A biological treatment process and device for high-sulfur and phenol-containing waste lye

A technology of biological treatment and waste lye, applied in the field of environmental engineering, can solve problems such as difficulty in meeting energy conservation and emission reduction policies, increase reactor load, increase operating costs, etc., achieve capacity improvement, reduce water consumption, and save floor space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

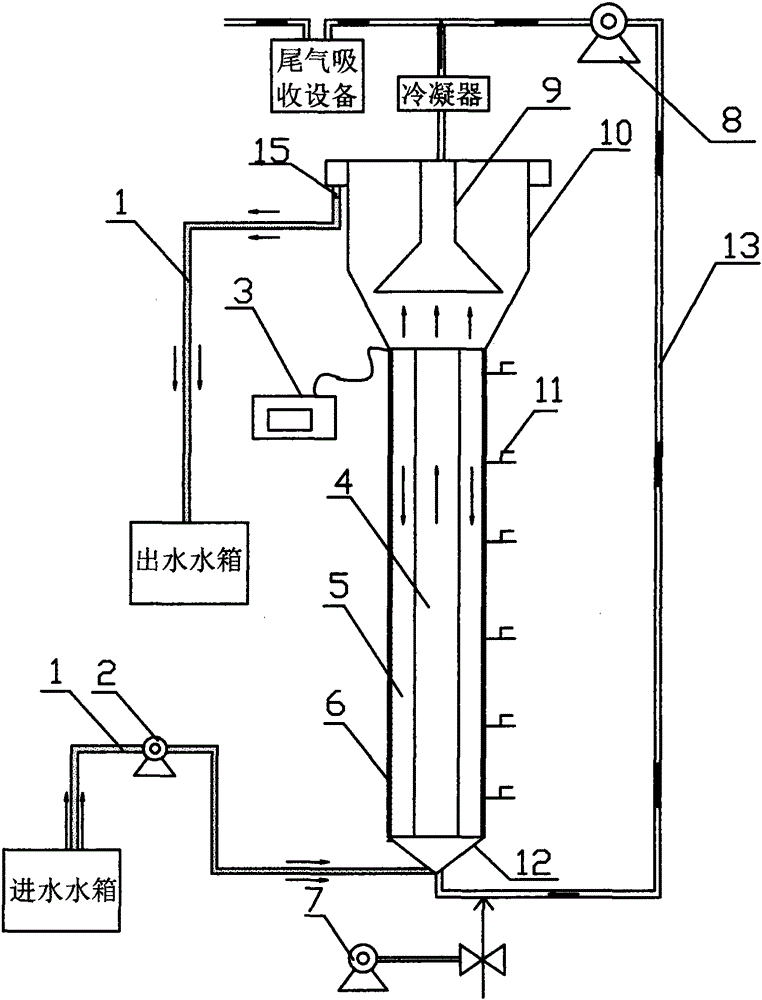

Image

Examples

Embodiment 1

[0034] HS in waste lye - Concentration is 5.0g / L, COD concentration is 15g / L, Na + The concentration is 0.4mol / L.

[0035] Process conditions: the reaction temperature is 35°C; the pH is 9.5; the hydraulic retention time is 96 hours.

[0036] Under above-mentioned processing condition, described waste lye is processed:

[0037] (1) Pretreatment: Add EDTA300mg / L, FeSO4 7H to the waste lye 2 O100mg / L, ZnSO4 ·7H 2 O10mg / L, MnCl 2 4H 2 O3mg / L, H 3 BO 3 20mg / L, CoCl 2 ·6H 2 O10mg / L, CuCl 2 2H 2 O1mg / L, NiCl 2 ·6H 2 O2mg / L, Na 2 MoO 4 2H 2 03mg / L and 25μg vitamin B12, in order to replenish the nutrient elements necessary for the growth and metabolism of saline-alkali-resistant microorganisms in the reactor, a small amount of waste lye is respectively divided into 10 times, 8 times, 5 times, 3 times, 1 times (undiluted) ) is diluted for the start-up of the reactor;

[0038] (2) Reactor startup: under aerobic conditions, set the pH at 9.0, Na + The river bed sedimen...

Embodiment 2

[0043] HS in waste lye - Concentration is 6.0g / L, COD concentration is 22g / L, Na + The concentration is 0.6mol / L.

[0044] Process conditions: the reaction temperature is 30°C; the pH is 9.2; the hydraulic retention time is 60 hours.

[0045] Under above-mentioned processing condition, described waste lye is processed:

[0046] (1) Pretreatment: Add EDTA300mg / L, FeSO 4 ·7H 2 O100mg / L, ZnSO 4 ·7H 2 O10mg / L, MnCl 2 4H 2 O3mg / L, H 3 BO 3 20mg / L, CoCl 2 ·6H 2 O10mg / L, CuCl 2 2H 2 O1mg / L, NiCl 2 ·6H 2 O2mg / L, Na 2 MoO 4 2H 2 O3mg / L and 25μg vitamin B12 are used to supplement the nutrients necessary for the growth and metabolism of saline-alkali-resistant microorganisms in the reactor, and at the same time dilute a small amount of waste lye according to 8 times, 5 times, 3 times and 1 times (undiluted) respectively , for the start-up of the reactor;

[0047] (2) Reactor startup: under aerobic conditions, set the pH at 9.5, Na + The salt lake bottom sludge with a...

Embodiment 3

[0052] HS in waste lye - Concentration is 7.0g / L, COD concentration is 25g / L, Na + The concentration is 0.8mol / L.

[0053] Process conditions: the reaction temperature is 20°C; the pH is 9.0; the hydraulic retention time is 24 hours.

[0054] Under above-mentioned processing condition, described waste lye is processed:

[0055] (1) Pretreatment: Add EDTA300mg / L, FeSO 4 ·7H 2 O100mg / L, ZnSO 4 ·7H 2 O10mg / L, MnCl 2 4H 2 O3mg / L, H 3 BO 3 20mg / L, CoCl 2 ·6H 2 O10mg / L, CuCl 2 2H 2 O1mg / L, NiCl 2 ·6H 2 O2mg / L, Na 2 MoO 4 2H 2 03mg / L and 25μg vitamin B12, in order to replenish the nutrient elements necessary for the growth and metabolism of saline-alkali-resistant microorganisms in the reactor, a small amount of waste lye is respectively divided into 10 times, 8 times, 5 times, 3 times, 1 times (undiluted) ) is diluted for the start-up of the reactor;

[0056] (2) Reactor startup: under aerobic conditions, set the pH at 10.0, Na + The soda lake bottom sludge with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com