Efficient, energy-saving and multipurpose sludge recycling device and efficient energy-saving multipurpose sludge recycling method

A sewage treatment device, high-efficiency and energy-saving technology, applied in the direction of sludge treatment, sludge treatment, biological sludge treatment, etc., can solve the problem of incomplete utilization of effective resources, to save the amount of alkali added, simplify the process, and reduce the cost of chemicals low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

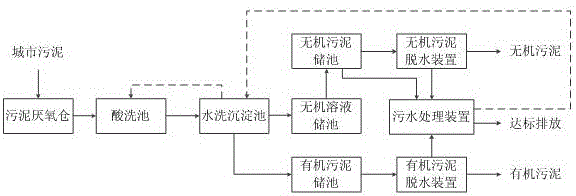

[0054] The sludge in a certain city has 35% organic content in dry matter. It is stored anaerobic in the sludge anaerobic silo for 2 days. The anaerobic black sludge is pickled with dilute sulfuric acid in the pickling tank, and the pickling pH=0.5 , The acid-washed sludge solution is washed and sedimented, and the pH of the washing sedimentation tank is 0.7; the sludge precipitated in the washing sedimentation tank enters the organic sludge storage tank, and CaO turbid liquid is added for neutralization, and the neutralized sludge Organic sludge is obtained by dehydration, and the organic content of the organic sludge is 75%; the supernatant of the washing sedimentation tank enters the inorganic solution storage tank, and NaOH solution is added to neutralize the precipitation, and the inorganic sludge is obtained after dehydration. The organic matter in the inorganic sludge content <3%; After the sewage in the system is treated by the sewage treatment device, the effluent reach...

Embodiment 2

[0056] The sludge in a certain city has 35% organic content in dry matter. It is stored anaerobic in the sludge anaerobic silo for 2 days. The anaerobic black sludge is pickled with dilute sulfuric acid in the pickling tank, and the pickling pH=0.5 , The solid content of the sludge solution in the pickling tank is 10%. All the pickling water comes from the supernatant of the washing sedimentation tank. The amount of acid added saves 80%; the sludge solution after pickling is washed and precipitated, and the sedimentation tank is washed with water. All water comes from the effluent of the system sewage physical device, the pH of the washing sedimentation tank is 0.9, and the supernatant of the washing sedimentation tank is partially returned to the acid washing tank; the sludge settled in the washing sedimentation tank enters the organic sludge storage tank, and NaOH is added The turbid liquid is neutralized, and the neutralized sludge is dehydrated to obtain organic sludge; the ...

Embodiment 3

[0058] The sludge in a certain city has an organic content of 42% in dry matter. It is stored anaerobic in the sludge anaerobic silo for 10 days. The anaerobic black sludge is pickled with dilute acetic acid in the pickling tank, and the pickling pH=4 , The solid content of the sludge solution in the pickling tank is 7%, all the pickling water comes from the supernatant of the washing sedimentation tank; the sludge solution after the acid washing is washed and sedimented, and the water used in the washing sedimentation tank is all from the system sewage physical device After the water is discharged, the supernatant of the washing sedimentation tank is partially returned to the pickling tank; the sludge settled in the washing sedimentation tank enters the organic sludge storage tank, and CaO turbid liquid is added for neutralization, and the neutralized sludge is dehydrated. Organic sludge, the organic content of the organic sludge is 68%; the supernatant of the washing sedimenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com