Low-weight long-service-life composite material hydrogen cylinder and manufacturing method thereof

A composite material and manufacturing method technology, applied in the field of hydrogen cylinders, can solve the problems of increasing the weight of gas cylinders and reducing the overall performance of the hydrogen fuel cell system, and achieve short manufacturing cycles, improved work fatigue times and service life, and low production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the technical means, creative features, achieved objects and effects of the present invention easy to understand and understand, the present invention is further described below.

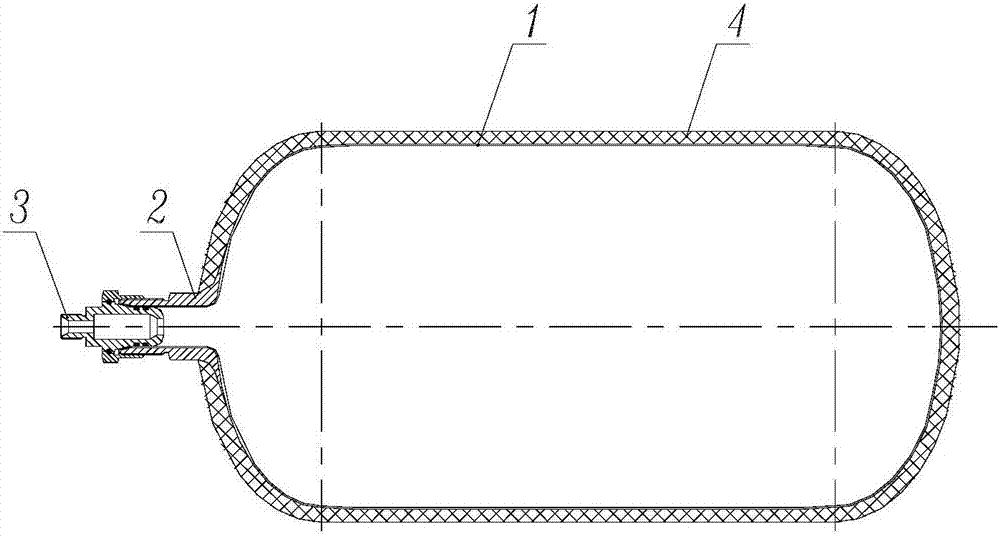

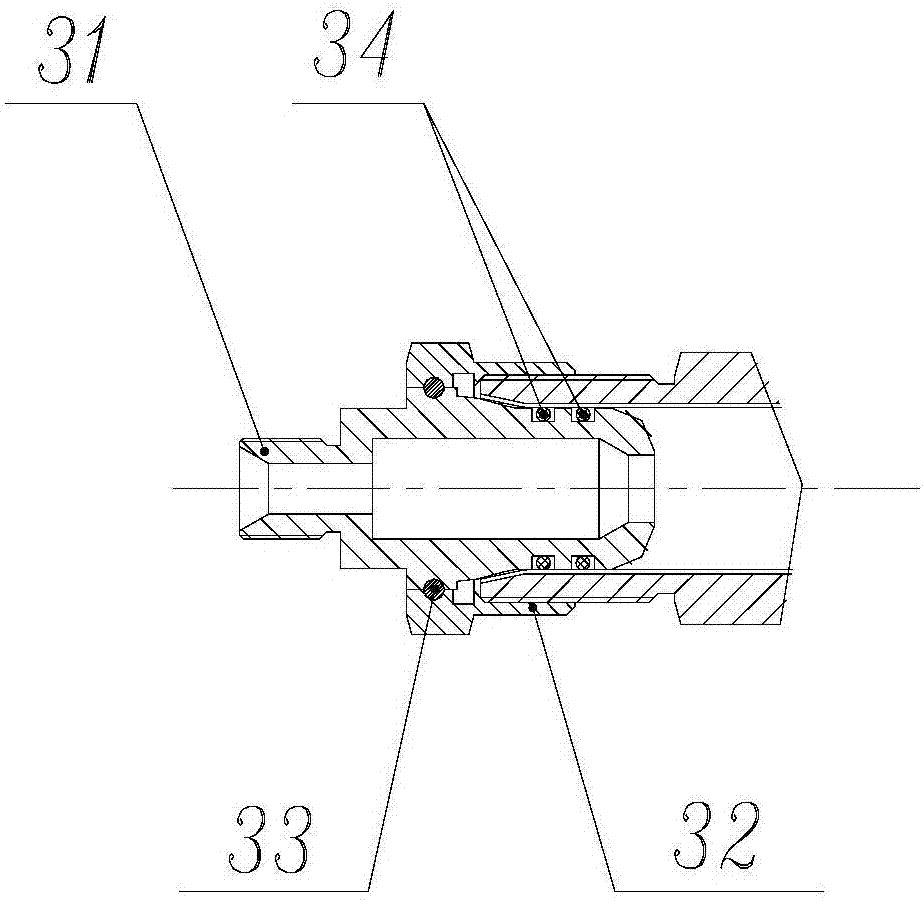

[0052] see figure 1 , figure 2 , a lightweight and long-life composite hydrogen bottle, comprising a hydrogen bottle body, the hydrogen bottle body includes a bottle body 4, the bottle body 4 is a bottle body 4 composed of carbon fiber; the inner wall of the bottle body 4 is provided with a non-metal elastic Material Constructed Liner 1. By optimizing the structure of the traditional hydrogen cylinder, the invention effectively increases the working fatigue times of the cylinder, reduces the weight of the cylinder, and has low production cost and short manufacturing cycle. Since the inner tank 1 made of non-metallic elastic material, such as the explosion of the hydrogen cylinder, will not produce any metal fragments, the safety of the hydrogen cylinder is very high.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com