Purification method for long-chain dicarboxylic acid

A long-chain dibasic acid and emulsifier technology, applied in chemical instruments and methods, preparation of organic compounds, separation/purification of carboxylic acid compounds, etc., can solve the problem of reducing the yield of long-chain dibasic acids and increasing the cost of sewage treatment , limit the scope of application and other issues, to achieve the effect of improving the purity of single acid, reducing loss and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

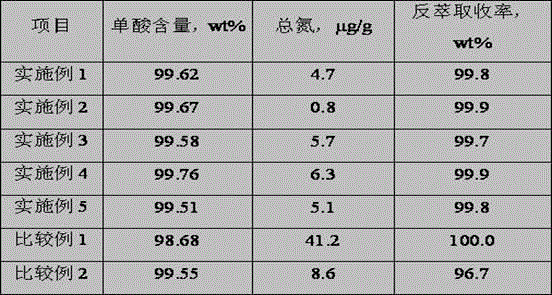

Examples

Embodiment 1

[0041] Take 2000ml and get C by fermenting Candida tropicalis 12 h 22 o 4 Fermented liquid, concentration is the fermented liquid of 160g / L. Heat the terminated fermentation broth at 85°C, let it stand for about 2 hours, then remove the residual liquid wax in the upper layer, then lower the temperature to 70°C, and filter through microfiltration to remove impurities such as bacteria cells to obtain the filtrated liquid. Add H to the filtrate 2 SO 4 Adjust the pH to 2.5 and heat to 90 °C to give C 12 h 22 o 4 The crystallized aqueous solution was cooled to room temperature and filtered to obtain a filter cake.

[0042] Put C 12 h 22 o 4 Filter cake and isobutyl ether (isobutyl ether and C 12 h 22 o 4 The weight ratio is 7:1) mixed, heated to 90°C, stood still for 30min, and separated the lower aqueous phase; then added 300mL deionized water to the solvent phase to wash the organic phase, and separated the aqueous phase again; then added to the organic phase 0.3g o...

Embodiment 2

[0045] Take 2000ml and get C by fermenting Candida tropicalis 12 h 22 o 4 Fermented liquid, concentration is the fermented liquid of 160g / L. The fermented liquid is heated to 85°C, and enters a microfiltration device to remove bacterial cells and liquid wax, etc., to obtain a clarified filtrate containing long-chain dibasic acid salts. Add H to the filtrate 2 SO 4 Adjust the pH to 3.0 and heat to 95 °C to give C 12 h 22 o 4 The crystallized aqueous solution was cooled to room temperature and filtered to obtain a filter cake.

[0046] Will C 12 h 22 o 4 Filter cake and n-butyl ether (n-butyl ether and C 12 h 22 o 4 The weight ratio is 6:1) mixed, heated to 95°C, stood still for 30min, and the lower aqueous phase was separated; 280mL deionized water was added to the solvent phase to wash the organic phase, and the aqueous phase was separated again; 0.2g was added to the organic phase Activated carbon was decolorized by heat preservation for 30 minutes, and then fil...

Embodiment 3

[0049] Take 2000ml and get C by fermenting Candida tropicalis 13 h 24 o 4 Fermented liquid, concentration is the fermented liquid of 154g / L. Heat to 70°C, filter through a ceramic microfiltration membrane, remove bacteria and residual liquid wax to obtain a filtrate. Add H to the filtrate 2 SO 4 Adjust the pH to 2.4 and heat to 95 °C to give C 13 h 24 o 4 The crystallized aqueous solution was cooled to room temperature and filtered to obtain a filter cake.

[0050] Put the obtained C 13 h 24 o 4 Filter cake and n-butyl ether (n-butyl ether and C 13 h 22 o 4 The weight ratio is 4:1), mix, mix and heat to 105°C, stand still for 45min, and remove the lower aqueous phase; then add 310mL deionized water to the solvent phase to wash the organic phase, and then separate the aqueous phase; add 0.15 g activated carbon was decolorized by heat preservation for 30min, and then the activated carbon was removed by filtration.

[0051] Add 130 μg / g of octylphenol polyoxyethyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com