Method for preparing high-purity germanium tetrafluoride through thermal decomposition of barium fluorogermanate

A technology of high-purity germanium tetrafluoride and barium fluorogermanate, which is applied in the direction of germanium halide, etc., can solve the problems of introducing too many impurities into germanium tetrafluoride and difficulty in obtaining fluorine gas, etc., achieving less impurities, wide application fields, and high yield high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

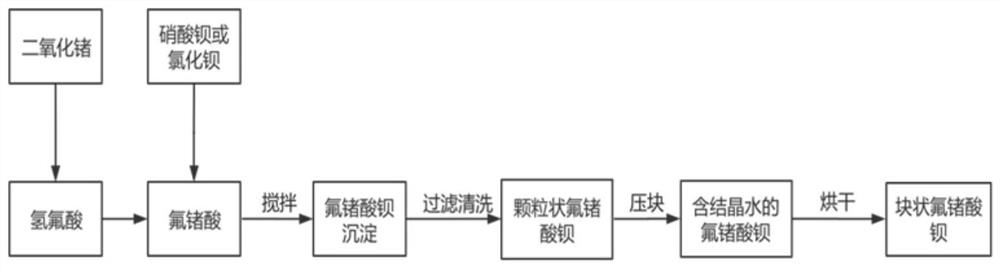

Method used

Image

Examples

Embodiment 1

[0046] At 25°C, 100g of soluble germanium dioxide was put into 250mL of 25mol / L HF hydrofluoric acid solution, and stirred for 10min. It can be seen that the obtained mixed solution of fluorogermanic acid and hydrofluoric acid was clear and transparent. Add 205g BaCl 2 Powder, stir for 10 minutes to make it fully precipitated, and white granular precipitates can be seen in the solution. After filtration, the crystals were washed once with pure water and three times with absolute ethanol. Press it into a block of 10*10*10mm, put it into an oven, set the drying temperature to 70°C, and dry it for 10 hours to obtain 311.7g of the product. The reaction between germanium dioxide and hydrofluoric acid is complete. The molar ratio of hydrofluoric acid solution to soluble germanium dioxide is 6.53:1, which is greater than 6-6.25:1. After the reaction of germanium dioxide is complete, a large amount of hydrogen fluoride remains in the solution, and barium salt is added. Afterwards, b...

Embodiment 2

[0048] Put 100g of soluble germanium dioxide into 235mL of 25mol / L HF hydrofluoric acid solution at 25°C and stir for 10min. It can be seen that the obtained mixed solution of fluorogermanic acid and hydrofluoric acid is clear and transparent. Add 205g BaCl 2 Powder, stir for 10 minutes to make it fully precipitated. It can be seen that white granular precipitates appear in the solution. After filtration, the crystals were washed once with pure water and three times with absolute ethanol. Press it into a block of 10*10*10mm, put it into an oven, set the drying temperature at 70°C, and dry it for 10 hours to obtain 307.9g of the product. The content of barium fluorogermanate is 99.6%, and the content of germanium is 99.6%. The comprehensive recovery rate was 99.0%.

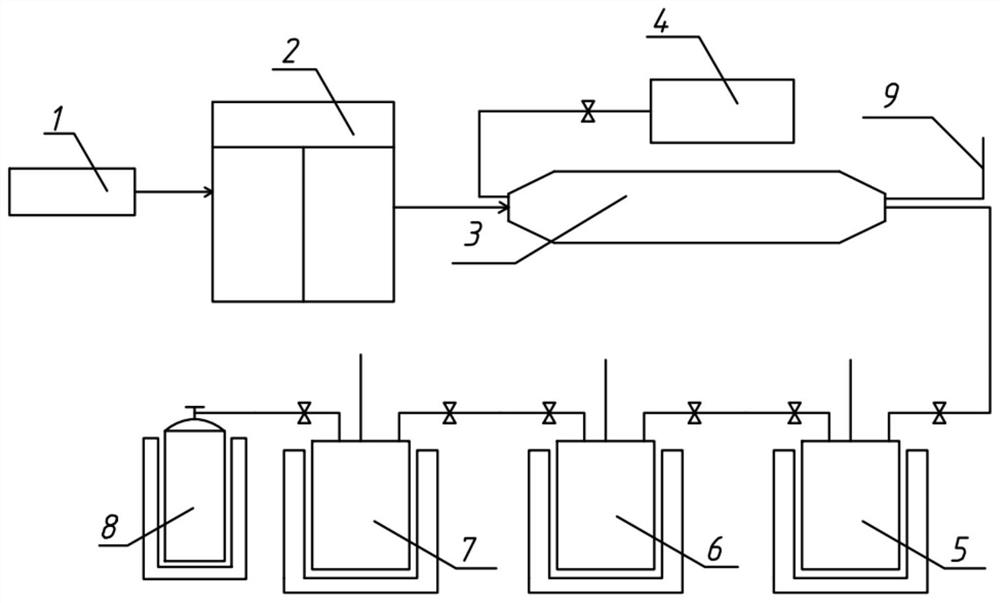

[0049] Dry nitrogen gas 4 was introduced into the quartz tube to replace the system, and 100.0 g of block barium fluorogermanate was taken and put into the quartz tube 3, and the pressure inside the quartz tube ...

Embodiment 3

[0052] At 25°C, put 500g of soluble germanium dioxide into 1.15L of 25mol / L HF hydrofluoric acid solution, and stir for 20min. It can be seen that the obtained mixed solution of fluorogermanic acid and hydrofluoric acid is clear and transparent. Add 990.0g BaCl 2 Powder, stir for 30 minutes to make it fully precipitated. It can be seen that white granular precipitates appear in the solution. After filtration, the crystals were washed once with pure water and three times with absolute ethanol. Press it into a block of 10*10*10mm, put it into an oven, set the drying temperature at 70°C, and dry it for 10 hours to obtain 1546.7g of the product. The content of barium fluorogermanate is 99.7%, and the content of germanium is The comprehensive recovery rate was 99.6%.

[0053] Dry nitrogen gas 4 was introduced into the quartz tube to replace the system, and 1000.0 g of block barium fluorogermanate was taken and put into the quartz tube 3, and the pressure inside the quartz tube w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com