Easily-pickled low-carbon steel wire rod and control method of surface scale of easily-pickled low-carbon steel wire rod

A control method and surface oxidation technology, applied in the field of steel rolling, can solve the problems of environmental pollution, large consumption of acid solution, and long pickling time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1-3

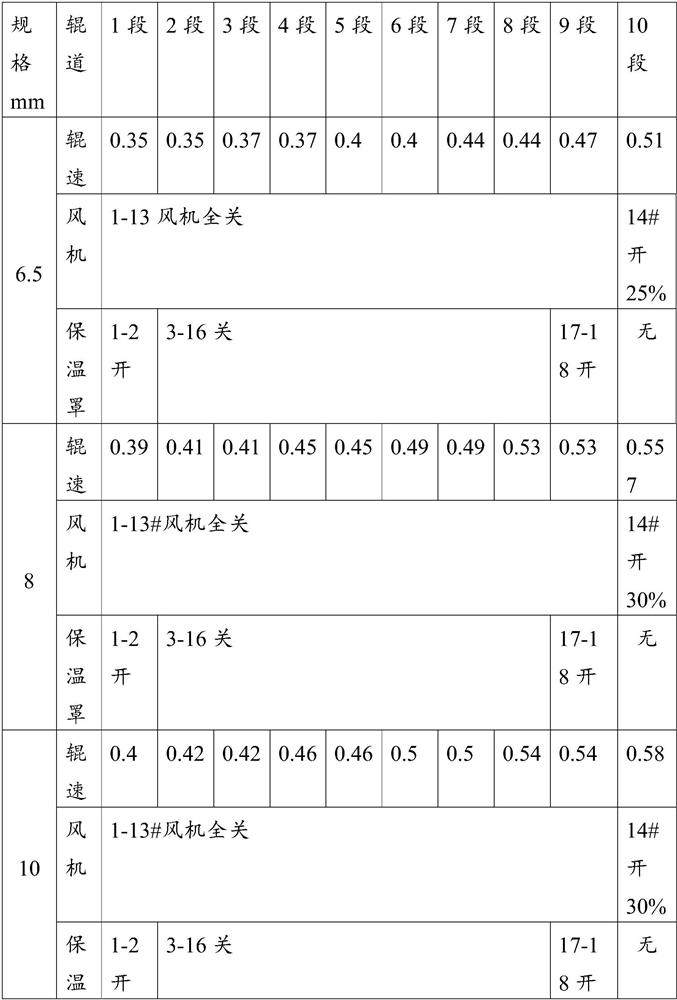

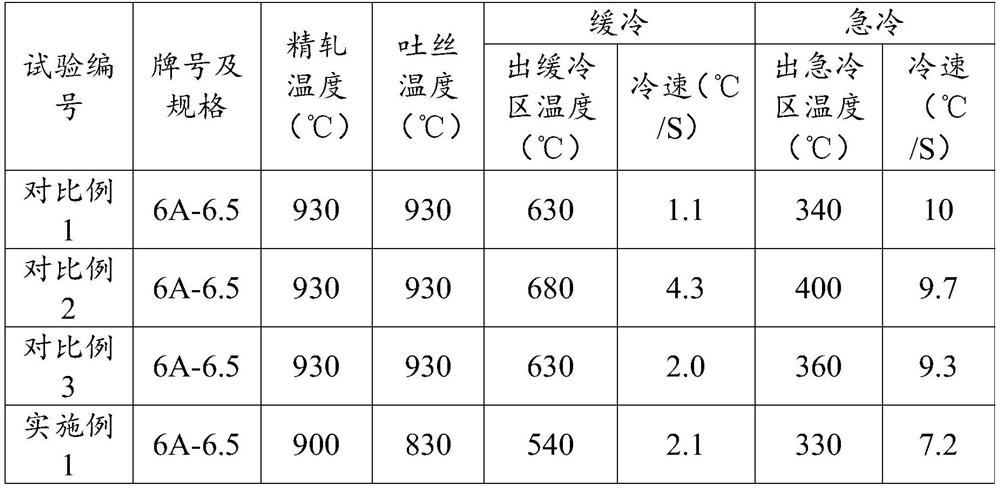

[0046]Table 1 is a specific parameters of the control method of the micro-iron oxide skin of the surface of the low carbon steel bar strip in Example 1 and Comparative Example 1-3, wherein the grades and specifications of low carbon steel employed in Example 1 and the proportion 1-3 are the same.

[0047]The tensile strength required for low-carbon steel strips of 6A-6.5 is: 300 ~ 360MPa, where 6a is a license, 6.5 indicates that the specification (diameter) is 6.5mm.

[0048]Table 1 Embodiment 1 and Specific parameters of the control method in ratio 1-3

[0049]

[0050]Among them, after the emergency area, it is placed in the air to cool to room temperature. The specific structure and properties of the surface iron oxide skin obtained by the low carbon steel strips obtained in Example 1-3 and Example 1 are shown in Table 2.

[0051]Table 2 Example 1 and the specific structure and properties of iron oxide skin in ratio 1-3

[0052]

[0053]According to Table 2, it can be seen that in the range of tensi...

Embodiment 2-3 and comparative example 4

[0056]Table 3 is a specific parameter of the control method of the iron oxide skin of the low carbon steel bar strip surface in Examples 2-3 and Comparative Example 4, wherein the grades and specifications of low carbon steel employed in Example 2-3 and the proportional 4 were the same. The tensile strength requirements of low carbon steel strips 22A-6.5 are: 450 ~ 550 MPa.

[0057]Table 3 Embodiment 2-3 and Specific parameters of the control method in Comparative Example 4

[0058]

[0059]Among them, after the emergency area, it is placed in the air to cool to room temperature. The specific structure and properties of the surface iron oxide skin obtained by the low carbon steel strip obtained in Example 4 and Example 2-3 are shown in Table 4.

[0060]Table 4 Example 2-3 and the specific structure and performance of iron oxide in ratio 4

[0061]

[0062]According to Table 2 and Table 4, it can be seen that the present application has a more significant effect on the thickness of the finished iron o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com