Driving force transmission assembly, rotating member, toner cartridge and electronic imaging equipment

A driving force and toner cartridge technology, which is applied in the fields of electronic imaging equipment, rotating parts and toner cartridges, can solve the problems that the toner cartridge cannot be installed, the driving force receiving part is difficult to slide, and the installation and use of the toner cartridge are affected.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

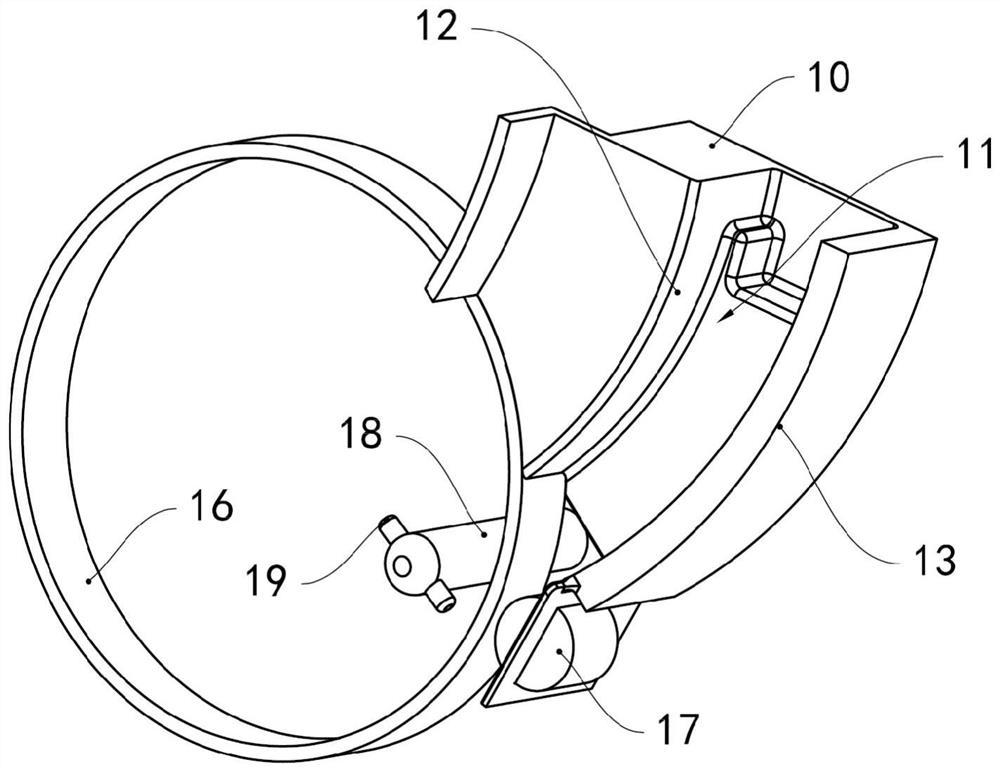

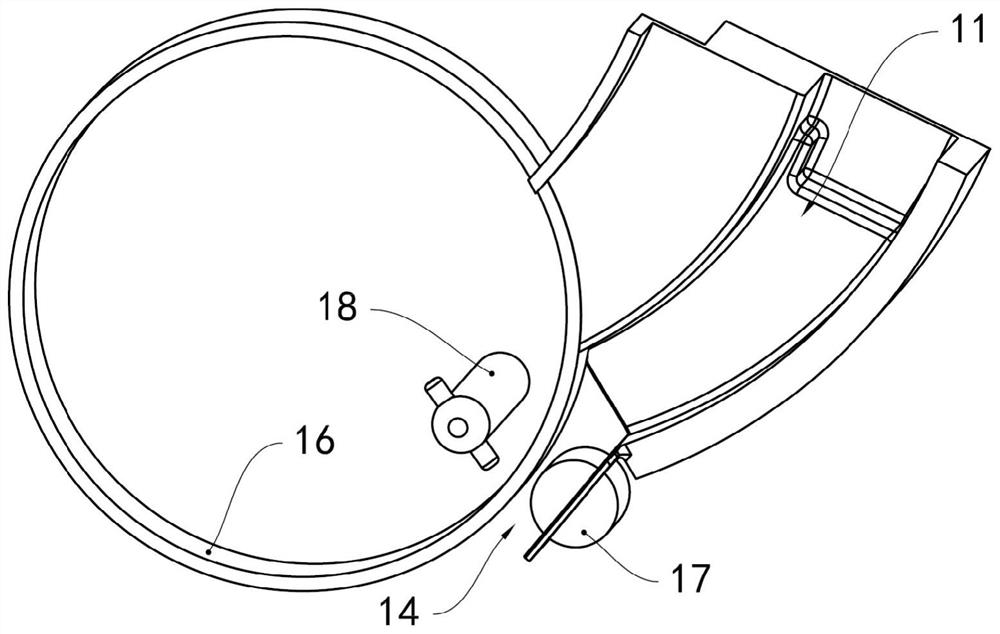

[0051] see Figure 6 to Figure 10 , the driving force transmission assembly 30 has a driving force receiving part 31 and a driving gear 40, the driving force receiving part 31 has a rod body 32 and a driving force receiving part 34 located at one end of the rod body 32, the rod body 32 is a cylindrical rod body, and the rod body 32 A pin shaft 33 is inserted in the middle. Preferably, the rod body 32 is provided with a through hole extending perpendicular to the axis of the rod body 32 , the pin shaft 33 is inserted into the through hole, and the pin shaft 33 is interference fit with the through hole. Therefore, the extension direction of the pin shaft 33 is perpendicular to the axis of the rod body 32 . The driving gear 40 has a cavity 42 with an open upper end, and the rod body 32 is inserted into the driving gear 40 , that is, protrudes into the cavity 42 of the driving gear 40 .

[0052] The driving force receiving portion 34 is exposed to the driving gear 40 , specifical...

no. 2 example

[0063] The driving force transmission assembly of this embodiment has a driving force receiving member and a driving gear, and is also provided with a mounting bracket and a spring. The difference from the first embodiment is that the two driving force receiving teeth on the driving force receiving member of this embodiment It is not integrally formed with the driving force receiver. see Figure 12 and Figure 13 , the driving force receiver 70 has a rod body 71 and a driving force receiving portion 72 located at one end of the rod body 71, a through hole 90 is provided in the middle of the rod body 71, the pin shaft can be inserted into the through hole 90, and the pin shaft and the through hole 90 interfere Cooperate.

[0064] The driving force receiving portion 72 is roughly in the shape of a circular truncated cone, wherein, the end surface of the driving force receiving portion 72 close to the driving gear is an inner end surface 74, and the end surface far away from th...

no. 3 example

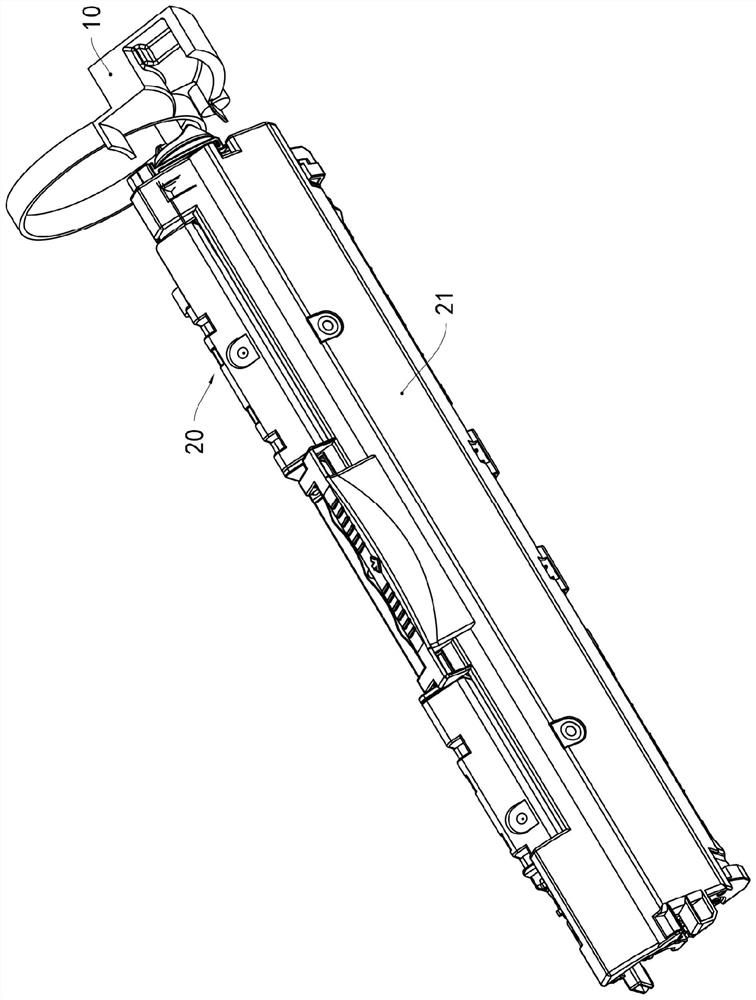

[0072] see Figure 14 and Figure 15 , The toner cartridge of this embodiment has a box body 100, a toner accommodating cavity is arranged in the box body 100, and at least one rotating member is arranged, for example, a developing roller 101 is arranged, and the developing roller 101 is driven by a driving gear 102. One end of the toner cartridge is provided with a driving force transmission assembly 110, see Figure 16 , the driving force transmission assembly 110 has a driving gear 111, the outer peripheral wall of the driving gear 111 is provided with teeth 112, the driving gear 111 meshes with the driving gear 102 and drives the developing roller 101 to rotate.

[0073] The third embodiment of the driving force transmission assembly:

[0074] see Figure 16 and Figure 17 , the driving force transmission assembly 100 also has a driving force receiving part 130, the driving force receiving part 130 has a rod body 131 and a driving force receiving part 133 located at on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com