Method for preparing silane by disproportionating dichlorosilane

A technology for dichlorodihydrosilicon and silane, which is applied in the field of preparing silane by disproportionation of dichlorodihydrosilicon, can solve the problems of complex process and great difficulty, achieve simple system and equipment, improve production rate, improve production economic benefits and social effect of benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

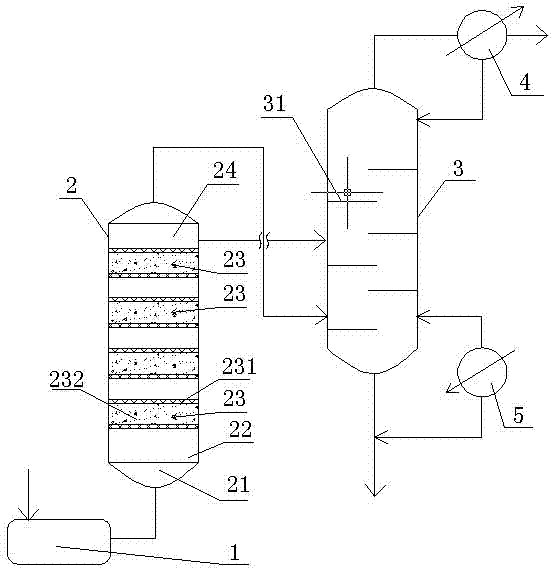

Embodiment 1

[0024] The present invention adopts such as figure 1 The shown device carries out the disproportionation of dichlorodihydrosilane to prepare silane, and the device includes a dichlorodihydrosilane storage tank 1, a reaction kettle 2 and a rectification tower 3 which are successively connected by pipelines, and the reaction kettle 2 is successively the bottom of the kettle from bottom to top Section 21, heating section 22, a plurality of catalytic reaction sections 23 and kettle top section 24 arranged at intervals in the reactor, heating section 22 has 4-8 dichlorodihydrosilane inlets, and dichlorodihydrosilane storage tank 1 passes through The pipeline is connected with the inlet of dichlorodihydrosilane, the bottom of the bottom section 21 has an inlet at the bottom of the kettle, the top of the top section 24 has an outlet at the top of the kettle, the middle part of the rectifying tower 3 and the top of the first baffle at the bottom have a material inlet, and the top of th...

Embodiment 2

[0034] The device and method that adopt are with embodiment 1, and difference is:

[0035] Mixed chlorosilane raw material composition: monochlorosilane: dichlorodihydrosilane: trichlorosilane=35:70:1 (molar ratio). The feed rate of mixed chlorosilane is 9.6t / h. There are 4 catalytic reaction sections in the reactor, and the filling height of each section is 1200mm. The catalyst in this example is obtained by mixing a solid amine-based macroporous resin (Rohm and Haas IRA402) and an organic amine at a ratio of 2:1 (molar ratio). Composite catalyst, composite catalyst is more effective than single-component catalyst, reducing the activation energy of the reaction, thereby accelerating the disproportionation reaction of dichlorodihydrosilane. The average particle diameter of the loaded solid amine-based macroporous resin is 0.5-0.8mm.

[0036] The temperature in the reaction kettle is controlled at 60°C, and the operating pressure is 3.0MPa. The top of the reaction kettle is m...

Embodiment 3

[0039] The device and method that adopt are with embodiment 1, and difference is:

[0040] Mixed chlorosilane raw material composition: monochlorosilane: dichlorodihydrosilane: trichlorosilane=35:70:1 (molar ratio). The feed rate of mixed chlorosilane is 9.6t / h. There are many sections of catalytic reaction sections in the reactor, and the filling height of each section is 1000mm, and the catalyst is the same as in Example 2. The temperature in the reaction kettle is controlled at 60°C, and the operating pressure is 3.0MPa. The top of the disproportionation reaction kettle is mainly silane and monochlorosilane gas entering the rectification tower, and the middle part of the disproportionation reaction kettle is mainly unreacted dichlorodihydrosilane, a small amount of three Chlorosilane and a small amount of monochlorosilane enter the rectification tower.

[0041] The rectification tower is a plate tower with 70 layers of trays, the operating pressure is 2.9MPa, the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com