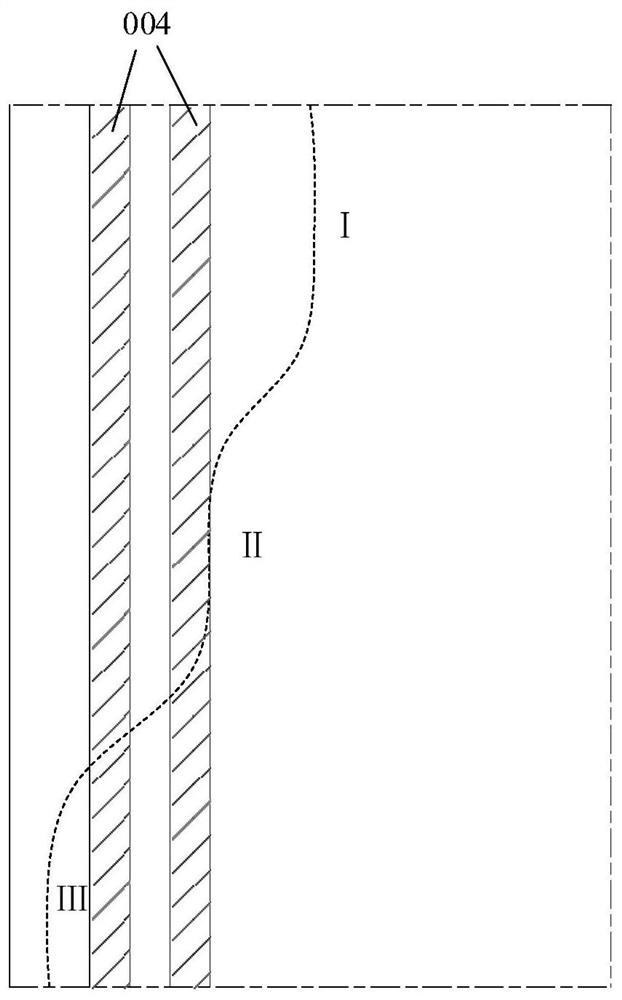

Display substrate, preparation method thereof and display device

ActiveCN111554714ASimple processLow body transformationSolid-state devicesPhotovoltaic energy generationStructural engineeringMechanical engineering

The invention provides a display substrate, a preparation method thereof and a display device. The display substrate comprises a substrate, wherein the substrate is provided with a plurality of pixelisland areas which are separated from one another, hole areas arranged between adjacent pixel island areas, and connecting bridge areas for connecting the adjacent pixel island areas; a first box dam,a groove and a packaging layer covering the groove are formed on the connecting bridge area; the first box dam is located on the side, which is close to the hole area, of the connecting bridge area;the groove is formed in the side, which is away from the hole area, of the first box dam on the connecting bridge area; and the first box dam is used for preventing a packaging layer material before curing from entering the hole area, and the groove is used for guiding the packaging layer material before curing to flow in the extending direction of the first box dam so as to prevent the packaginglayer material before curing from overflowing out of the first box dam, so that the problems of packaging failure and the like of the display device are solved.

Owner:BOE TECH GRP CO LTD

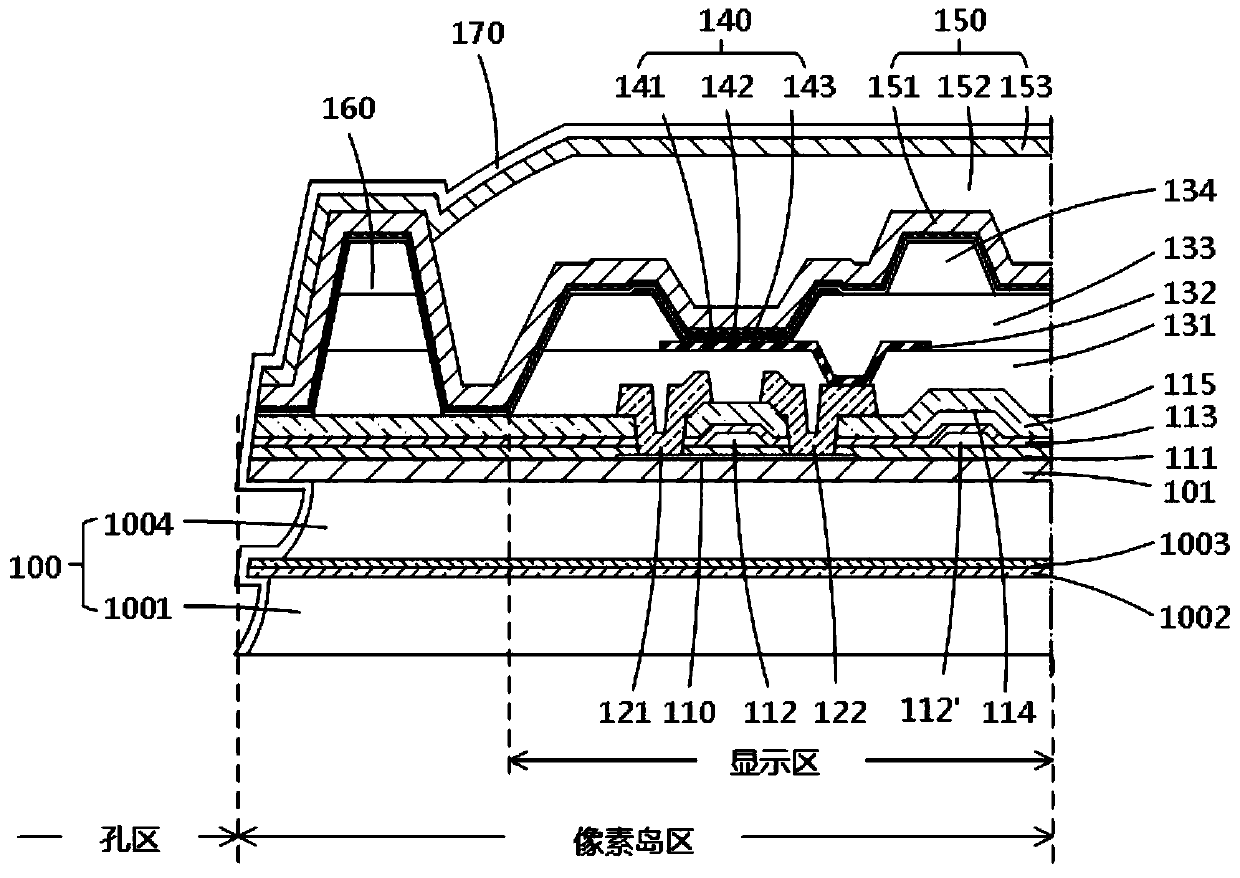

Display panel and display device

ActiveCN110993660AImprove reliabilitySolve the problem of hacking the public layerSolid-state devicesSemiconductor devicesTransistor arrayDisplay device

The invention relates to the field of display, and discloses a display panel and a display device. The display panel comprises a substrate base plate; a thin film transistor array layer which comprises a first inorganic layer and a second inorganic layer, wherein the second inorganic layer is located at the side, away from the substrate, of the first inorganic layer; a partition groove which penetrates through the first inorganic layer and the second inorganic layer, wherein the orthographic projection of an opening of the surface, far away from the substrate, of the first inorganic layer on the substrate is covered by the orthographic projection of an opening of the surface, close to the substrate, of the second inorganic layer on the substrate, and the orthographic projection of an opening, located on the surface of the side, close to the substrate, of at least one inorganic layer of the thin film transistor array layer, on the substrate is larger than and covers the orthographic projection of an opening, located on the surface of the side, away from the substrate, of the inorganic layer, on the substrate; and a light-emitting functional film layer which is located at the side, away from the substrate, of the thin film transistor array layer, wherein a common layer in the light-emitting functional film layer is disconnected at the partition groove.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

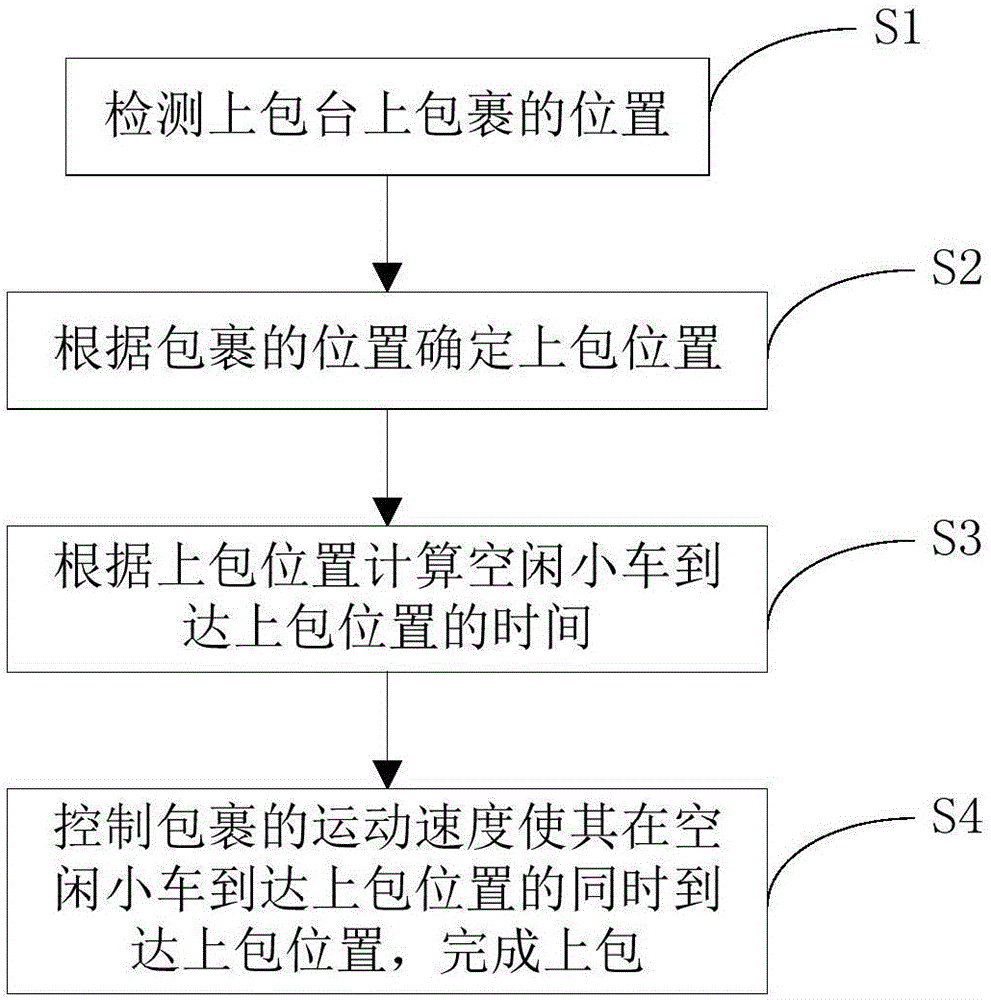

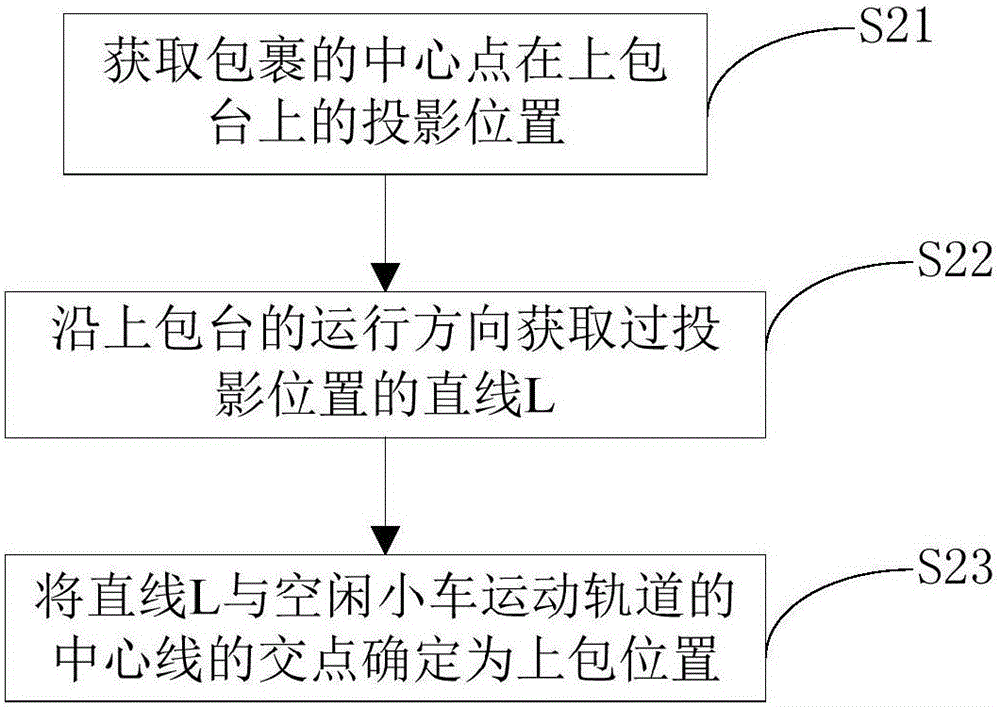

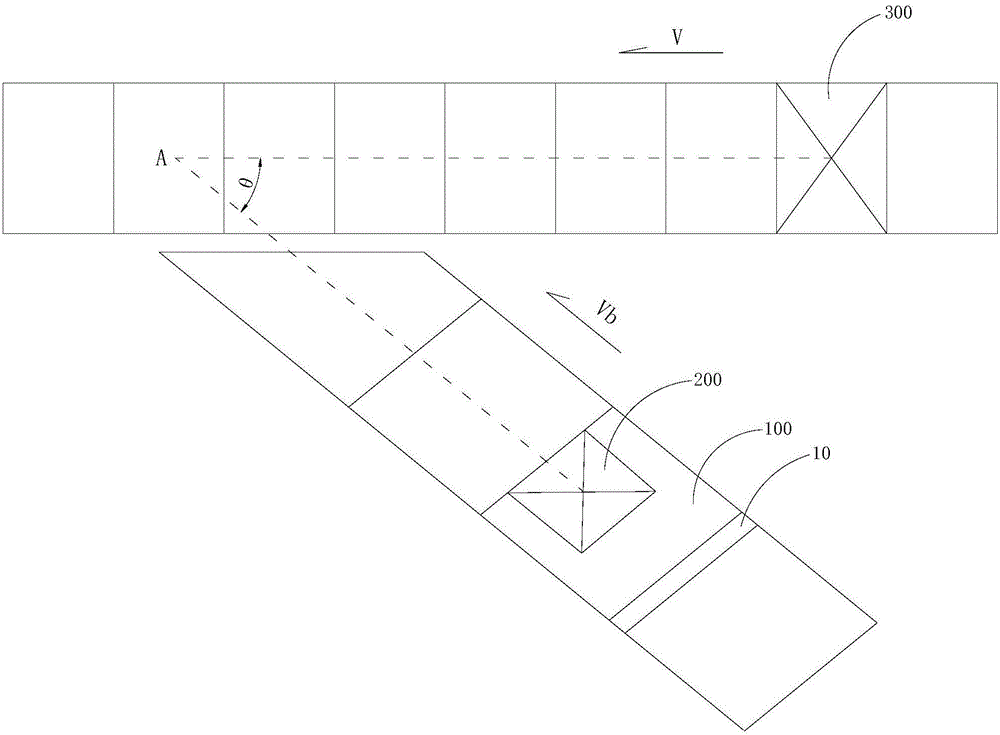

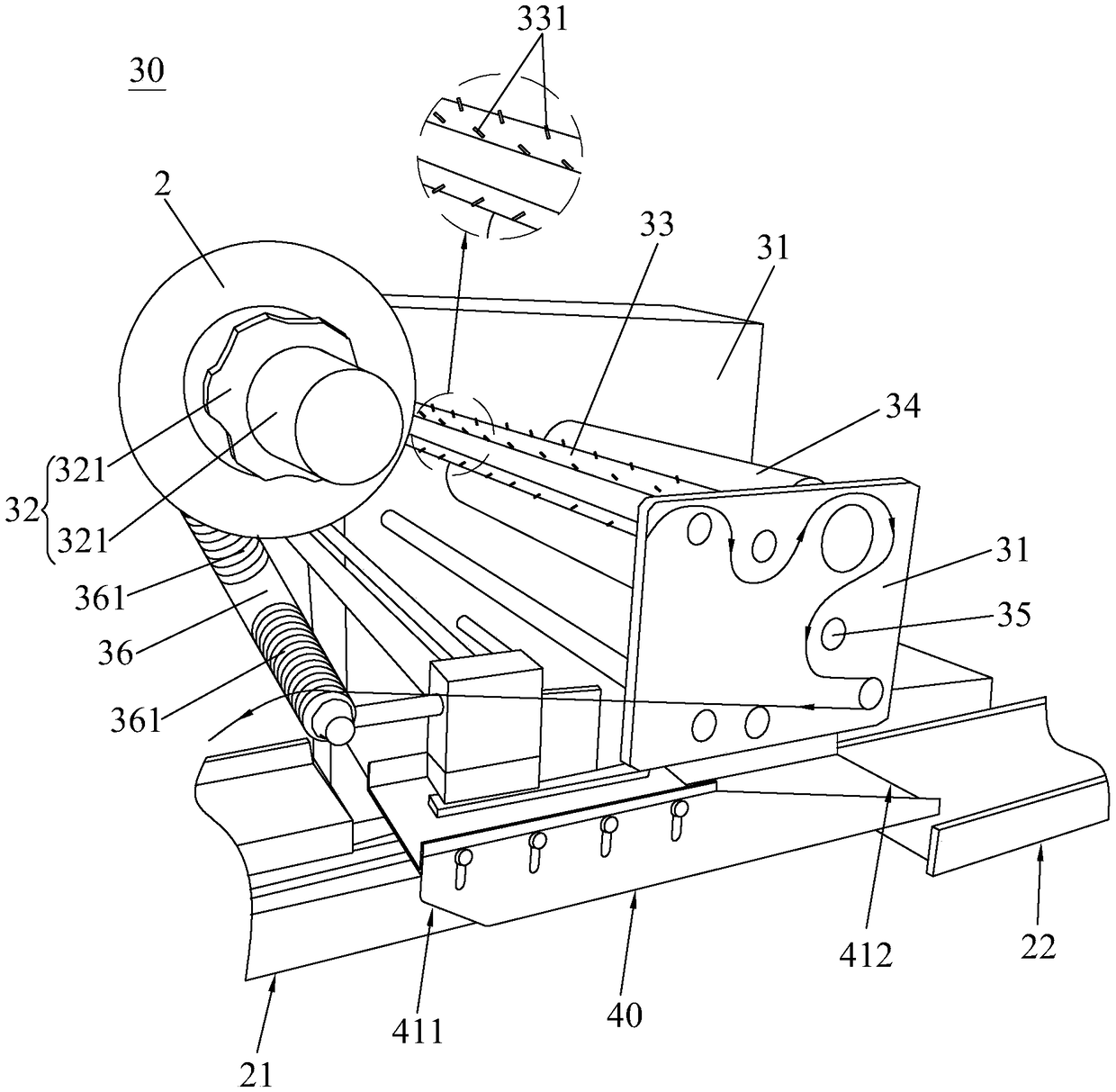

Logistics parcel feeding control method and system

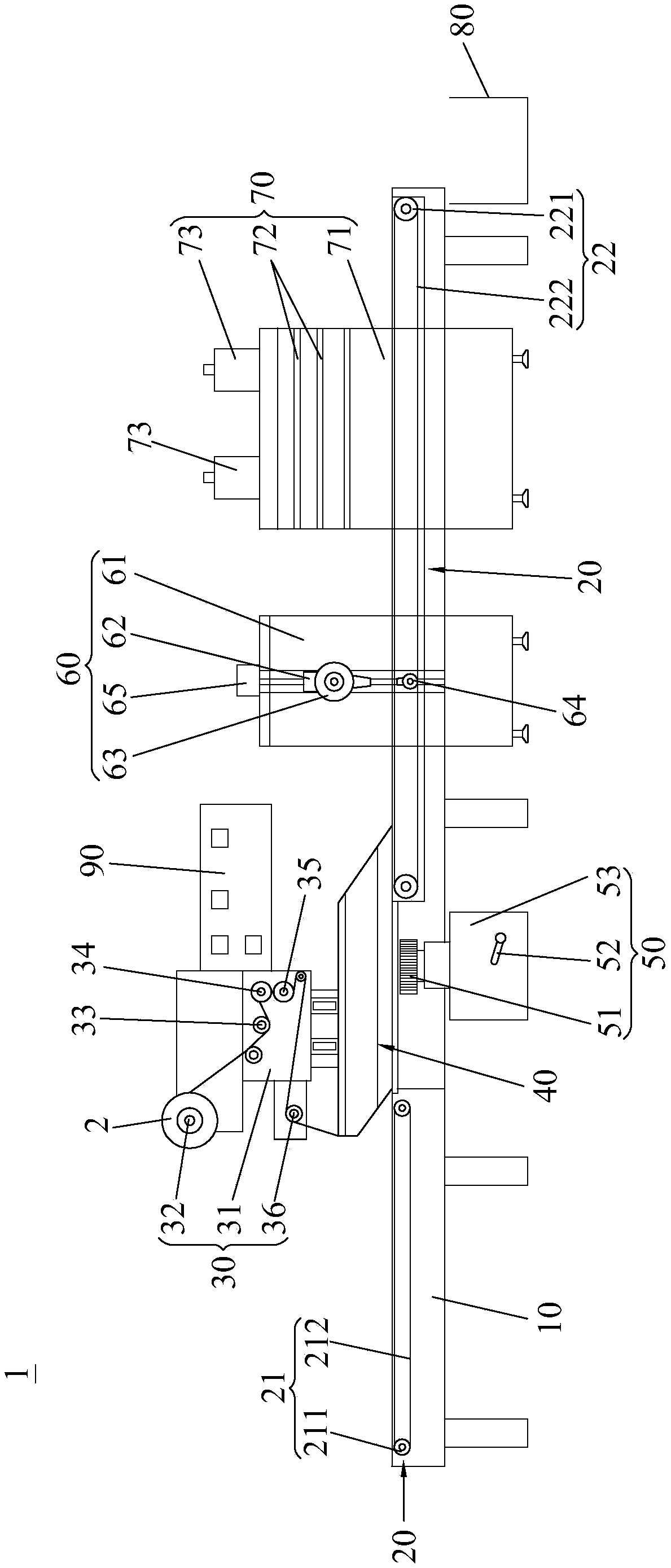

InactiveCN106743340AAvoid package failureGuaranteed smoothness and accuracyControl devices for conveyorsMechanical conveyorsMoving speedBiology

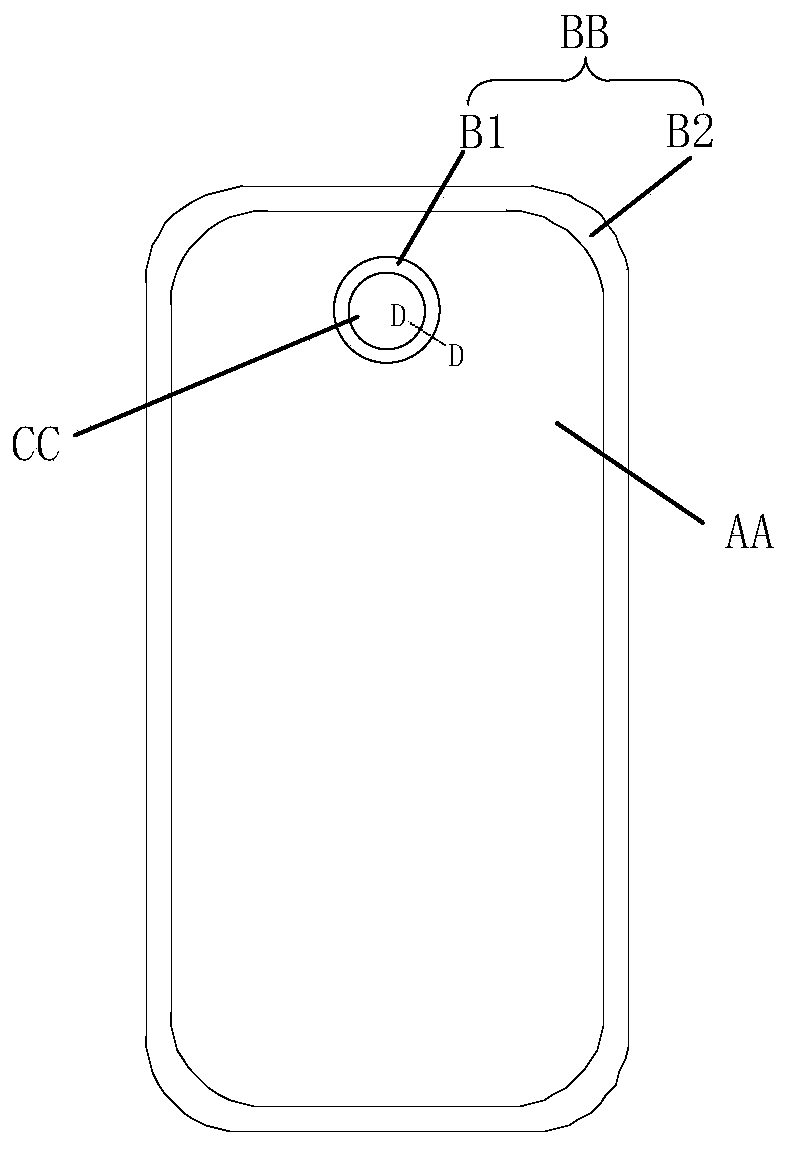

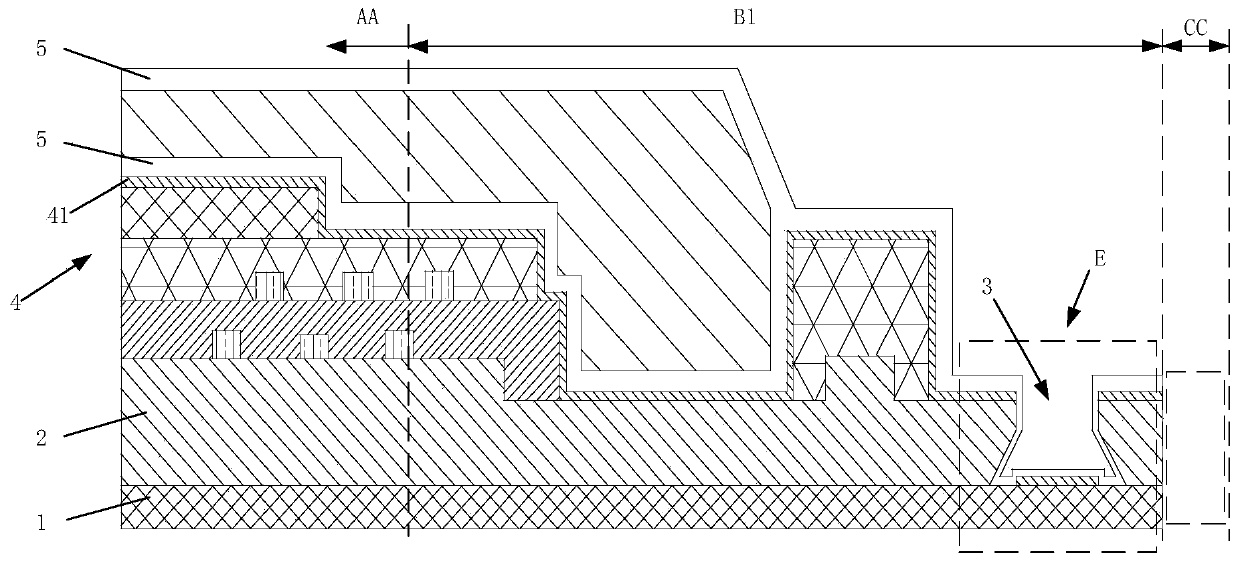

The invention provides a logistics parcel feeding control method and system. The logistics parcel feeding control method includes the steps of detecting a parcel feeding position of a parcel feeding table, determining the parcel feeding position according to the position of a parcel, calculating the time when an idle trolley arrives in the parcel feeding position according to the parcel feeding position, and controlling the moving speed of the parcel to enable the parcel to arrive in the parcel feeding position while the idle trolley arrives in the parcel feeding position so as to complete parcel feeding.

Owner:HANGZHOU COMFIRMWARE TECH CO LTD

Display panel and preparation method thereof, and display device with same

ActiveCN109888126ASpeed up poolingIncreased diffusion areaSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention relates to a display panel and a preparation method thereof, and a display device. A barrier in the related display panel comprises an upper section and a lower section extending reversely with respect to the upper section; a cambered surface is formed at the end part, extending to the bottom of the groove, of the lower section; the display panel also comprises an opening area; the barrier dam is arranged around the opening area, and an included angle of more than 90 DEG is formed between the side wall and the bottom of the opening area. According to the display panel provided bythe embodiment of the invention, the moisture collection and diffusion area is significantly enlarged via the structure that the end part of the lower section is the cambered surface; meanwhile the barrier dam deeply stretches into a barrier layer, so that the invalid packaging caused by laser drilling is avoided through improving the forming mode of the opening area, and the water oxygen entrance path is further prolonged; the technology is simple, the cost is low, the water oxygen is effectively isolated, and the packaging effect is improved.

Owner:YUNGU GUAN TECH CO LTD

Display device and display panel

PendingCN112002831AAvoid deficienciesThe problem of preventing overflow (over the first barrier dam)Solid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceInorganic layer

The invention relates to a display device and a display panel, and relates to the technical field of display. The display panel comprises a substrate, a driving layer, a light-emitting device layer, afirst blocking dam, a plurality of drainage strips and a packaging layer, wherein the driving layer is arranged on one side of the substrate and provided with a pixel circuit area, a peripheral circuit area and an edge area; the light-emitting device layer is arranged on one side, deviating from the substrate, of the pixel circuit region; the first barrier dam is arranged in the edge region and surrounds the peripheral circuit region; the drainage strips are arranged on the side, deviating from the substrate, of the edge area and located in the first blocking dam in a surrounding mode; each drainage strip extends to the peripheral circuit area from the edge area; the packaging layer comprises a first inorganic layer, an organic layer and a second inorganic layer; the first inorganic layercovers the light-emitting device layer, the first barrier dam and the drainage strip and protrudes in an area corresponding to the first barrier dam and the drainage strip; the organic layer is arranged on the surface, deviating from the substrate, of the first inorganic layer and is limited within the range surrounded by the first barrier dam; the second inorganic layer covers the organic layerand the first inorganic layer.

Owner:BOE TECH GRP CO LTD

Display panel and display device

ActiveCN110211990AMake full use of spaceIncrease the screen ratioSolid-state devicesTelephone set constructionsDisplay deviceComputer science

The embodiment of the invention discloses a display panel and a display device. The display panel comprises a display area and a non-display area. The non-display area comprises a light-transmitting area and a non-light-transmitting area surrounding the display area and the light-transmitting area. The display panel comprises a substrate, a display driving circuit, a first electrode, a light emitting functional layer, a second electrode and a packaging layer which are laminated in order. The display driving circuit and the first electrode are arranged in the display area and the non-light-transmitting area. The light-transmitting area is provided with the substrate and the packaging layer. The first electrode is a reflection electrode. According to the scheme, the screen-to-body ratio of the display device can be enhanced and problems of edge and corner collapse and packaging failure in the manufacturing process of the display panel can be avoided.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

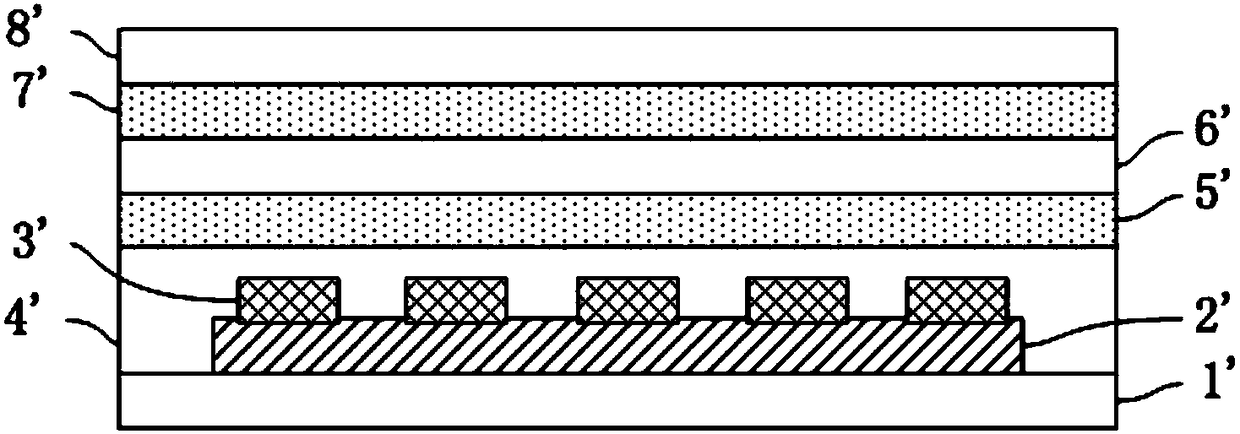

OLED display device and preparation method thereof

InactiveCN108565360APrevent penetrationReduce penetrationSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

The invention provides an OLED display device and a preparation method thereof. The method comprises a step of preparing a TFT layer on a glass substrate, a step of preparing an OLED device layer on the TFT layer, a step of preparing a barrier layer and a buffer layer on the glass substrate, wherein the barrier layer covers the OLED device layer, a step of preparing a plurality of grooves on the barrier layer and preparing water absorbing material layers in the grooves. According to the OLED display device and the preparation method, the permeability of water and oxygen is reduced, the risk ofthe breakage of the barrier layer and the buffer layer is reduced, and the service life of the OLED display device is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Decorative aluminum alloy door window

PendingCN111827842AScientific and reasonable structureEasy to useWrapping material feeding apparatusInsect protectionEngineeringStructural engineering

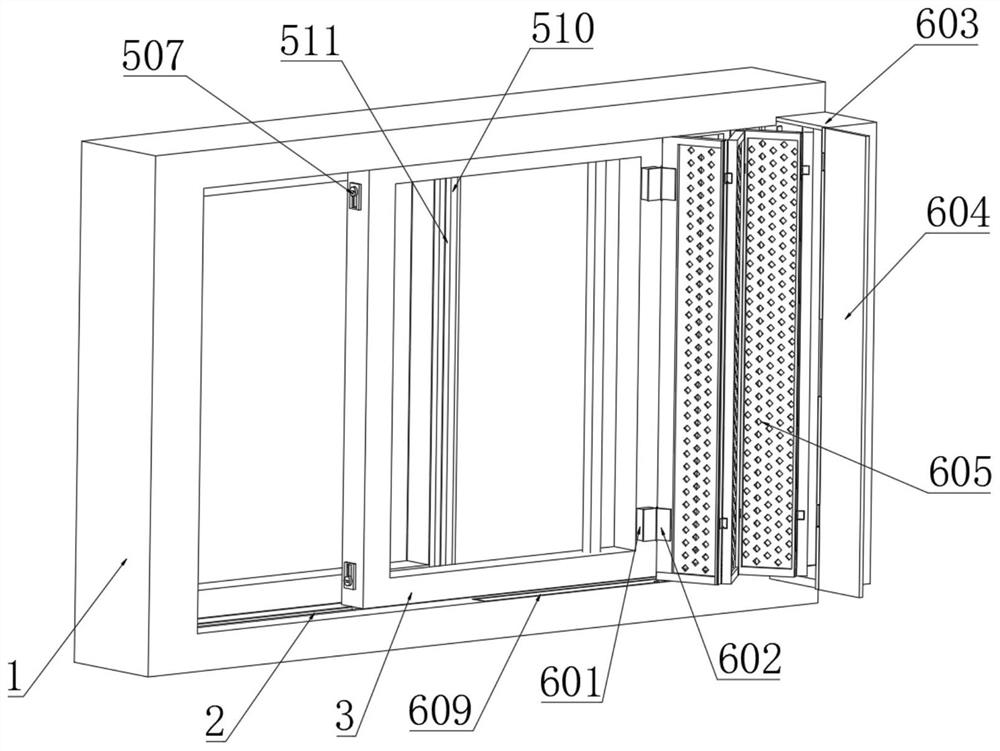

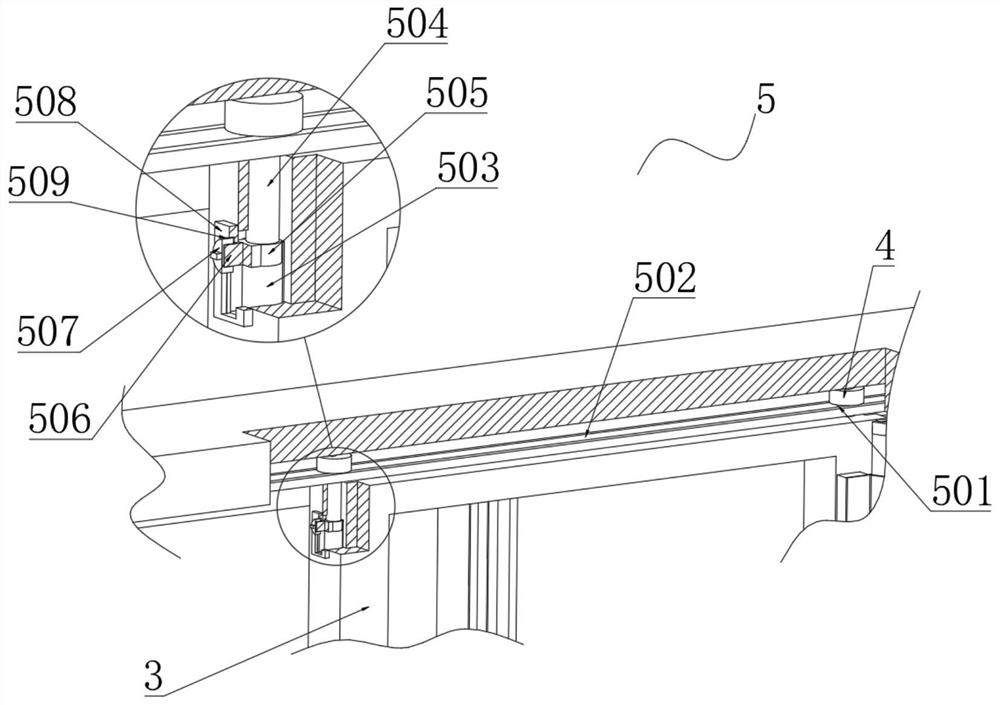

The invention discloses a decorative aluminum alloy door window. A rotating shaft is fixedly mounted at one end of a window frame, a connecting rod is fixedly connected between two window frame pulleys, movable grooves are symmetrically formed in the end, which is away from the rotating shaft, of the middle of the window frame, a movable column is movably mounted in each movable groove, a connecting block is fixedly connected to the bottom end of each movable column, a connecting rod is fixedly mounted at one end of the middle of each connecting block, and a fastening knob is connected to oneend of each connecting rod. Through cooperative use of the movable columns and the connecting blocks, one end of the window frame is separated from the window frame pulleys; through use of the rotating shaft, it is ensured that the window frame and an aluminum alloy window body can rotate, the window frame is conveniently turned over, great convenience is provided for cleaning the window frame andglass, the circumstances that the outward face of the glass of the window frame is inconvenient to clean, consequently, dust is gathered on the surface of the glass, and normal sunlight irradiation is affected are avoided, cleaning personnel can clean the glass without standing outside the window, and the safety is improved.

Owner:林兰根

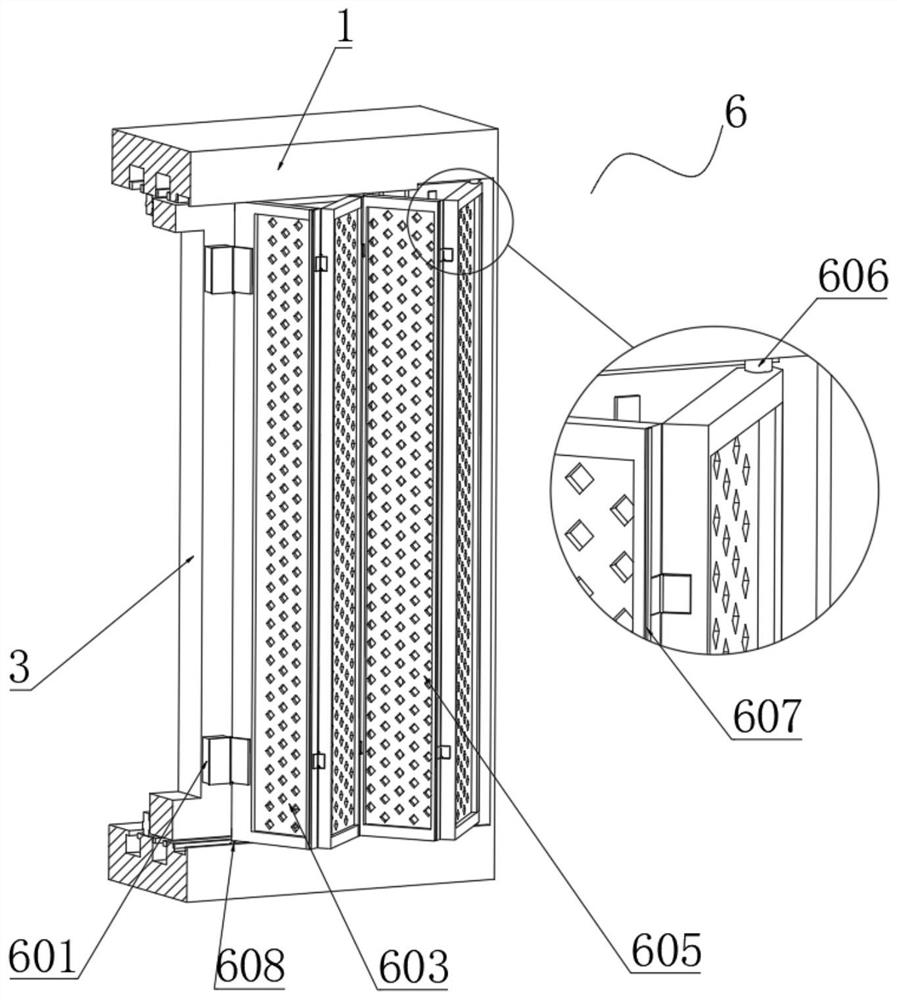

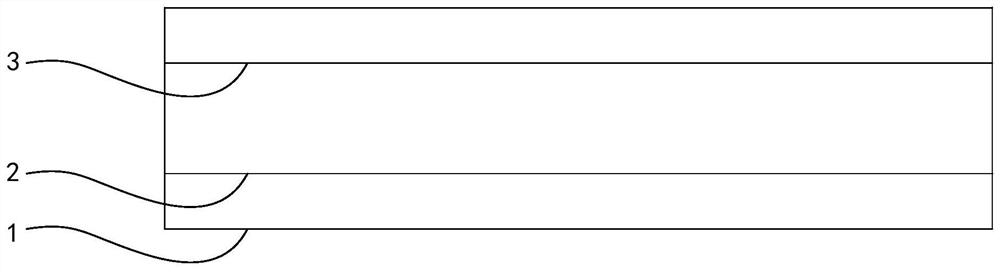

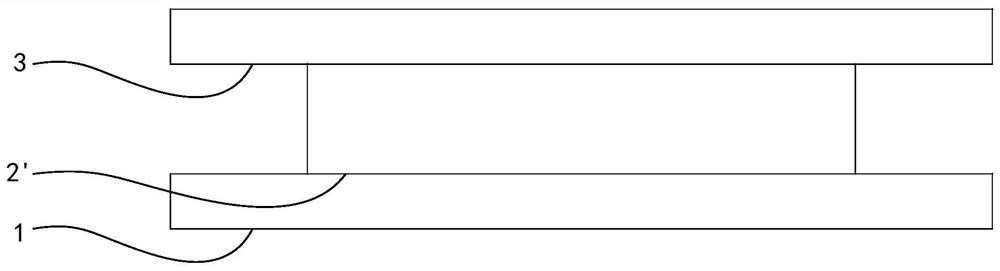

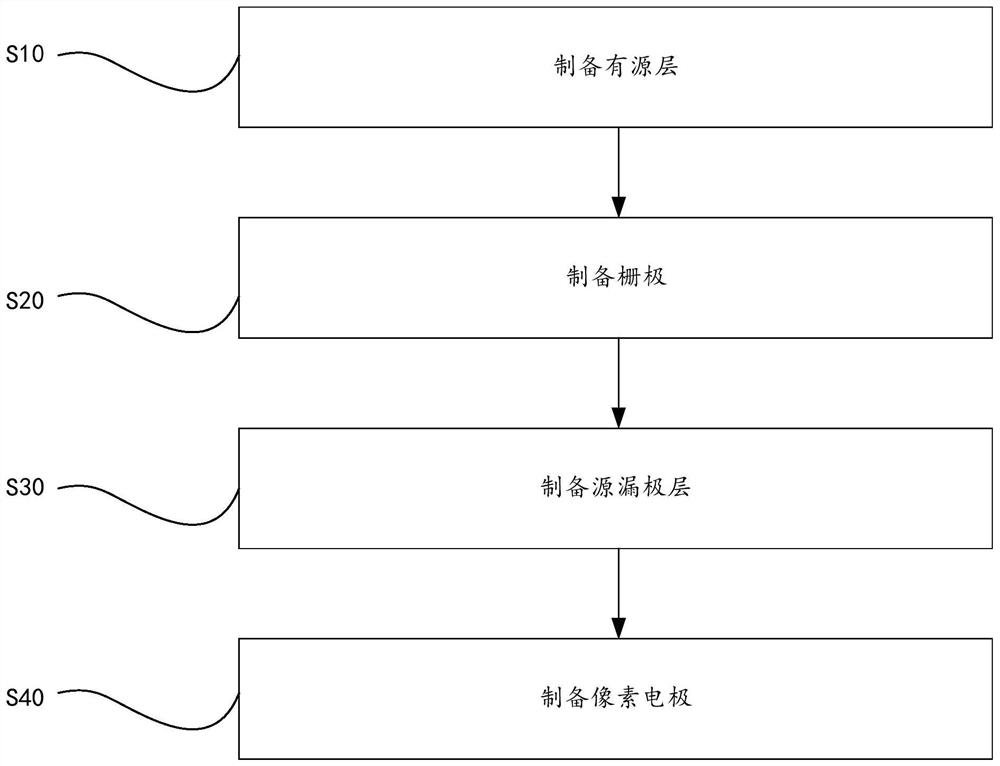

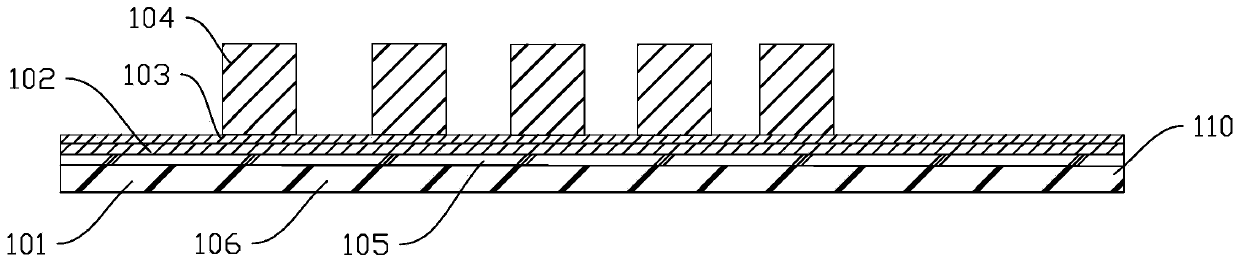

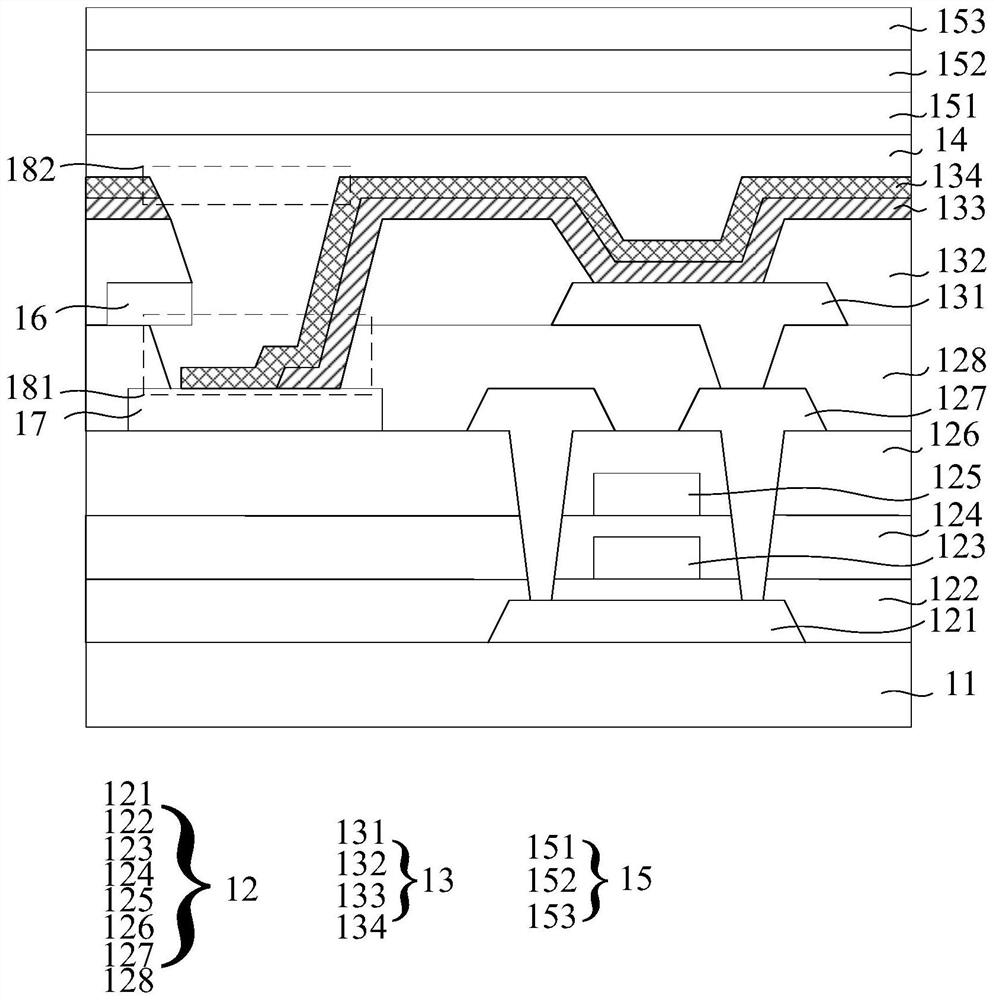

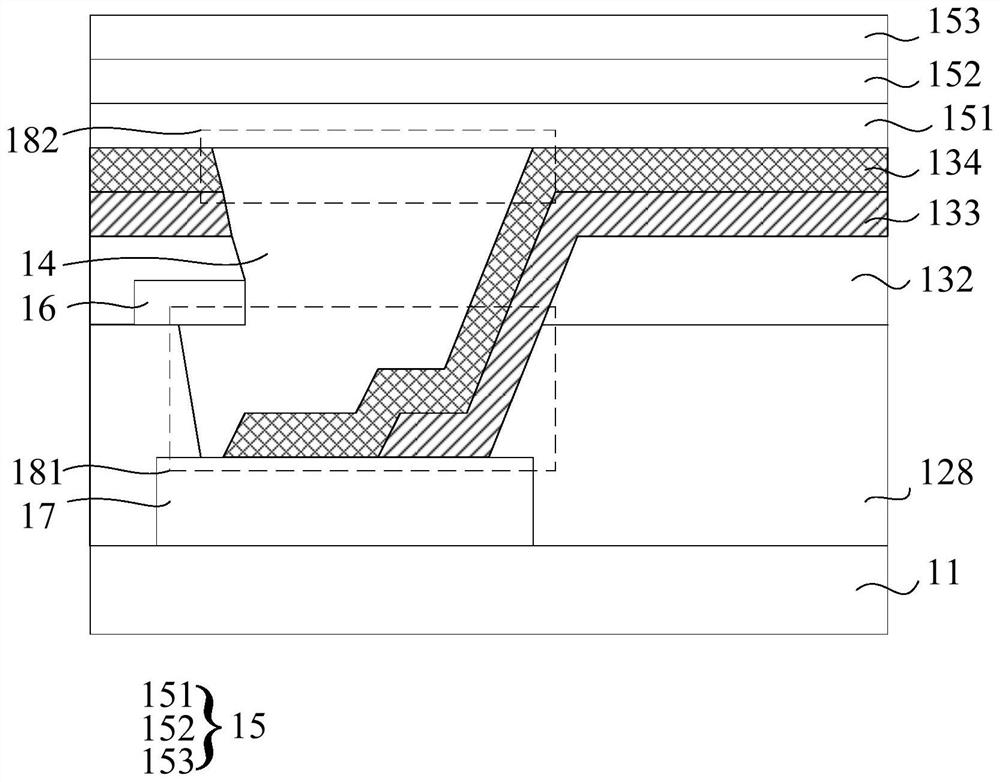

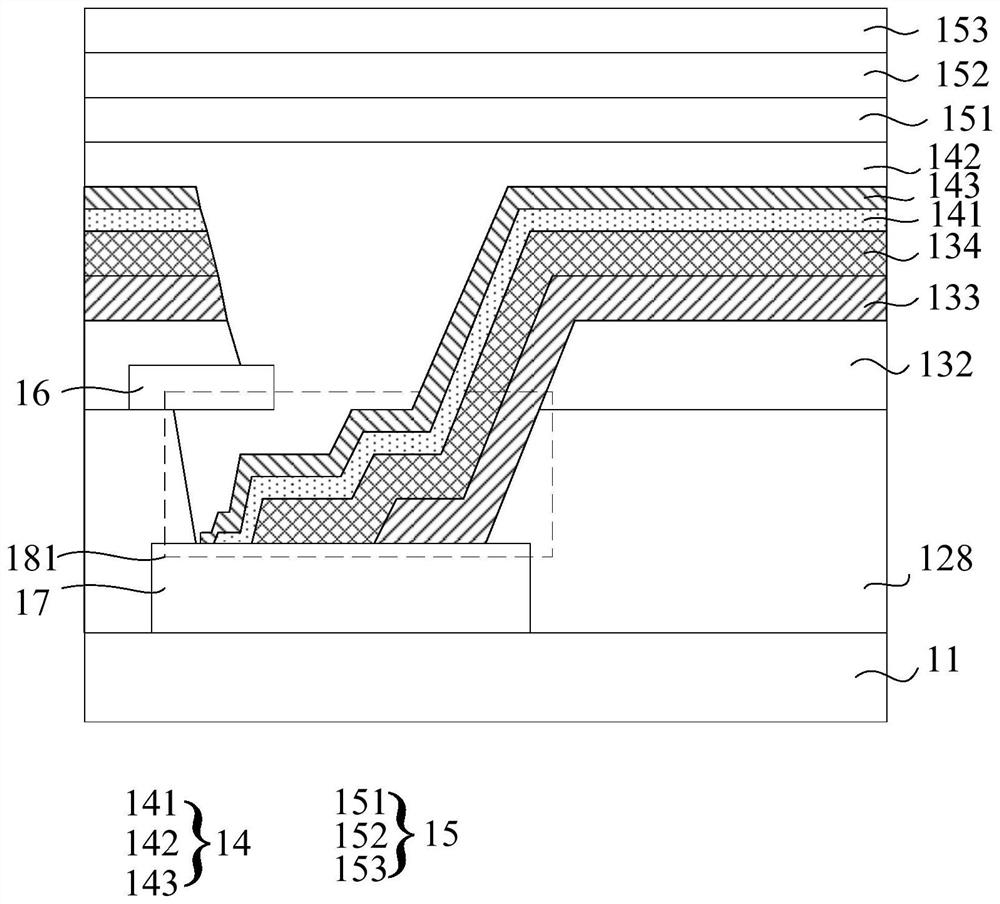

Array substrate, preparation method thereof and display panel

PendingCN112002636AAvoid bad displayAvoid package failureSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsComposite material

The invention provides an array substrate, a preparation method thereof and a display panel. In the preparation method of the array substrate, a source-drain electrode layer is prepared by adopting alaminated metal layer. The laminated metal layer comprises a first metal layer, a second metal layer and a third metal layer which are laminated. The laminated metal layer is etched twice, so that inthe formed source electrode and drain electrode, the width of the third metal layer is smaller than or equal to the width of the second metal layer, and the width of the third metal layer is smaller than the width of the first metal layer. The problem that a laminated metal electrode in an existing array substrate has an undercut phenomenon is solved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Display panel, and preparation method thereof and display device

ActiveCN112909202AExtended service lifePrevent overflowSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses a display panel, and a preparation method thereof and a display device, which are used for improving the packaging yield. The embodiment of the invention provides a display panel. The display panel comprises: a substrate; and a display panel which is provided with a display area and a peripheral area located outside the display area. The peripheral area comprises a retaining wall and a magnetic structure which are arranged on the substrate and surround the display area; the magnetic structure is located between the retaining wall and the display area; the display area comprises an electroluminescent device arranged on the substrate and a packaging layer for sealing the electroluminescent device; the encapsulation layer includes: an organic encapsulation layer covering the magnetic structure and extending to the retaining wall; the organic encapsulation layer comprises a magnetic part; and the magnetic structure is used for generating magnetic force to the magnetic part in the organic packaging layer and preventing the organic packaging layer from crossing the retaining wall.

Owner:MIANYANG BOE OPTOELECTRONICS TECH CO LTD +1

Automatic packaging system for steel rail fastening assemblies

PendingCN108928517ARealize deliveryAchieve replacementWrappers shrinkageWrapping material feeding apparatusEngineeringMaterial resources

The invention discloses an automatic packaging system for steel rail fastening assemblies. The automatic packaging system comprises a conveying device, a film supporting device, a bag making device, alongitudinal sealing device, a transverse cutting device and a shrinkage device. The film supporting device is rotationally arranged above the conveying device and used for mounting packaging films;the bag making device comprises a cylinder, a sealing groove extending in the conveying direction is formed in the bottom of the cylinder in a penetrating mode, and the longitudinal sealing device isarranged below the cylinder and located at the rear end of the bag making device; the transverse cutting device comprises an upper sealing roller assembly and a lower sealing roller assembly which aremutually staggered with the conveying direction, and the upper sealing roller assembly and the lower sealing roller assembly are engaged separably so as to achieve transverse cutting and sealing of the packaging film; and the shrinkage device is arranged behind the transverse cutting device and used for conducting heating shrinkage on the packaging films and the fastening assemblies in the packaging films. Through the automatic packaging system for the steel rail fastening assemblies, the fastening assemblies overlapped according to a certain order can be packaged automatically, so that overall delivery and replacement of the fastening assemblies are achieved during maintenance and replacement of a railway steel rail, the replacement efficiency is improved, and manpower and material resources are saved.

Owner:GUANGZHOU PUBLIC WORKS OVERHAUL SEGMENT GUANGZHOU RAILWAY GRP CORP

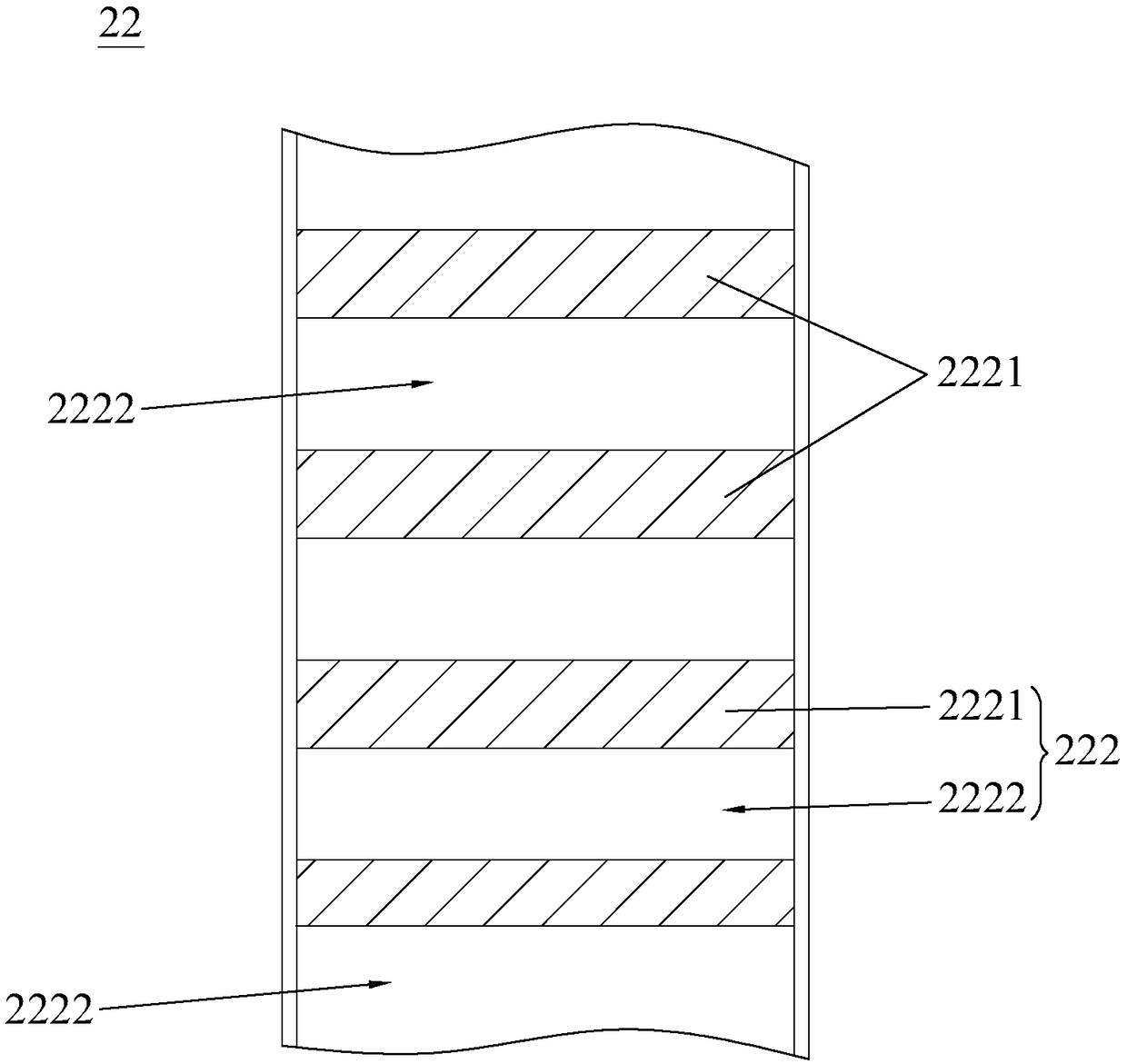

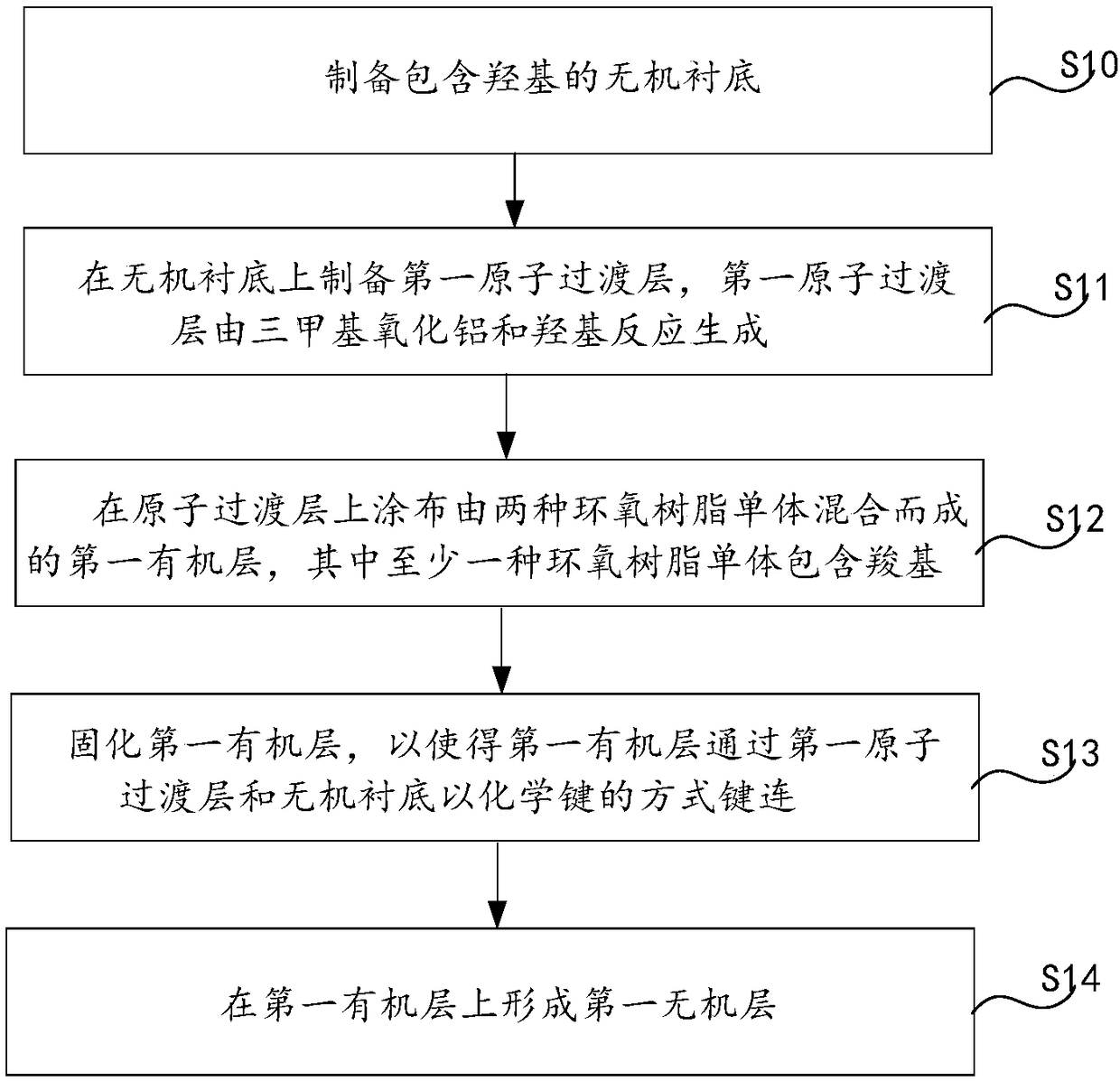

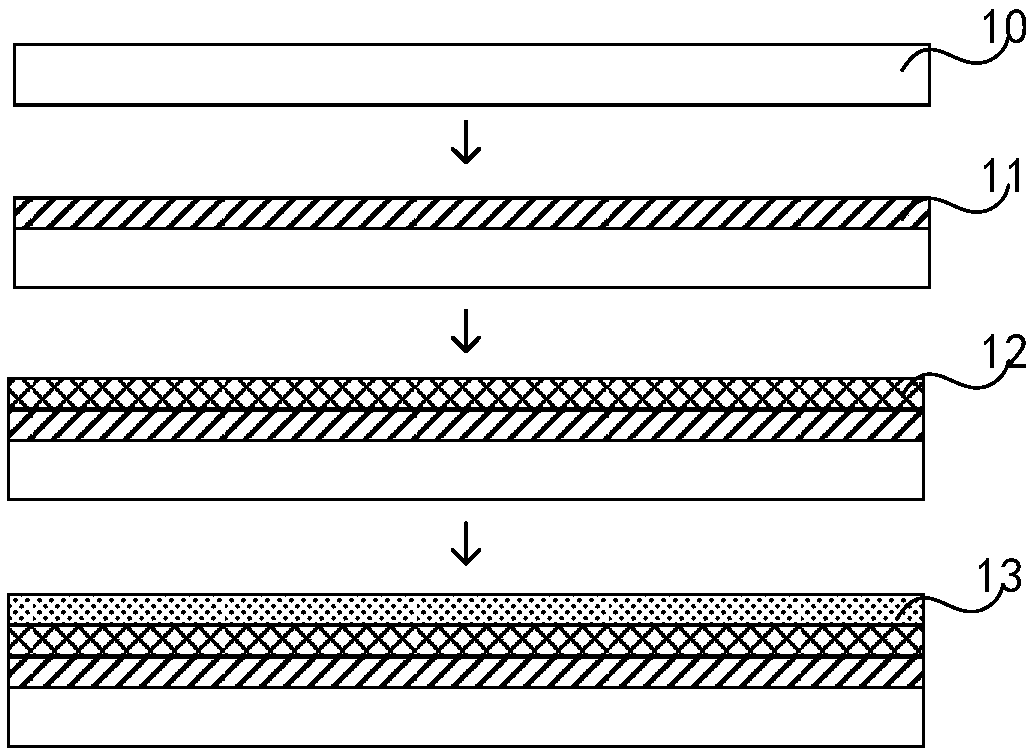

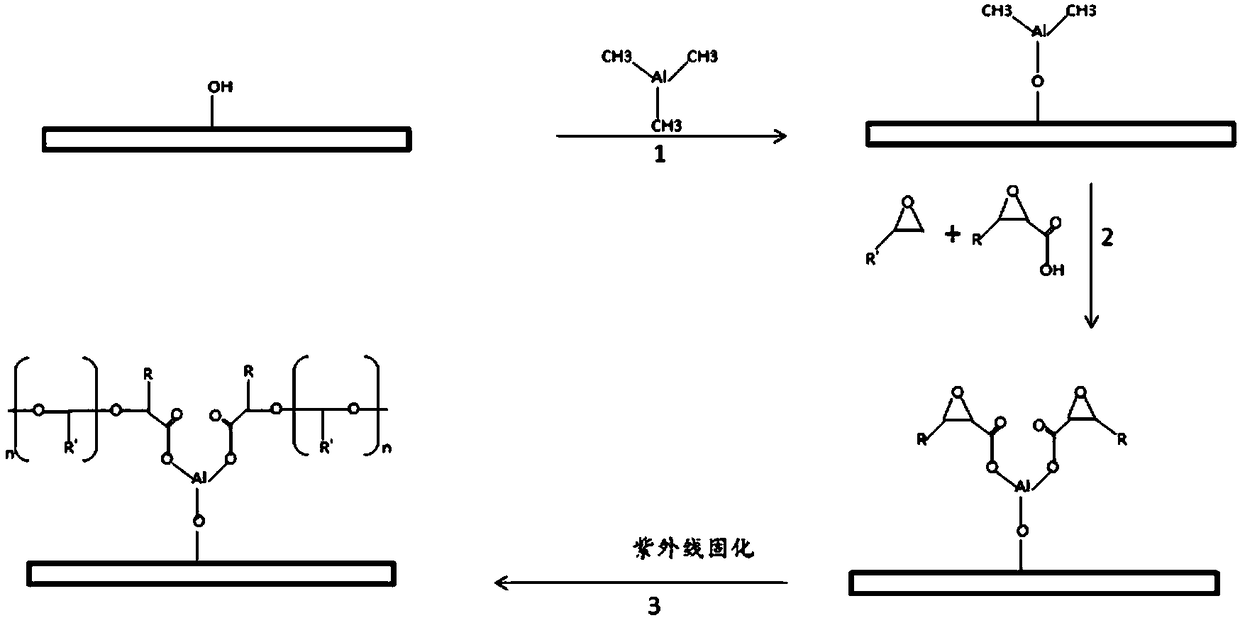

Organic light emitting diode packaging structure and manufacturing method thereof as well as display device

InactiveCN108400255AImprove adhesionGuaranteed reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingEpoxyDisplay device

The invention discloses an organic light emitting diode packaging structure and a manufacturing method thereof as well as a display device. The manufacturing method comprises the steps: manufacturingan inorganic substrate including hydroxyl; manufacturing a first atom transition layer on the inorganic substrate; coating a first organic layer, formed by mixing two epoxy resin monomers, on the atomtransition layer; and solidifying the first organic layer, so that the first organic layer is bonded with the inorganic substrate through the first atom transition layer in a chemical bond manner. Bythe above mode provided by the invention, the adhesiveness between the organic layer and the inorganic layer is increased, and a problem of package failure caused by packaging layer peeling in a display device bending or folding the procedure is avoided.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

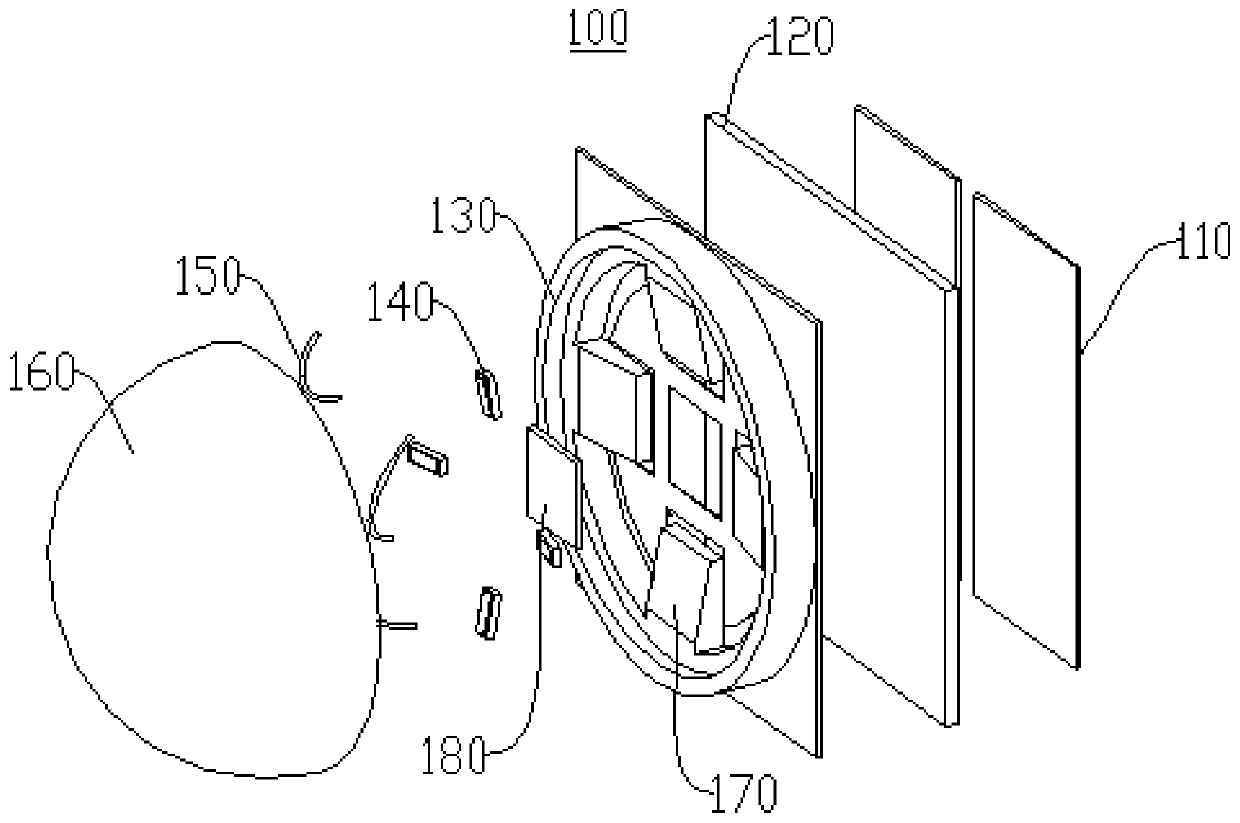

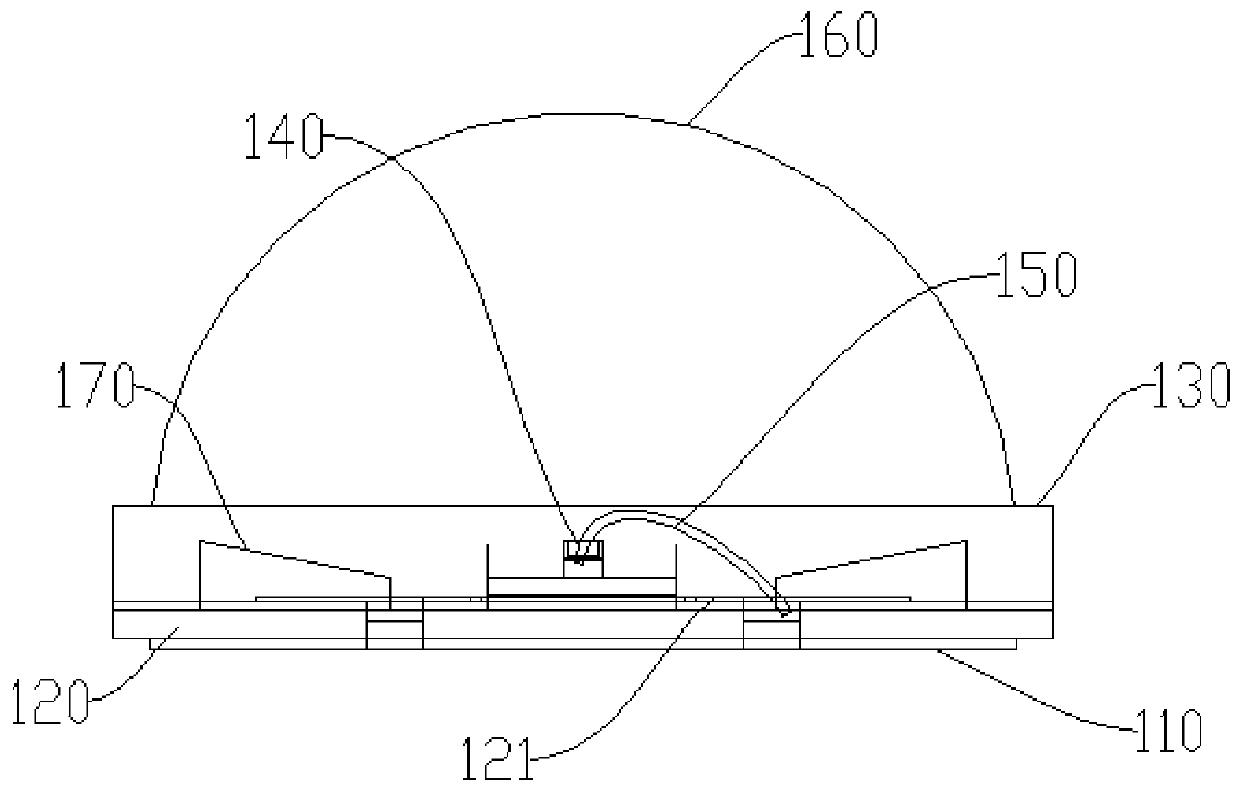

LD light-emitting device and preparation method thereof

The invention relates to the field of optical elements, in particular to an LD light-emitting device and a preparation method thereof. The LD light-emitting device comprises a substrate, a fluorescentlayer, a heat sink, an LD chip and an optical lens. The backlight surface of the fluorescent layer is attached to the substrate; the LD chip is mounted on the heat sink, and at least part of light beams emitted by the LD chip can irradiate the reflective surface of the fluorescent layer; the optical lens is connected with the substrate. The whole backlight surface of the fluorescent layer can conduct heat through the substrate, the direct contact area of the fluorescent layer and the substrate is increased, and the heat transfer efficiency is improved. The heat of the fluorescent layer is quickly dissipated through the substrate; light of the LD chip can only irradiate the reflective surface of the fluorescent layer, so that heat conducted to the fluorescent layer by the LD chip is reduced, and the heat dissipation problem of the fluorescent layer is improved to a great extent. The situation that the fluorescent layer fails due to poor heat dissipation is effectively improved, and theproblem of light attenuation or color drift of the LD light-emitting device is further solved

Owner:SONGSHAN LAKE MATERIALS LAB +1

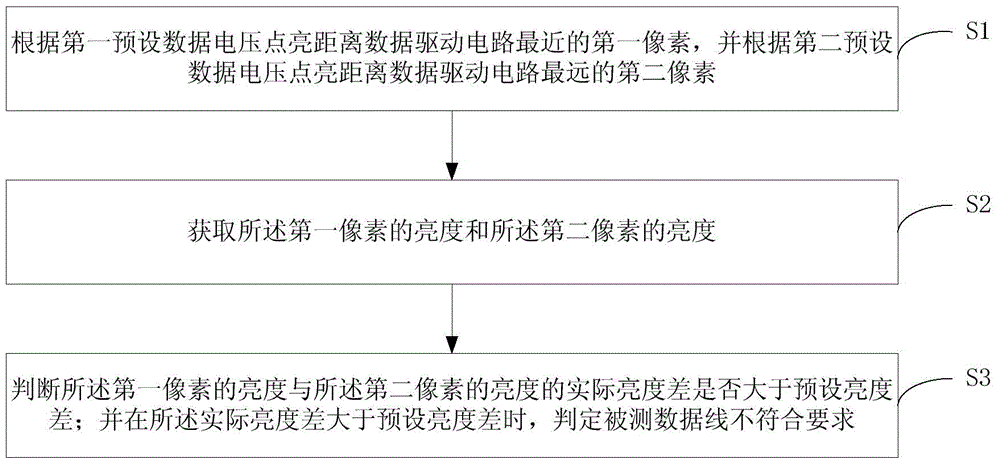

Method and device for testing qualification of data line, array substrate and manufacturing method thereof

ActiveCN104637834AAvoid package failureSemiconductor/solid-state device testing/measurementStatic indicating devicesFailure causesData-driven

The invention provides a method and a device for testing qualification of a data line, an array substrate and a manufacturing method thereof. The method for testing the qualification of the data line comprises the following steps of according to first preset data voltage, illuminating a first pixel which is closest to a data driving circuit, and according to second preset data voltage, illuminating a second pixel which is farthest from the data driving circuit; correspondingly connecting the first pixel and the second pixel to the same to-be-tested data line; obtaining the brightness of the first pixel and the brightness of the second pixel; judging whether the actual brightness difference between the brightness of the first pixel and the brightness of the second pixel is greater than the preset brightness difference or not; when the actual brightness difference is greater than the preset brightness difference, judging that the tested data line does not meet the requirement. The method for testing the data line has the advantages that the qualification test of the data line can be completed under the condition of no arrangement of the metal line, and the problem of packaging failure caused by the arrangement of the metal line is fundamentally solved.

Owner:BOE TECH GRP CO LTD +1

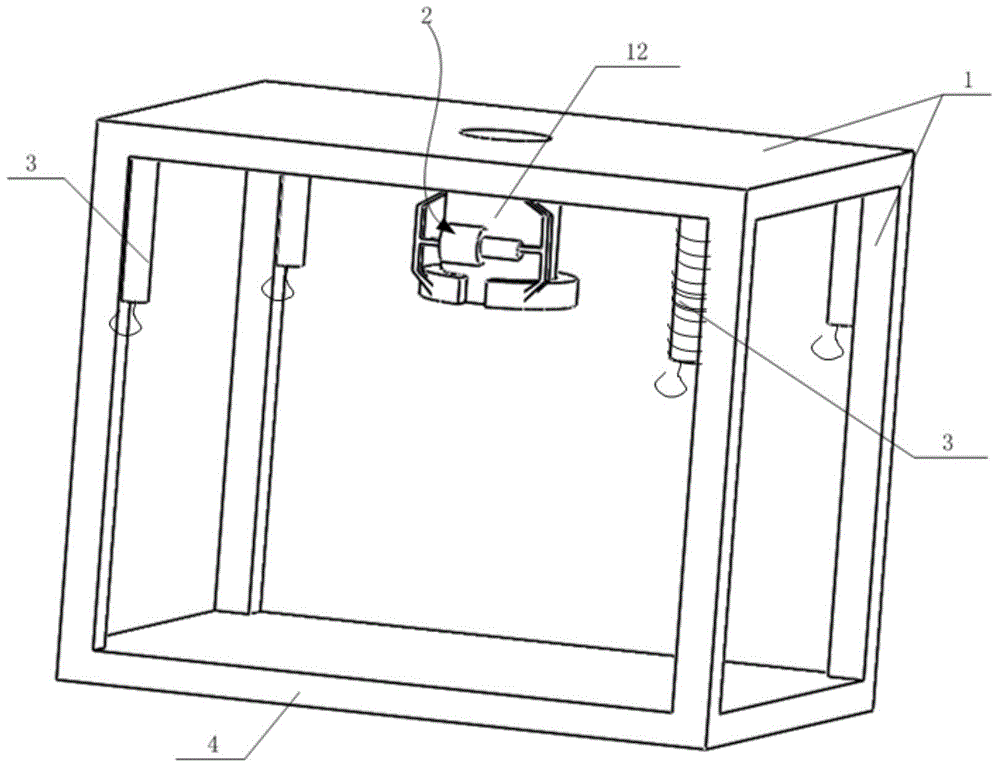

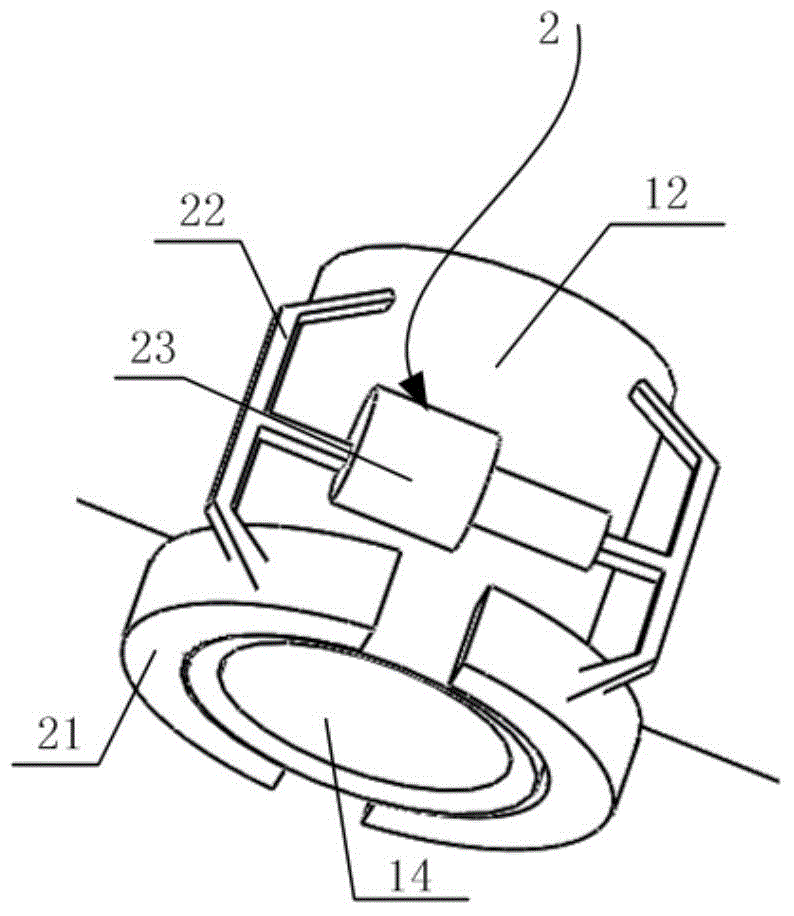

Manufacturing method of electrowetting display device, and curved-surface electrowetting display device

InactiveCN111538151AAvoid the problem of circumventing the wallAvoid package failureOptical elementsEngineeringElectrowetting

The invention discloses a manufacturing method of an electrowetting display device, and a curved-surface electrowetting display device. The manufacturing method of the electrowetting display device comprises the following steps: S1, a curved-surface-shaped upper substrate and a curved-surface-shaped lower substrate are aligned and attached; and S2, the upper substrate, the lower substrate and a device located between the upper substrate and the lower substrate are packaged to form the curved-surface electrowetting display device. Before packaging, as the upper substrate and the lower substrateare of curved-surface structures, the electrowetting display device is manufactured by adopting the method of forming the curved-surface substrate firstly and then packaging, so that the problem of packaging failure caused by stress generated by a packaging material after bending and the problem of ink rollover caused by internal liquid pressure concentration are avoided. The invention also provides the curved-surface electrowetting display prepared by the method.

Owner:SOUTH CHINA NORMAL UNIVERSITY +1

Haydite sand packaging equipment

InactiveCN104443554AStrong structural stabilityAvoid package failurePackagingHigh probabilityEngineering

The invention discloses haydite sand packaging equipment, relates to the technical field of packaging of products and solves the problems that an existing simple packaging frame is poor in stability, an unpacking frame has high probability of dumping, and a plastic inner lining cannot be fixed, so that the plastic inner lining is easy to fall into a packaging bag, the unpacking fails, and the weight of haydite sand cannot be measured in real time. The haydite sand packaging equipment disclosed by the invention is characterized in that the haydite sand packaging equipment is used for loading materials into the packaging bag with an inner lining; the haydite sand packaging equipment comprises the unpacking frame and an inner lining locking device, wherein the unpacking frame comprises a table top, the edges and the angles of the table top are fixedly connected with landing legs, and a feed pipeline is arranged in the middle of the table top; the inner lining locking device comprises a first support arm, a first clamp ring, a second support arm, a second clamp ring and a first telescopic cylinder, wherein one end of the first support arm is hinged to the feed pipeline, the first clamp ring is fixed to the other end of the first support arm, one end of the second support arm is hinged to the feed pipeline, the position of the second support arm is opposite to that of the first support arm, the second clamp ring is fixed to the other end of the second support arm, one end of the first telescopic cylinder is connected with the middle of the first support arm, and the other end of the telescopic cylinder is connected with the middle of the second support arm.

Owner:嘉晟新材料(遂宁)有限公司

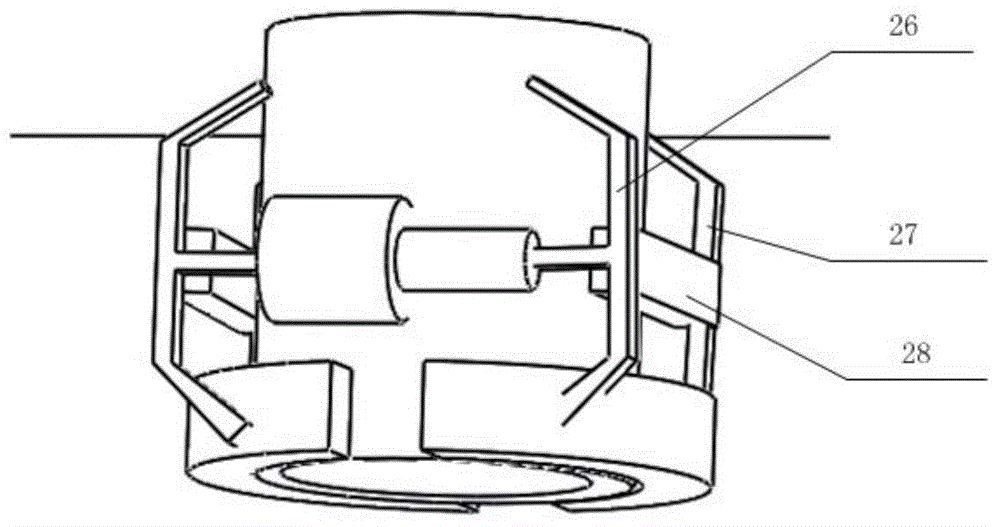

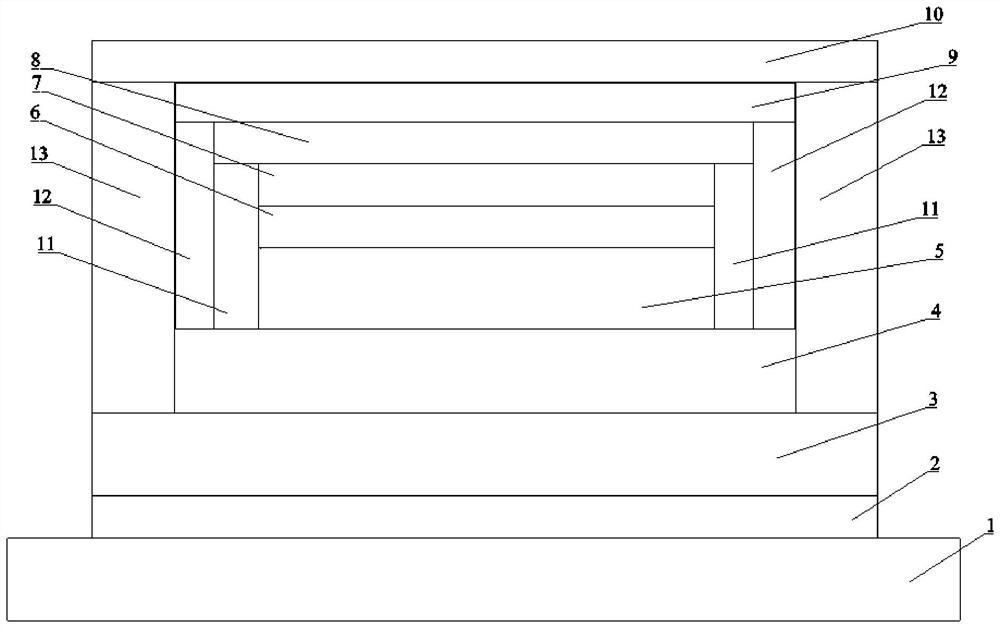

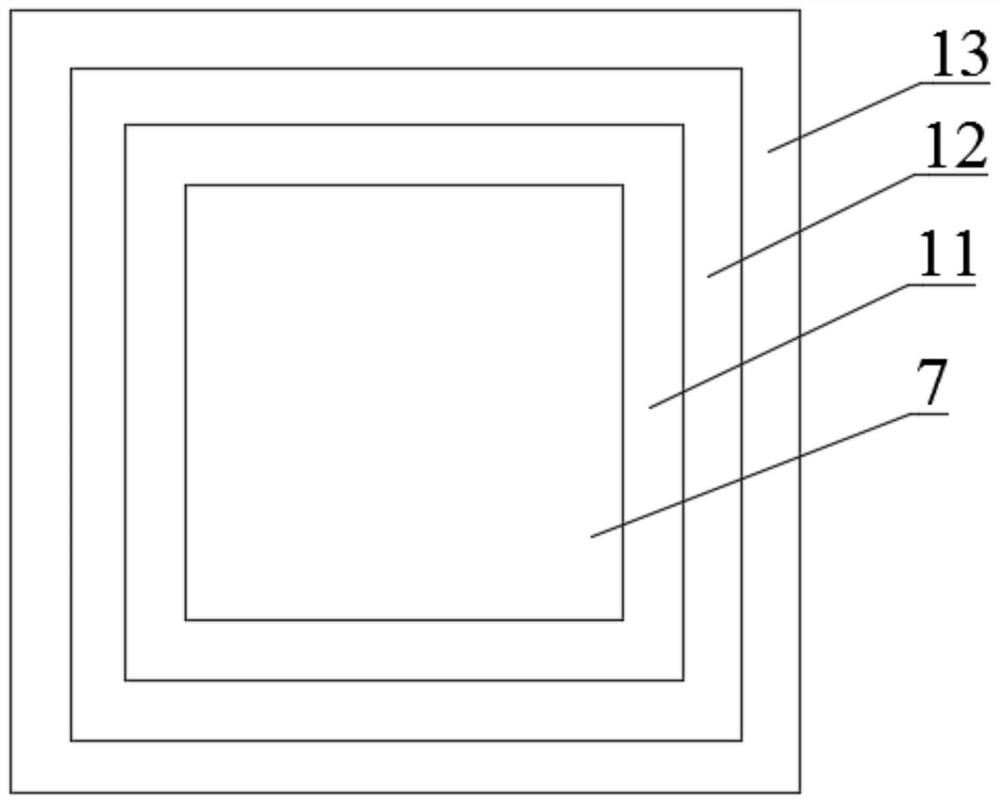

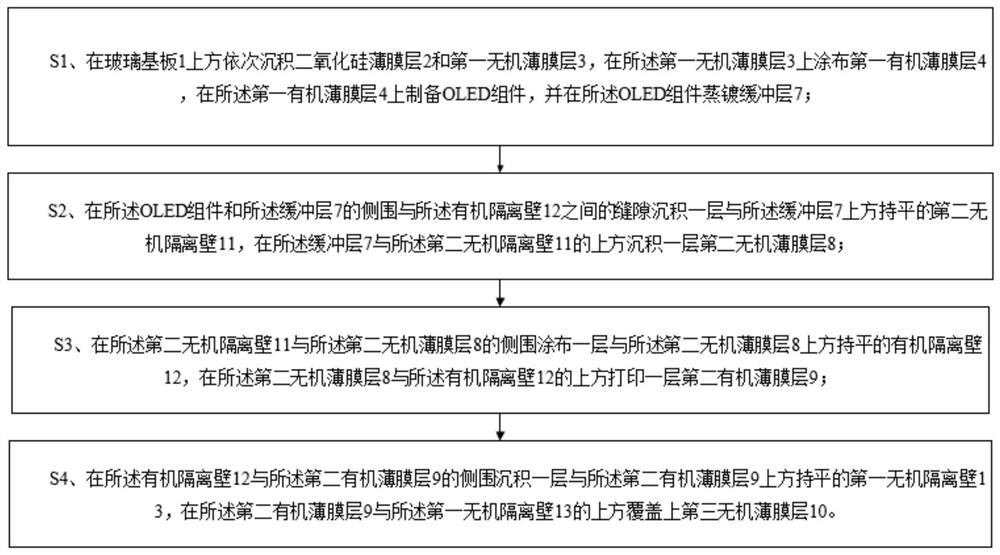

Flexible thin film packaged OLED structure and manufacturing method

PendingCN111952479AReduce warpageSolve the adhesionSolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmThin membrane

The invention discloses a flexible film packaging OLED structure and a manufacturing method, the side wall of an OLED assembly is sequentially wrapped by a second inorganic isolation wall, an organicisolation wall and a first inorganic isolation wall from inside to outside, the heights of the isolation walls are sequentially increased from inside to outside, and the isolation walls are matched with a first organic film layer and a first inorganic film layer; therefore, a stepped groove structure in which the OLED assembly can be placed is formed, the organic thin film and the inorganic thin film are fully combined with each other, and the problems of different contact surface characteristics of organic matters and inorganic matters on the side edge of thin film packaging, poor adhesion between contact surfaces and easy formation of water / oxygen permeation on the side edge of the thin film are solved. The side edges of the device can achieve the effects of collision prevention, pressure prevention and edge stress concentration relief, flexible packaging of the film is achieved, and the manufacturing yield of the OLED device is increased.

Owner:FUJIAN HUAJIACAI CO LTD

OLED display panel and OLED display device

ActiveCN114203775AReduce depthEliminate gapsSolid-state devicesSemiconductor devicesDisplay deviceAuxiliary electrode

The invention provides an OLED (Organic Light Emitting Diode) display panel and an OLED display device. According to the OLED display panel, the filling layer is arranged in the undercut structure, and the filling layer is arranged on the side, away from the auxiliary electrode layer, of the common electrode layer, so that the depth of the undercut structure is reduced or the undercut structure is filled and leveled up by the filling layer, and the segment difference of the undercut structure is eliminated; the depth of the area in contact with the inorganic layer in the packaging layer is relatively low or relatively flat, so that the inorganic layer is prevented from being broken, and packaging failure is avoided.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Method for laser sealing glass frit and laser sealing system

ActiveCN106425088BAvoid tightnessAvoid package failureSolid-state devicesSemiconductor/solid-state device manufacturingBeam splitterLaser beams

The present invention relates to a method and a laser sealing system for laser sealing glass frit, the method comprising: emitting a laser beam; dispersing the laser beam into a laser beam with a longer spot and more uniform energy than before dispersion through a beam splitter; The laser beam is introduced into the chamber used for sealing the glass frit; the laser beam is focused and corrected to form a line laser, and the line laser is irradiated on the glass frit used for sealing the semiconductor components. In the present invention, the point laser in the traditional technology is processed into a line laser with a long spot and uniform energy, and then the semiconductor components are sealed by melting the glass frit through the line laser, which well avoids the overlapping (Overlap) area in the laser sealing process due to laser An incomplete or broken seal caused by energy instability.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

Method for sealing glass grit with laser and laser sealing system

ActiveCN106425088AAvoid incomplete or broken sealsAvoid tightnessSolid-state devicesSemiconductor/solid-state device manufacturingInstabilityBeam splitter

The invention relates to a method for sealing glass grit with laser and a laser sealing system; the method comprises: transmitting a laser beam; splitting, by a beam splitter, the laser beam into laser beams longer than pre-splitting spots and having more uniform energy; guiding the laser beams into a chamber for sealing glass grit; focusing and correcting the laser beams to form line laser that irradiates the glass grit which is used to seal a semiconductor device. Point laser in the prior art is processed into line laser having long spots and uniform energy, glass grit is melted by the line laser to seal a semiconductor device, and incomplete seal or seal breakage for an overlap area in laser sealing due to laser energy instability is well avoided.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

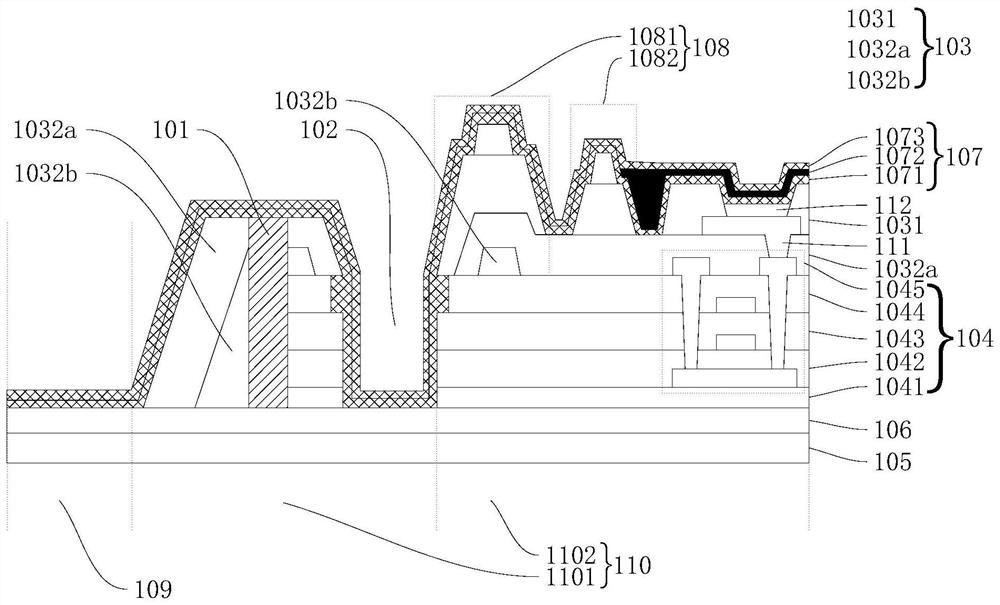

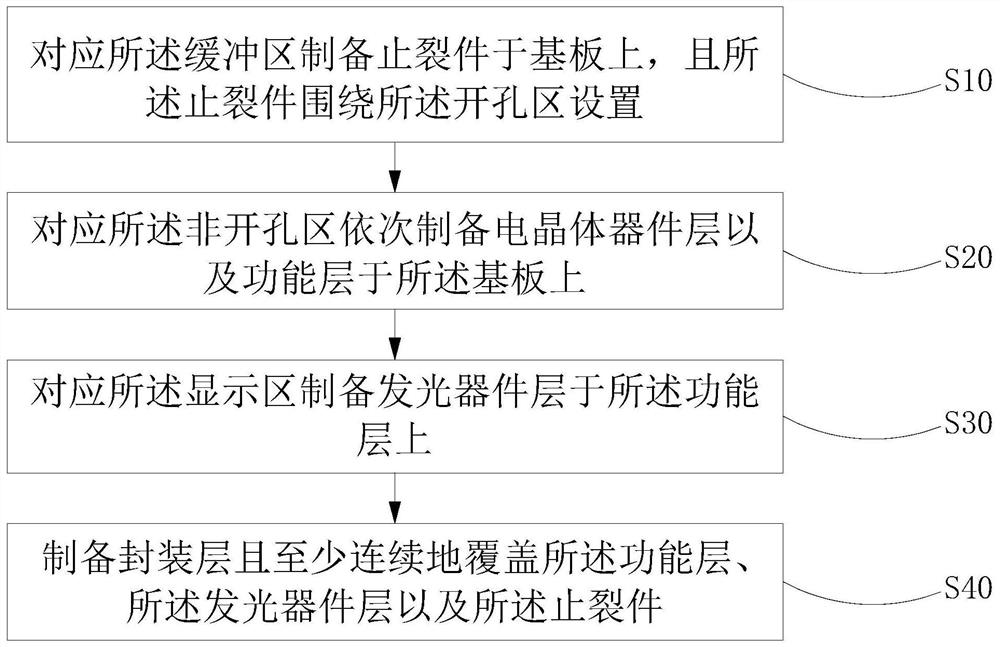

Display panel, manufacturing method thereof, and display device

ActiveCN111403627BAvoid crackingExtended service lifeSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceMechanical engineering

The present application discloses a display panel, a manufacturing method thereof, and a display device. The display panel includes an opening area and crack stoppers arranged around the opening area. The transistor device layer and the functional layer in the hole are separated from the hole area; compared with the prior art, the present application effectively prevents cracks in the film layer around the hole area due to cutting during the hole hole process, Furthermore, the encapsulation failure caused by the crack is prevented, the display device in the display panel is protected, and the yield rate of the product is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

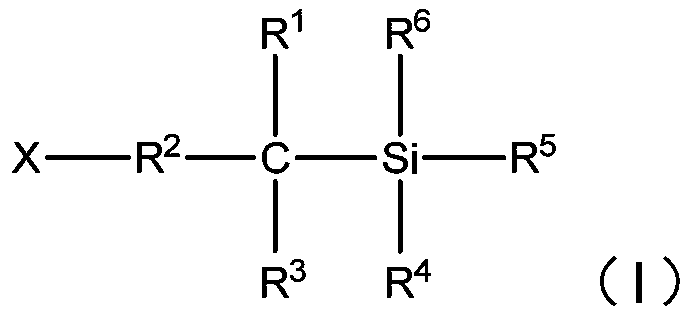

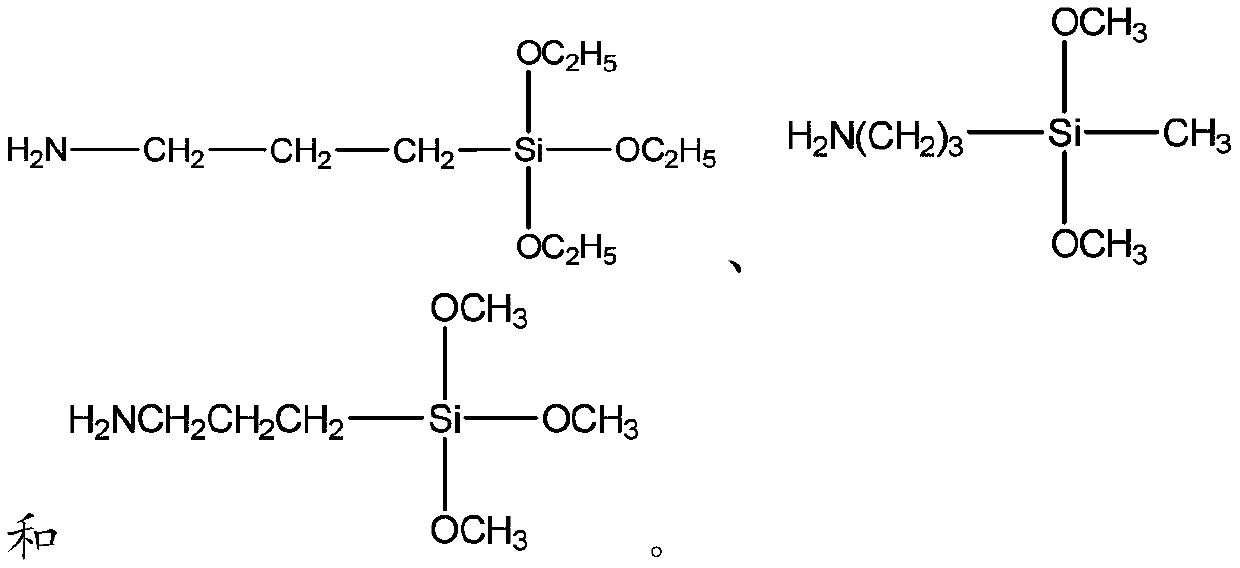

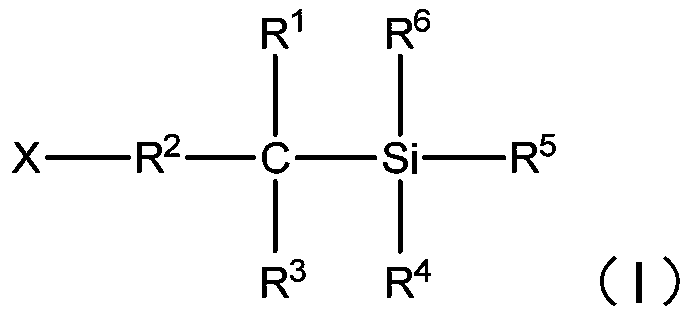

A kind of encapsulation method and encapsulation structure

ActiveCN108933088BImprove bindingFacilitate depositionSemiconductor/solid-state device detailsSolid-state devicesPlasma depositionPlasma activation

The invention provides a packaging method and a package structure adopting the method. The packaging method provided in the invention is characterized in that at least part of a surface of a substrateis exposed to a plasma, and plasma activation and plasma deposition are sequentially performed so that a compound represented by a formula (I) forms a plasma deposition layer on the surface of the substrate, so a bonding force between the substrate and a packaging material can be effectively improved, and a package failure caused by delamination between the substrate and the packaging material isprevented. In addition, according to the method provided by the invention, the plasma activation and the plasma deposition on the surface of the substrate are completed in the same cavity and in thesame process, the plasma deposition layer formed on the surface of the substrate by the method is solid and requires no additional curing, and then the overall packaging process is convenient and faster.

Owner:上海稷以科技有限公司

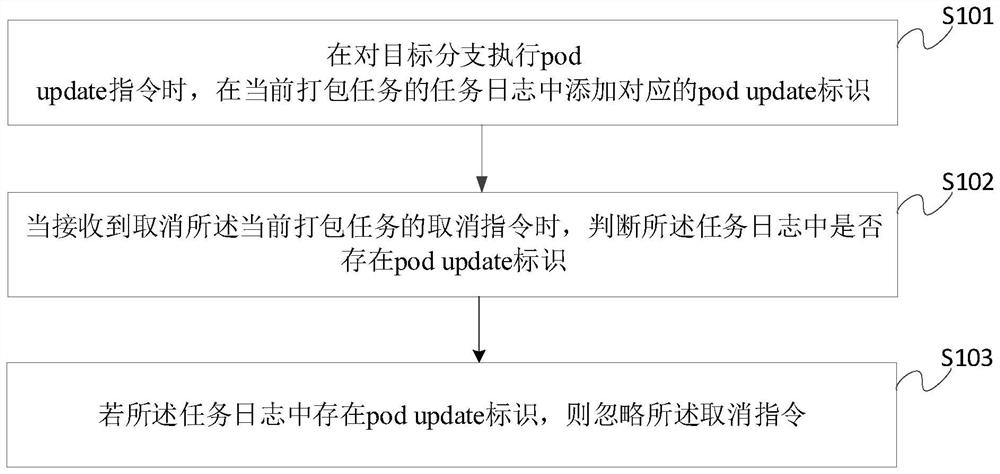

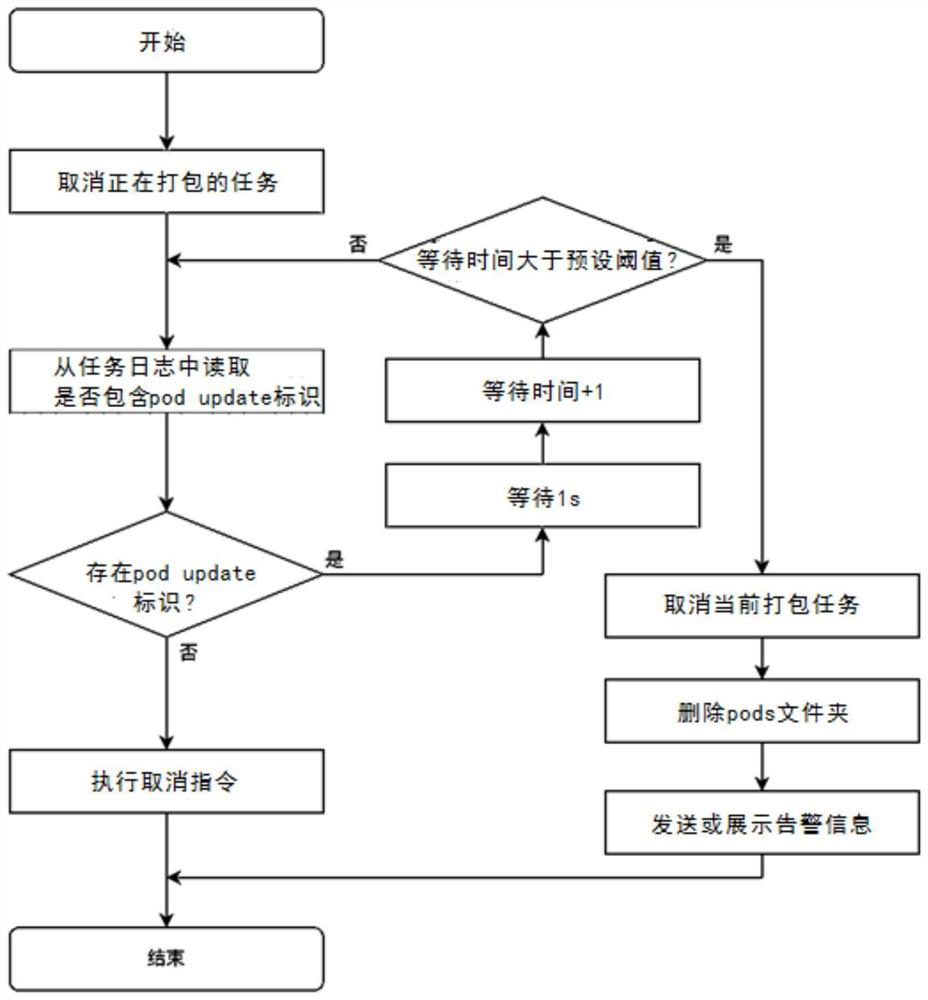

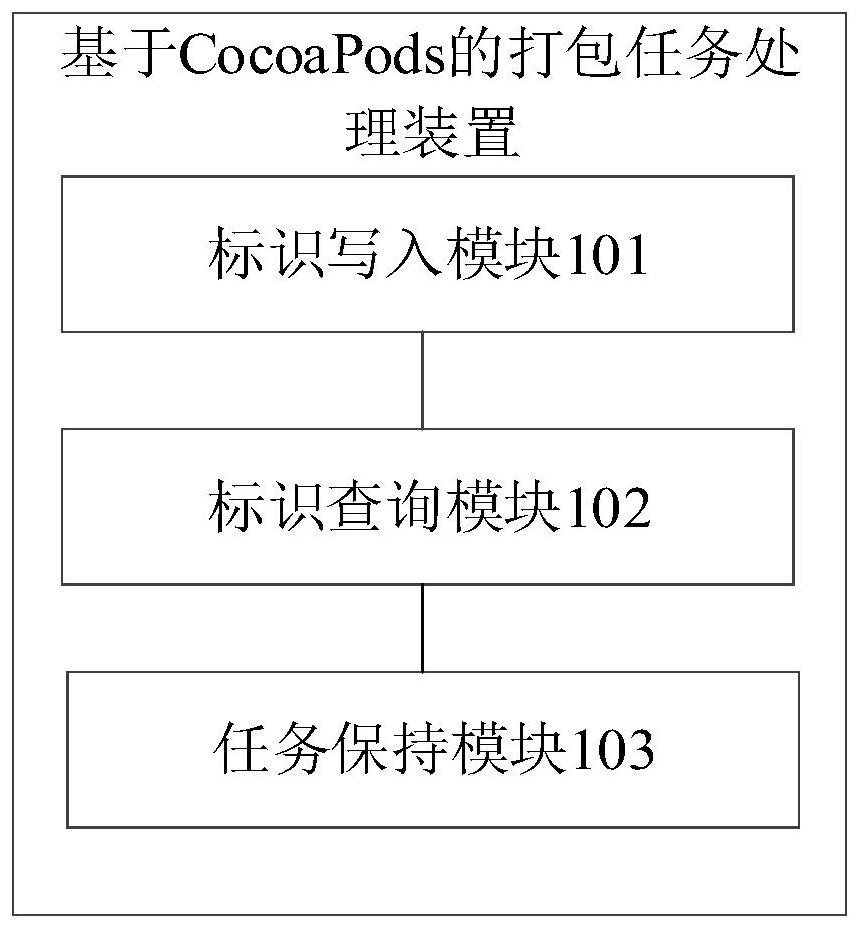

CocoPods-based packaging task processing method and apparatus, and electronic device

PendingCN114691341APreventing Situations That Become Problematic CodeNo need for manual follow-upProgram initiation/switchingOperating systemReliability engineering

The invention discloses a packaging task processing method and device based on CocoPods and electronic equipment, the method is applied to a packaging machine, and the method comprises the steps that when a pod update instruction is executed on a target branch, a corresponding pod update identifier is added in a task log of a current packaging task; when a cancelling instruction for cancelling the current packaging task is received, judging whether a pod update identifier exists in the task log or not; and if the pod update identifier exists in the task log, the cancel instruction is ignored. According to the technical scheme provided by the invention, when the process of executing the pods is interrupted, the situation that the components in the pods folder lack part of codes and become problem codes due to package interruption is prevented in advance.

Owner:北京自如信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com