Novel extraction process method for purifying germanium tetrachloride

A technology of germanium tetrachloride and process method, applied in the direction of germanium halide, etc., can solve the problems of good purification and purification effect, achieve good mixing effect, meet environmental protection requirements, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

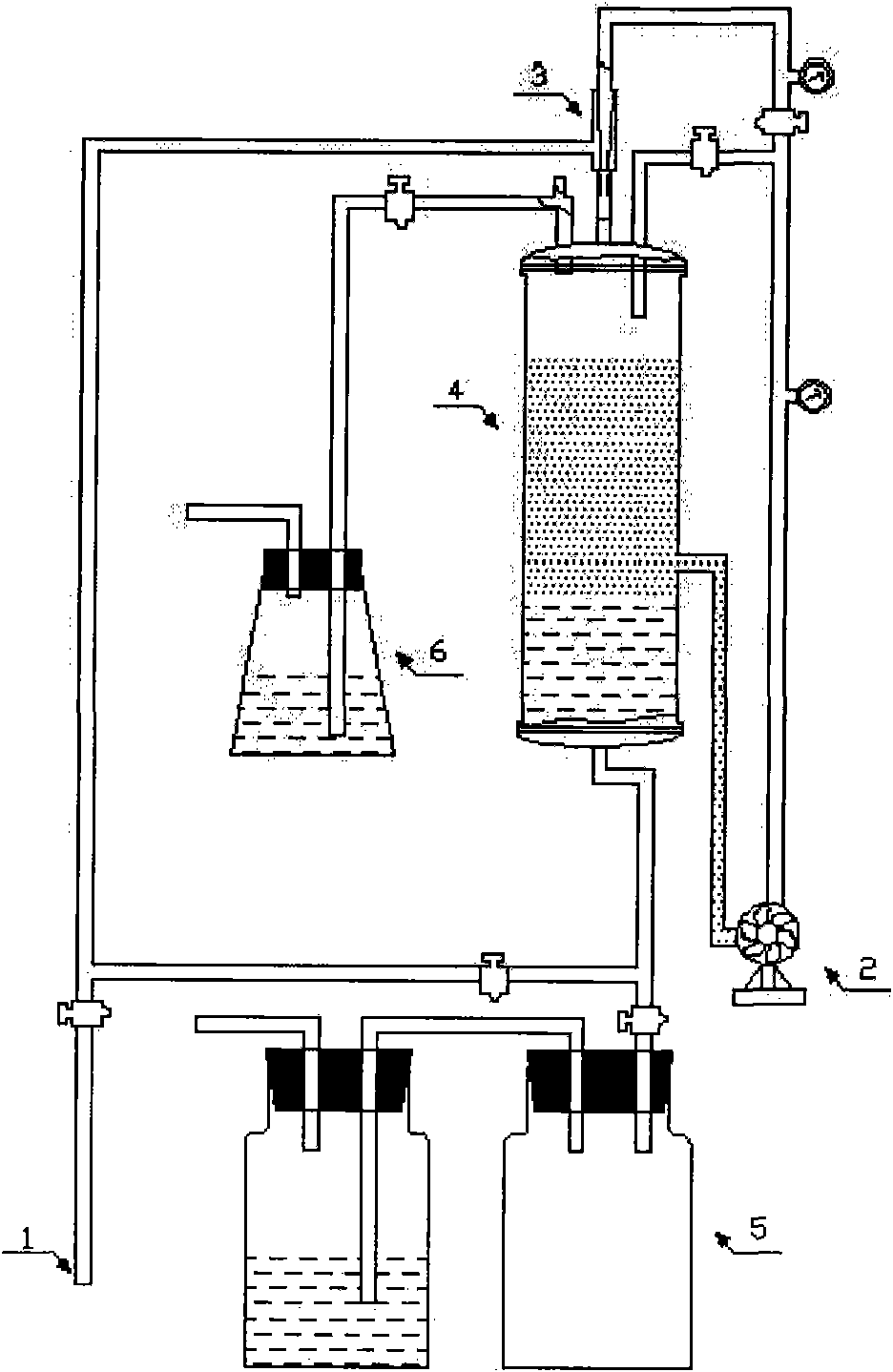

Method used

Image

Examples

Embodiment Construction

[0013] chemical principle

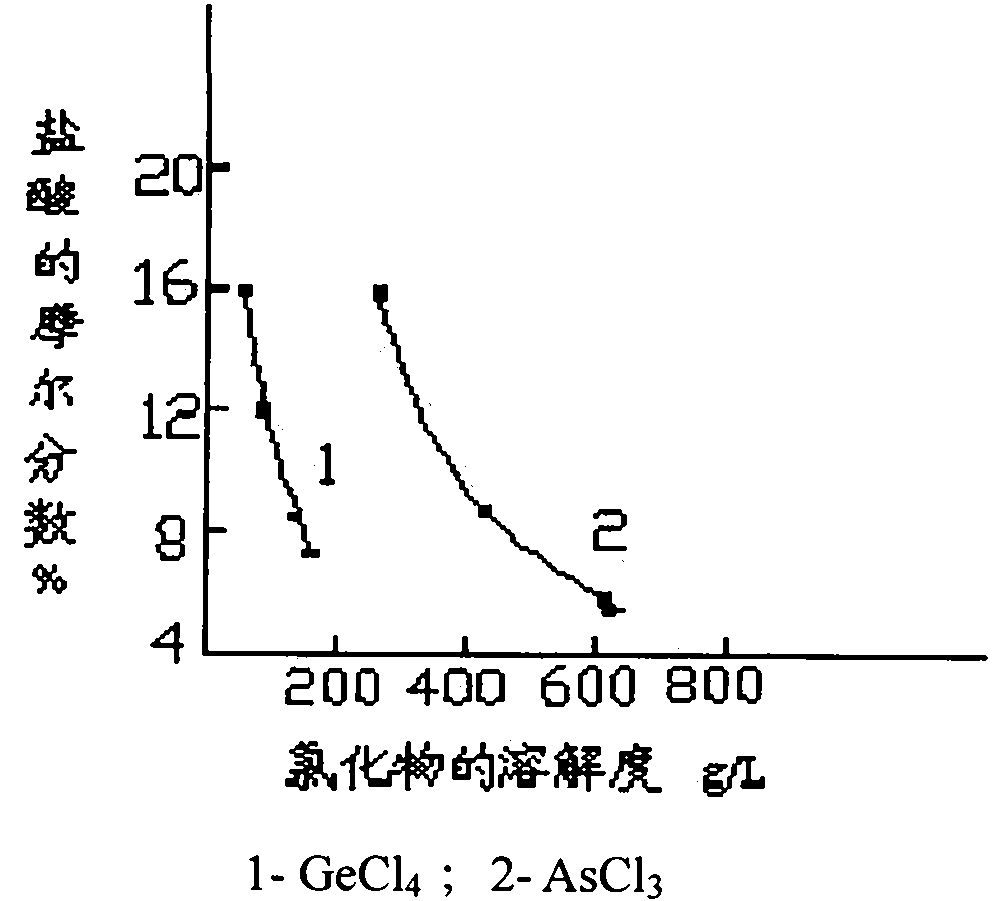

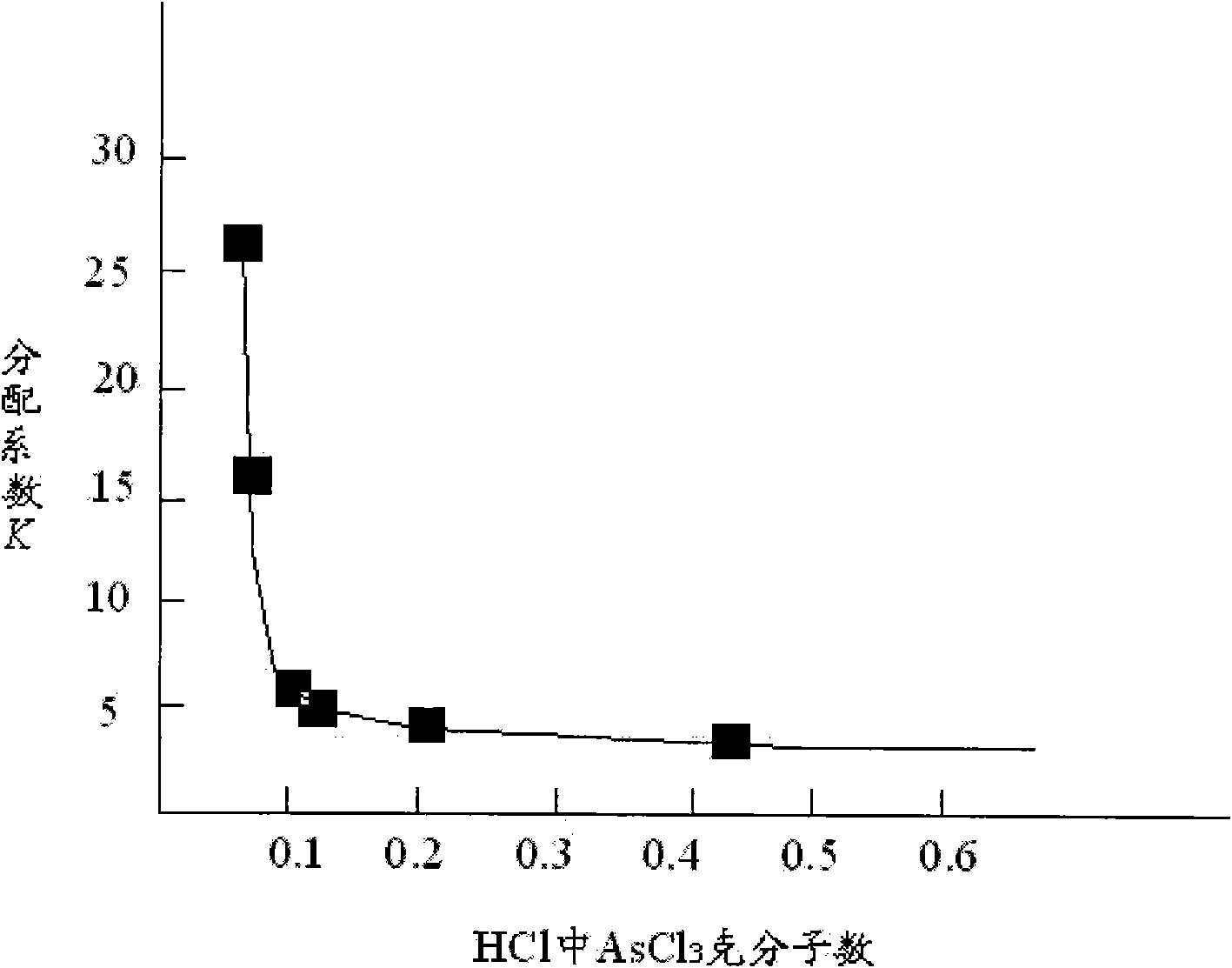

[0014] Due to the complex structure of the raw material and the production of the distillation process does not have the ability to finely remove impurities, the crude germanium tetrachloride produced contains a considerable part of AsCl 3 Mainly a variety of impurities. This method to remove GeCl 4 AsCl in 3 etc. as the main purpose, based on GeCl 4 and AsCl 3 Different solubility in concentrated hydrochloric acid and mist elution increase the mixing and contact of each fraction with hydrochloric acid to enhance the extraction effect.

[0015] GeCl 4 The solubility in concentrated hydrochloric acid is not large, and when it reaches saturation, it will separate with hydrochloric acid. AsCl 3 It has high solubility in concentrated hydrochloric acid, mainly enters the hydrochloric acid phase, and only a small amount remains in GeCl 4 middle. Such as figure 1 is GeCl 4 and AsCl 3 The solubility in concentrated hydrochloric acid varies with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com