Rectification column for removing hydrogen containing foreign matter in germanic chloride

A technology of germanium tetrachloride and rectification tower, which is applied in the field of rectification tower for removing CH and HCl impurities, can solve the problems of high equipment requirements, complicated operation, inability to effectively remove hydrogen-containing impurities, etc., and achieve simple structure and easy High operation and impurity removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

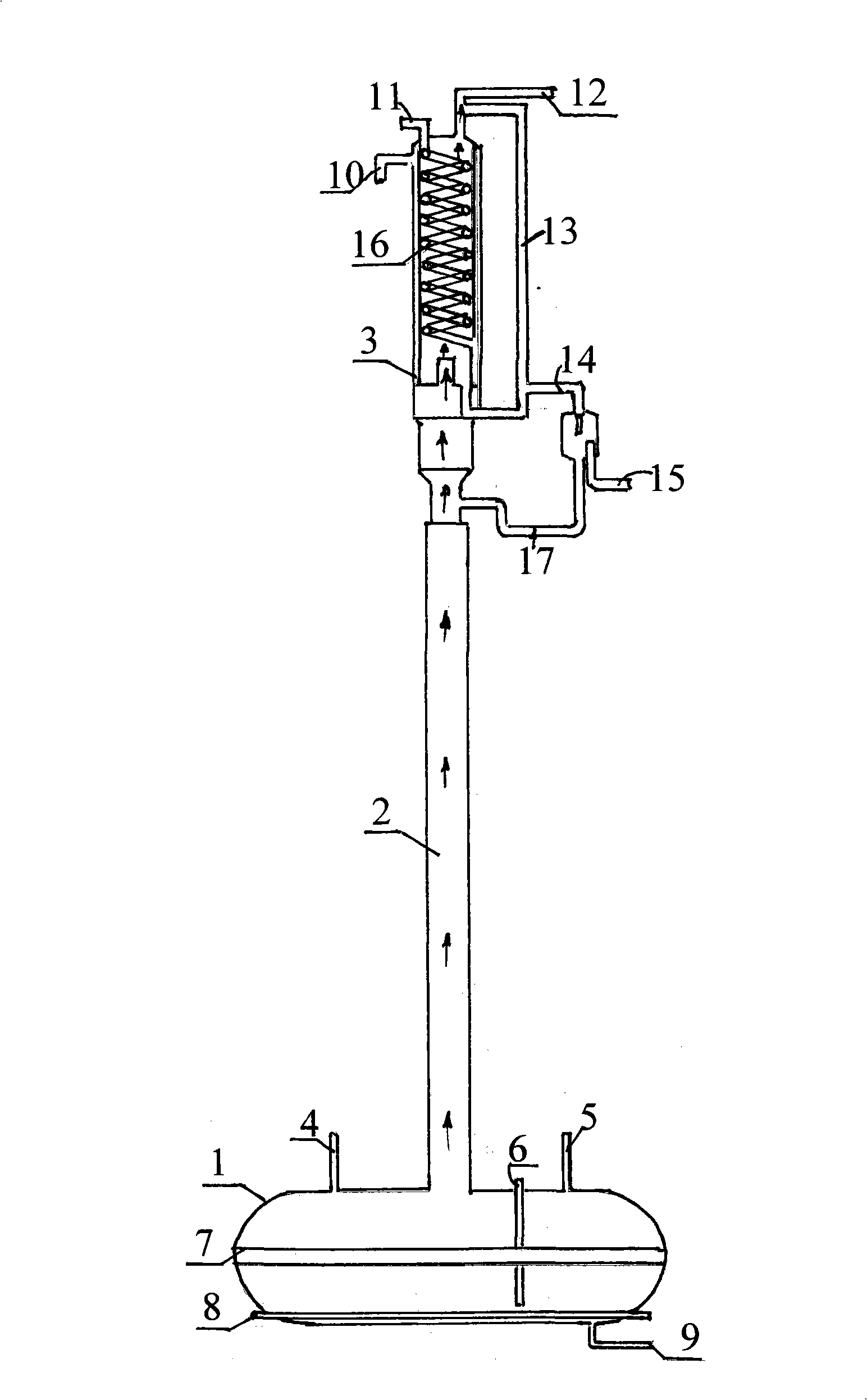

[0013] Embodiment: the rectifying tower is made of the tower kettle 1 at the bottom, the tower head 3 of the top and the middle tower tube 2 connecting tower kettle 1 and tower head 3, and a heating pipe 8 and an ultraviolet emitter 7 are arranged in the tower kettle 1. A feed port 4 and a gas supply port 5 are left at the top of the tower kettle 1, a temperature monitoring port 6 is opened at the side of the tower kettle 1, and a waste discharge port 9 is opened at the bottom of the tower kettle 1.

[0014] The tower head 3 is provided with a spiral water pipe 16, a cooling water inlet 10 and a cooling water outlet 11. There is an exhaust gas outlet 12 at the highest point of the tower head 3, and a liquid collection pipe 14 is connected to the lower right part of the tower head 3. The liquid collection pipe 14 and the tail gas outlet 12 are formed by The tail gas residual liquid return pipe 13 is connected, and the bottom of the liquid collecting pipe 14 is connected with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com