Bicycle frame embodied with installation sleeve

A technology for bicycle racks and mounting sleeves, applied in bicycle racks, bicycle accessories, transportation and packaging, etc., can solve the problems of undiscovered patent documents, etc., and achieve the effect of good processability and good absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

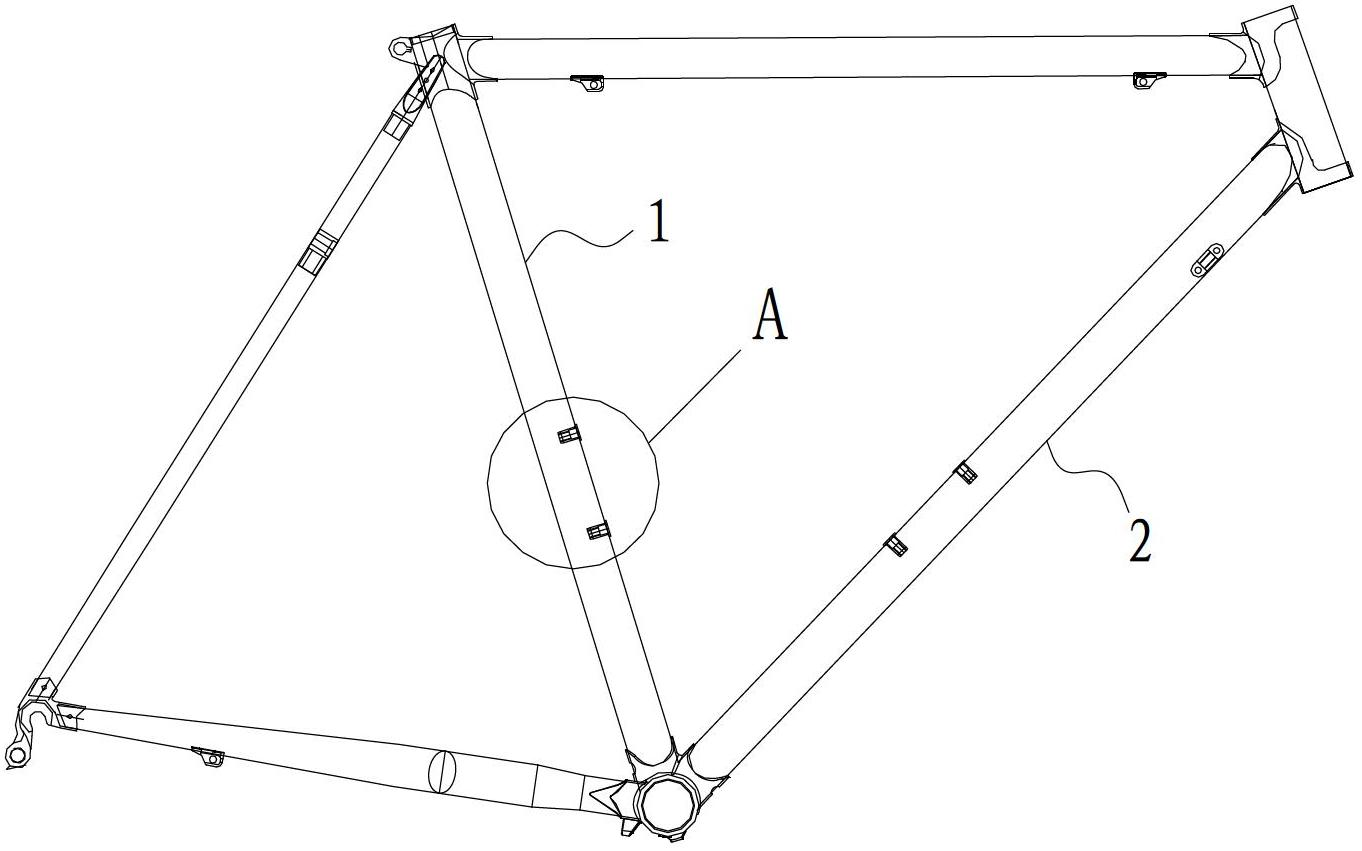

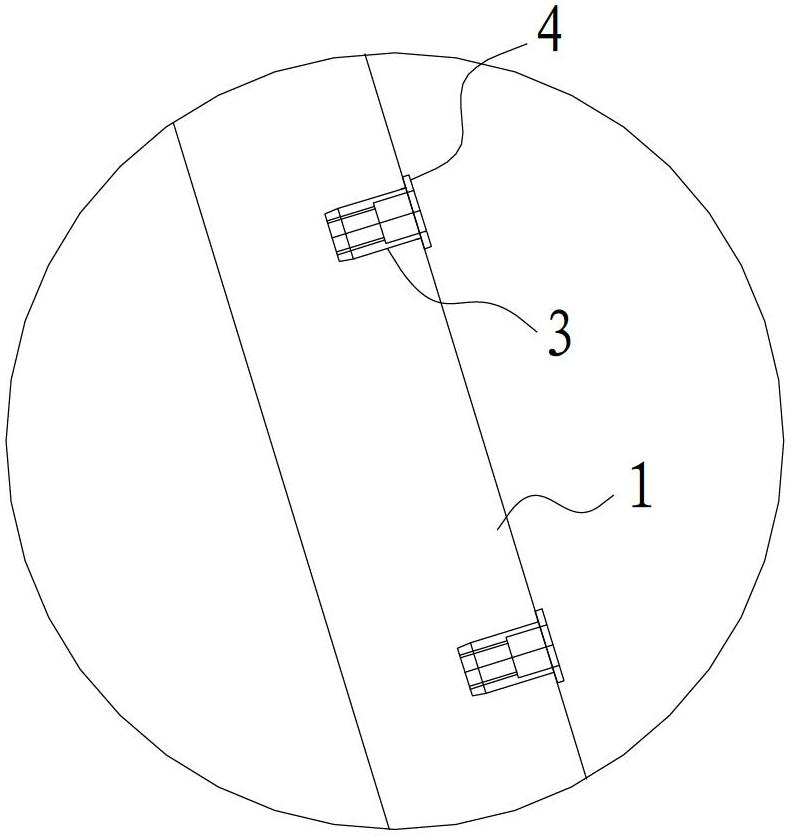

[0019] A kind of bicycle frame pre-embedded with mounting sleeve, see figure 1 , 2 , including inclined beam 2 and upright beam 1, on the inclined beam, a radial inclined beam installation hole is formed, and an inclined beam installation sleeve 3 is coaxially pre-embedded and fixed in the inclined beam installation hole.

[0020] Or, the vertical beam installation hole is also shaped on the vertical beam, and the vertical beam installation sleeve is coaxially pre-embedded in the vertical beam installation hole.

[0021] Or, it is also possible to make respective installation holes on the inclined beam or the vertical beam at the same time, and pre-embed and fix the respective installation sleeves in the respective installation holes. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com