Method for determining proper pelletization parameters of sintering mixer based on numerical simulation

A technology of numerical simulation and method determination, which is applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., and can solve problems such as long test period, difficulty in judging material movement state, and influence on sintering production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

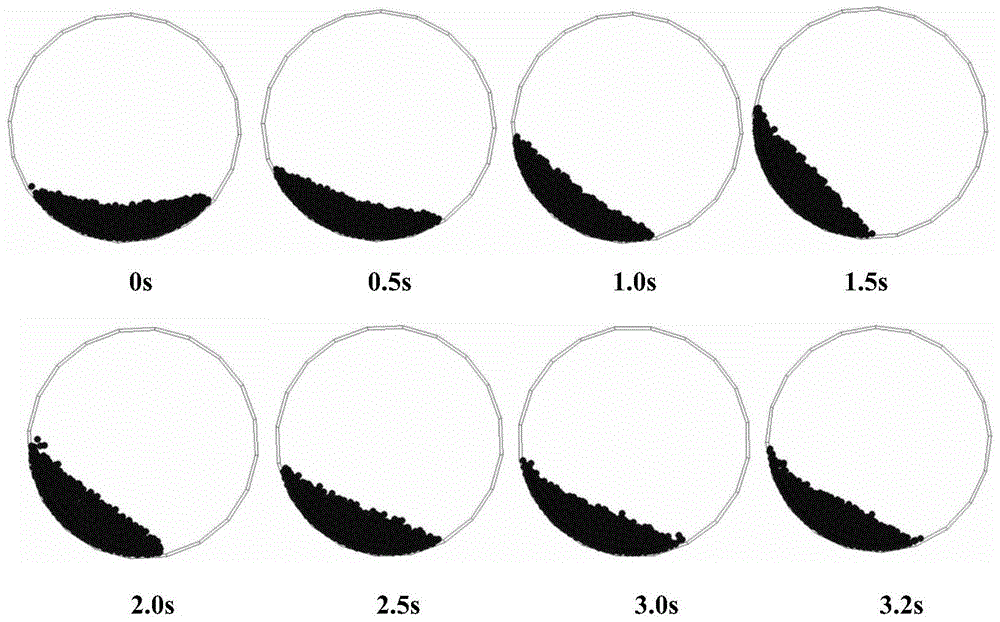

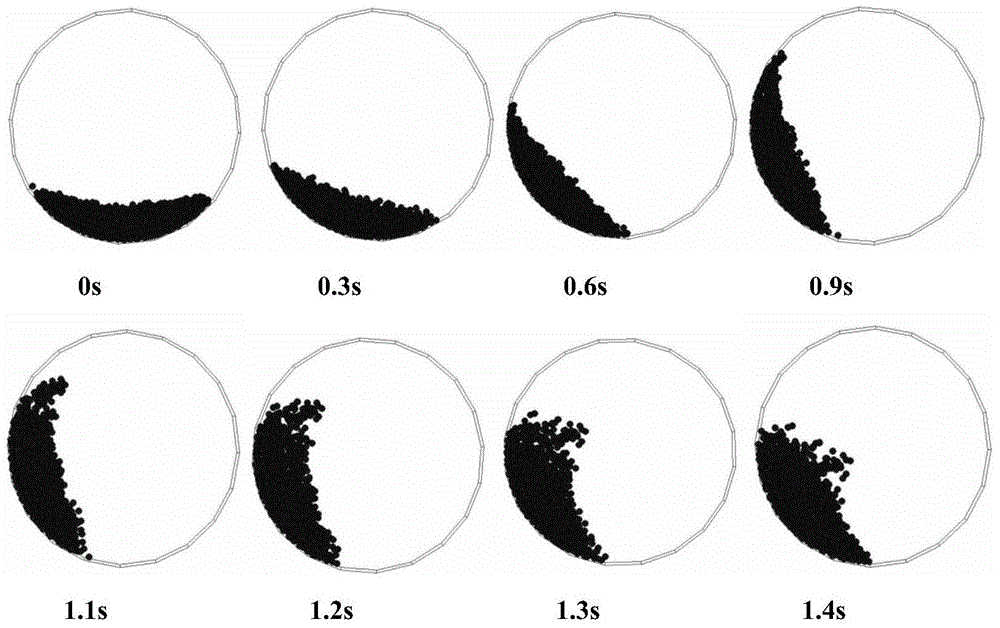

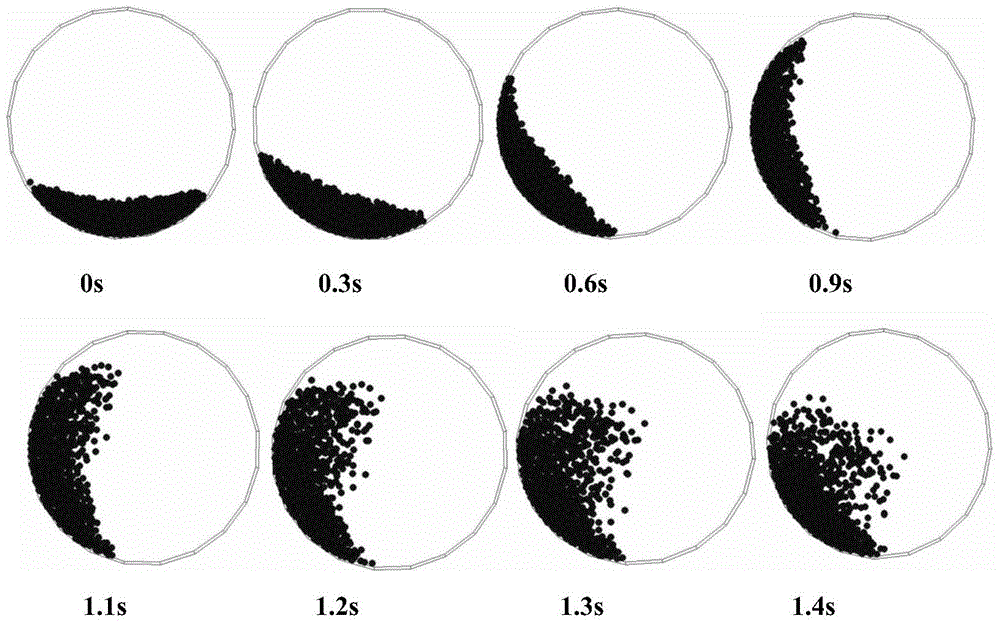

Image

Examples

Embodiment Construction

[0043] In order to illustrate the technical scheme of the present invention in more detail, the diameter of Wuhan Iron and Steel is D below s =5100mm, length L s The determination of the suitable granulation parameters of the actual production mixer of =24500mm is taken as an example, and the specific embodiment of the present invention is further described in detail.

[0044] It should be noted that the specific embodiments are only used to illustrate the content of the technical solution of the present invention, which is convenient for technical personnel to understand, and should not be construed as limiting the present invention.

[0045]A method for determining suitable granulation parameters of a sintering mixer based on numerical simulation, including the following refinement steps:

[0046] (1) Use PFC (Particle Flow Code) numerical simulation software for simulation.

[0047] (2) The diameter D of the simulated cylinder m =100mm, the length L of the simulated cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com