Steel cord cleaning process and device

A cleaning device and steel cord technology, applied in the field of steel cord surface treatment, can solve the problems of affecting the quality and output of steel cord products, failing to meet the requirements of the electroplating process, and high degree of automation, achieving good pickling effect and structural Reasonable, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with some specific embodiments.

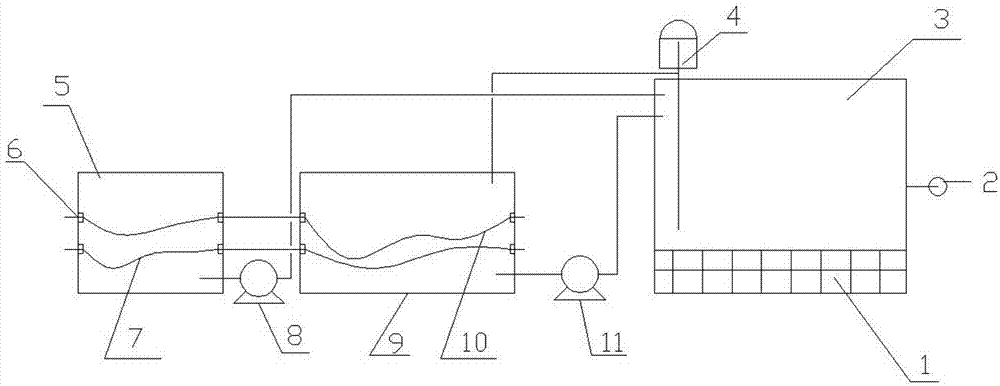

[0018] see figure 1 and figure 2 , The meaning of each symbol in the figure: 1-heating rod, 2-temperature control meter, 3-acid liquid pool, 4-acid liquid lifting pump, 5-cold water washing tank, 6-wire hole, 7-steel cord ⅰ, 8-acid water circulation pump, 9-pickling tank, 10-steel cord ⅱ, 11-acid liquid circulation pump.

[0019] To achieve the above object, the present invention adopts the following technical solutions:

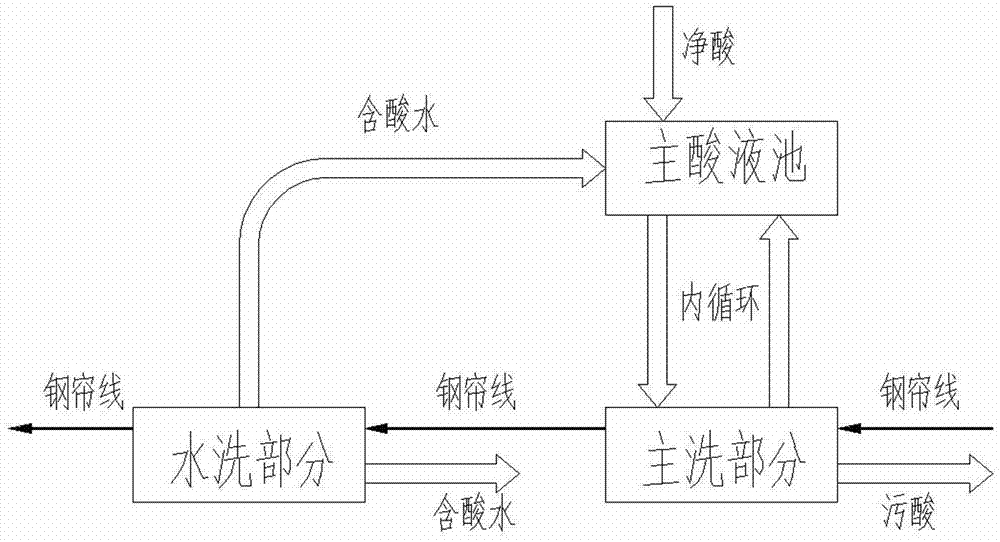

[0020] A steel cord cleaning process, including a pickling part and a water washing part, the steel cord is first cleaned through the pickling part, and then through the water washing part for the second cleaning, and a part of the acid-containing water in the washing part circulates into the pickling Partially used, excess acidic water drains at the bottom of the cold water wash sink.

[0021] The acid liquid in the pickling part and the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com