Display panel and display device

A display panel and display area technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problem of intrusion into evaporated film layers, etc., and achieve the effects of reducing package failure, improving reliability, and preventing deposition dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

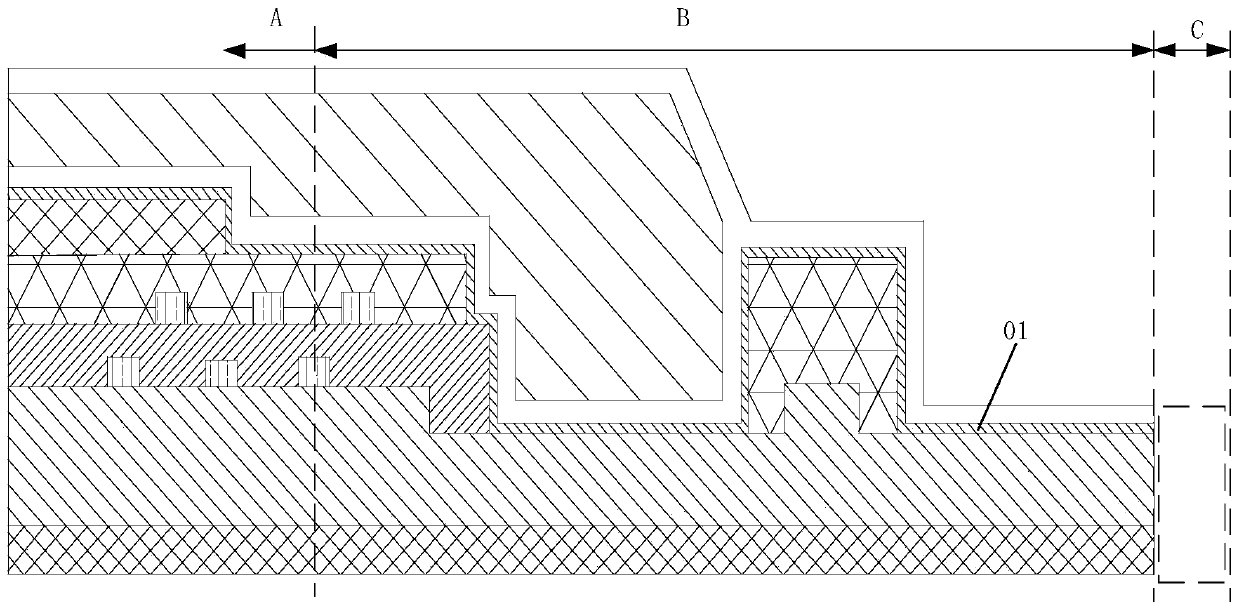

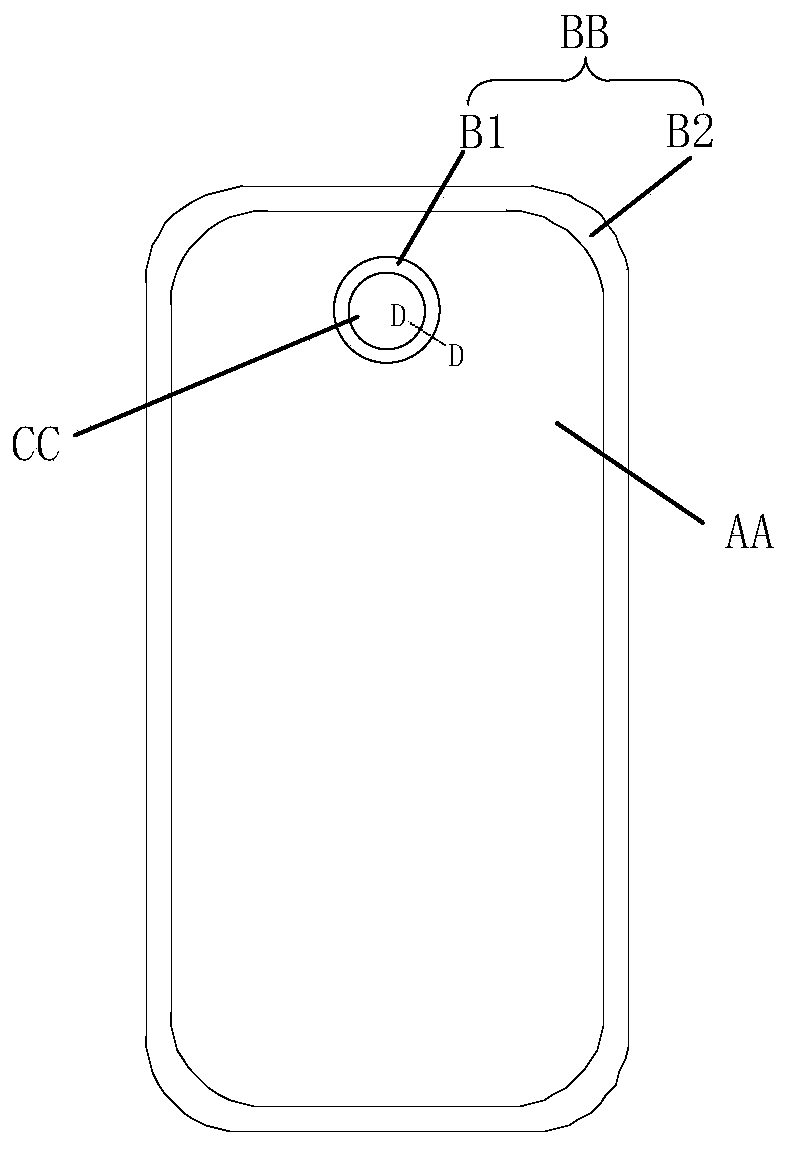

[0039] Currently, if figure 1 as shown, figure 1 It is a schematic structural diagram of a display panel in the related art. The display panel with an aperture area for the display area A includes a display area A, an aperture area C, and a non-display area B between the display area A and the aperture area C. , the hole-digging process on the display panel will lead to the direct exposure of the luminescent functional film layer 01 evaporated on the entire surface, and the external water and oxygen will enter the luminescent functional film layer 01 in the non-display area B from the opening area C, and then along the oxidation The light-emitting functional film layer 01 enters the display area A inside the display panel, which eventually leads to failure of the display panel packaging.

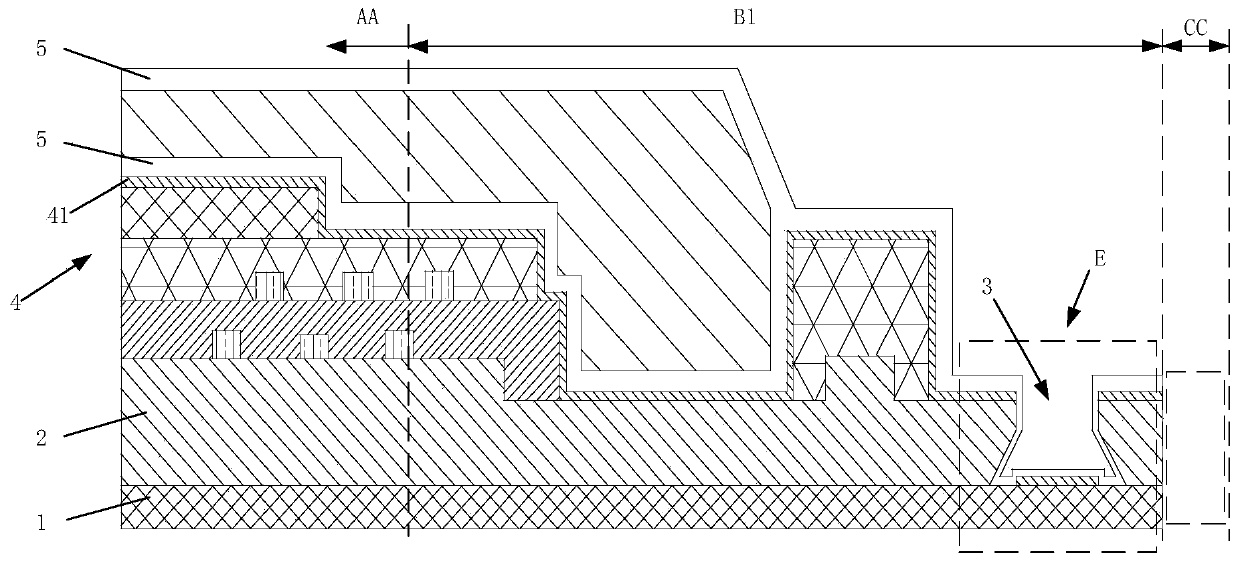

[0040] Aiming at the problem that the display panel in the related art suffers from water vapor intrusion, the embodiments of the present invention provide a display panel and a display dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com