Flexible thin film packaged OLED structure and manufacturing method

A flexible film and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems of ink flow, easy separation, uneven ink diffusion, etc., to reduce warpage and ease side edges The effect of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

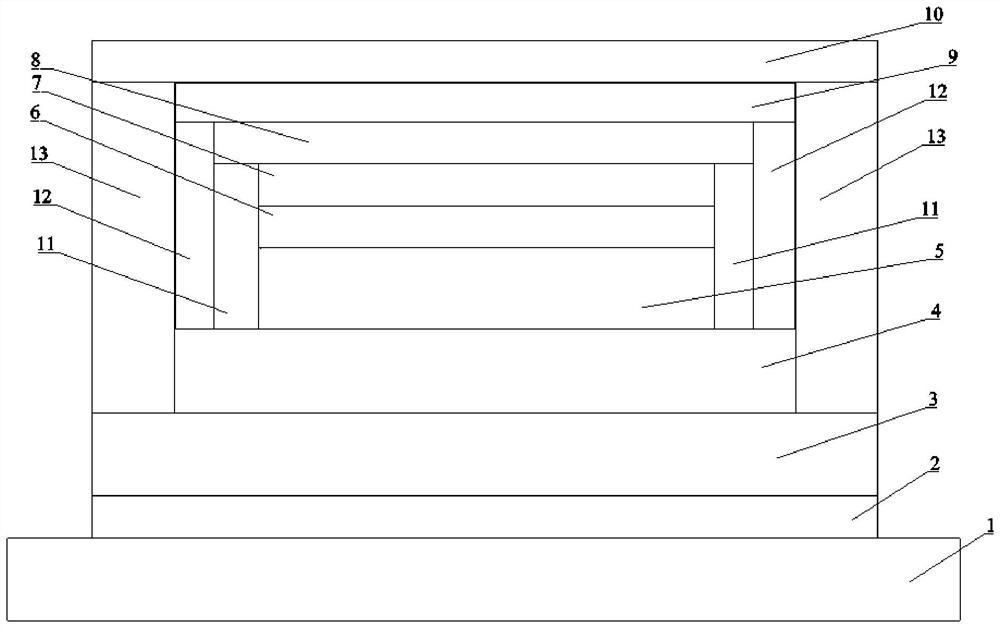

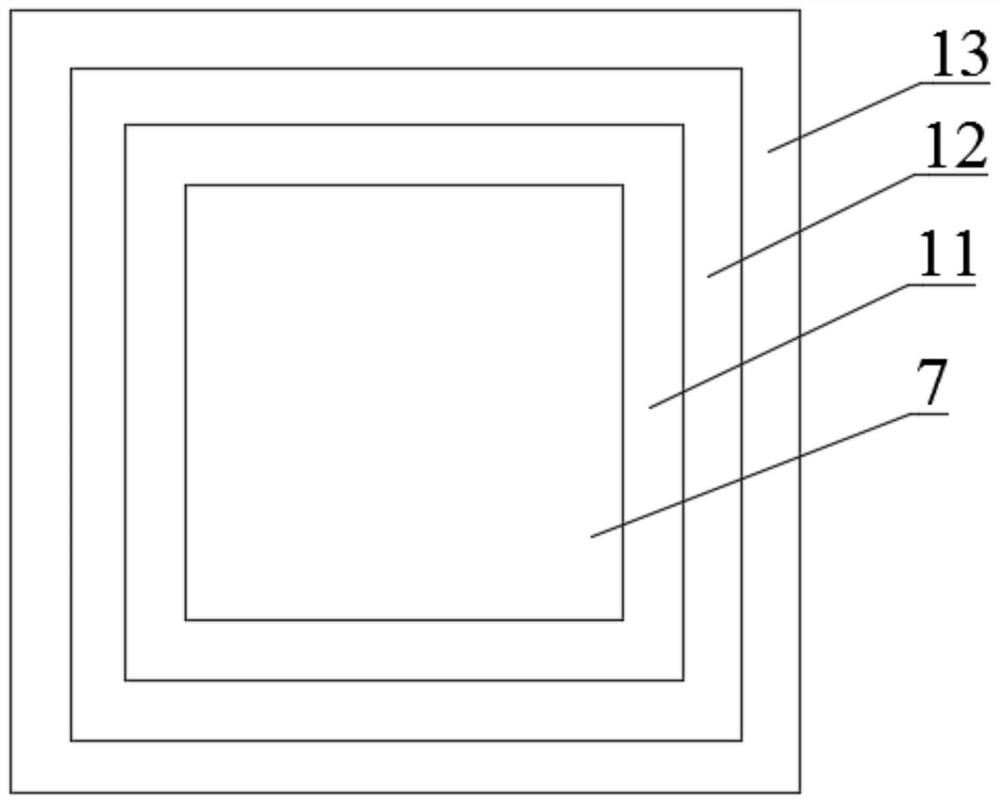

[0072] Please refer to Figure 1 to Figure 2 , Embodiment 1 of the present invention is:

[0073] A flexible film-encapsulated OLED structure, comprising a glass substrate 1, a first inorganic partition wall 13, an organic partition wall 12, a second inorganic partition wall 11, and a first inorganic thin film layer 3 stacked sequentially above the glass substrate 1 from bottom to top , the first organic thin film layer 4, the OLED assembly, the buffer layer 7, the second inorganic thin film layer 8, the second organic thin film layer 9 and the third inorganic thin film layer 10;

[0074] Wherein, the second inorganic partition wall 11 wraps the sides of the OLED assembly and the buffer layer 7, and is located between the first organic thin film layer 4 and the second inorganic thin film layer 8, and the organic partition wall 12 wraps the second inorganic partition wall 11 and the side of the second inorganic thin film layer 8, and between the first organic thin film layer 4...

Embodiment 2

[0078] Please refer to Figure 1 to Figure 2 , the second embodiment of the present invention is:

[0079] A flexible film-encapsulated OLED structure, further comprising a silicon dioxide film layer 2 on the basis of the first embodiment above;

[0080] The silicon dioxide thin film layer 2 is located between the glass substrate 1 and the first inorganic thin film layer 3 , and the thickness of the silicon dioxide thin film layer 2 ranges from 0.2um to 0.4um, preferably 0.3um.

Embodiment 3

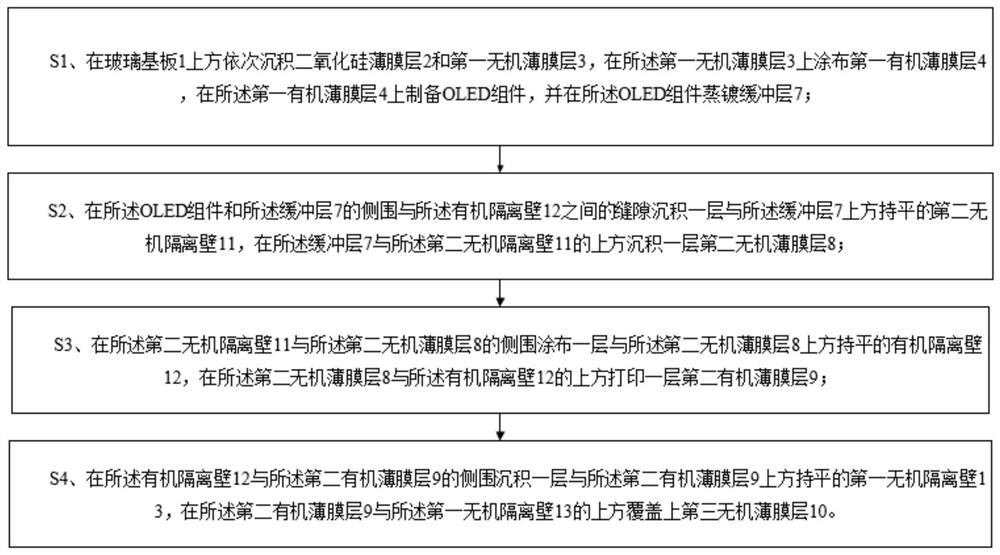

[0081] Please refer to image 3 , Embodiment three of the present invention is:

[0082] A method for manufacturing a flexible film-encapsulated OLED, comprising the steps of:

[0083] S1, deposit silicon dioxide thin film layer 2 and first inorganic thin film layer 3 sequentially on glass substrate 1, coat first organic thin film layer 4 on first inorganic thin film layer 3, prepare OLED on first organic thin film layer 4 component, and evaporate a buffer layer 7 on the OLED component;

[0084] S2. Deposit a second inorganic barrier wall 11 on the sides of the OLED assembly and the buffer layer 7 that is level with the buffer layer 7, and deposit a second inorganic thin film layer on the buffer layer 7 and the second inorganic barrier wall 11. 8;

[0085] S3, coating a layer of organic partition wall 12 on the side of the second inorganic partition wall 11 and the second inorganic thin film layer 8 that is flat with the top of the second inorganic thin film layer 8, and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com