Catalyst used in preparation of silane by disproportionation, preparation method for catalyst and method for preparing SiH4 by disproportionating SiH2C12

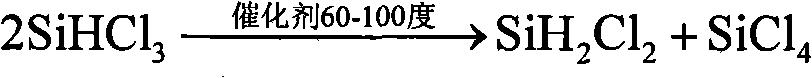

A catalyst and silane technology are applied in the field of disproportionating halosilane to prepare catalysts with higher hydrogen-containing halosilanes and silanes, catalyst preparation, and disproportionating SiH2Cl2 to prepare SiH4 fields, which can solve the problems of limiting primary conversion efficiency, low service temperature, etc., Achieve the effect of being beneficial to large-scale production and application, improving yield, and high silane conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The present invention also provides a preparation method for the above-mentioned catalyst, the steps comprising: (1) contacting the salt solution of metal M with an acidic cation exchange resin, ion exchange reaction and M diffusion adsorption take place; (2) washing and drying the product obtained in step (1) , and then activated by heating with hydrogen to prepare the catalyst, the preparation method is simple and easy to realize.

[0024]Wherein, M in the salt solution of M can be selected from one or more of Ru, Rh, Fe, Co, Ni, Pd, Cd, Cu, Zn, Ag, Pt, Au, etc., and the specific salt solution can be M Sulfate, chlorate, nitrate, acetate and other salt solutions; the acidic cation exchange resin has a styrene or acrylic acid backbone, and the exchangeable group is connected to the backbone, and the exchangeable group can be selected from -SO 3 H, -COOH, -OH, -NHR, -NR 2 , -NH 2 Wait. The specific acidic cation exchange resin can be various strongly acidic and weakl...

Embodiment 1

[0032] 1) Catalyst preparation: mix 500ml of cobalt chloride solution of 1mol / L with 200g of D001 acidic cation exchange resin (pore diameter is 10-15nm, porosity is 0.09-0.21ml / g, particle diameter is 0.31-1.25mm, specific surface is 20-36m 2 / g) mixed evenly, ultrasonically dispersed at 60°C for 20h, then washed with high-purity water until neutral, dried in vacuum at 100°C for 48h, and then heated to 120°C for hydrogen activation for 4h to obtain a Co / D001 resin catalyst. After the prepared catalyst was ground into powder, the content of Co element in it was tested by EDS elemental analyzer to be 11.8% by weight (based on the dry weight of the acidic cation exchange resin).

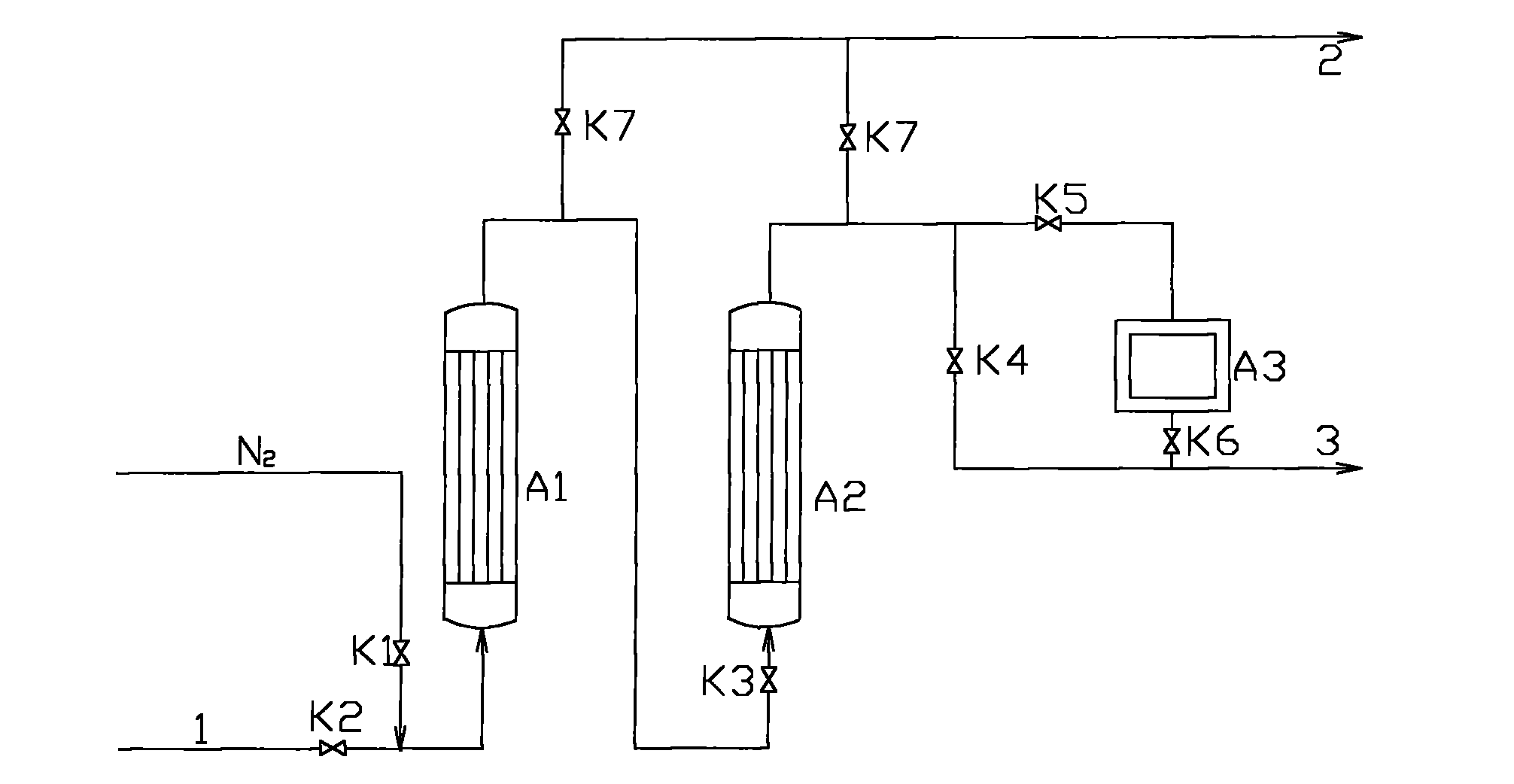

[0033] 2) Disproportionation of SiH 2 Cl 2 Preparation of SiH 4 : Load the catalyst prepared above on the catalytic bed of the sealed reactor A2, the filling height is 500mm, open the valve K1, purge the whole preparation system 5 times with high-purity nitrogen, remove the air in the system, open t...

Embodiment 2

[0035] Adopt the same method as embodiment 1 to prepare Rh / D001 catalyst and disproportionated SiH 2 Cl 2 Preparation of SiH 4 . The difference is that the metal salt solution used is RhCl 3 .

[0036] Using the same method to measure the dry weight of the acidic cation exchange resin as a benchmark, the weight percentage of M is 14.6%. The primary conversion efficiency of silane was measured to be 15.8%, and the primary conversion efficiency of the catalyst after 200 hours of reaction was 15.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com