Apparatus for separating hydrochloric acid from germanic chloride for optical fiber

A germanium tetrachloride and separation device technology, applied in germanium halide and other directions, can solve the problems of technology blockade and preparation technology monopoly, and achieve the effects of avoiding secondary pollution, simple structure and high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

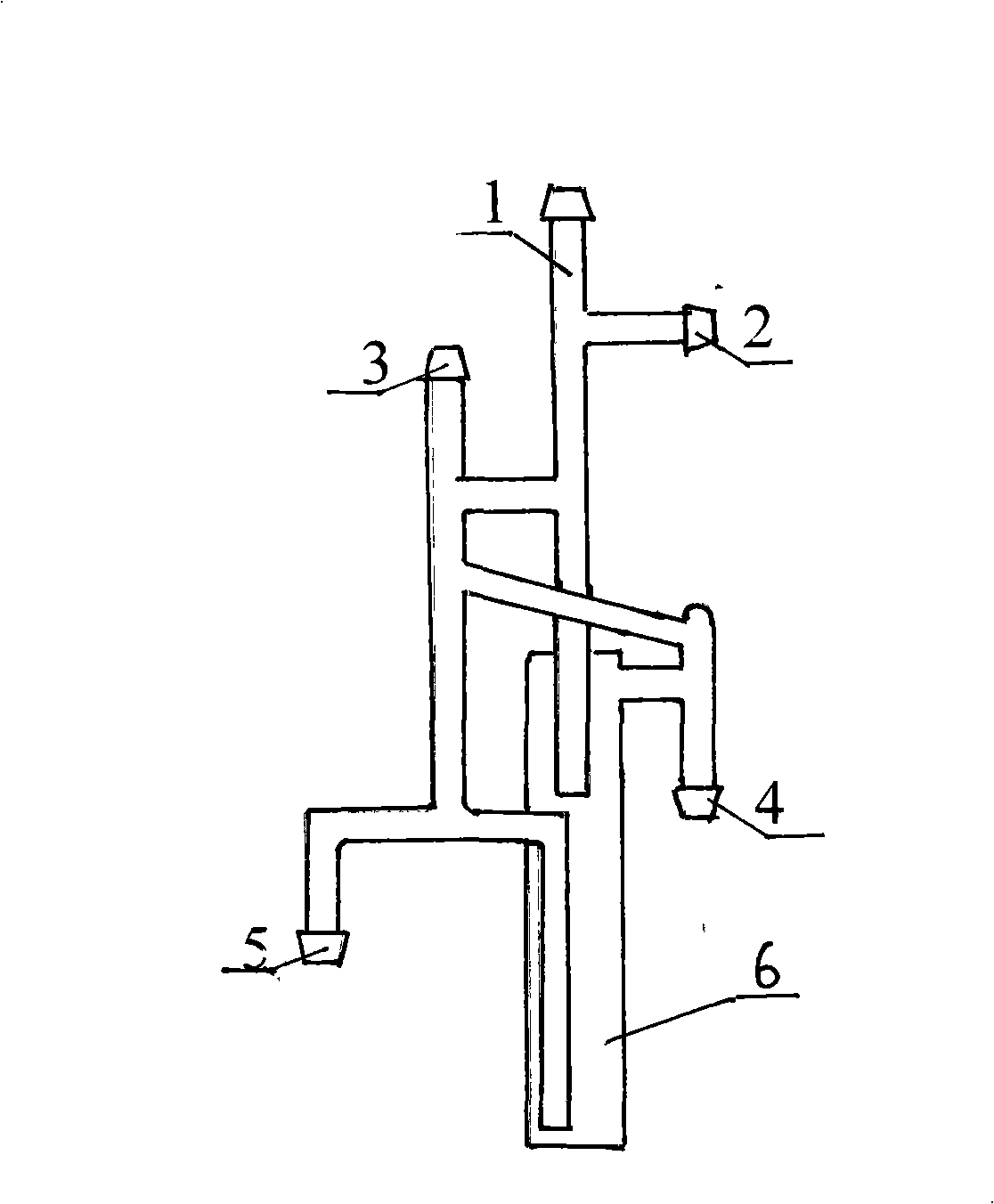

[0016] Embodiment: separation device is made of main separation tower (6), feed pipe (1), tail gas discharge pipe (2), atmosphere supply pipe 3, acid discharge pipe 4 and discharge pipe 5, and the top of its main separation tower 6 A feed pipe 1 is connected, the tail gas discharge pipe 2 is connected to the side of the feed pipe 1, the acid discharge pipe 4 is connected to the upper side of the main separation tower 6, and a discharge pipe 5 is connected to the middle section of the main separation tower 6. The nozzle of the pipe 5 extends to the bottom of the main separation tower 6, and the discharge pipe 5 is connected with the atmosphere supply pipe 3, and the sides of the atmosphere supply pipe 3 are respectively connected with the acid discharge pipe 4 and the feed pipe 1 through two independent pipes .

[0017] The entire separation device is a transparent body, all made of quartz material, which has strong corrosion resistance, and is clear and transparent, allowing r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com