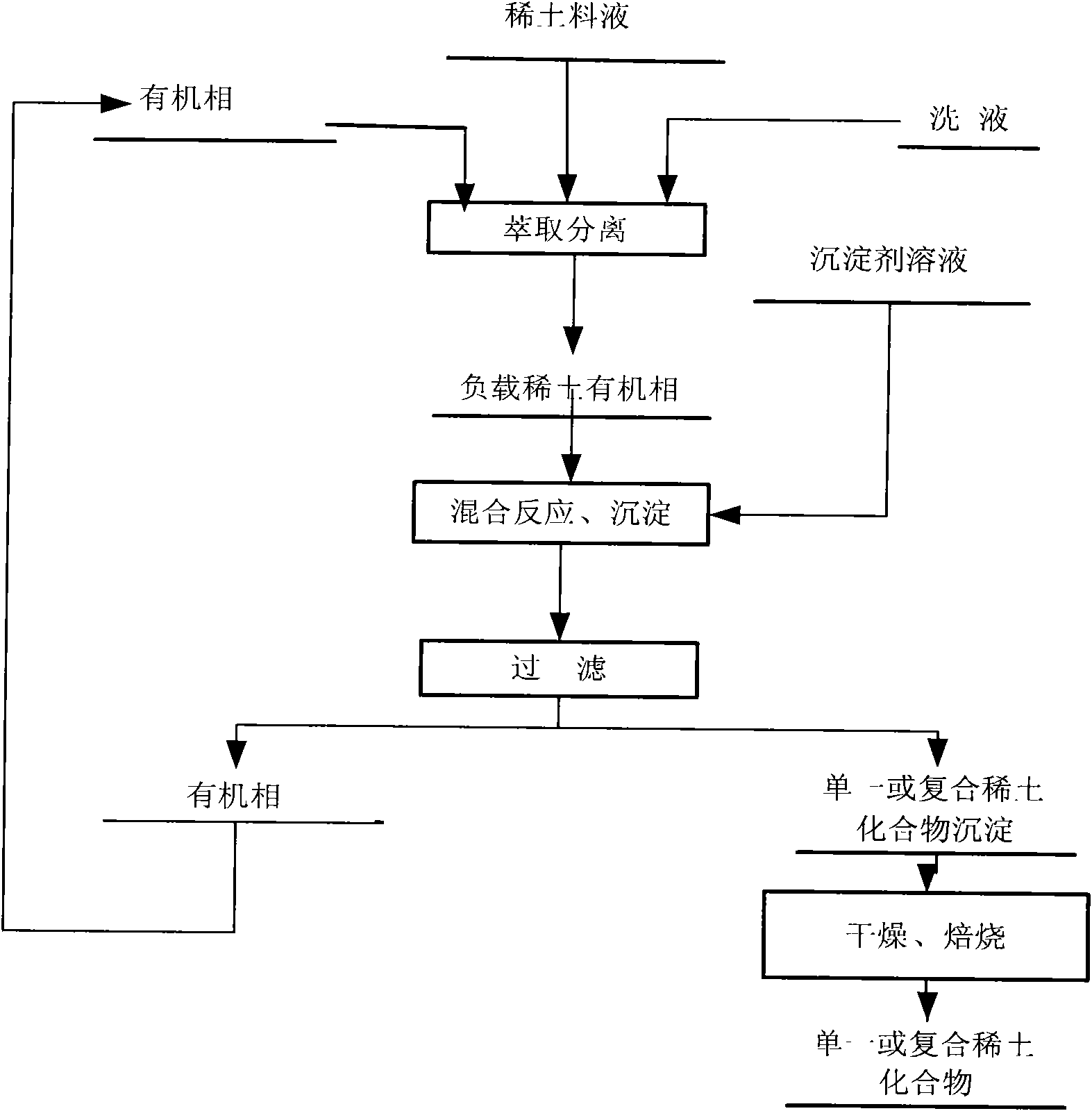

Process of directly preparing rare-earth compound from extraction separation load organic phase

A technology of rare earth compounds and organic phases, which is applied in the field of rare earth compound preparation, rare earth hydrometallurgy and the preparation of rare earth compounds, can solve the problems of medium and heavy rare earth stripping difficulties, large acid consumption, particle agglomeration, etc. The effect of removing organic phase saponification process, reducing mutual adsorption, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] LaCePrNd rare earth chloride solution (acidity is 0.00001mol / L, rare earth content is 1.5mol / L REO), containing NH 4+ The P507 extraction agent concentration is 1.5mol / L (diluent is kerosene) and acidity is that the hydrochloric acid washing liquid of 5.0mol / L is added in the 70-stage extraction tank and carries out Ce / Pr cascade fractionation extraction separation; Part of the organic phase of praseodymium and neodymium is continuously drawn into the settling tank, and a theoretical amount of 130% ammonium bicarbonate (concentration is 0.1wt%) solution is added, stirred for 1 hour at a temperature of 40° C., and the precipitated slurry is obtained by suction filtration. The rare earth filter cake is washed with kerosene and ethanol, dried by azeotropic distillation, and calcined at 900°C for 3 hours to obtain praseodymium and neodymium oxide powder. The particle size test results are shown in Table 1. Contains NH 4+ The P507 organic phase is directly returned to the ...

Embodiment 2

[0034] LaCePrNd sulfuric acid rare earth solution (acidity is 0.0001mol / L, rare earth content is 0.1mol / L REO), containing Na + The P204 (40%vol) and P507 (60%) mixed extractant (diluent is kerosene) concentration is that 1.5mol / L, acidity are that the hydrochloric acid wash of 5.5mol / L is added in 70 grades of extraction tanks respectively and carries out Ce / Pr cascade fractional distillation extraction and separation; at 65 grades, part of the organic phase loaded with cerium is continuously drawn into the settling tank, and a theoretical amount of 120% sodium carbonate (concentration is 30wt%) solution is added, and stirred for 2 hours at a temperature of 20°C. The precipitated slurry was suction filtered to obtain a rare earth carbonate filter cake, washed with kerosene, and dried in vacuum to obtain praseodymium and neodymium carbonate powder. The particle size test results are shown in Table 1. Contains Na + After standing and stratifying, the mixed extractant is direc...

Embodiment 3

[0036] LaCe rare earth chloride solution (acidity is 0.001mol / L, rare earth content is 1.4mol / L REO), containing Na + The P204 extraction agent concentration is 1.3mol / L (diluent is kerosene) and acidity is that the hydrochloric acid washing solution of 5.5mol / L is added respectively in the 60-stage extraction tank and carries out La / Ce cascade fractionation extraction separation; Part of the organic phase of cerium is continuously drawn into the settling tank, and a mixed solution of sodium carbonate and oxalic acid (the molar ratio is 1:1, and the average concentration is 15wt%) is added in a theoretical amount of 100%, and stirred for 1 hour at a temperature of 65°C. After precipitation, The slurry was suction filtered to obtain a rare earth carbonate filter cake, washed with ethanol, and dried by azeotropic distillation to obtain cerium carbonate powder. The particle size test results are shown in Table 1. Contains Na + The P204 organic phase is directly returned to the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com