Silicon tetrachloride hydrogenating process of producing trichloro hydrosilicon

A technology of silicon tetrachloride and trichlorosilane, applied in halogenated silicon compounds, silicon hydrides, halogenated silanes, etc., can solve the problems of low copper salt catalyst activity, high reaction conversion conditions, low primary conversion rate, etc. The equipment is easy to handle, the one-time conversion rate is high, and the unit consumption is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

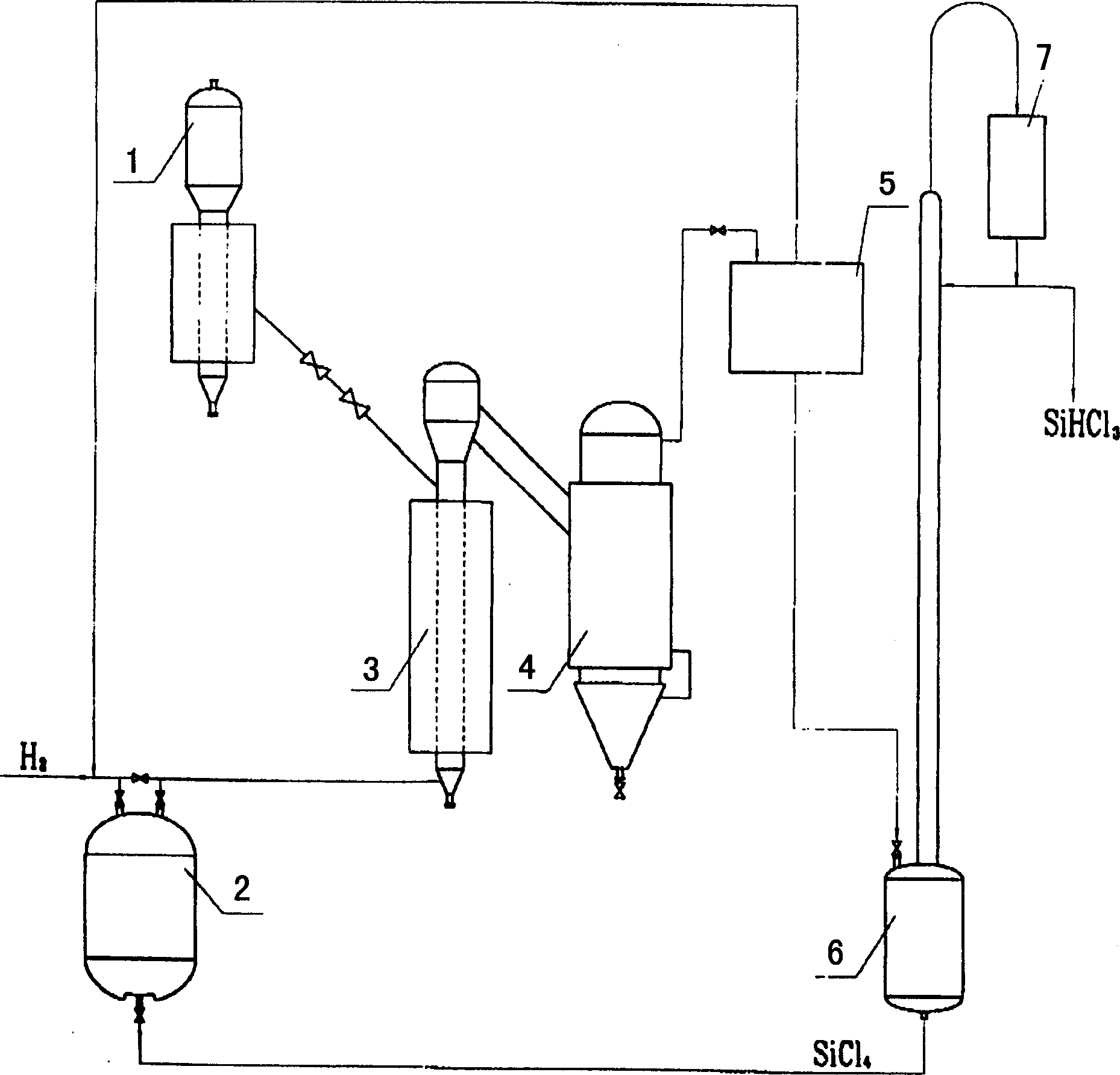

[0027] see figure 1 In this embodiment, the powdered hydrogenation nickel catalyst and silicon powder are evenly mixed in proportion and then placed in the activator 1 for activation. The fully activated mixture can be used for hydrogenation reaction and continuous supplementation of the process. SiCl 4 Liquid phase temperature keeps temperature and gas phase total pressure in storage tank 2; Catalyst and silicon powder mixed material layer after activation treatment in hydrogenation reactor 3 pass through H 2 with SiCl 4 Mixed gas; SiHCl can be obtained in the mixed gas leaving the mixed material layer 3 . After the mixed gas at the outlet of the hydrogenation reactor 3 is dedusted and filtered by the dust collector 4, the chlorosilane is separated in a liquid state in the condenser 5, and the non-condensable H 2 The gas is returned to the storage tank 2 for recycling. After the liquid chlorosilane is fractionated by the fractionating tower 6, the light component SiHCl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com